Best professional 3d printer price

mix of features, performance, and price

What is the best professional desktop 3D printer?

There are so many different 3D printers on the market today that it can be a real challenge to choose one. When every penny of your quarterly budget counts, you want to make sure your professional 3D printer is adapted to your needs. Material compatibility, build size, ease of use, workflow, software, and many more elements come into play.

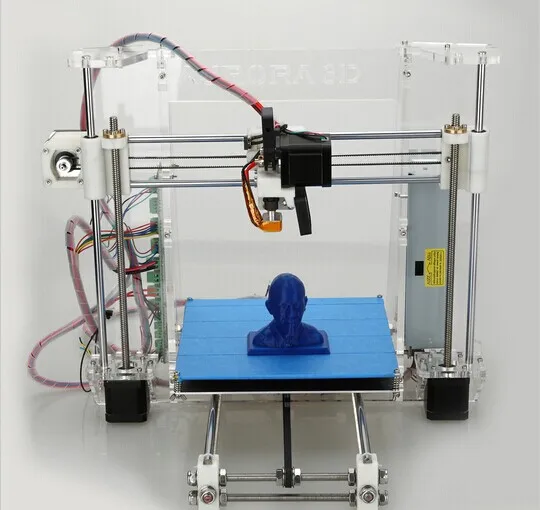

To help you cut through the clutter, we made a shortlist of some of the best professional 3D printers available this year. These benchtop and desktop FFF (fused filament fabrication) 3D printers for professionals offer a great combination of features, performance, and reliability, and come from well-established brands. They are ideal tools for rapid prototyping and iterative design processes, and are also suitable for low-volume production series. Keep in mind, though, that while part quality does depend on your printer’s performance, it also greatly relies on your choice of materials.

Towards the end of this article, we also provide a brief buying guide where you can learn more about different 3D printer specifications such as printing temperatures, layer thickness, dual extrusion, and more.

Best benchtop 3D printers for professionals in 2022: our selection

The table below recaps our selection of some of the best professional 3D printing options for office use. Our goal is to provide a quick, visual overview of the market; there are of course numerous other factors to take into account (material compatibility, certifications, customer service, software, etc.) before making the right choice.

| Brand | Product | Build size | Country | Price Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …). | |

|---|---|---|---|---|---|

| Prusa Research | Original Prusa i3 MK3S This product has been reviewed by our team. | 250 × 210 × 210 mm9.84 × 8.27 × 8.27 in | Czech Republic | $ 9991 015 €886 £148,907 ¥ | Buy |

| BCN3D Technologies | Sigma D25 | 420 × 300 × 200 mm16.54 × 11.81 × 7.87 in | Spain | $ 3,9953 495 €3,544 £595,479 ¥ | Quote |

| Ultimaker | Ultimaker S5 | 330 × 240 × 300 mm12.99 × 9.45 × 11.81 in | Netherlands | $ 5,9955 495 €5,318 £893,591 ¥ | Quote |

| MakerBot | Method X | 190 × 190 × 196 mm7.48 × 7.48 × 7.72 in | United States | $ 6,4996 606 €5,765 £968,715 ¥ | Quote |

| Raise3D This brand is a certified partner from our network. | Pro3 Plus This product has been reviewed by our team. | 300 × 300 × 605 mm11.81 × 11.81 × 23.82 in | United States | $ 7,2496 249 €6,430 £1,080,507 ¥ | Quote |

| Markforged | Onyx Pro | 320 × 132 × 154 mm12. 6 × 5.2 × 6.06 in 6 × 5.2 × 6.06 in | United States | $ 9,60010 000 €8,516 £1,430,938 ¥ | Quote |

| Stratasys | F120 | 254 × 254 × 254 mm10 × 10 × 10 in | United States | $ 12,00011 000 €10,644 £1,788,672 ¥ | Quote |

Expand to see more specs

The products in the table are ranked by price (low to high).

| Brand | Product | Build size | Build volume | Extruder temp. | Country | Price Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …). | |

|---|---|---|---|---|---|---|---|

| Prusa Research | Original Prusa i3 MK3S This product has been reviewed by our team. | 250 × 210 × 210 mm9.84 × 8.27 × 8.27 in | 11.03 L | 300°C | Czech Republic | $ 9991 015 €886 £148,907 ¥ | Buy on Prusa |

| BCN3D Technologies | Sigma D25 | 420 × 300 × 200 mm16. 54 × 11.81 × 7.87 in 54 × 11.81 × 7.87 in | 25.2 L | 300°C | Spain | $ 3,9953 495 €3,544 £595,479 ¥ | Get a quote |

| Ultimaker | Ultimaker S5 | 330 × 240 × 300 mm12.99 × 9.45 × 11.81 in | 23.76 L | 280°C | Netherlands | $ 5,9955 495 €5,318 £893,591 ¥ | Get a quote |

| MakerBot | Method X | 190 × 190 × 196 mm7.48 × 7.48 × 7.72 in | 7.08 L | 260°C | United States | $ 6,4996 606 €5,765 £968,715 ¥ | Get a quote |

| Raise3D This brand is a certified partner from our network. | Pro3 Plus This product has been reviewed by our team. | 300 × 300 × 605 mm11.81 × 11.81 × 23.82 in | 54.45 L | 300°C | United States | $ 7,2496 249 €6,430 £1,080,507 ¥ | Get a quote |

| Markforged | Onyx Pro | 320 × 132 × 154 mm12.6 × 5.2 × 6.06 in | 6.5 L | – | United States | $ 9,60010 000 €8,516 £1,430,938 ¥ | Get a quote |

| Stratasys | F120 | 254 × 254 × 254 mm10 × 10 × 10 in | 16. 39 L 39 L | – | United States | $ 12,00011 000 €10,644 £1,788,672 ¥ | Get a quote |

Overview of the best professional 3D printers in 2022

In this section, we give some more context and information about each pro 3D printer from our selection.

The Prusa Research Original Prusa i3 MK3S+ is a desktop 3D printer manufactured by Prusa Research, based in the Czech Republic. Prusa Research is a well-known brand created by Josef Prusa, inventor of the open-source Prusa i3 3D printer design.

Prusa 3D printers are highly reliable machines and can produce excellent parts right out of the box. Priced just under $1,000, the MK3S+ offers a very good price-to-performance ratio. With its open chassis and customizable “everything”, it’s a great option for those that like to get manual. Professionals who are looking for easy and low-maintenance operation may want to look at options in a higher price range.

Full review: Original Prusa i3 MK3S review

Buy on Prusa Add to comparison

The BCN3D Sigma D25 is a large desktop 3D printer for office use made by BCN3D Technologies. BCN3D, or BCN3D Technologies, is based in Spain and is one of the desktop 3D printer market leaders. They produce high-quality 3D printers for professionals, the Sigma being their flagship series.

BCN3D, or BCN3D Technologies, is based in Spain and is one of the desktop 3D printer market leaders. They produce high-quality 3D printers for professionals, the Sigma being their flagship series.

The Sigma D25 pro 3D printer offers a relatively big build volume and boasts BCN3D’s IDEX technology. This means that there are two separate print heads that can both move independently to either print two identical objects at the same time or print in mirror mode.

Contact manufacturer Get a quote Add to comparison

The Ultimaker S5 is a professional desktop 3D printer made by Ultimaker, a manufacturer based in the Netherlands. Users may control their S5 from a distance thanks to the Ultimaker App and a Wi-Fi connection. There is also an onboard camera to monitor 3D prints from a distance. Furthermore, to maximize production efficiency, it is possible to group multiple S5 3D printers together with Cura Connect.

Today, the Ultimaker S5 is often referred to as the best professional 3D printer, especially when equipped with the Pro Bundle. The Pro Bundle includes a “material station” where up to 6 spools of filament can be loaded and automatically managed (auto-switch, humidity control, etc.), and an “air manager” that closes up the build area and filters particles.

The Pro Bundle includes a “material station” where up to 6 spools of filament can be loaded and automatically managed (auto-switch, humidity control, etc.), and an “air manager” that closes up the build area and filters particles.

Contact manufacturer Get a quote Add to comparison

The Method X is a professional benchtop 3D printer produced by MakerBot (a Stratasys-owned brand). It was designed to 3D print ABS filament reliably and efficiently, thanks to a number of features– including a 100°C heated build chamber– than enable comprehensive environmental control.

Makerbot’s Method X is equipped with a 5-inch touchscreen with real-time feedback and status on print jobs, and offers automatic calibration. This pro 3D printer also boasts “SmartAssist Material Loading”, for fast and easy filament changing. Users can log in to the manufacturer’s proprietary CloudPrint software to monitor prints remotely at any time.

Contact manufacturer Get a quote Add to comparison

The Markforged Onyx Pro is a professional desktop 3D printer made by Markforged, a manufacturer based in Somerville, Massachusetts (USA). With its dual printhead, the Onyx Pro reinforces plastic parts with a continuous strand of fiberglass.

With its dual printhead, the Onyx Pro reinforces plastic parts with a continuous strand of fiberglass.

The main available materials for the Onyx Pro are Onyx (a carbon fiber filled nylon) and Precise PLA. Markforged advertises parts up to ten times stronger than non-reinforced plastic ones.

The MarkForged Onyx Pro is delivered with Markforged’s browser-based Eiger software, powerful and easy to use. Eiger allows precise control over the 3D printing process.

Contact manufacturer Get a quote Add to comparison

The Raise3D Pro3 Plus is a professional, industrial-grade 3D printer made by Raise3D, an ISO9001:2015 and ISO14001-certified manufacturer based in the US (California). Raise3D also has offices in the Netherlands (Rotterdam) and in China (Shanghai).

This 3D printer for office environments is a true workhorse, capable of printing for hours without any hiccups. It does an impressive job with complex overhangs and features an intuitive, user-friendly workflow. The printer comes with an air filtration system, an onboard camera, and a dual extruder. Its control software is also available as a smartphone app for convenient remote monitoring.

The printer comes with an air filtration system, an onboard camera, and a dual extruder. Its control software is also available as a smartphone app for convenient remote monitoring.

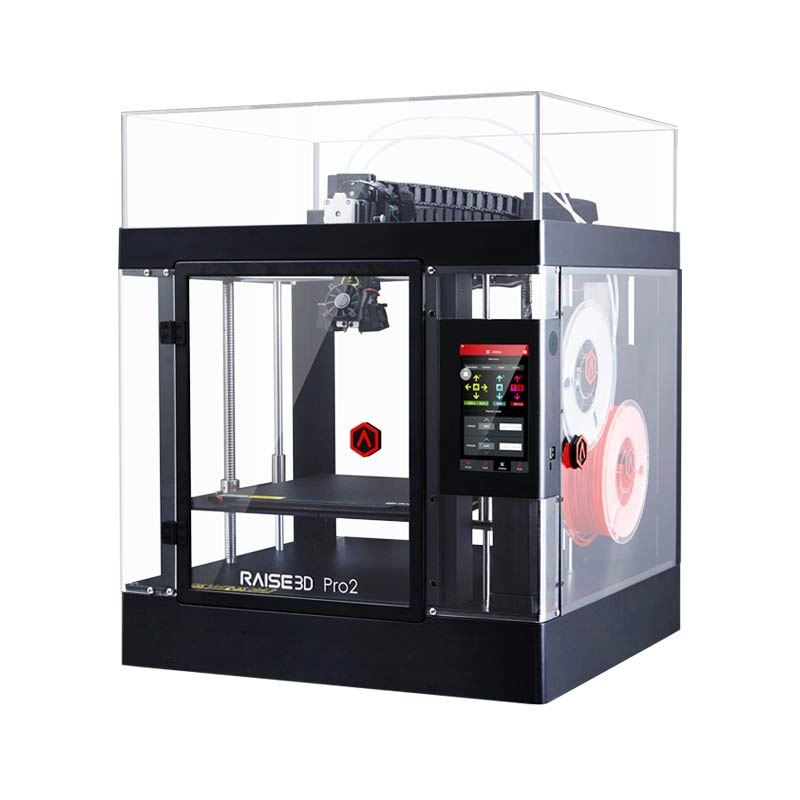

Raise3D’s Pro3 series also includes the Pro3, featuring a smaller build volume. Both printers are a follow-up to the Pro2 Series.

Full review: Raise3D Pro3 Plus review

Contact manufacturer Get a quote Add to comparison

Stratasys is the Apple of the 3D printing industry. Their 3D printers, including the F120, are reliable machines with industrial-grade components and printing quality. However, Stratasys 3D printers generally only work with Stratasys materials and hardware. At the moment, less than a handful of filaments are available for the Stratasys F120.

The F120 is one of the most affordable FDM printers from Stratasys and is destined to be a desktop workhorse for professionals. Stratasys emphasizes on the printer’s ease of use, durability, and industrial quality.

Contact manufacturer Get a quote Add to comparison

Professional 3D printer buying guide

There are several features and specifications to take into account when choosing the best professional 3D printer for your needs.

Technology

For this professional desktop 3D printer selection, we focused on FFF (fused filament fabrication) 3D printers. They are ideal for creating both prototypes and end-use parts.

For professionals in dental or jewelry industries where high precision and detail are required, resin 3D printers are more adapted, with SLA, DLP, or LCD-based technologies.

There are also desktop SLS 3D printers (powder 3D printers), PEEK 3D printers, continuous fiber 3D printers, and more for advanced applications. Explore these topics with all of our other 3D printer guides.

Build plate or print bed

A heated print bed is mandatory for users that need to 3D print with ABS and other more demanding materials. The heat helps prevent warping and offers better first-layer adhesion.

While today’s 3D printers almost always feature heated build plates, they don’t all reach the same temperatures. It is best to know which thermoplastics you will be printing and to choose your desktop 3D printer accordingly.

It is best to know which thermoplastics you will be printing and to choose your desktop 3D printer accordingly.

Some professional 3D printers have interchangeable build trays to help speed up the workflow, enabling users to quickly launch new prints while the previous build plate cools down. On higher-end 3D printers, there can even be vacuum systems for instant part release from the print bed.

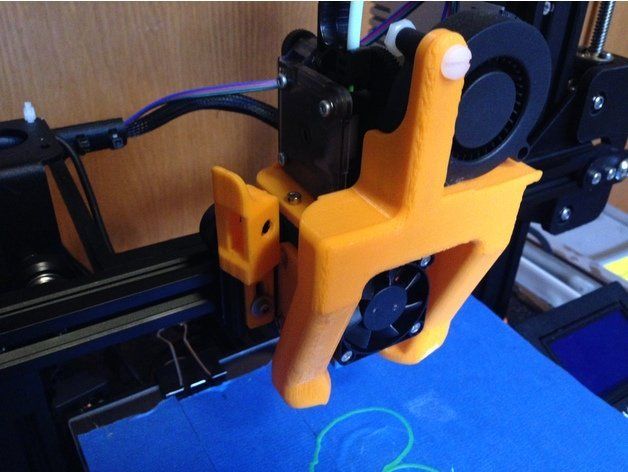

Print head

PLA and ABS can be considered the most common and basic 3D printing materials in general. Professionals, however, often need to print more complex materials, such as Nylon, Polycarbonate, PETG, ASA, or other engineering-grade polymers.

They don’t all have the same melting or glass transition temperature and therefore have to be 3D printed at different temperatures. For example, PLA can be extruded at around 200°C, PC at around 260°C, and some high-performance materials like PEEK or PEKK need the extruder to reach at least 450°C.

Popular professional filaments also include plastics filled with carbon fiber or glass fiber for increased strength and resistance. These materials are abrasive and require tough nozzles; many professional printers are already compatible with these composites, but it’s important to make sure beforehand.

Some 3D printers are compatible with multiple types of nozzles with varying diameters, and even paste-type print heads exist to 3D print clay.

Automatic calibration

Most professional 3D printer systems are equipped with automatic calibration features to make the process as plug-n-play as possible. It’s important to recalibrate a 3D printer from time to time to ensure consistent print quality.

There are two main types of calibration:

- Print bed leveling (making sure the print bed is perfectly parallel to the nozzle, and not tilted)

- Nozzle offset (determining the right gap between the nozzle and the print bed)

Most 3D printers for professionals feature a probe attached to the print head to automate these processes instead of users having to use a piece of paper or business card.

Some 3D printers also have NFC readers to automatically adjust their temperature settings according to the detected material (so long as the spool is chipped, too).

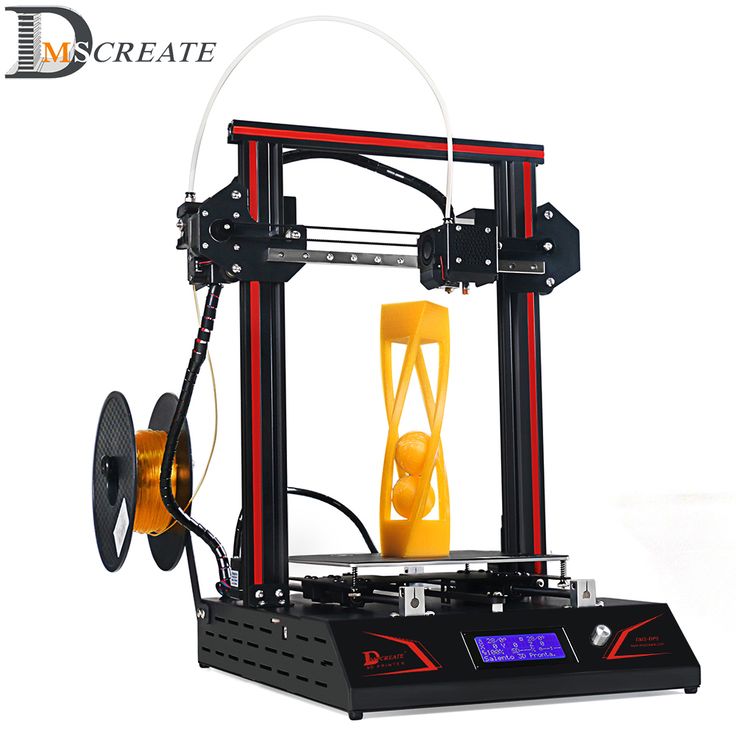

Dual extrusion and independent dual extrusion (IDEX)

A dual extruder enables users to 3D print with two different colors or materials simultaneously, including soluble support material for complex objects.

If there are two separate print heads, the system is referred to as IDEX (independent dual extruder). BCN3D Technologies was one of the first manufacturers to offer this feature a few years back.

In addition to being able to 3D print two materials at a time, independent dual extrusion offers different 3D printing possibilities:

- Duplication mode: 3D prints two identical objects at the same time.

- Mirror mode: to 3D print an object twice as fast as with just one extruder, each nozzle completes one-half of the object.

Onboard camera

Some 3D printers are equipped with an onboard camera that monitors prints remotely or saves time-lapse videos. This feature can be useful if the printer must be left unattended for long periods of time. We found it to be quite practical when we launched a long print for our Pro3 Plus review.

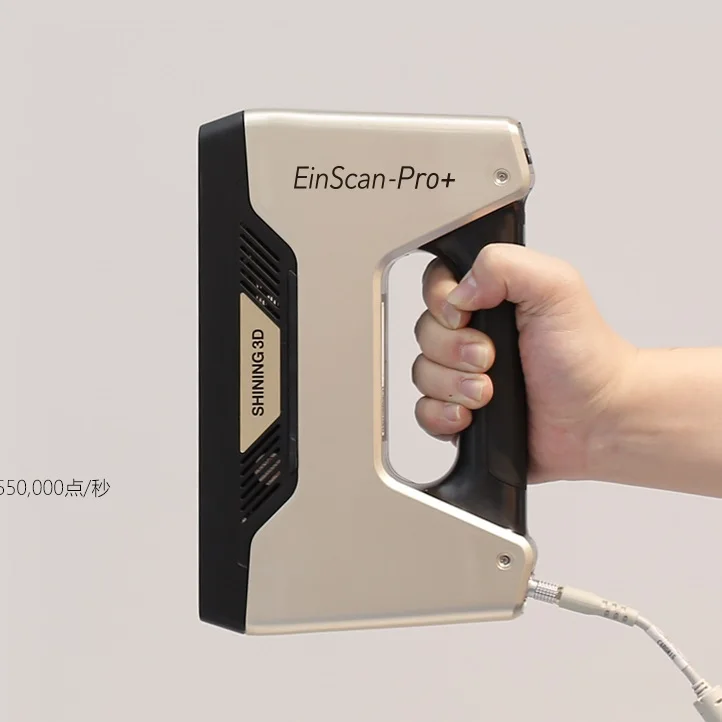

With the right 3D software, onboard cameras can help with quality control. Quality control can also be done during post-processing workflows with a metrology 3D scanner.

Minimum layer thickness

3D print quality is intricately linked to layer thickness, a.k.a. layer height or Z resolution. It’s the minimum height of each successive layer that forms the 3D printed object. The thinner the layers, the less they are distinguishable and the smoother the object will be (similar to the ratio of pixels in an image).

Thinner layers also mean that more layers are required to complete the object, which translates into more 3D print time. Layer thickness can be adjusted depending on if you need a quick print (thicker) or a high-resolution print (thinner).

Layer thickness can be adjusted depending on if you need a quick print (thicker) or a high-resolution print (thinner).

The typical minimum layer thickness for mid-range FFF 3D printers is 100 microns or 0.1 millimeters, but it can go down to 0.01 mm in some cases.

A simple representation of layer height. Source: Primantes3DBuild volume

The build volume is the maximum size that your prints can be. If you need a bigger volume than what the 3D printers in this guide provide, you may be interested in these selections:

- L: Large volume 3D printers

- XL: Large format 3D printers

- XXL: Large scale 3D printers

Now, there are even large-sized resin 3D printers for those that need both volume and finer surface quality.

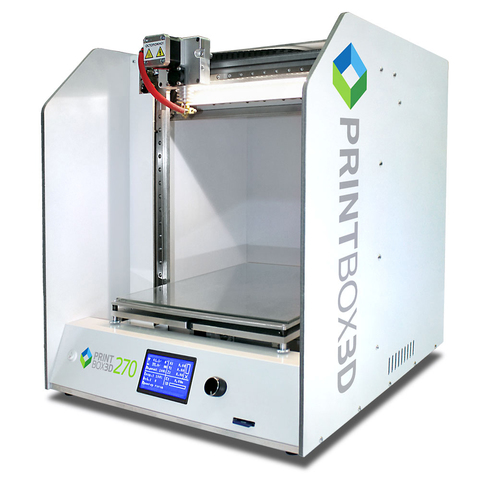

Closed frame

Many variables can interfere with 3D print quality, such as temperature changes and room drafts. Hence, 3D printers with an enclosed build chamber tend to provide better quality prints, in addition to reducing noise, odors, and– with a HEPA filter– harmful particle emissions.

A closed frame is almost mandatory when 3D printing with basically anything other than PLA. Today it is quite rare to see a professional 3D printer without an enclosure.

FAQ

Are 3D printers safe?

With basic precaution, 3D printers are relatively safe to use, although there has been some concern over harmful particle emissions from the melted filament. It’s best to use closed 3D printers with filters and to use 3D printers in well-ventilated areas. Users should also be careful not to burn themselves on a hot build plate or extruder; some 3D printers feature door safety sensors to lock the printer while it is printing.

Can 3D printers print metal? What 3D printers can print metal?

Yes, some FFF 3D printers are able to print metal-filled filaments. This is called metal FFF. Once the part has been 3D printed, however, it must undergo two processes called debinding and sintering. Other types of 3D printers (much more expensive and industrial-grade) are able to 3D print metal powder using various metal 3D printing technologies like L-PBF (laser powder bed fusion) or metal binder jetting, among others.

Other types of 3D printers (much more expensive and industrial-grade) are able to 3D print metal powder using various metal 3D printing technologies like L-PBF (laser powder bed fusion) or metal binder jetting, among others.

What is the best 3D printer for jewelry?

For jewelry, resin 3D printers are more adapted than FFF 3D printers. They use SLA, DLP, or LCD-based technologies to produce objects with fine details and smooth surfaces.

Can 3D printers print in color?

Yes, some 3D printers can print in color. They are called full-color 3D printers and often use powder-based technologies. Systems that mix CMYK filaments exist, but cannot reproduce photorealistic colors like powder-based 3D printers.

Commercial & Professional 3D Printer Buyer's Guide 2022 (Under $10,000)

Commercial 3D printers are changing how small businesses manufacture, how designers create and iterate, and how schools, healthcare professionals and engineers work.

These professional 3D printers, more expensive than standard desktop 3D printers but less than $10,000+ industrial 3D printers, allow small businesses to be more effective than ever in prototyping and improving their products.

This article focuses on highlighting the best commercial 3D printers, also known as prosumer 3D printers, production 3D printers, commercial grade 3D printers, or high end 3D printers, that are capable of producing professional-grade parts at decent scale, but cost less than $10,000. We therefore categorize commercial 3D printer price as up to $10,000, with no low end price provided it meets professional and small business 3D printer requirements.

What to expect in a commercial 3D printer?

Commercial grade 3D printers can take many forms: some need an FDM 3D printer that can 3D print PEEK or Ultem filaments, create extremely precise prototypes, or create multi-colored architectural models.

On the other hand, you may need a professional resin 3D printer to create ultra smooth resin prototypes for dental, aesthetic prototypes for items like sunglasses, and much more.

You may also be looking for a professional SLS 3D printer — though they often cost more than $10,000 — for high quality PA12 prototypes, functional parts, and various useful parts for engineers and designers.

Generally however, you should expect the following from a professional 3D printer:

- Commercial grade 3D printing performance: such as powerful heated chambers in FDM 3D printers for tougher material printing and systems for consistent and accurate printing.

- Wide material compatibility: with heated beds and extruders that can reach high temperatures for printing tougher filaments like Nylon, PC, PP, and perhaps even Ultem or PEEK.

- Fast printing and workflow: the best 3D printers for small businesses not only print quickly (at least twice the speed of desktop printers), but the entire workflow — from CAD software, to slicing, to printing, and then to iterating again — needs to be efficient for overall rapid prototyping.

- Very accurate: where resin 3D printers and SLS printers have advantages are in accuracy and surface finish.

Resin printers can reach precisions that FDM printers cannot, so for precise and intricate models, such as characters for films or games, or wax molds for casting into precious metal jewelry, they’re ideal commercial 3D printers. SLS 3D printers require less post processing as they do not print with supports, making them ideal production 3D printers for ready-to-go prototypes made from Nylon.

Resin printers can reach precisions that FDM printers cannot, so for precise and intricate models, such as characters for films or games, or wax molds for casting into precious metal jewelry, they’re ideal commercial 3D printers. SLS 3D printers require less post processing as they do not print with supports, making them ideal production 3D printers for ready-to-go prototypes made from Nylon. - Large printing area: commercial 3D printers should have large enough build areas to support either large prototypes, or the printing of multiple small parts simultaneously, as a scalable production 3D printing system. 3D printers for commercial uses we recommend are typically larger for effective batch production 3D printing.

Our commercial 3D printer comparison sorts low to high price, making recommendations on the best 3D printer for business, for production, and many other 3D printers for different commercial uses.

Prusa i3 MK3S+ — low cost commercial 3D printer for small businesses on a budget

- Price: $999 fully assembled — Available on Prusa Store here / $749 as a kit — Available on Prusa Store here

- Build volume: 250 x 210 x 210 mm

With a price of under $1,000 you’d expect the Prusa i3 MK3S to be limited to standard consumer uses like printing fun models from Thingiverse, or fun basic 3D printing projects. However, it excels far beyond this, functioning as one of the best 3D printers for small businesses if you’re on a tight budget.

However, it excels far beyond this, functioning as one of the best 3D printers for small businesses if you’re on a tight budget.

It can’t compete with higher end 3D printers in some areas, like size of build area, but it’s a fantastic commercial 3D printer for standard size prototypes in materials like PETG, ASA, Nylon, PC, PP, HIPS, and carbon fiber filaments.

Prusa 3D printers are known for their reliability and with an above 200mm/s travel speed, it’s fairly quick for the price. These factors, combined with precise 50-micron minimum layer heights, make it a great overall commercial 3D printer for professional and precise prototype production.

For those looking for a larger 3D printer, a 3D printer for materials like PEEK, or more precise resin 3D printers, keep reading.

Ultimaker S3 — accurate commercial 3D printer for high quality prototypes

- Price: $4,080 — Available on Dynamism here / Available on Matterhackers here

- Build volume: 230 x 190 x 200 mm

The Ultimaker S3 follows the incredibly popular Ultimaker 3, and is an effective production 3D printer for small businesses and engineers capable of fantastic 20-micron resolutions. It can extrude composite filaments from either of its extruders, and can easily print soluble filaments with the dual extruder for easier post processing.

It can extrude composite filaments from either of its extruders, and can easily print soluble filaments with the dual extruder for easier post processing.

Ultimaker created and develop Cura, the world’s most loved 3D slicer, but also offer more professional 3D printer software as part of their Enterprise packages for commercial 3D printing needs. These premium 3D printer options include the ability to open CAD files in Cura, unlimited storage of your parts in their digital parts library, as well as integrating 3D modeling software like SolidWorks and Autodesk Inventor into your workflow with their plugins. All these make for an efficient commercial 3D printing workflow for quick and effective iterating and part production.

The touchscreen is easy to navigate, and WiFi connectivity makes it quick to access and print your files remotely in their digital library.

As a professional 3D printer, Ultimaker serve not just 3D printers for small businesses, but also huge clients like Volkswagen. The German multinational used Ultimaker 3D printers to produce over 1,000 parts, remarking on the productivity and ergonomics of Ultimaker’s printers.

The German multinational used Ultimaker 3D printers to produce over 1,000 parts, remarking on the productivity and ergonomics of Ultimaker’s printers.

The only factor affecting the Ultimaker S3’s usefulness as a full professional grade 3D printer is the build volume size, which could be larger. However, Ultimaker also offer the S5 for larger print needs, so read on for more information on this.

Ultimaker S5 — all-round excellent production 3D printer

- Price: $6,355 — Available on Dynamism here / Available on Matterhackers here

- Build volume: 330 x 240 x 300 mm

The Ultimaker S5 is the big brother of the already very powerful S3, and a commercial grade 3D printer for high quality engineering parts and accurate prototypes.

The main difference between the S3 and S5 is the larger print volume, a major improvement for those looking for a 3D printer for their small business capable of large prototype printing. It still features the same workflow options, dual extrusion, 20-micron layer heights, and trademark reliability and and precision.

However, you can also turn the S5 into a scalable production 3D printer with the Ultimaker’s S5 Pro Bundle for another few thousand dollars. This bundle adds both a spool holder and top filter. The material handler can hold up to six filament spools, and can automatically change them in and out for different uses as well as protecting filaments from moisture that would deteriorate print quality and protect them from dust, with the environment control filtering out fumes.

- The Ultimaker S5 Pro Bundle costs around $9,550 — Available on Dynamism here / Available on Matterhackers here

The Pro Bundle turns the S5 into the complete commericial 3D printer, able to print continuously, accurately, large parts — everything except super high grade material printing like PEEK and Ultem.

The Ultimaker S5, alongside the S5 Pro Bundle with material holder and environment control add-ons.Formlabs Form 3 — precise professional 3D printer for accurate resin parts

- Price: $3,499 — Available on Dynamism here

- Build volume: 145 x 145 x 185 mm

The Form 3 is sold as a professional quality 3D printer at desktop prices, building on the Form 2’s stellar reputation with incredible resolutions and able to create parts you can barely see the individual layer lines on.

Featuring their LFS (low force stereolithography) tech, layer spot clarity, as well as consistency, surface quality and better translucent material printing are some of the improvements made to the Form 3.

For production engineers looking for a workhorse production 3D printer that can go non-stop, the Form 3 is more than capable, with data on ongoing print performance constantly relayed and alerts if print performance changes so you can make alterations.

You can print in standard resins, or castable wax for jewelry casting, as well as specialized biocompatible commercial grade 3D printing resins for dental uses — which you should instead get the Form 3B for.

Their PreForm software makes preparing your prints easy, and if you’re looking to scale up to a 3D printing factory with multiple printers Formlabs have specialized consulting teams to help, and offer software for managing multiple 3D printers simultaneously.

Raise3D Pro2 Plus — large production 3D printer for small businesses

- Price: $5,999 — Available on Dynamism here / Available on Matterhackers here

- Build volume: 305 x 305 x 605 mm

A true workhorse production 3D printer, the Raise3D Pro2 Plus can work 24/7 without much issue. Able to reach 300°C extruder temperatures, printing with filaments ranging from HIPS, ASA, PP, PVA, flexible filaments like TPU and TPE, Nylon, glass, carbon fiber, metal and wood filled filaments is no problem.

Able to reach 300°C extruder temperatures, printing with filaments ranging from HIPS, ASA, PP, PVA, flexible filaments like TPU and TPE, Nylon, glass, carbon fiber, metal and wood filled filaments is no problem.

As well as the huge build volume and wide material compatibility, the Raise3D Pro2 Plus also offers great precision, with up to 0.01 mm layer heights and 5-micron repeatability. You can change the nozzle out to a smaller or larger one depending on whether your project favors speed or precision.

The large 7-inch touchscreen simplifies your workflow and makes it easy to switch settings or choose your model to print — made easier by Raise3D’s visual model selection previewer. And, if during printing you run into any problems with the power or any other error, the printer can resume from whenever it was stopped without issue.

Marking itself as one of the best 3D printer for business uses, it has some of the largest print areas, as well as an aerospace grade build plate offering excellent adhesion, durability, and preventing warping that can affect or ruin prints — as well as making prints easy to remove. It’s all fully enclosed, so you can effectively maintain and control the chamber temperature to minimize warping and prevent fumes from spreading.

It’s all fully enclosed, so you can effectively maintain and control the chamber temperature to minimize warping and prevent fumes from spreading.

If you want the workhorse benefits of the Raise3D Pro2 Plus, but don’t need the extra Z-axis height building, you can save a couple thousand dollars by going with their standard Pro2 model instead, with a 300mm maximum print height instead of the Pro2 Plus’ 605mm.

Intamsys Funmat HT Enhanced — professional 3D printer for PEEK & Ultem printing

- Price: $7,500 — Available on Matterhackers here

- Build volume: 260 x 260 x 260 mm

For those looking for a specialized PEEK and Ultem 3D printer, the Intamsys Funmat HT Enhanced is the best professional 3D printer for PEEK that’s in most small business’s budget. Costing $6,000 rather than the $20,000+ commonly seen among commercial 3D printers for PEEK, the Intamsys Funmat HT is a great entry-level production 3D printer.

With 90°C constant chamber temperatures, a 160°C heated build plate, and 450°C maximum extruder temperatures from its all-metal hot end, printing PEEK, PEKK, PPSU and Ultem are no problem. However, if you want to use it for printing PEEK as well as more standard plastics you can also do that, with interchangeable nozzles for different printing plastics like PLA and ABS, PC, Nylon, ASA, and more.

However, if you want to use it for printing PEEK as well as more standard plastics you can also do that, with interchangeable nozzles for different printing plastics like PLA and ABS, PC, Nylon, ASA, and more.

Therefore, the Intamsys Funmat HT is a great entry-level production 3D printer for high performance polymer printing. It can automatically level itself with its four advanced drivers offering great precision, and the industrial build platform quality and design features PEI film and glass ceramic materials for great durability and minimal deformation during printing — as well as being safe to use with biocompatible materials like PEEK that may be used to print medical or dental parts.

With PEEK’s extensive use in medical parts, electrical engineering, aerospace, dental, Ultem’s industrial uses, and PPSU’s medical applications, the Intamsys Funmat HT capitalizes on 3D printing’s fastest growing material segment, but at a low price. Intamsys sell their own Ultem and PEEK filaments, and overall, the Funmat HT Enhanced is one of the best 3D printers for small businesses looking to print high performance plastics to either create parts for other companies, or iterate in-house. The Intamsys Funmat HT Enhanced is an ideal professional 3D printer for PEEK without breaking the bank.

The Intamsys Funmat HT Enhanced is an ideal professional 3D printer for PEEK without breaking the bank.

Some other articles you may be interested in:

- The best 3D printers for small business

- Best PEEK 3D printers

- Best industrial 3D printers

- Best 3D printers under $2,000

- Best 3D printers under $5,000

- Best metal 3D printers

Desktop 3D printers for the home

Anet Anycubic Creality3D CreatBot Dremel Elegoo Felix Flash Forge FLSUN Flying Bear Formlabs IBRIDGER imprinta MakerBot Peopoly Phrozen PICASO 3D QIDI Raise3D Tiertime Ultimaker Uniz Voxelab wanhao XYZPrinting ZENIT Zortrax

Availability

In stock

Manufacturer

Phrozen Raise3D Creality wanhao Flash Forge

PICASO 3D Anycubic Formlabs Tiertime Flyingbear QIDI Uniz CreatBot Dremel DigiLab Felix Zortrax XYZprinting Ultimaker imprinta Elegoo MakerBot Anet FLSUN iBridger Peopoly snapmaker Voltera Voxelab ZENIT

Delivery

Assembled printer Assembly kit

Application

Architecture For large objects For beginners The medicine Education

Orthopedics Production prototyping Reverse engineering Advertising, exhibitions Sculpture Dentistry Hobby jewelry

Print technology

DLP/LCD/SLA FDM/FFF LFS

Thread diameter

1. 75 mm 2.85 mm 3.00 mm

75 mm 2.85 mm 3.00 mm

Material type

ABS PLA PETG Photopolymers Flex

Nylon (Nylon) ASA Carbon HIPS PC PEEK PP TPU other Metal (Ultrafuse 316L, Ultrafuse 17-4PH)

Number of extruders (print heads)

Heating table

Yes Not

Wi-Fi or other wireless network

Yes Not

Country of origin

China Russia USA Taiwan Hong Kong

Netherlands Poland

Add to compare

Product added to compare Go

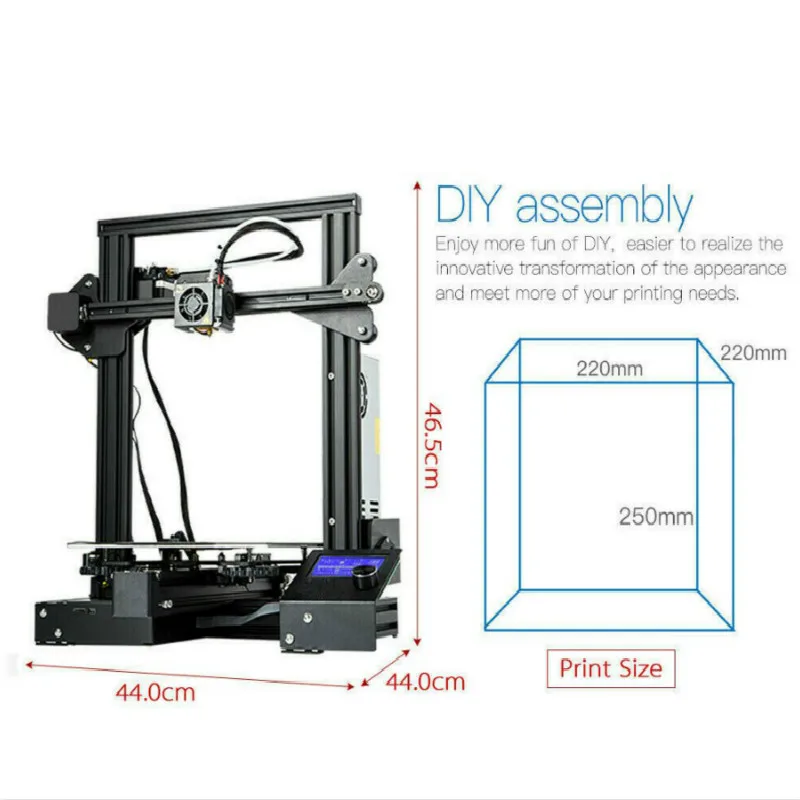

| Manufacturer | Creality |

| Construction area size | 220x220x250 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Add to compare

Product added to compare Go

| Manufacturer | Creality |

| Construction area size | 220x220x250 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Add to compare

Product added to compare Go

| Manufacturer | Creality |

| Construction area size | 220 x 220 x 250 mm |

| Number of extruders (print heads) | 1 |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Anycubic |

| On order/Transit | Goods in transit |

| Construction area size | 220x220x250 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Add to compare

Product added to compare Go

| Manufacturer | Creality |

| Construction area size | 235x235x250 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Add to compare

Product added to compare Go

| Manufacturer | Creality |

| Construction area size | 220 x 220 x 250 mm |

| Number of extruders (print heads) | 1 |

Add to compare

Product added to compare Go

| Manufacturer | Creality |

| Construction area size | 220x220x250 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Anycubic |

| On order/Transit | Goods in transit |

| Construction area size | 180 x 163 x 102 mm |

| Country of origin | China |

Add to compare

Product added to compare Go

| Manufacturer | Creality |

| On order/Transit | Goods in transit |

| Construction area size | 220x220x270 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Creality |

| Construction area size | 200x200x200 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Add to compare

Product added to compare Go

| Manufacturer | Creality |

| Construction area size | 300 x 300 x 400 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Add to compare

Product added to compare Go

| Manufacturer | Flyingbear |

| Construction area size | 255x210x210 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Creality |

| On order/Transit | Goods on the way |

| Construction area size | 250x250x400 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Add to compare

Product added to compare Go

| Manufacturer | Creality |

| On order/Transit | Goods in transit |

| Construction area size | 350x350x400 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Anycubic |

| Construction area size | 102x57x165 mm |

| Country of origin | China |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Anycubic |

| On order/Transit | Goods in transit |

| Construction area size | 197 x 122 x 245 mm (5. 9 l) 9 l) |

| Chamber volume | 5.9 l |

| Country of origin | China |

3D printing is one of the most promising areas of technological development in the 21st century. Having gone a long way from bulky and heavy boxes to compact desktop devices, 3D printers have ceased to be something inaccessible to a wide range of users. The era of mass additive manufacturing has already arrived, and every home can now house a real desktop factory.

You can buy a 3D printer capable of printing small models and prototyping of medium complexity today at the price of an entry-level laptop. The price of PLA or ABS plastic, which acts as a consumable, also no longer seems exorbitant. In a word, if you have long dreamed of getting to know the world of 3D printing and joining the ranks of makers, the right moment has come!

To save you time and make it easier to select equipment, we have collected in one section all desktop 3D printers optimized for home and office use. These are the real "workhorses" with the perfect balance of functionality, quality and price. Even a beginner can understand the settings, mount and calibrate a 3D printer, and as he gains experience, he will be able to print more and more complex three-dimensional models.

These are the real "workhorses" with the perfect balance of functionality, quality and price. Even a beginner can understand the settings, mount and calibrate a 3D printer, and as he gains experience, he will be able to print more and more complex three-dimensional models.

How much does a 3D printer cost?

3D printing is a one-stop solution for a wide range of applications, from high-resolution model production to rapid prototyping, rapid tooling for traditional manufacturing processes, production of aids and end-use models.

However, when you consider investing in a 3D printer, the viability of a solution usually boils down to a simple question: Is it cost-effective for your business? How much does a 3D printer cost and how much time and money can it save your business?

3D printer prices range from $200 to $500,000 depending on the printing process, materials, and complexity of the solution.

In this guide, we'll break down 3D printing costs by technology, compare outsourcing versus in-house manufacturing, list factors to consider when calculating the cost of each model, and look at what else to look for when comparing different solutions. for 3D printing and other production methods.

for 3D printing and other production methods.

Interactive

This interactive ROI tool will help you find out how much time and money you can save by 3D printing with a Formlabs 3D printer.

Calculate Your Costs

The three most well-known plastic 3D printing technologies today are Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS).

Each technology has its advantages and disadvantages - take a look at the infographic:

Download this high resolution infographic here. Interested in learning more about FDM, SLA and SLS 3D printing technologies? Check out our detailed guide.

Prices for 3D printers have dropped significantly in recent years, and today all three technologies are available in compact, low cost systems.

FDM generally produces models at a lower cost if you only print relatively simple prototypes in limited numbers. SLA technology offers higher resolution and quality, as well as a wide choice of 3D printing materials at a slightly higher price. But this difference is quickly offset when you print complex designs or larger batches due to the less labor-intensive post-processing process. Finally, SLS technology is the most cost effective for medium to high volume production of high quality functional models.

SLA technology offers higher resolution and quality, as well as a wide choice of 3D printing materials at a slightly higher price. But this difference is quickly offset when you print complex designs or larger batches due to the less labor-intensive post-processing process. Finally, SLS technology is the most cost effective for medium to high volume production of high quality functional models.

Comparing the total cost of different 3D printers by price tags alone will not give you a complete picture of how the cost of a 3D printer and a printed model will compare. The cost of 3D printing materials and labor significantly affects the cost of a model, depending on the application and your production needs.

Let's look at the different factors and costs for each process.

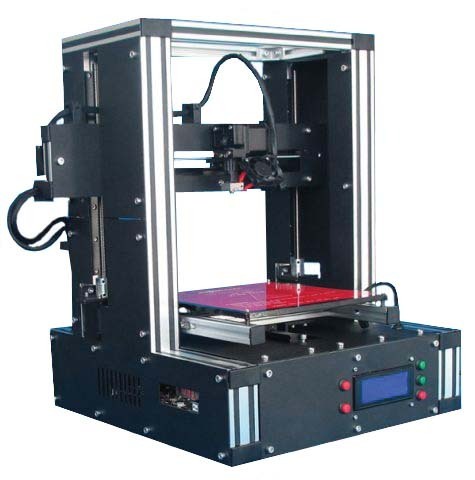

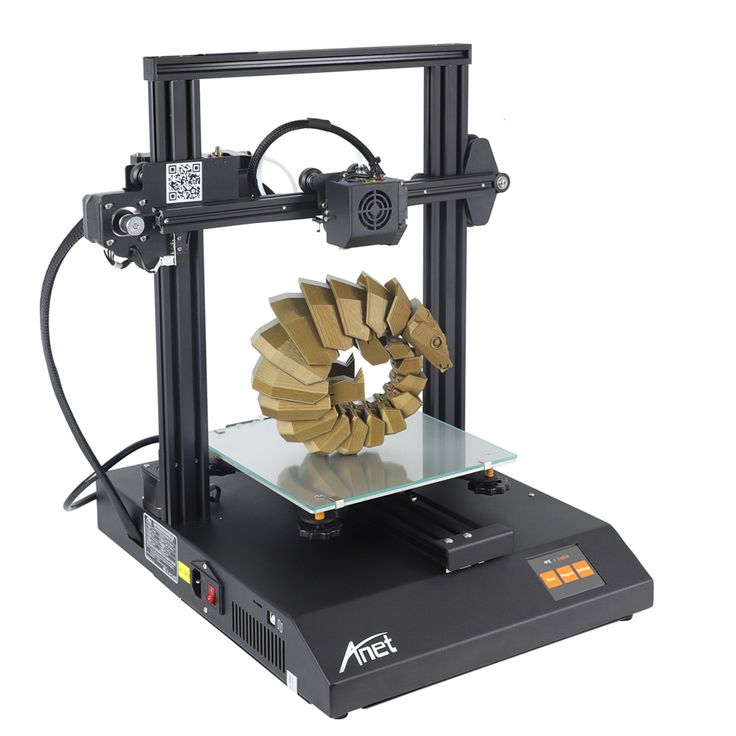

FDM, also known as Fused Filament Manufacturing (FFF), is a printing method where the parts of a model are made by melting and extruding a thermoplastic filament, which the printer's nozzle applies layer by layer onto the model being made.

FDM is the most popular form of consumer grade 3D printing, fueled by the proliferation of hobbyist 3D printers. However, professional and industrial FDM printers are also popular among professionals.

The cheapest 3D printers are FDM printers. DIY kits for FDM 3D printers start at $200. However, most of these models are more like toys or DIY projects that require a significant amount of time to build, set up and calibrate. The quality of the print largely depends on the success of these operations. In addition, machines require repairs and regular maintenance to keep them working, so they are more suitable for people with a higher engineering education who have a lot of time and patience.

Hobbyist FDM 3D printers cost between $500 and $1,500, come pre-assembled or unassembled, require less setup, but have the same disadvantages as the cheapest 3D printers. More expensive models are capable of large print volumes and work with a wide variety of materials besides low temperature ones such as PLA.

Professional 3D FDM printers start at $2,500 and large format professional FDM printers are available from $4,000. The cost of the most modern industrial FDM printers can exceed 10,000 US dollars. Most of these printers come pre-assembled and calibrated in the box, or they can be automatically calibrated. Printers in this category offer better print quality, a wider range of media, higher print volumes, improved reliability, and ease of use and maintenance. In addition, professional 3D printer manufacturers offer customer support services for troubleshooting.

Material costs for FDM 3D printing range from $50 to $150/kg for most standard and engineering filaments, and $100 to $200/kg for auxiliary materials. There are also cheaper alternatives, but they are of lower quality.

In addition, FDM printing can be very labor intensive. Successful printing of complex models requires support structures that must be removed manually or dissolved in water. To obtain a high quality surface and remove layer lines, lengthy manual post-processing of models, such as sanding, is necessary.

SLA 3D printers use the process of photopolymerization, that is, the conversion of liquid polymers into hardened plastic using a laser. SLA is one of the most popular processes among professionals due to its high resolution, accuracy and material versatility.

Models printed on SLA printers have the highest precision, sharpest detail and smoothest surface possible of any plastic 3D printing technology. But the main advantage of the SLA method is its versatility. SLA polymers have a wide range of optical, mechanical and thermal properties that match those of standard, engineering and industrial thermoplastics.

SLA 3D printers can handle a wide range of resin materials for a wide variety of applications.

SLA used to be used only in large and complex industrial 3D printers costing over $200,000, but the process is now much more affordable. With the Formlabs Form 3+ Printer, businesses can now use industrial quality SLA printing for as little as $3,750. With Form 3L, large format SLA printing starts at just $11,000.

Stereolithographic 3D printers will be shipped in a box assembled and calibrated. These are professional tools that are highly reliable and require virtually no maintenance. Technical support is also always available. It provides troubleshooting in a critical situation (but its probability is extremely small).

Most standard and engineered polymers for SLA technology cost between $149 and $200 per liter.

SLA printers are easy to use and many workflow steps such as rinsing and final curing can be automated to reduce labor costs. Printed models have a high quality surface immediately after printing and require only simple post-processing to remove supporting structures.

Selective Laser Sintering (SLS) 3D printers use a high power laser to sinter fine polymer powder particles. The unsprayed powder supports the model during printing and eliminates the need for special support structures. This makes SLS ideal for complex geometries, including internal features, grooves, thin walls, and negative taper.

Models produced using SLS printing have excellent mechanical characteristics - their strength can be compared with the strength of injection molded parts. As a result, SLS technology is the most popular plastic 3D printing process for industrial applications.

SLS printed nylon models are ideal for a range of functional applications, from consumer product design to healthcare applications.

Like SLA, SLS was previously only available in large format, complex 3D printing systems costing $200,000 or more. With the Formlabs Fuse 1 stereolithography printer, businesses can now solve industrial-scale tasks with SLS technology starting at $18,500. The complete kit, which includes the post-processing and powder recovery system, costs $31,845.

As with SLA printers, stereolithographic printers are shipped assembled and calibrated in the box. They are reliable and can operate 24/7. The package includes in-depth training and fast technical support.

SLS nylon print materials cost about US$100/kg. SLS does not require supporting structures and unused powder can be reused, reducing material costs.

SLS does not require supporting structures and unused powder can be reused, reducing material costs.

SLS is the least labor-intensive plastic 3D printing process in the production environment, because the printed models are of high quality right away, and to remove excess powder, they simply need to be cleaned.

There are several processes for 3D printing not only plastics but also metals.

Metal FDM printers are similar in design to traditional FDM printers, but use extruded metal rods held together by a resin binder. The finished parts of the model are sintered in an oven to remove the binder.

SLM and DMLS printers are similar to SLS printers, but instead of polymer powders, they fuse metal powder particles layer by layer using a laser. SLM and DMLS-based 3D printers create strong, precise, and complex metal products, making the process ideal for the aerospace, automotive, and medical industries.

Prices for metal 3D printers have also begun to decline, ranging from $100,000 to $1 million today. However, these systems are still out of reach for most businesses.

However, these systems are still out of reach for most businesses.

SLA 3D printing is available as an alternative for casting workflows that allow metal models to be produced cheaper and faster than traditional methods and provide greater design freedom.

Technical report

Get design guides for 3D printing samples, see the step-by-step direct investment casting process, and study guides for indirect investment casting and sand casting.

Download white paper

Different plastic and metal 3D printing processes have unique qualities that make them suitable for different applications. Below is a comparison of different printing technologies.

| Fused Deposition Modeling (FDM) | Stereolithography (SLA) | Selective Laser Sintering (SLS) | Metal FDM Printing | Selective Laser Melting (SLM)4 (SLM) and Direct Laser Sintering 940606LS4 | |

|---|---|---|---|---|---|

| Resolution | ★cle ★☆ | 0060 0060 ventary | ★cle ★ Look | ★ Look | ★ opa |

| Surface quality | ★cle | ★ opa | ★ ★cle ☆ ☆ | ★ ☆☆☆ | ★ opa ☆ |

| performance | ★ Look | ★ opa | ★ Look | ★ Look ☆ | ★ opa |

| Simplicity of use | ★ opa | ★ opa | ★cle | ★cle | Seal volume | to ~ 300 x 300 x 600 mm (Desktop and Workshop 3D printers) | Up to ~300 x 335 x 200 mm (Desktop and Workshop 3D printers) | Up to 165 x 165 x 300 mm (3D - workshop printers) | Up to 300 x 200 x 200 mm | Up to 400 x 400 x 400 mm |

| Price range | DIY kits for 3D printers start at $200, while hobby printers cost $500-1500. Professional 3D FDM printers start at $2,500, while large format professional FDM printers are available from $4,000. Professional 3D FDM printers start at $2,500, while large format professional FDM printers are available from $4,000. | Professional desktop printers start at $3,750 and high-volume large format desktop printers are available from $11,000. | Industrial workshop printers start at $18,500 and traditional industrial printers start at $100,000. | Metal FDM printers start at $100,000, but complete solutions including an oven are much more expensive. | DMLS/SLM solutions start at around $200,000. These printers require special infrastructure conditions, which can further increase costs. |

| Cost of materials | US$50-150/kg for most standard and engineering yarns and US$100-200/kg for auxiliary materials. | $50-150/L for most standard and engineering polymers. | $100/kg for nylon. SLS does not require supporting structures and unused powder can be reused, reducing material costs. | Depends on material and technology. Significantly higher than plastic. Significantly higher than plastic. | Depends on material and technology. Significantly higher than plastic. |

| Labor | Manual removal of support structures (soluble support structures may be used in some cases). Long post-processing is required to obtain a high quality surface. | Washing and final polymerization (both can be automated). Simple post-processing to remove supporting structures. | Easy cleaning to remove excess powder. | Washing and sintering (both can be automated). It is possible to use mechanical processing and other types of surface treatment. | Stress relief, support structure removal, heat treatment, and mechanical and other surface treatments. |

| Materials | Standard thermoplastics such as ABS, PLA and their various blends. | Various polymers (thermosetting plastics). Standard, engineering (similar to ABS and PP, similar to silicone, flexible, heat resistant, rigid), injection molding, dental and medical (biocompatible). | Engineering thermoplastics - typically nylon and its composites (nylon 12 biocompatible + sterilizable). | Stainless steel, tool steel, inconel, copper, titanium. | Stainless steel, tool steel, titanium, cobalt-chromium, copper, aluminium, nickel alloys. |

| Applications | Basic experimental models, low cost rapid prototyping of simple parts. | Prototypes with a high level of detail requiring tight tolerances and smooth surfaces: molds, tooling, templates, medical models and functional parts. | Complex geometries, functional prototypes, low volume production or limited trial production. | Strong and durable models, tools and production aids. | Strong and durable models with complex geometries; ideal for the aerospace, automotive and medical industries. |

When calculating the cost of one model, the cost of ownership of equipment, material costs and labor costs are usually taken into account. It is important to understand the factors that affect each of these cost components, as well as the questions to ask in order to evaluate alternative production methods and uncover hidden costs.

It is important to understand the factors that affect each of these cost components, as well as the questions to ask in order to evaluate alternative production methods and uncover hidden costs.

Hardware ownership costs are fixed costs: 3D printer price, service contracts, installation and maintenance. These amounts must be paid whether your printer is idle or produces dozens of models per week.

Add up all projected fixed costs over the lifetime of the equipment, then divide by the number of models you plan to make. As a rule, the higher the performance and efficiency of your 3D printer, the lower the cost of ownership of equipment per model.

In recent years, desktop 3D printers have shown excellent results in reducing the cost of ownership of equipment. With a price 10 to 100 times lower than traditional industrial 3D printers and the ability to produce thousands of models over a lifetime, the cost of ownership can be negligible.

Questions:

-

Are there installation, training or additional initial costs other than the cost of the machine itself?

-

Do I need to sign a (mandatory) service contract? What does it include?

-

What accessories and tools are needed to make the final models?

-

What kind of maintenance is required for the machine to function properly? What is the expected annual maintenance cost? Will it change with an increase in production volumes?

The 3D printing raw materials and consumables you need to create models at an affordable price. These costs largely depend on the number of models you produce.

These costs largely depend on the number of models you produce.

When calculating the cost of materials, determine how much material is required to create one model, and multiply this figure by the cost of the material. Count the amount of waste and any other consumables. As production grows, the cost of ownership of equipment decreases, and the cost of 3D printing materials tends to become more balanced.

Be sure to check what materials you need to create specific models, as the cost of 3D printing consumables can vary greatly. Please note that some 3D printers only work with their proprietary materials and thus limit your ability to use third party materials.

Questions:

-

What is the cost of each type of 3D printing material?

-

How much material is required to create one particular model, including waste?

-

What is the shelf life of the materials?

-

Do I need other consumables to create models?

-

Can the machine work with third-party materials?

While 3D printing can replace complex traditional manufacturing methods and provide significant time savings, depending on the 3D printing technology, it can still be quite labor intensive.

Professional desktop 3D printers are generally optimized for ease of use. DIY kits for 3D printers and hobby printers often require additional effort to adjust settings, while regular maintenance or material changes on traditional industrial machines can involve time-consuming tasks that require the assistance of a skilled operator.

Post-processing workflows vary depending on the 3D printing process, but in most cases include cleaning up models and removing support structures or excess material. However, there are solutions to automate some specific tasks. For example, Formlabs Form Wash and Form Cure simplify the wash and finish process for Formlabs SLA 3D printers, while Fuse Sift offers a turnkey post-processing and powder recovery system for the Fuse 1 SLS printer.

More complex processes such as SLA and SLS do not take long to achieve high quality models, while FDM models require lengthy manual post-processing to improve quality and remove layer lines.

Questions:

-

What is the whole model production workflow? What specific steps are required to set up printing, change materials, and post-process models?

-

How long does it take to post-process one particular model?

-

Are there any tools or devices available to automate some of these tasks?

Outsource production orders to third-party service bureaus or labs when you use 3D printing only occasionally or to make large models in non-standard materials. Typically, the bureau has several in-house 3D printing processes such as SLA, SLS, FDM, as well as metal 3D printers. They can also provide advice on a variety of materials and offer additional services such as design or improved finishes.

Typically, the bureau has several in-house 3D printing processes such as SLA, SLS, FDM, as well as metal 3D printers. They can also provide advice on a variety of materials and offer additional services such as design or improved finishes.

The main disadvantages of outsourcing are the high cost and duration of production. One of the main advantages of 3D printing is its speed compared to traditional production methods. But it is noticeably reduced if the delivery of the model produced by the involved organization takes several days or even weeks. And as demand and capacity grow, the costs of outsourcing are rising rapidly.

Desktop 3D printers are the perfect solution for fast model production. Depending on the number of parts needed and the volume of prints, the investment in a professional 3D printer can pay for itself in just a few months.

With desktop and workshop printers, you can pay for the capacity that matches your business needs and scale your production by adding more devices as demand grows, without the heavy investment of a large format 3D printer. Using multiple 3D printers also allows you to print models from different materials at the same time. But if there is a need for the production of large parts or the use of non-standard materials, service bureaus can come to the rescue.

Using multiple 3D printers also allows you to print models from different materials at the same time. But if there is a need for the production of large parts or the use of non-standard materials, service bureaus can come to the rescue.

Investment, material and labor costs are relatively easy to calculate. But what about indirect costs and hard-to-calculate factors that affect your business? Let's look at some of the main considerations when comparing a desktop 3D printer to outsourcing or other manufacturing methods.

Save time: What if you could bring products to market a few months faster? Or reduce the delivery time of your products by a few days or weeks? 3D printing simplifies traditional prototyping and manufacturing workflows, helping you save time and stay ahead of the competition.

Best results: 3D printing allows you to create more iterations, overcome failures faster, and produce better end products. Troubleshooting a design early on also helps avoid costly redesign and the use of additional tools.