Israeli 3d printer

Israeli scientists produce 3D printer 'ink' capable of producing wood products

Researchers at Jerusalem’s Hebrew University have unveiled a 3D printer “ink” capable of producing printed wooden materials.

The technology takes organic “wood derivatives” and develops them into a paste, which is then used as ink by a 3D printer. As the paste dries, it warps into the desired shape.

Doron Kam, a PhD student working on the project, told The Times of Israel that the technology contains two main stages.

Firstly, organic material is broken down into “wood flour” and then combined with two other organic products which act as a glue.

In the second stage, the material is placed in a 3D printer, which proceeds to print a flat, 2D object. In regular tree wood, the structure of the cells determines the shape the wood will warp into as it dries. However, with the Hebrew University’s new technology, scientists can themselves control the cell structure, and therefore control the exact shape that the product will form as it dries and warps.

Get The Times of Israel's Daily Edition by email and never miss our top stories

Newsletter email addressBy signing up, you agree to the terms

“We are trying to make a material that won’t last forever, that’s what plastic is for. We are not looking for that,” Kam said.

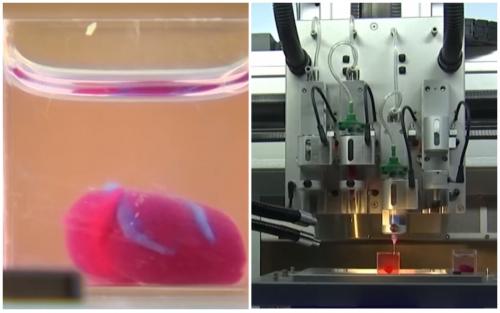

ICYMI: Israeli scientists at the Hebrew University of Jerusalem have developed a wood-based paste that after being 3D-printed, dries up and warps into a design set in advance pic.twitter.com/blq2A5DVHQ

— Reuters (@Reuters) September 18, 2022

Rather, Kam’s team envisions a material that lasts for “three or four years of use, and then you can grind it down and print it again. This is sustainability in our product, this is our principle.”

The team at Hebrew University is focusing its resources on the scientific process behind the concept, and has thus far only produced small example pieces.

The technology’s ability to produce large-scale items remains unproven. Kam insisted that it could be done, telling The Times of Israel that the printed wood product would maintain the same strength and durability as regular tree wood.

The printed wood can even maintain the aesthetic properties of its original source, allowing a user to select between different types of wood, such as oak or pine.

A ‘saddle-like’ curved piece produced by a wood-based 3D printing ink developed by researchers at Jerusalem’s Hebrew University, September 20, 2022. (Supplied)

Kam said that even after the process of grinding and printing, the wood maintains a distinct smell based on the species of tree it was originally derived from.

Products such as his could lead to a “sustainable economy at home,” Kam said.

With the cost of living continuing to soar, Kam said consumers can expect to see reusable 3D printed wooden products “very very soon.”

About | Massivit 3D

Transforming Manufacturing of Large Parts

Massivit 3D Printing Technologies Ltd. is a pioneer of large format 3D printing solutions for the Engineering, Visual Communications, Entertainment, Academia, Interior Design, and Architectural markets. Leveraging its proprietary Gel Dispensing Printing (GDP) technology, the company’s solutions enable rapid and cost-effective production of scale 1 models and parts.

is a pioneer of large format 3D printing solutions for the Engineering, Visual Communications, Entertainment, Academia, Interior Design, and Architectural markets. Leveraging its proprietary Gel Dispensing Printing (GDP) technology, the company’s solutions enable rapid and cost-effective production of scale 1 models and parts.

Founded in 2013 by a team of recognized industry experts, Massivit 3D is headquartered in Lod, Israel and provides its worldwide community with end-to-end services supported through an extensive dealer network.

Read more about Massivit 3d | Hebrew

OUR

valuesINNOVATION. We continually develop innovative, large additive manufacturing systems as well as brand new applications that grow our customers’ businesses in exciting new ways.

PASSION. It’s exciting to be able to shift the paradigm across multiple industries such as Engineering, Visual Communicaitons, Entertainment, and Academia. We’re passionate about bringing to market fresh and cost-effective fabrication methods and applications, with a solid track record of 57 patent assets.

We’re passionate about bringing to market fresh and cost-effective fabrication methods and applications, with a solid track record of 57 patent assets.

SIMPLICITY. Large format 3D printing is not only digital, but in our case, intuitive and easy to learn. A friendly user interface, simple operation, and truly outstanding customer services make a difference.

PARTNERSHIP. Supporting our customers’ ambition to make 3D printing a profitable dimension of their business is key. Through fast-turnaround solutions, intuitive technology, training & support and industry leading expertise – we support customer success every step of the way.

OUR

TeamDreaming big

We are a young company building on a rich legacy of industry innovation. Founded by Gershon Miller, Moshe Uzan and Igor Yakubov, pioneers in wide format printing & 3D printing, Massivit 3D is rapidly expanding the possibilities of large format 3D printing across multiple industries.

Our team of visionary co-founders and printing innovators is breaking new ground with revolutionary products and applications. As our customers make the exciting leap into digital, large format 3D printing, we’re supporting them every step of the way.

The leading team

Yaron Yecheskel

Chairman

Yaron Yecheskel

Chairman

Yaron Yecheskel is the founder and CEO of Opal Family Office – which provides financial strategy and management for family wealth. Previously, Yaron served as Manager of a private banking branch of Ubank, which is a part of the FIBI banking group, and as VP Marketing and Sales of a portfolio management company and a mutual fund company. Yaron holds a bachelor’s and master’s degree in Business Administration with a specialization in Finance and Capital Markets. He holds an investment advisor and investment portfolio manager license, issued by the Israeli Securities Authority. Yaron leads the controlling group of Massivit 3D and has served as Director of the company’s Board of Directors since 2016. In recent years, Yaron has greatly assisted in raising Massivit 3D’s capital and led the company to a successful IPO in the Tel Aviv Stock Exchange in 2021.

In recent years, Yaron has greatly assisted in raising Massivit 3D’s capital and led the company to a successful IPO in the Tel Aviv Stock Exchange in 2021.

Yaron Yecheskel

Chairman

Yaron Yecheskel is the founder and CEO of Opal Family Office – which provides financial strategy and management for family wealth. Previously, Yaron served as Manager of a private banking branch of Ubank, which is a part of the FIBI banking group, and as VP Marketing and Sales of a portfolio management company and a mutual fund company. Yaron holds a bachelor’s and master’s degree in Business Administration with a specialization in Finance and Capital Markets. He holds an investment advisor and investment portfolio manager license, issued by the Israeli Securities Authority. Yaron leads the controlling group of Massivit 3D and has served as Director of the company’s Board of Directors since 2016. In recent years, Yaron has greatly assisted in raising Massivit 3D’s capital and led the company to a successful IPO in the Tel Aviv Stock Exchange in 2021.

Erez Zimerman

CEO

Erez Zimerman

CEO

Erez Zimerman served as VP Global Sales at Massivit 3D for three years before being appointed CEO. He has a successful track record in sales & marketing and vast experience in multi-disciplinary systems. Before joining Massivit 3D, Erez served as VP Marketing & Business Development at Matan Digital Printers, which was acquired by EFI. Prior to Matan, Erez worked at Objet Geometries (which later merged with Stratasys) as Asia Pacific Marketing Manager and Product Manager. Erez also worked at Scitex Vision serving in various management positions both in R&D and Marketing. Erez holds a BSc in Electrical Engineering and an MBA from Bar Ilan University, Israel.

Erez Zimerman

CEO

Erez Zimerman served as VP Global Sales at Massivit 3D for three years before being appointed CEO. He has a successful track record in sales & marketing and vast experience in multi-disciplinary systems. Before joining Massivit 3D, Erez served as VP Marketing & Business Development at Matan Digital Printers, which was acquired by EFI. Prior to Matan, Erez worked at Objet Geometries (which later merged with Stratasys) as Asia Pacific Marketing Manager and Product Manager. Erez also worked at Scitex Vision serving in various management positions both in R&D and Marketing. Erez holds a BSc in Electrical Engineering and an MBA from Bar Ilan University, Israel.

Before joining Massivit 3D, Erez served as VP Marketing & Business Development at Matan Digital Printers, which was acquired by EFI. Prior to Matan, Erez worked at Objet Geometries (which later merged with Stratasys) as Asia Pacific Marketing Manager and Product Manager. Erez also worked at Scitex Vision serving in various management positions both in R&D and Marketing. Erez holds a BSc in Electrical Engineering and an MBA from Bar Ilan University, Israel.

Gershon Miller

Co-Founder & Chief Innovation Officer

Gershon Miller

Co-Founder & Chief Innovation Officer

A serial innovator and entrepreneur, Gershon founded Idanit, a pioneering developer of large format digital printing solutions. In 1998, Idanit was sold to Scitex Corporation where it was rebranded as Scitex Vision, and later sold to HP. Mr. Miller was the co-founder of Objet Ltd, a developer and manufacturer of 3D printers. In 2012 Objet merged with Stratasys, to become the leading 3D printing company (traded on NASDAQ under “SSYS”). He holds an BSc in Electro optics from The Jerusalem College of Technology in Israel.

He holds an BSc in Electro optics from The Jerusalem College of Technology in Israel.

Gershon Miller

Co-Founder & Chief Innovation Officer

A serial innovator and entrepreneur, Gershon founded Idanit, a pioneering developer of large format digital printing solutions. In 1998, Idanit was sold to Scitex Corporation where it was rebranded as Scitex Vision, and later sold to HP. Mr. Miller was the co-founder of Objet Ltd, a developer and manufacturer of 3D printers. In 2012 Objet merged with Stratasys, to become the leading 3D printing company (traded on NASDAQ under “SSYS”). He holds an BSc in Electro optics from The Jerusalem College of Technology in Israel.

Igor Yakubov

Co-Founder & VP R&D

Igor Yakubov

Co-Founder & VP R&D

Igor began his career as a programmer at Idanit, before gaining promotion to HP Scitex R&D Application & Color Group Manager where he led a group comprising 60 people covering all products. In 2011 Igor moved to AdOM, where he headed up software and algorithm development for analyzing 3D imaging files in a company offering advanced treatments for the retina. With extensive experience of multi-disciplinary products, Igor holds an MSc in physics from Makhachkala University, Russia. Igor also serves as a Director on the Massivit 3D board.

In 2011 Igor moved to AdOM, where he headed up software and algorithm development for analyzing 3D imaging files in a company offering advanced treatments for the retina. With extensive experience of multi-disciplinary products, Igor holds an MSc in physics from Makhachkala University, Russia. Igor also serves as a Director on the Massivit 3D board.

Igor Yakubov

Co-Founder & VP R&D

Igor began his career as a programmer at Idanit, before gaining promotion to HP Scitex R&D Application & Color Group Manager where he led a group comprising 60 people covering all products. In 2011 Igor moved to AdOM, where he headed up software and algorithm development for analyzing 3D imaging files in a company offering advanced treatments for the retina. With extensive experience of multi-disciplinary products, Igor holds an MSc in physics from Makhachkala University, Russia. Igor also serves as a Director on the Massivit 3D board.

Moshe Uzan

Co-Founder & COO

Moshe Uzan

Co-Founder & COO

A specialist in innovative multi-disciplinary printing systems, Moshe Uzan has built a distinguished career in the large format digital printing industry. One of the first members of Scitex Vision, Moshe subsequently became R&D manager of the drum machines product line at HP, including leading the development of the company’s ~1$ billion-generating Turbojet project line. He holds a BSc in Electronics Engineering from Ben Gurion University in Israel.

One of the first members of Scitex Vision, Moshe subsequently became R&D manager of the drum machines product line at HP, including leading the development of the company’s ~1$ billion-generating Turbojet project line. He holds a BSc in Electronics Engineering from Ben Gurion University in Israel.

Moshe Uzan

Co-Founder & COO

A specialist in innovative multi-disciplinary printing systems, Moshe Uzan has built a distinguished career in the large format digital printing industry. One of the first members of Scitex Vision, Moshe subsequently became R&D manager of the drum machines product line at HP, including leading the development of the company’s ~1$ billion-generating Turbojet project line. He holds a BSc in Electronics Engineering from Ben Gurion University in Israel.

Dana Erez

General Counsel and Company Secretary

Dana Erez

General Counsel and Company Secretary

Dana Erez

General Counsel and Company Secretary

Avi Cohen

VP Global Sales

Avi Cohen

VP Global Sales

Avi Cohen’s career started in sales, marketing, and high-level management positions in various companies, his over 20-year association with the additive manufacturing sector beginning in 1999 when he joined Stratasys (formally Objet). At Stratasys for 16 years, Cohen became Director of Healthcare Sales and Marketing, focusing his expertise on evangelizing about 3D printing technology, with a special concern for the medical and dental sectors. Cohen comes to Massivit after a 5-year stint as the Vice President at XJet Ltd a position he took up after moving on from Stratasys in 2015, and over two years at Nano Fabrica (acquired by Nano Dimension). Working at the forefront of the digital manufacturing revolution, Avi Cohen commands the respect of the entire international 3D printing community, and he is recognized as a strategically astute technology leader.

At Stratasys for 16 years, Cohen became Director of Healthcare Sales and Marketing, focusing his expertise on evangelizing about 3D printing technology, with a special concern for the medical and dental sectors. Cohen comes to Massivit after a 5-year stint as the Vice President at XJet Ltd a position he took up after moving on from Stratasys in 2015, and over two years at Nano Fabrica (acquired by Nano Dimension). Working at the forefront of the digital manufacturing revolution, Avi Cohen commands the respect of the entire international 3D printing community, and he is recognized as a strategically astute technology leader.

Avi Cohen

VP Global Sales

Avi Cohen’s career started in sales, marketing, and high-level management positions in various companies, his over 20-year association with the additive manufacturing sector beginning in 1999 when he joined Stratasys (formally Objet). At Stratasys for 16 years, Cohen became Director of Healthcare Sales and Marketing, focusing his expertise on evangelizing about 3D printing technology, with a special concern for the medical and dental sectors. Cohen comes to Massivit after a 5-year stint as the Vice President at XJet Ltd a position he took up after moving on from Stratasys in 2015, and over two years at Nano Fabrica (acquired by Nano Dimension). Working at the forefront of the digital manufacturing revolution, Avi Cohen commands the respect of the entire international 3D printing community, and he is recognized as a strategically astute technology leader.

Cohen comes to Massivit after a 5-year stint as the Vice President at XJet Ltd a position he took up after moving on from Stratasys in 2015, and over two years at Nano Fabrica (acquired by Nano Dimension). Working at the forefront of the digital manufacturing revolution, Avi Cohen commands the respect of the entire international 3D printing community, and he is recognized as a strategically astute technology leader.

Hadar Friedland

VP HR

Hadar Friedland

VP HR

Hadar Friedland

VP HR

Vegan steak 3D printer invented in Israel

Favorites

-

Society: 29 thousand Kazakh officials hide their income

-

Society: The Ministry of Health proposes to reduce the punishment for medical error

-

Society: Damage to victims of a utility accident is compensated in Ekibastuz

-

Society: The required temperature is raised in the schools of Ekibastuz

-

Economy: Kazakhstan proposes to extend the ban on the export of fuel and lubricants

-

Society: Journalist Kozachkov was arrested for two months

nine0031

391

In Israel, they came up with a 3D printer for vegan steaks. And in the States, 199 people voluntarily signed up for cryogenic freezing. About these and other news in the field of modern technologies, in the material of the Khabar 24 correspondent.

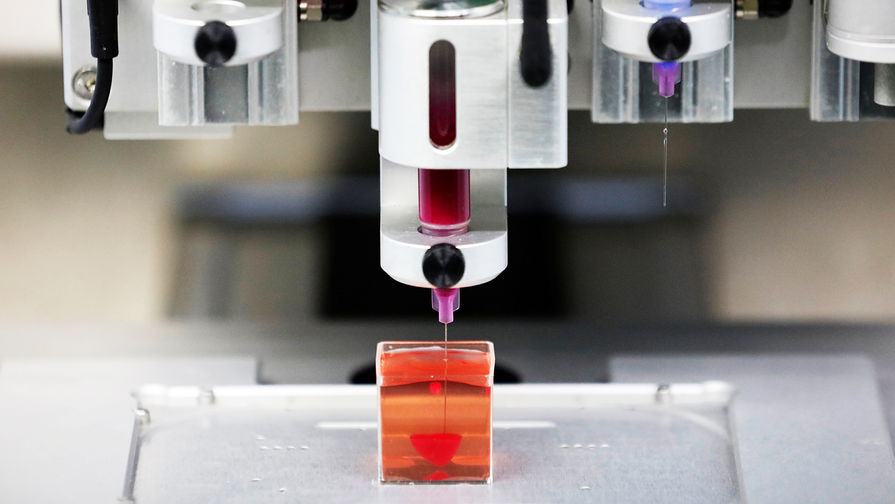

This is an Angus 3D printer. It was developed by an Israeli company. Innovative technology produces vegan steaks. They are already served in 1,000 restaurants in Israel, the UK, the Netherlands and Germany. A kilogram of unique meat can be bought for $40. To create a separate piece, the company's employees use layer-by-layer building. Then the plant base is saturated with fats, moisture, smell and taste are added. So the final product is as close as possible to real meat. In total, the company has eight 3D printers. Two are in Israel. Six - in the Netherlands, where the plant will be fully operational in December. nine0005

Two are in Israel. Six - in the Netherlands, where the plant will be fully operational in December. nine0005

Yaron Eshel, manager of the 3D printer manufacturer:

- This is a touch interface. With it, you can select a steak from the library. Also, the options for roasting, the amount of fat and the category of marbling are loaded into the system. Cooking time takes 15-20 minutes. The steak is built up layer by layer. Thanks to this, we can control the structure of the fibers in order to then fill with fat and moisture. This allows you to get as close as possible to the biological meat that we are used to eating. nine0050

CRYO FREEZING

And there is a so-called cryonics center in Arizona. It's hard to believe, but the bodies of 199 people who once voluntarily agreed to cryopreservation are frozen here. Their goal is to revive when the field of medicine takes a step forward. Many of the people are terminally ill with cancer and other ailments. The bodies are stored inside tanks filled with liquid nitrogen. Meanwhile, scientists are skeptical about the activities of the cryonics center and the so-called cryofreezing. nine0005

The bodies are stored inside tanks filled with liquid nitrogen. Meanwhile, scientists are skeptical about the activities of the cryonics center and the so-called cryofreezing. nine0005

Arthur L. Kaplan NYU professor:

- The people who sort of specialize in studying the distant future are the people who are interested in your money. I don't see people lining up to really study brain structure, physiology, or psychotherapy.

A NEW GENERATION OF EXOSKELETONS

A new generation of exoskeletons has been introduced at Stanford University. It is a device that assists people with mobility problems in walking. The so-called "robotic boot" is equipped with a special engine. It works the calf muscles and gives extra push with every step. According to the creators, their offspring differs from previous exoskeletons in lower energy consumption. They also claim that the invention helps to walk 9% faster and spend 17% less energy than conventional shoes. Technological progress does not stand still, and the discoveries of the last few days are proof of this.

Technological progress does not stand still, and the discoveries of the last few days are proof of this.

Authors: Akerke Baktybaykyzy, Sandugash Baiguanysh

#Israel #freeze #USA #Khabar 24 #technologies

Articles by tag

nine0002 © 2022, Khabar 24 TV channel. All rights reserved.Israel creates a 3D printer to print "meat" on an industrial scale | Meat Technology

Israel has created a 3D printer to print "meat" on an industrial scale | Meat technologies | Industry NewsSign in

Welcome!Log into your account

Your username

Your password

Have you forgotten your password? nine0005

Password recovery

Recover your password

Your email address

The idea of replacing meat with plant foods has penetrated deeply into modern society. People even learned how to print "steaks" on a 3D printer. Until now, only a few restaurateurs could indulge in such exoticism. But now everything can change.

Until now, only a few restaurateurs could indulge in such exoticism. But now everything can change.

- Advertisement -

Israeli company Redefine Meat has unveiled a 3D printer that can produce "meat" from vegetable ingredients on an industrial scale, NTDTV reports. nine0005

According to the developers, it can produce several tons of products every day.

According to one of the founders of the company, Eshar Ben-Shitrit, the printed "meat" has the same characteristics as the real one.

“It feels like a good steak, a tasty piece of animal meat, but without the use of an animal,” he noted.

Remarkably, this effect is created by a combination of soy, peas, chickpeas, beets, nutritional yeast and coconut oil. From these products, the machine creates muscle, fat and blood, and then combines them to obtain "meat". By the way, the printer settings allow you to create “steaks” of different hardness. nine0005

nine0005

With the new machine, Redefine Meat hopes to compete with traditional meat producers. Currently, eight such printers have already been assembled, six of them are working in Israel, and two more have been sent to the Netherlands, where a plant for the production of meat from plant components is due to open by the end of this year.

However, time will show how successful this idea is now. Against the backdrop of inflation, Europeans are trying to save on everything, and natural meat in the store is still much cheaper than an analogue from a 3D printer. In addition, fast food chains, which use artificial meat the most, are now in crisis due to a lack of staff. nine0005

Latest news

Kursk Meat Processing Plant increased labor productivity

At the Kursk meat processing plant, which is located in the village.