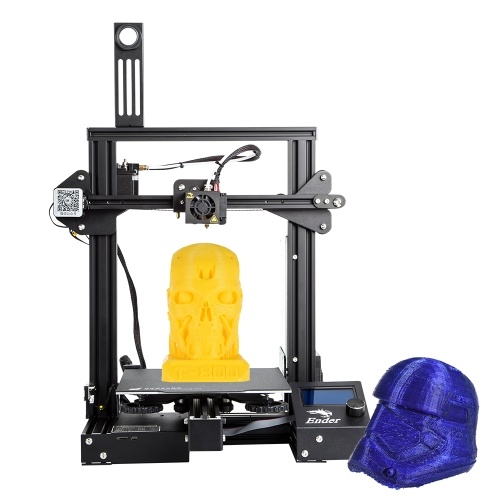

Profesional 3d printer

mix of features, performance, and price

What is the best professional desktop 3D printer?

There are so many different 3D printers on the market today that it can be a real challenge to choose one. When every penny of your quarterly budget counts, you want to make sure your professional 3D printer is adapted to your needs. Material compatibility, build size, ease of use, workflow, software, and many more elements come into play.

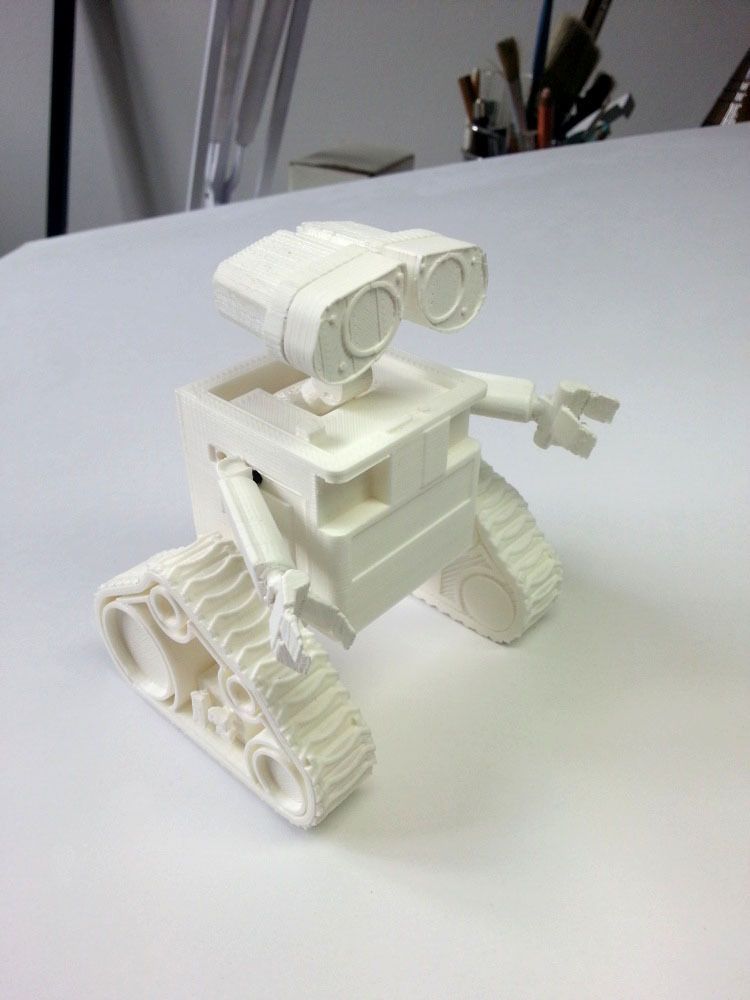

To help you cut through the clutter, we made a shortlist of some of the best professional 3D printers available this year. These benchtop and desktop FFF (fused filament fabrication) 3D printers for professionals offer a great combination of features, performance, and reliability, and come from well-established brands. They are ideal tools for rapid prototyping and iterative design processes, and are also suitable for low-volume production series. Keep in mind, though, that while part quality does depend on your printer’s performance, it also greatly relies on your choice of materials.

Towards the end of this article, we also provide a brief buying guide where you can learn more about different 3D printer specifications such as printing temperatures, layer thickness, dual extrusion, and more.

Best benchtop 3D printers for professionals in 2022: our selection

The table below recaps our selection of some of the best professional 3D printing options for office use. Our goal is to provide a quick, visual overview of the market; there are of course numerous other factors to take into account (material compatibility, certifications, customer service, software, etc.) before making the right choice.

| Brand | Product | Build size | Country | Price Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …). | |

|---|---|---|---|---|---|

| Prusa Research | Original Prusa i3 MK3S This product has been reviewed by our team. | 250 × 210 × 210 mm9.84 × 8.27 × 8.27 in | Czech Republic | $ 9991 015 €886 £148,907 ¥ | Buy |

| BCN3D Technologies | Sigma D25 | 420 × 300 × 200 mm16.54 × 11.81 × 7.87 in | Spain | $ 3,9953 495 €3,544 £595,479 ¥ | Quote |

| Ultimaker | Ultimaker S5 | 330 × 240 × 300 mm12.99 × 9.45 × 11.81 in | Netherlands | $ 5,9955 495 €5,318 £893,591 ¥ | Quote |

| MakerBot | Method X | 190 × 190 × 196 mm7.48 × 7.48 × 7.72 in | United States | $ 6,4996 606 €5,765 £968,715 ¥ | Quote |

| Raise3D This brand is a certified partner from our network. | Pro3 Plus This product has been reviewed by our team. | 300 × 300 × 605 mm11.81 × 11.81 × 23.82 in | United States | $ 7,2496 249 €6,430 £1,080,507 ¥ | Quote |

| Markforged | Onyx Pro | 320 × 132 × 154 mm12. 6 × 5.2 × 6.06 in 6 × 5.2 × 6.06 in | United States | $ 9,60010 000 €8,516 £1,430,938 ¥ | Quote |

| Stratasys | F120 | 254 × 254 × 254 mm10 × 10 × 10 in | United States | $ 12,00011 000 €10,644 £1,788,672 ¥ | Quote |

Expand to see more specs

The products in the table are ranked by price (low to high).

| Brand | Product | Build size | Build volume | Extruder temp. | Country | Price Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …). | |

|---|---|---|---|---|---|---|---|

| Prusa Research | Original Prusa i3 MK3S This product has been reviewed by our team. | 250 × 210 × 210 mm9.84 × 8.27 × 8.27 in | 11.03 L | 300°C | Czech Republic | $ 9991 015 €886 £148,907 ¥ | Buy on Prusa |

| BCN3D Technologies | Sigma D25 | 420 × 300 × 200 mm16. 54 × 11.81 × 7.87 in 54 × 11.81 × 7.87 in | 25.2 L | 300°C | Spain | $ 3,9953 495 €3,544 £595,479 ¥ | Get a quote |

| Ultimaker | Ultimaker S5 | 330 × 240 × 300 mm12.99 × 9.45 × 11.81 in | 23.76 L | 280°C | Netherlands | $ 5,9955 495 €5,318 £893,591 ¥ | Get a quote |

| MakerBot | Method X | 190 × 190 × 196 mm7.48 × 7.48 × 7.72 in | 7.08 L | 260°C | United States | $ 6,4996 606 €5,765 £968,715 ¥ | Get a quote |

| Raise3D This brand is a certified partner from our network. | Pro3 Plus This product has been reviewed by our team. | 300 × 300 × 605 mm11.81 × 11.81 × 23.82 in | 54.45 L | 300°C | United States | $ 7,2496 249 €6,430 £1,080,507 ¥ | Get a quote |

| Markforged | Onyx Pro | 320 × 132 × 154 mm12.6 × 5.2 × 6.06 in | 6.5 L | – | United States | $ 9,60010 000 €8,516 £1,430,938 ¥ | Get a quote |

| Stratasys | F120 | 254 × 254 × 254 mm10 × 10 × 10 in | 16. 39 L 39 L | – | United States | $ 12,00011 000 €10,644 £1,788,672 ¥ | Get a quote |

Overview of the best professional 3D printers in 2022

In this section, we give some more context and information about each pro 3D printer from our selection.

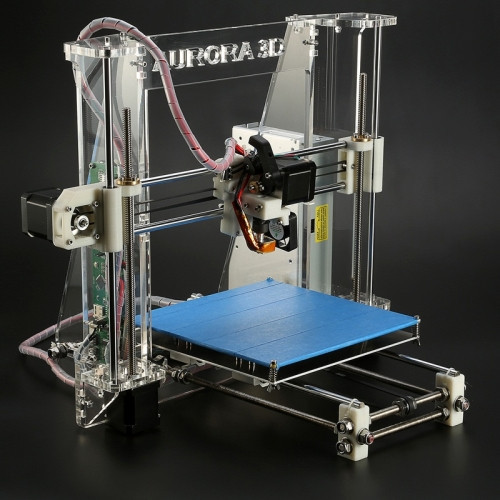

The Prusa Research Original Prusa i3 MK3S+ is a desktop 3D printer manufactured by Prusa Research, based in the Czech Republic. Prusa Research is a well-known brand created by Josef Prusa, inventor of the open-source Prusa i3 3D printer design.

Prusa 3D printers are highly reliable machines and can produce excellent parts right out of the box. Priced just under $1,000, the MK3S+ offers a very good price-to-performance ratio. With its open chassis and customizable “everything”, it’s a great option for those that like to get manual. Professionals who are looking for easy and low-maintenance operation may want to look at options in a higher price range.

Full review: Original Prusa i3 MK3S review

Buy on Prusa Add to comparison

The BCN3D Sigma D25 is a large desktop 3D printer for office use made by BCN3D Technologies. BCN3D, or BCN3D Technologies, is based in Spain and is one of the desktop 3D printer market leaders. They produce high-quality 3D printers for professionals, the Sigma being their flagship series.

BCN3D, or BCN3D Technologies, is based in Spain and is one of the desktop 3D printer market leaders. They produce high-quality 3D printers for professionals, the Sigma being their flagship series.

The Sigma D25 pro 3D printer offers a relatively big build volume and boasts BCN3D’s IDEX technology. This means that there are two separate print heads that can both move independently to either print two identical objects at the same time or print in mirror mode.

Contact manufacturer Get a quote Add to comparison

The Ultimaker S5 is a professional desktop 3D printer made by Ultimaker, a manufacturer based in the Netherlands. Users may control their S5 from a distance thanks to the Ultimaker App and a Wi-Fi connection. There is also an onboard camera to monitor 3D prints from a distance. Furthermore, to maximize production efficiency, it is possible to group multiple S5 3D printers together with Cura Connect.

Today, the Ultimaker S5 is often referred to as the best professional 3D printer, especially when equipped with the Pro Bundle. The Pro Bundle includes a “material station” where up to 6 spools of filament can be loaded and automatically managed (auto-switch, humidity control, etc.), and an “air manager” that closes up the build area and filters particles.

The Pro Bundle includes a “material station” where up to 6 spools of filament can be loaded and automatically managed (auto-switch, humidity control, etc.), and an “air manager” that closes up the build area and filters particles.

Contact manufacturer Get a quote Add to comparison

The Method X is a professional benchtop 3D printer produced by MakerBot (a Stratasys-owned brand). It was designed to 3D print ABS filament reliably and efficiently, thanks to a number of features– including a 100°C heated build chamber– than enable comprehensive environmental control.

Makerbot’s Method X is equipped with a 5-inch touchscreen with real-time feedback and status on print jobs, and offers automatic calibration. This pro 3D printer also boasts “SmartAssist Material Loading”, for fast and easy filament changing. Users can log in to the manufacturer’s proprietary CloudPrint software to monitor prints remotely at any time.

Contact manufacturer Get a quote Add to comparison

The Markforged Onyx Pro is a professional desktop 3D printer made by Markforged, a manufacturer based in Somerville, Massachusetts (USA). With its dual printhead, the Onyx Pro reinforces plastic parts with a continuous strand of fiberglass.

With its dual printhead, the Onyx Pro reinforces plastic parts with a continuous strand of fiberglass.

The main available materials for the Onyx Pro are Onyx (a carbon fiber filled nylon) and Precise PLA. Markforged advertises parts up to ten times stronger than non-reinforced plastic ones.

The MarkForged Onyx Pro is delivered with Markforged’s browser-based Eiger software, powerful and easy to use. Eiger allows precise control over the 3D printing process.

Contact manufacturer Get a quote Add to comparison

The Raise3D Pro3 Plus is a professional, industrial-grade 3D printer made by Raise3D, an ISO9001:2015 and ISO14001-certified manufacturer based in the US (California). Raise3D also has offices in the Netherlands (Rotterdam) and in China (Shanghai).

This 3D printer for office environments is a true workhorse, capable of printing for hours without any hiccups. It does an impressive job with complex overhangs and features an intuitive, user-friendly workflow. The printer comes with an air filtration system, an onboard camera, and a dual extruder. Its control software is also available as a smartphone app for convenient remote monitoring.

The printer comes with an air filtration system, an onboard camera, and a dual extruder. Its control software is also available as a smartphone app for convenient remote monitoring.

Raise3D’s Pro3 series also includes the Pro3, featuring a smaller build volume. Both printers are a follow-up to the Pro2 Series.

Full review: Raise3D Pro3 Plus review

Contact manufacturer Get a quote Add to comparison

Stratasys is the Apple of the 3D printing industry. Their 3D printers, including the F120, are reliable machines with industrial-grade components and printing quality. However, Stratasys 3D printers generally only work with Stratasys materials and hardware. At the moment, less than a handful of filaments are available for the Stratasys F120.

The F120 is one of the most affordable FDM printers from Stratasys and is destined to be a desktop workhorse for professionals. Stratasys emphasizes on the printer’s ease of use, durability, and industrial quality.

Contact manufacturer Get a quote Add to comparison

Professional 3D printer buying guide

There are several features and specifications to take into account when choosing the best professional 3D printer for your needs.

Technology

For this professional desktop 3D printer selection, we focused on FFF (fused filament fabrication) 3D printers. They are ideal for creating both prototypes and end-use parts.

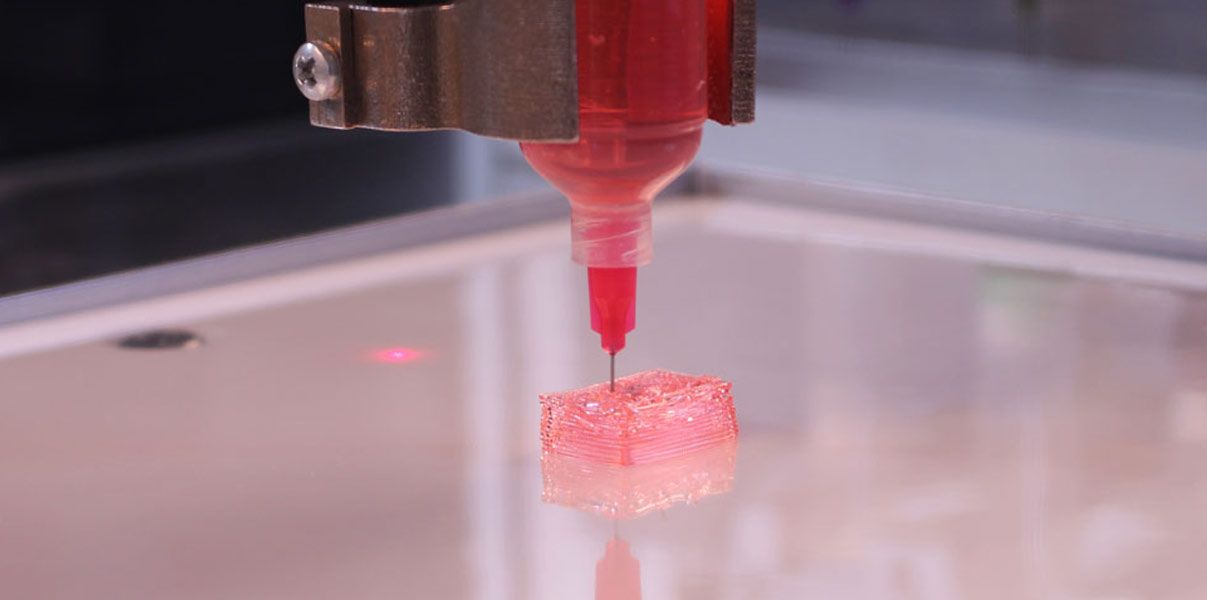

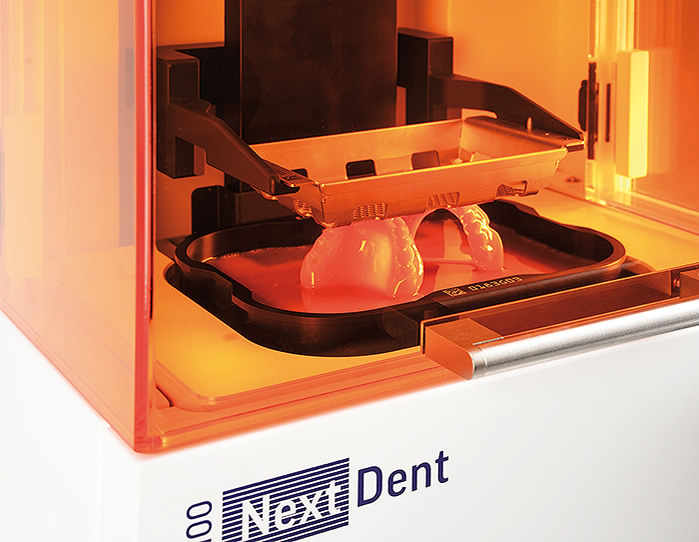

For professionals in dental or jewelry industries where high precision and detail are required, resin 3D printers are more adapted, with SLA, DLP, or LCD-based technologies.

There are also desktop SLS 3D printers (powder 3D printers), PEEK 3D printers, continuous fiber 3D printers, and more for advanced applications. Explore these topics with all of our other 3D printer guides.

Build plate or print bed

A heated print bed is mandatory for users that need to 3D print with ABS and other more demanding materials. The heat helps prevent warping and offers better first-layer adhesion.

While today’s 3D printers almost always feature heated build plates, they don’t all reach the same temperatures. It is best to know which thermoplastics you will be printing and to choose your desktop 3D printer accordingly.

It is best to know which thermoplastics you will be printing and to choose your desktop 3D printer accordingly.

Some professional 3D printers have interchangeable build trays to help speed up the workflow, enabling users to quickly launch new prints while the previous build plate cools down. On higher-end 3D printers, there can even be vacuum systems for instant part release from the print bed.

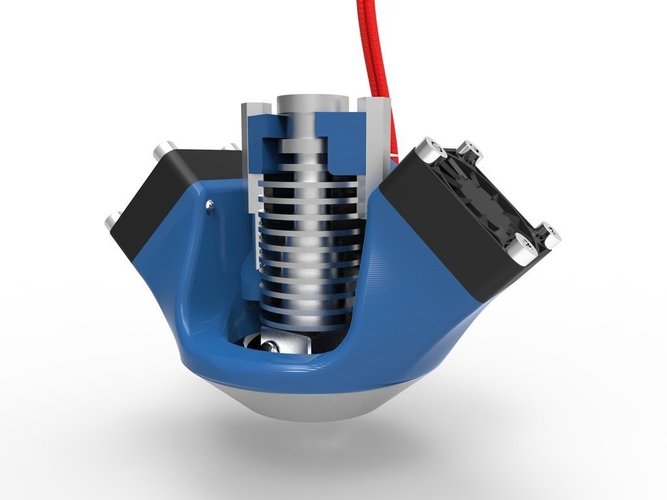

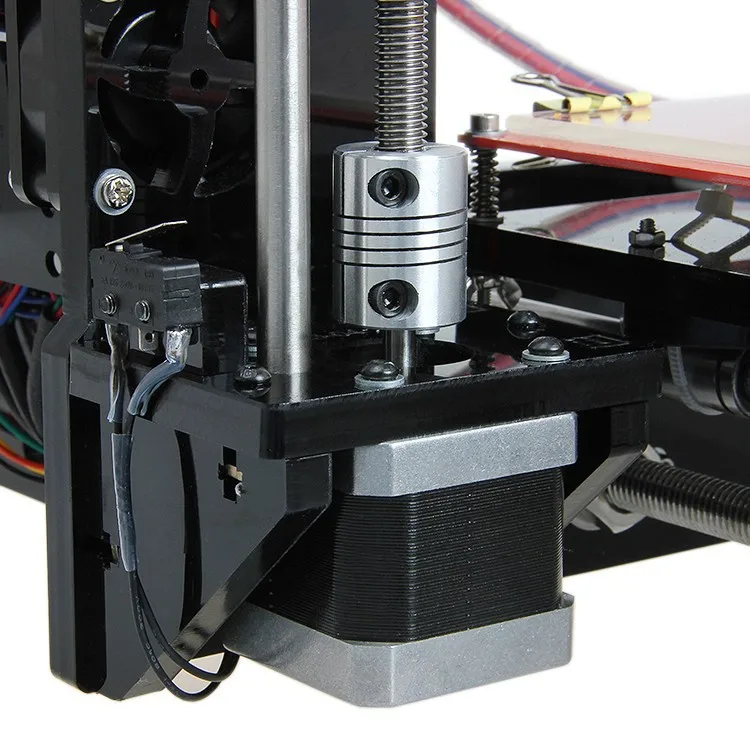

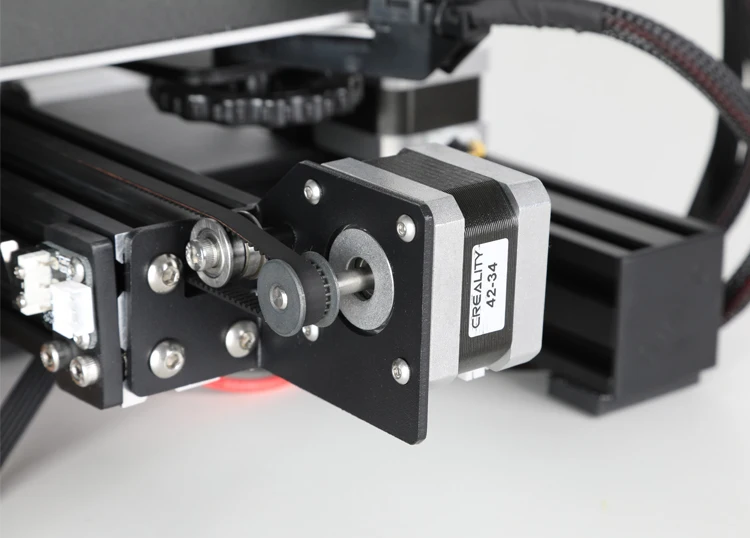

Print head

PLA and ABS can be considered the most common and basic 3D printing materials in general. Professionals, however, often need to print more complex materials, such as Nylon, Polycarbonate, PETG, ASA, or other engineering-grade polymers.

They don’t all have the same melting or glass transition temperature and therefore have to be 3D printed at different temperatures. For example, PLA can be extruded at around 200°C, PC at around 260°C, and some high-performance materials like PEEK or PEKK need the extruder to reach at least 450°C.

Popular professional filaments also include plastics filled with carbon fiber or glass fiber for increased strength and resistance. These materials are abrasive and require tough nozzles; many professional printers are already compatible with these composites, but it’s important to make sure beforehand.

Some 3D printers are compatible with multiple types of nozzles with varying diameters, and even paste-type print heads exist to 3D print clay.

Automatic calibration

Most professional 3D printer systems are equipped with automatic calibration features to make the process as plug-n-play as possible. It’s important to recalibrate a 3D printer from time to time to ensure consistent print quality.

There are two main types of calibration:

- Print bed leveling (making sure the print bed is perfectly parallel to the nozzle, and not tilted)

- Nozzle offset (determining the right gap between the nozzle and the print bed)

Most 3D printers for professionals feature a probe attached to the print head to automate these processes instead of users having to use a piece of paper or business card.

Some 3D printers also have NFC readers to automatically adjust their temperature settings according to the detected material (so long as the spool is chipped, too).

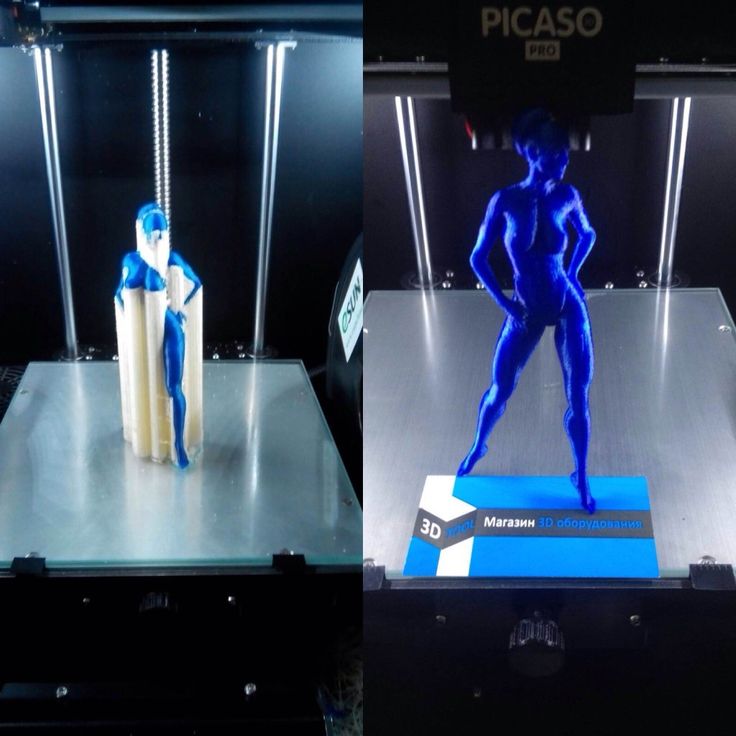

Dual extrusion and independent dual extrusion (IDEX)

A dual extruder enables users to 3D print with two different colors or materials simultaneously, including soluble support material for complex objects.

If there are two separate print heads, the system is referred to as IDEX (independent dual extruder). BCN3D Technologies was one of the first manufacturers to offer this feature a few years back.

In addition to being able to 3D print two materials at a time, independent dual extrusion offers different 3D printing possibilities:

- Duplication mode: 3D prints two identical objects at the same time.

- Mirror mode: to 3D print an object twice as fast as with just one extruder, each nozzle completes one-half of the object.

Onboard camera

Some 3D printers are equipped with an onboard camera that monitors prints remotely or saves time-lapse videos. This feature can be useful if the printer must be left unattended for long periods of time. We found it to be quite practical when we launched a long print for our Pro3 Plus review.

With the right 3D software, onboard cameras can help with quality control. Quality control can also be done during post-processing workflows with a metrology 3D scanner.

Minimum layer thickness

3D print quality is intricately linked to layer thickness, a.k.a. layer height or Z resolution. It’s the minimum height of each successive layer that forms the 3D printed object. The thinner the layers, the less they are distinguishable and the smoother the object will be (similar to the ratio of pixels in an image).

Thinner layers also mean that more layers are required to complete the object, which translates into more 3D print time. Layer thickness can be adjusted depending on if you need a quick print (thicker) or a high-resolution print (thinner).

The typical minimum layer thickness for mid-range FFF 3D printers is 100 microns or 0.1 millimeters, but it can go down to 0.01 mm in some cases.

A simple representation of layer height. Source: Primantes3DBuild volume

The build volume is the maximum size that your prints can be. If you need a bigger volume than what the 3D printers in this guide provide, you may be interested in these selections:

- L: Large volume 3D printers

- XL: Large format 3D printers

- XXL: Large scale 3D printers

Now, there are even large-sized resin 3D printers for those that need both volume and finer surface quality.

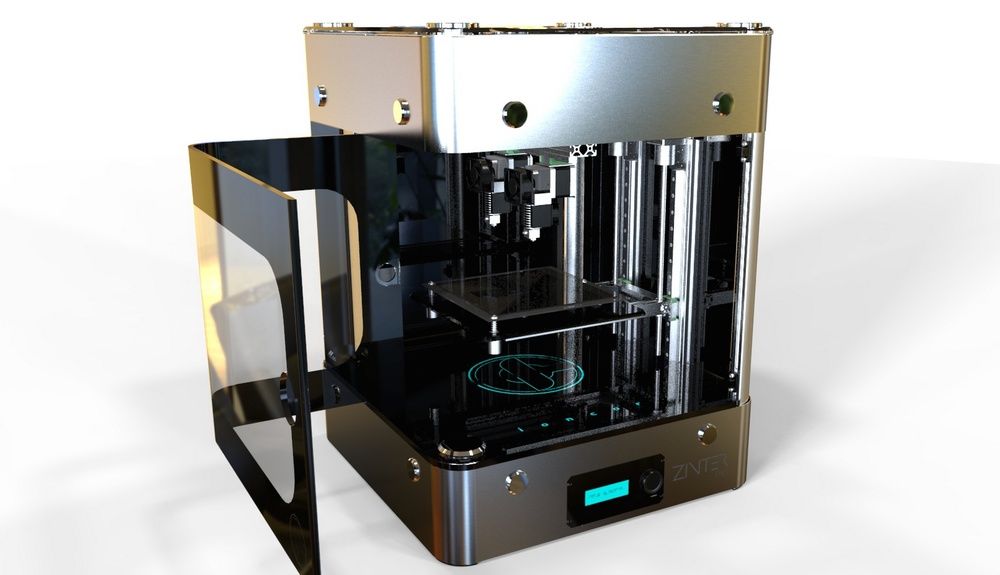

Closed frame

Many variables can interfere with 3D print quality, such as temperature changes and room drafts. Hence, 3D printers with an enclosed build chamber tend to provide better quality prints, in addition to reducing noise, odors, and– with a HEPA filter– harmful particle emissions.

A closed frame is almost mandatory when 3D printing with basically anything other than PLA. Today it is quite rare to see a professional 3D printer without an enclosure.

FAQ

Are 3D printers safe?

With basic precaution, 3D printers are relatively safe to use, although there has been some concern over harmful particle emissions from the melted filament. It’s best to use closed 3D printers with filters and to use 3D printers in well-ventilated areas. Users should also be careful not to burn themselves on a hot build plate or extruder; some 3D printers feature door safety sensors to lock the printer while it is printing.

Can 3D printers print metal? What 3D printers can print metal?

Yes, some FFF 3D printers are able to print metal-filled filaments. This is called metal FFF. Once the part has been 3D printed, however, it must undergo two processes called debinding and sintering. Other types of 3D printers (much more expensive and industrial-grade) are able to 3D print metal powder using various metal 3D printing technologies like L-PBF (laser powder bed fusion) or metal binder jetting, among others.

Other types of 3D printers (much more expensive and industrial-grade) are able to 3D print metal powder using various metal 3D printing technologies like L-PBF (laser powder bed fusion) or metal binder jetting, among others.

What is the best 3D printer for jewelry?

For jewelry, resin 3D printers are more adapted than FFF 3D printers. They use SLA, DLP, or LCD-based technologies to produce objects with fine details and smooth surfaces.

Can 3D printers print in color?

Yes, some 3D printers can print in color. They are called full-color 3D printers and often use powder-based technologies. Systems that mix CMYK filaments exist, but cannot reproduce photorealistic colors like powder-based 3D printers.

Engineering-Grade 3D Printers | MatterHackers

- Home

- Store

- 3D Printers

- Engineering-Grade 3D Printers

Exacting and accurate 3D printers that can 3D print with a variety of advanced materials to achieve their prototyping and production needs. These 3D printers are also capable of reaching temperatures of up to 400°C for robust material applications. For companies and businesses looking to get started in additive manufacturing and prototyping with 3D printing, while using advanced materials like PEI, PEEK, Polycarbonate, polypropylene and carbon-infused nylons like NylonX, these 3D printers are an excellent choice.

These 3D printers are also capable of reaching temperatures of up to 400°C for robust material applications. For companies and businesses looking to get started in additive manufacturing and prototyping with 3D printing, while using advanced materials like PEI, PEEK, Polycarbonate, polypropylene and carbon-infused nylons like NylonX, these 3D printers are an excellent choice.

Engineering-Grade 3D Printers Collections

All Engineering-Grade 3D Printers 3D Printers

Engineering-Grade 3D Printers

Ultimaker

Professional, engineering-grade 3D printers for rapid digital manufacturing.

Intamsys 3D Printers

3D Printers capable of printing high-performance functional materials.

MakerBot

High-performance, reliable, tinker-free 3D Printers

Raise3D

All Raise3D products: 3D printers, nozzles, filament, parts, etc

BCN3D

Accurate & Reliable IDEX 3D Printers and branded filament and accessories

LulzBot 3D Printers

Open-Source, Robust 3D Printers

MakerGear 3D Printers

Precise, Compact 3D Printers

Phenom 3D Printers

Fast, large-format MSLA 3D printers from Peopoly.

Guides & Articles

How to Succeed with Quantum Dichromatic PLA Filament

Follow this guide for tips and tricks on how to get the best results when 3D printing with Quantum Dichromatic PLA filament.

How To Succeed with LayerLock SLA Build Surfaces

Successfully achieve strong bed adhesion for Laser, DLP, and SLA resin prints using LayerLock SLA Resin 3D Printing Build Surfaces.

How To Build A Successful Makerspace

Find out the necessary components to create an effective space for your maker community.

How to Succeed When 3D Printing with Polypropylene

Successfully produce 3D printed parts out of polypropylene filament with these tips on achieving stronger bed adhesion and minimizing shrinkage.

Tech Breakdown and How to Succeed: Ionic Hybrid Support Material

Supporting engineering-grade filament has been difficult without a support material dedicated to higher temperature 3D printing. Ionic aims to solve that.

Ionic aims to solve that.

How To Succeed with OBC 3D Printing Filament

From Dow Chemical, OBC combines flexible and rigid into one unique material with properties of both.

How To Succeed with LayerLock Garolite Build Surfaces

Successfully achieve strong bed adhesion for NylonX, NylonG, and standard filaments using LayerLock Garolite Build Surfaces.

How to Succeed with LayerLock Powder Coated PEI Build Plates

Powder coated PEI steel sheets are a great alternative build surface for strong bed adhesion. Here's how you can succeed using this durable build plate.

How To Succeed When 3D Printing With Nylon

Learn how to 3D print Nylon like a pro. Nylon is a stronger and more durable alternative to PLA or ABS and easy to 3D print with using these Tips and Tricks.

How To Succeed When 3D Printing With ASA Filament

Follow this step-by-step guide to learn how to print with ASA, the perfect material for any outdoor projects.

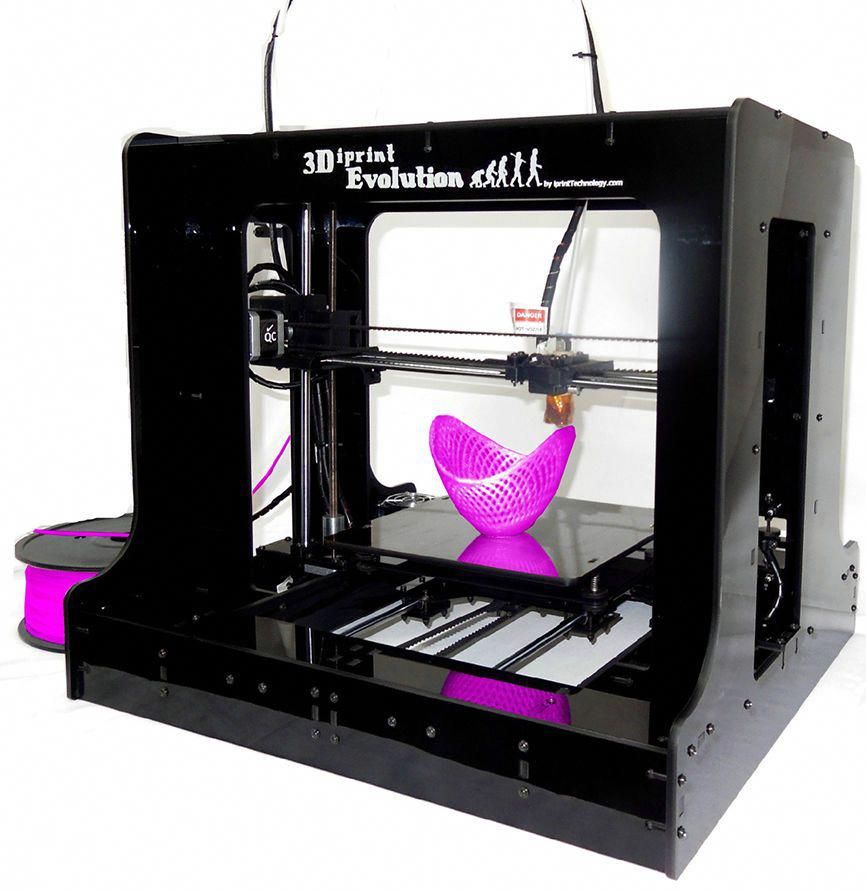

Professional 3D printers

Professional 3D printers

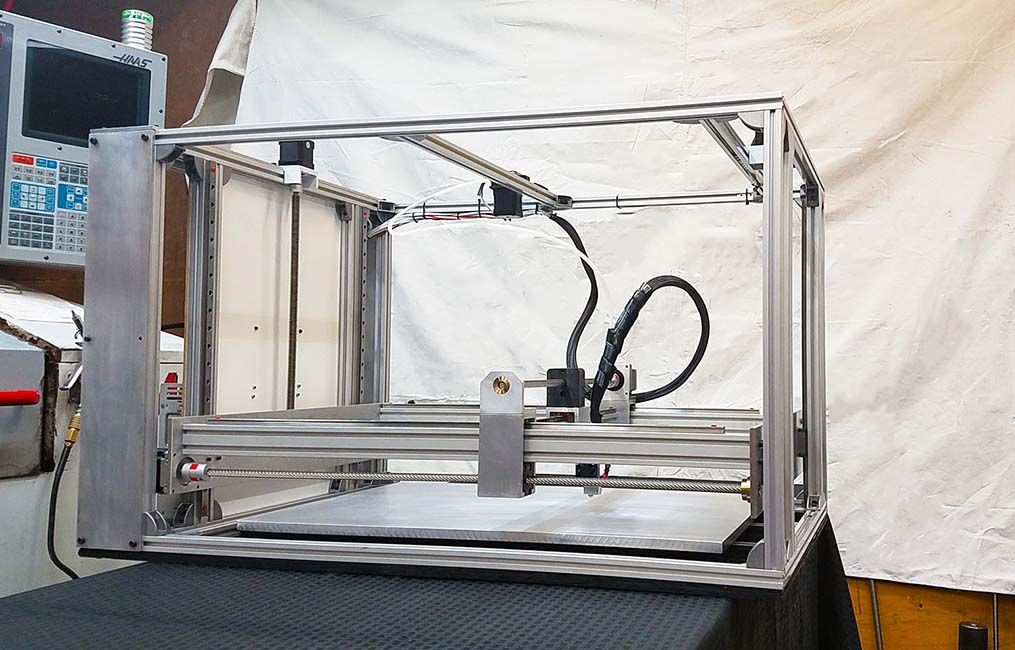

Our company has extensive experience in designing and manufacturing 3D printers for your needs. We design a professional printer strictly according to your requirements, which gives you 100% efficiency and reliability.

What is the difference between a professional 3D printer and a regular one?

First of all, development features. The device is not created as a toy for children, but as a professional 3D machine for printing with polymers. First of all, the reliability necessary for long and uninterrupted printing is laid in the model.

The case is designed to be very rigid, which eliminates problems with geometry, print quality, resonances and other companions of conventional low cost devices. A professional 3D printer contains only branded components for electronics. We repeat - first of all for reliability. Tests carried out have confirmed that printing can last between 40 hours and 80 without failure.

In mechanics, at the request of the customer, branded rail guides and ball screws are used to increase the accuracy and speed of printing.

In the electrical part, we use branded power supplies for more reliable operation, as well as proven and widely used components, which will allow, if necessary, to quickly replace a faulty board and restore functionality in a matter of minutes.

Professional 3D printer case can be made both open and closed - it depends on the choice of materials for solving your printing tasks. If you use polymers such as PLA, PETG, SBS, an open 3D printer will suffice. If the print will be with filaments such as ABS or HIPS, a closed case will be needed here to protect the part from shrinkage and premature delamination from the tabletop.

The development and production of professional 3D printers according to the customer's specifications has its advantages. In this case, we get a machine that is strictly tailored to your requirements for 3D printing - the dimensions of the print area you have chosen, for specific types of filament, and so on. If desired, the printer is equipped with an uninterruptible power supply to reduce the effect of power surges on the control electronics.

If desired, the printer is equipped with an uninterruptible power supply to reduce the effect of power surges on the control electronics.

Where are professional 3D printers used?

Such 3D printers are used in various industries, for printing tooling or master models. In design studios for printing layouts or molds, in injection molding for investment casting, in auto tuning, for printing custom body kits or decorative elements. It’s impossible to list everything - the list of examples of applications is growing every day.

Sort: DefaultName (A - Z)Name (Z - A)Price (low > high)Price (high > low)Rating (highest first)Rating (lowest first)Model (A - Z)Model (Z - A)

Show: 15255075100

3D printer BigFarm 1000x1000

Professional large 3D printer with huge build area. BigFarm 1000x1000 is designed for..

1500000r.

3D printer BigFarm 1000x500

Professional 3D printer with a large 3D print area - 0. 5 cubic meters. Designed to ..

5 cubic meters. Designed to ..

1200000r.

3D printer BigFarm 600x600

Large area 3D printer. BigFarm 600x600 is designed for an optimal price ratio.

Farm 3D printer 600x300

Industrial 3D printer with medium build area for small farms. Farm 600x300 is designed for..

600000r.

Showing 1 to 4 of 4 (total 1 pages)

Professional Budget 3D Printers

04/17/2020

Professional 3D printing equipment is becoming more affordable than ever. If earlier such models had rather bulky designs at exorbitant prices, now you can even put a professional budget 3D printer in your kitchen. At the same time, the gradation of devices from "amateur" to "professional" is often blurry and does not have a clear definition. By and large, professional 3D printers include all models that allow you to print with high-temperature plastics, the so-called "engineering" ones. This is not strong, but still narrows the search for the necessary 3D printer.

This is not strong, but still narrows the search for the necessary 3D printer.

To begin with, you need to decide what material you will print from and how much construction area you need for your tasks.

The Wanhao line includes several models of professional 3D printers in the budget price category.

First of all, this is model Wanhao Duplicator 6 Plus . The printer is equipped with a very reliable extruder with an all-metal print head - MK11 and a heated print platform. The heating temperature of the extruder reaches 260 C, which allows printing with ABS, Flex, Nylon, Polycarbonate, etc. plastics.

Full-scale printing with these materials makes it possible to create engineering prototypes and functional models.

The printer is available in two versions in a closed plastic case and with an open chamber. A closed chamber is, of course, preferable for high temperature plastics. It allows you to control the ambient temperature throughout the print, thereby getting the best results.

It allows you to control the ambient temperature throughout the print, thereby getting the best results.

Wanhao D6 Plus gives a very good print resolution: XY-axis positioning accuracy is 12.5 µm, and Z-axis positioning accuracy is 5 µm, layer thickness is from 20 to 200 µm.

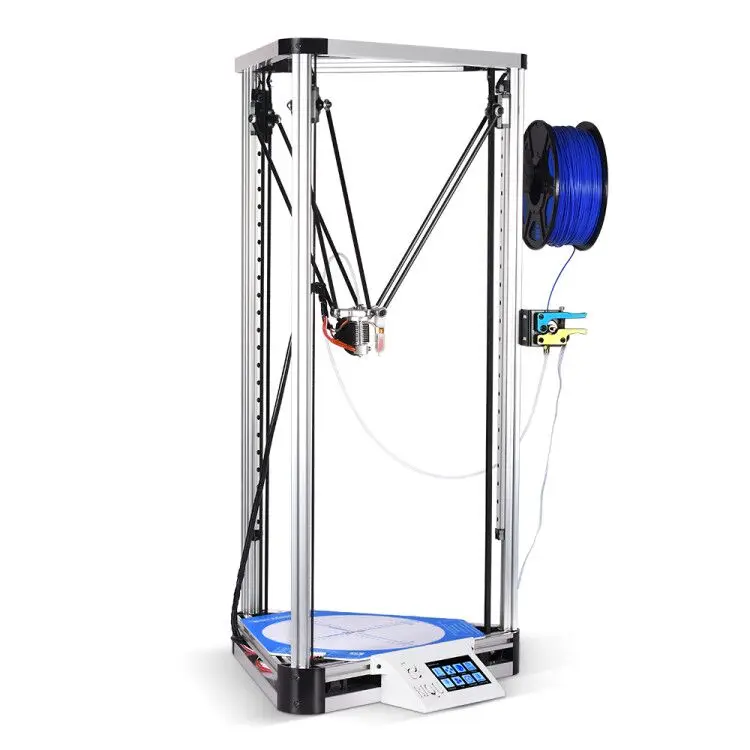

The Wanhao Duplicator 9 mark II line of models has the largest build area compared to other models from the manufacturer. The model is presented in several versions 300, 400 and 500. The model number corresponds to the size of the construction area: D9 / 300 - 30x30x40 cm, D9/400 - 40x40x40 cm, D9/500 50x50x50 cm.

Printers D9 mark II are equipped with an all-metal extruder MK10 with an operating temperature of up to 250 C and a heated platform. Models D9/300 and D9/400 have a two-sided printing surface of corrugated glass and PVC, while model D9/500 has only PVC surface.

The minimum layer thickness of D9 mark II 3D printers is less than that of D6 Plus, from 100 to 400 microns.