Ipf 3d printing

About IPF ltd - Treatstock

Select photo

Share on

Share the affiliate link and earn a 50% recurring commission from each completed order. Make money while you sleep.

Upload a CAD model to get an online quote for manufacturing services

Drag and drop or

1

Upload your 3D models

Browse files

STL, PLY, OBJ, 3MF, CDR, DXF, EPS, PDF or SVG files are supported

Paste a link to the 3D model

Processing...

Choose Manufacturing Service *

Project Description *

Plastic Machining, Fabrication and 3D Printing Specialists. On demand prototyping and production plastic parts.

Established 1969, IPF ltd utilise top of the range 3D printing and CNC technologies to produce quality parts for medical, defence, product development, motorsport & scientific industries. Services include laser welding and diffusion bonding for microfluidics or pneumatic manifolds, high speed milling and routing, laser cutting and fabrication as well as an extensive range of Polyjet, SLA, HP MJF and FDM 3D print technologies.

Shipping options

Location

London, England, GB

| Business type | Manufacturing Business |

| Ownership | Limited Liability Company (LLC) |

| Incoterms | EXW |

| Total Employees | 10-49 |

| Year established | 1969 |

| Annual turnover ($) | 1800000 |

Certifications

Showing 1-1 of 1 item.

| File | Certification | Certifier | Application | Issue Date | Expire Date |

|---|---|---|---|---|---|

| Quality Management System ISO 9001:2015 | BSI | Quality Control | Apr 19, 2019 | Apr 18, 2022 |

Reviews

Aug 15, 2019

| Speed | |

| Quality | |

| Communication |

IPF ltd is a prototyping company that specialized in highly detailed and quality custom parts in demand. The vendor printed our item in black Nylon powder in a timely manner. Our test model came out fine, the surface is pretty neat and smooth, all the tricky details such as thin "antennas" look solid enough. The proportions are also accurate.

| Printed on: | HP Jet Fusion 3D 4200 |

| Material: | HP PA-12 |

Buy Now

More reviews

IPF Archives - Blog | 3D Printing Articles and Innovation

CrossNibbleUncategorized

Computer Numerical Control (CNC) technology has existed in commercial manufacturing for decades now. In this technology, the production output is achieved by automating machine tools via a complex set of computers executing multiple pre-programmed sequences of machine control commands using Computer Aided Design (CAD) and Computer Aided Manufacturing (CAM) software applications. The modern 3D printers […]

In this technology, the production output is achieved by automating machine tools via a complex set of computers executing multiple pre-programmed sequences of machine control commands using Computer Aided Design (CAD) and Computer Aided Manufacturing (CAM) software applications. The modern 3D printers […]

CrossNibbleUncategorized

The year 2017 was a transformative one for Divide By Zero Technologies. Not only did our company grow in terms of size and product offerings but it also won accolades and appreciation from prestigious institutions. The month of December was a harbinger of good news for our company and we want to share our success […]

CrossNibble3D Printing World Awards

International Recognition to Divide By Zero Technologies for being Fastest Growing Innovative Manufacturing SME. We’re extremely proud to announce that Divide By Zero Technologies has won the WASME SME Excellence Awards 2017. At a gala event flanked by the Hon. Vice President of India, H. E. Mr. M. Venkaiah Naidu and other key dignitaries, the […]

We’re extremely proud to announce that Divide By Zero Technologies has won the WASME SME Excellence Awards 2017. At a gala event flanked by the Hon. Vice President of India, H. E. Mr. M. Venkaiah Naidu and other key dignitaries, the […]

CrossNibble3D Printing World Awards

3D printing is taking over all aspects of innovation and research. This technology’s contribution to prototyping and to slashing the time required for a product to reach the market is something everyone is taking notice of and rightly so. Right from 3D printing skin tissues using bio-ink to prototyping in defense, architecture, medical implants, and […]

CrossNibble3D Printing Articles

When comparing additive manufacturing techniques to its traditional predecessors, one challenge to anticipate is the contrasting differences in material properties. The chart to the left provides an overview of performance criteria and how 3D printing and CAE compare. Each 3D printing technique yields a different set of mechanical and thermal properties, as well as layer […]

The chart to the left provides an overview of performance criteria and how 3D printing and CAE compare. Each 3D printing technique yields a different set of mechanical and thermal properties, as well as layer […]

CrossNibble3D Printing Articles

3D Printing is one of the most promising upcoming technologies. With its applicability spread across industries, not designers and engineers but doctors and architects are exploring the possibilities. It has allowed these professionals to print their ideas into prototypes and physically see the structure coming to life before going into the manufacturing stage. From a […]

3D printing is successfully introduced into the economy

Arguments of the Week Nizhny Novgorod → Economy → No. 13(757) April 7 - 13, 2021 13+

13(757) April 7 - 13, 2021 13+

April 7, 2021, 10:09 Konstantin BARANOVSKY

For the ordinary, mass consciousness, 3D printers seem to be a kind of high-tech, but a toy, fun for a narrow layer of technologists. This hasn't been the case for a long time.

Wide range of applications

In particular, 3D printing is widely used in dentistry, in several areas of activity of dentists and dental technicians. In Nizhny Novgorod, the most advanced companies that care about the comfort of their customers have long since switched to 3D printing. Moreover, it is increasingly being used by the largest Russian dental holding VladMiVa, located in Belgorod. For understanding, the holding is headed by Vladimir Chuev - one of the key figures in the Russian dental industry, Doctor of Technical Sciences, Professor, Academician of the Academy of Technical Sciences of the Russian Federation, Head of the Basic Department of Medical and Technical Systems of Belgorod State University, Vice President of the Association of Trade and Industrial Enterprises of Dentistry "Dental Industry" . Author of 12 patents in the field of dentistry, dental composite materials and polymers. Author (co-author) of more than 120 scientific publications on the production and use of dental materials, as well as their chemical properties.

For understanding, the holding is headed by Vladimir Chuev - one of the key figures in the Russian dental industry, Doctor of Technical Sciences, Professor, Academician of the Academy of Technical Sciences of the Russian Federation, Head of the Basic Department of Medical and Technical Systems of Belgorod State University, Vice President of the Association of Trade and Industrial Enterprises of Dentistry "Dental Industry" . Author of 12 patents in the field of dentistry, dental composite materials and polymers. Author (co-author) of more than 120 scientific publications on the production and use of dental materials, as well as their chemical properties.

VladMiVa supplies its products to 65 countries.

And recently Chuev visited Nizhny Novgorod, where he met with Kirill Belov, founder of 3D Additive Technologies Research and Production Enterprise, and Kirill Kornilov, CEO. The parties agreed on cooperation, and the first batch of Nizhny Novgorod photopolymer resins, developed specifically for VladMiVA, has already left for Belgorod.

And here is what Alexey Novozhilov, a dentist of the highest category, Candidate of Medical Sciences, who, in particular, taught at the Nizhny Novgorod State Medical Academy, said:

– 3D printing is entering all spheres of life, including dentistry. In order to keep up with progress, I began to study this issue, then I bought a scanner, a printer and began to try. It's hard to learn new technology from scratch, but the developers of Gorky Liquid photopolymer helped me figure it out.

In the manufacture of temporary crowns, for example, photopolymers are of great help. Firstly, it is convenient, you are independent of dental technicians, especially in quarantine. Secondly, you make the prosthesis the way you see it yourself. Thirdly, it is fast, no more than 1 hour passes from the impression to the crown or bridge. Fourth, it is an accuracy reaching 1 micron. However, a 3D printed crown can be used for more than just a temporary option.

Unless it is necessary to train dentists in 3D printing technologies, there are many nuances. Undoubtedly, 3D printing in dentistry has a great future.

Undoubtedly, 3D printing in dentistry has a great future.

We will return to the Nizhny Novgorod developer and manufacturer of photopolymers, but for now we will continue our journey through the world of 3D printing.

As it turned out, it is quite widely used in science and industry. In particular, a company such as the Burevestnik Central Research Institute uses 3D printing.

The Institute of Applied Physics of the Russian Academy of Sciences did not bypass it either.

– We use photopolymer resins produced by the 3D Additive Technologies Research and Production Enterprise for the manufacture of dielectric parts, since, as a rule, it is faster and cheaper to print complex objects than to machine them using turn-mill equipment. In addition, we use these photopolymers in the co-production of ultrasonic antennas for optoacoustics (http://photoacoustics.ru). The quality and technical parameters of photopolymers from NPP "3D Additive Technologies" are more than satisfied, - said Pavel Subochev, Head of the Laboratory of Ultrasonic and Optoacoustic Diagnostics of the IAP RAS.

Subochev is sure that in the next decade photopolymers will find the widest application:

– They make it possible to reduce the cost and speed up the production of parts for devices and mechanisms many times over. Photopolymers are suitable for both prototyping and industrial applications. I am sure that every year the scope of photopolymers will only expand.

Research and development and production - in Nizhny Novgorod

We are habitually proud of Nizhny Novgorod science and Nizhny Novgorod industry, not always guessing even what forms both of these are pouring into today. Here, for example, is the Research and Production Enterprise “3D Additive Technologies”, which we have already mentioned. The Nizhny Novgorod company has been operating since 2016, and it does not just repackage purchased at Chinese online flea markets. NPP "3D Additive Technologies" has its own laboratory and production. That is, R&D is carried out here and high-tech photopolymer resins are produced under the Gorky Liquid brand. The founder of the company, Kirill Belov, explains that it took a long time to come up with a trademark. It turned out either a big and awkward name, or meaningless. And then the current CEO of NPP "3D Additive Technologies" Kirill Kornilov proposed the name Gorky Liquid.

The founder of the company, Kirill Belov, explains that it took a long time to come up with a trademark. It turned out either a big and awkward name, or meaningless. And then the current CEO of NPP "3D Additive Technologies" Kirill Kornilov proposed the name Gorky Liquid.

- There is a message to the history of the native city, both brevity and sonority. And this brand came in handy for us when we entered the US markets - it was easy for our overseas counterparties to remember and pronounce it, - says Belov.

A small touch: the Nizhny Novgorod manufacturer is the only Russian company that produces photopolymer resins in metal containers, which are placed in a box lined with a lodgment from the inside. This increases the overhead costs, but the consumer receives the resin in an undamaged container, exactly as much as ordered (nothing leaks along the way). The aesthetic point is also important. The containers offered to customers start from 0.25 kg and end in volumes of tens of kilograms (yes, photopolymer resins are measured in kilograms) - as it is more convenient for users.

Kirill Belov is an ardent supporter of import substitution:

– With a Russian product that is similar or even superior to imported resins, its prices are two to three times lower, which allows the consumer to reduce costs and improve their financial condition. Domestic manufacturers of photopolymer resins can completely replace imported products. There are all prerequisites for this. For example, we use raw materials from Dzerzhinsk, located, as they say, at arm's length from Nizhny Novgorod. Our laboratory is headed by a graduate of the Faculty of Chemistry of UNN. At the end of February, cooperation began with the largest Russian dental holding VladMiVa; American consumers have “tasted” our product. What more evidence is needed for the competitiveness of regional photopolymer resins? Unless attention and support from the state would not interfere.

RPE "3D Additive Technologies" is preparing to join the Association of Trade and Industrial Enterprises of Dentistry "Dental Industry".

In addition, together with Nizhny Novgorod doctors, a Corporate University is being opened, where dentists will be trained to use 3D printers. According to the collected data, about 90% of dentists and dental technicians know that 3D printing can be used, but they are in no hurry to do it: the sphere is new, unknown, no matter what happens.

– Dentists can understand that the use of new materials can carry certain risks. In addition, there are various kinds of features in the use of 3D printers. So far, word of mouth has been a big influence in the industry: someone has to be the first to try and tell others. In order to teach dentists and dental technicians how to handle 3D printers, we are opening our Corporate University, , explained Kirill Kornilov, General Director of 3D Additive Technologies Research and Production Enterprise LLC.

Development - in-house

Having our own laboratory allows us to carry out R&D and achieve materials with new properties. At least in the Volga region, 3D Additive Technologies was the first to produce a conductive polymer for 3D printing. The laboratory was used to 100% of its capabilities - both the "gray matter" of the staff and the available equipment.

At least in the Volga region, 3D Additive Technologies was the first to produce a conductive polymer for 3D printing. The laboratory was used to 100% of its capabilities - both the "gray matter" of the staff and the available equipment.

As a result, it was possible to create a photopolymer whose electrical resistance is only a few tens of kiloohms - that is, it conducts current, unlike a conventional polymer, whose resistance is close to infinity (and, accordingly, zero conductivity).

A conductive photopolymer developed by 3D Additive Technologies Research and Production Enterprise was sent for experiments to the IAP RAS.

Another recent development is Gorky Powder, a polyamide powder for SLS 3D printers. This is the first step towards introducing a line of polyamide powders into our own production.

The first batch of polyamide powder is in beta testing.

Why do we know so little about this?

Unfortunately, so far, companies that use 3D printing in their activities are not very good with contacts with the media. Of course, news in the specialized media comes out regularly, but so far the only ones that have broken through the boundaries of a kind of ghetto are the 3D Additive Technologies Research and Production Enterprise. Yes, and the sphere, I must say, is specific, a kind of training is required for journalists writing on economic topics, otherwise mistakes and stupidities cannot be avoided. Perhaps people working with photopolymers and 3D printing realize the need for information transparency, and then we will all learn a lot of new and interesting things.

Of course, news in the specialized media comes out regularly, but so far the only ones that have broken through the boundaries of a kind of ghetto are the 3D Additive Technologies Research and Production Enterprise. Yes, and the sphere, I must say, is specific, a kind of training is required for journalists writing on economic topics, otherwise mistakes and stupidities cannot be avoided. Perhaps people working with photopolymers and 3D printing realize the need for information transparency, and then we will all learn a lot of new and interesting things.

Subscribe to Arguments of the week: News | Zen | Telegram

Advertising

- photopolymer resins

- IAP RAS

- 3D printing

- dentistry

- innovation

News Mirtesen

Air pollution in 3D printing

Main page

Articles

Smoke from a 3D printer

Smoke from a 3D printer

Introduction How the printer pollutes the air How BOFA filters

What is 3D printing

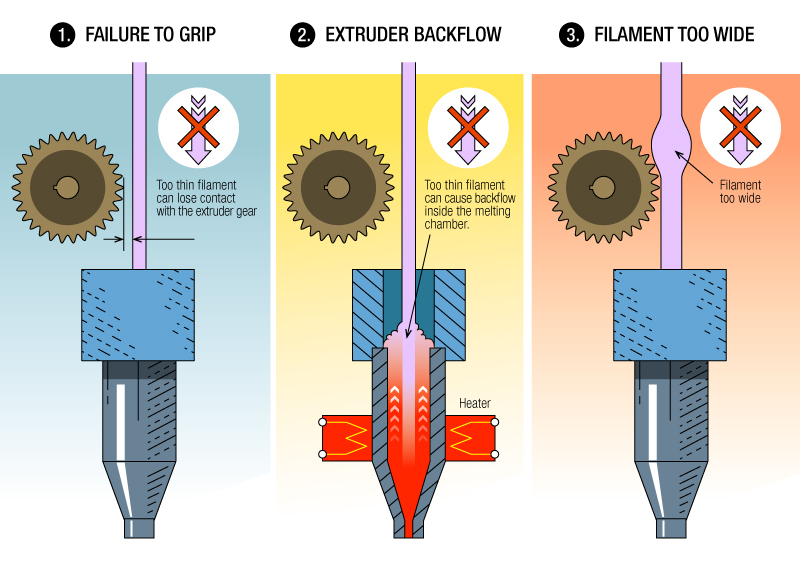

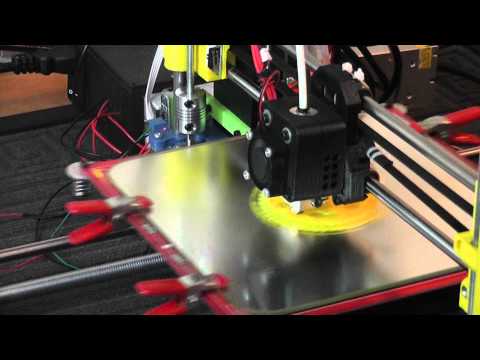

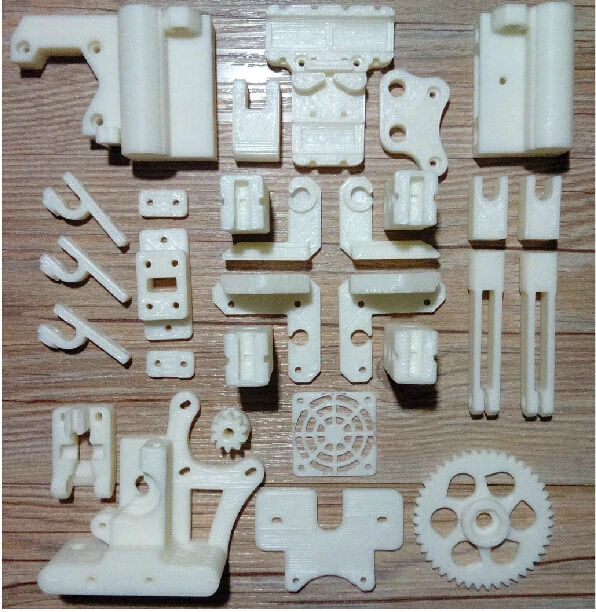

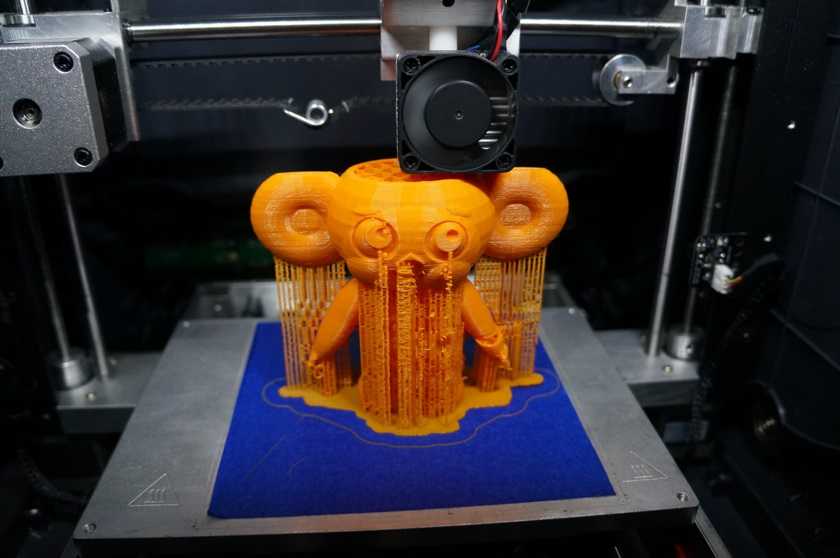

3D printing is also known as additive manufacturing. This means that the product is created by adding material in layers. The process is controlled by a coordinate XYZ robot with digital control. Printers work with plastic or metal. The material is fed to the deposition point in the form of wire or powder. The printer is melting the material. Then it connects to the previously applied base.

This means that the product is created by adding material in layers. The process is controlled by a coordinate XYZ robot with digital control. Printers work with plastic or metal. The material is fed to the deposition point in the form of wire or powder. The printer is melting the material. Then it connects to the previously applied base.

A 3D printer will produce objects of complex shape. This favorably distinguishes the additive process from the subtractive one, when excess is removed from a large piece of material. Machining, laser processing, soldering or welding generate more contamination. And a lot of material is wasted. 3D printing does not consume a lot of extra material. It appears to be a clean process, but it still pollutes the air.

Anyone using 3D printing needs to be aware of the health risks. The 3D printer seems safe. But it can generate toxic fumes and hazardous substance particles. Technological processes that transform the material pollute the air in the workplace. This applies to cutting, engraving, thermal decomposition in a laser machine, soldering with a toxic flux, etc. Molten metals and polymers are no exception.

This applies to cutting, engraving, thermal decomposition in a laser machine, soldering with a toxic flux, etc. Molten metals and polymers are no exception.

Why is a 3D printer dangerous?

Ultrafine particles

Heating a substance causes the release of solid particles, droplets and vapors. They may be harmful if inhaled.

European scientists are gradually revealing the dangers of 3D printing to health. According to the 3D Printer Emissions Report , plastic melting releases small nanoparticles of material into the air. They cannot be seen without special equipment. But that doesn't mean they are safe.

PLA plastic nanoparticles are used in pharmaceuticals as a means of delivering drugs to various organs, including the brain. Cosmetics use the same effect. Ultrafine particles penetrate the skin. By themselves, PLA particles are not toxic. But no one knows about the consequences of accumulation in human organs. Nanoparticles condense into relatively large formations. It is known for certain about the harmfulness of nanoparticles of soot from automobile exhausts . They are associated with degenerative brain diseases, such as Alzheimer's disease.

Nanoparticles condense into relatively large formations. It is known for certain about the harmfulness of nanoparticles of soot from automobile exhausts . They are associated with degenerative brain diseases, such as Alzheimer's disease.

ABS plastic is toxic when melted. Nanoscopic ABS particles are just as toxic. These particles are very small. During inhalation, they enter the brain through the olfactory nerve. They spread throughout the body through the bloodstream. Most organs can get rid of them naturally, but the brain and lungs become clogged for a long time.

In fact, particles as small as 10-200nm easily enter the bloodstream through the lungs. Their toxic action differs from the original substance in the usual shapes and sizes. According to study by the Italian Institute of Health and Consumer Protection nanoparticles are deposited in the lungs in greater quantities than e-cigarette smoke.

Gases or vapors

Molten ABS gives off a particularly unpleasant odor. Other plastics including nylon, HIPS and HDPE emit the same toxic fumes but have less odor.

Other plastics including nylon, HIPS and HDPE emit the same toxic fumes but have less odor.

Polymer materials can vaporize some of their constituents. Dioctyl phthalate is often added to them for flexibility and mold resistance. During high heat or laser treatment, benzene is released in hazardous quantities. And while working with PVC, HCl aerosol condenses in the air.

The high temperature in the area of the printer head causes the air to expand. Vapors quickly spread in the work area along with plastic particles. Thermal degradation products of polymers are shown in the diagram below.

How does BOFA work?

A smoke extractor is an extractor hood with filters placed in one device. She got her name at the time when she removed the smoke of a soldering iron or a laser engraver. But these same devices with special filters are also suitable for a three-dimensional printer. The smoke extractor block for the printer is not much different from the soldering block.

3D printing is sensitive to changes in air temperature. Therefore, he is afraid of drafts. If you are using a small open printer, then the polluted air can be removed with a conventional smoke extractor. In order not to disturb the climate in the printer, select the minimum air suction speed.

If your 3D printer model is closed, there is a protective cover, then you can install a cleaning curtain. During operation, while the printer window is closed, it can be turned off. But it will clean the outgoing air when you open the box to take out the finished product.

If your printer is large and completely enclosed, then it will most likely have built-in pipes for connecting the hood. They can be connected to a smoke extractor with large filters. It can operate continuously or turn on at the command of the printer. The fume extractor captures dirty air and returns it back to the printer so as not to change the air temperature during the printing process.

3-stage filtration

A complete smoke extractor is equipped with three filters. The first is the pre-filter. It does not let in coarse dust, so as not to clog the main fine filter with it. The fine filter is HEPA. Particles of all sizes, including aerosols and nanoparticles, settle on its fibers. The gas filter completes the cleaning. It consists of densely packed activated carbon granules with interlayers of fiberglass. Activated carbon traps VOCs and nanoparticles that HEPA missed.

Smoke extractor against exhaust

The cheapest way to remove smoke is a duct fan and air ducts. The emission of polluted air through the window is prohibited by SanPin standards. And the smoke extractor has advantages.

- Good air purification from all kinds of solid particles and aerosols

- There will be no odors from melted plastic or metal in the room

- You will be sure that your health will not suffer

- The microclimate in the 3D printing machine will be stable

- Supply ventilation with heating or air conditioning is not needed, as for the hood in the window

Eliminate the harmful agent

The hood with filters will solve the problems with harmful emissions from 3D printing with polymers and metal powder.