3D printer filament usage

3 ways to estimate how much filament you will need for 3D printing

The question of how much filament to keep on-hand is one that bugs every FDM 3D printer user at one point or another. Most of us usually just limit our prints to how much filament we have. Or we reschedule any bigger project based on when we would buy a new spool.

There is a better way to go about this though. And that is what we will discuss here today.

While both weight and length are useful ways to gauge filament consumption, the simple fact that 99% of filament purchases are in terms of weight of the filament means that it is a better ballpark to use when estimating 3D printer filament usage.

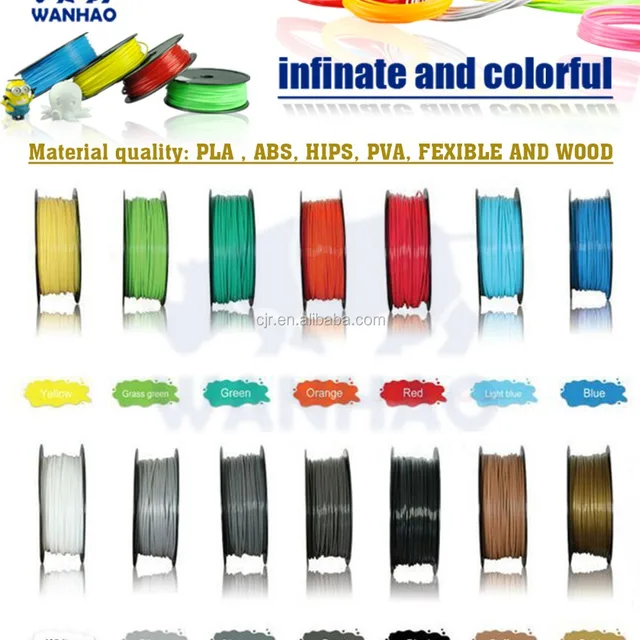

Most slicers automatically calculate an estimated weight of the 3D print on the basis of the type of material (PLA, ABS, HIPS, PETG etc.) upon slicing an STL file into G-Code. Look for “sliced information” or some similar information dialog within the slicer.

For simplicity, we’ll be talking about the weight of 3D prints in PLA. If you use another type of filament as a daily driver, then simply adjust the weights given in this article according to the difference in density between your type of filament with the density of PLA.

By “general use” we mean 3D printing parts, tools and thingamabobs every now and again, but not too often, nor on a daily basis. Basically, anything short of a full-blown project.

In this case, most 3D prints would not exceed 50 grams of filament (PLA). You can easily get away with keeping 2 or 3 spools of 1KG filament on-hand. If you use a 3D printer capable of printing with 2 or 3 filaments at the same time, then your requirement would also increase accordingly.

At the very least, every user should have 1 spare spool – recommended to be a neutral color – as a fail-safe reserve.

If you routinely take up entire 3D printing projects, then you would go through filament much quicker than the general user. You would also probably need different materials or at least different colors on-hand to ease out your post-processing.

In this case, it is much better to stock your filaments on the basis of your running project needs.

But how exactly does one go about accounting for all the filament that a particular project would use? If you had a final STL file ready to go, then of course you could simply slice it to find out the estimated weight of the filament.

Speaking for the broad majority of tinkerers and 3D printing enthusiasts, however, reaching a final STL file isn’t something that one does on the first day of the project and is only near the final stretch that the STL is also set in stone. Of course, the answer to this problem is, we estimate!

Estimate based on prior experienceOne of the easiest ways to go about estimating the amount of filament you would need is to compare it to previous projects already completed.

For example, your current project requires you to 3D print a hexagonal container of some sort. By prior experience you know that a similar sized round container would use up 76 grams of PLA filament when printed with 20% infill.

Now a hexagon has more defined edges than a round container and perhaps you’d like to use 40% infill to make it extra sturdy, so as a rough estimate we increase the expected weight of the hexagonal container by 20% and add an extra 5% to account for the difference in shape.

Increasing the 76 grams by a total of 25%, we’d get a ball-park estimate of around 95 grams. Since this 95-grams is estimated from the consumed material of the prior project, this method has the added advantage of accounting for things such as failed prints, support structures, varying levels of in-fill as well.

Approximation (order of magnitude estimation)The more mathematically inclined readers would be familiar with this concept named after famed physicist Enrico Fermi.

A fermi approximation only considers the order of magnitude or for our purposes, weight in grams rounded to 1, 10, 100 and so on to reach a close enough estimate of the weight of the filament.

Say, for example you want to 3D print a cosplay helmet for your own head size, but are unsure exactly how much filament it would take. A good starting point would be to consider the size of the helmet in comparison to say a 10 cm3 3D printed cube at 100% in-fill with PLA.

A good starting point would be to consider the size of the helmet in comparison to say a 10 cm3 3D printed cube at 100% in-fill with PLA.

Surely the helmet would not be only 10 cm3 or 100 cm3, and it cannot possibly be a 1000 (10,000 cm3) times the size of the cube as well. So as the only reasonable selection, we will say that the helmet would be around 100 times the size of the cube.

Since the density of PLA is 1.25 grams per cubic centimeter, our 100% in-fill cube would weigh exactly 12.5 grams. So, our helmet at an order of magnitude of 100 times more should be around the ballpark of 1250 grams at 100% in-fill. If we are printing at 20% in-fill, then it would reduce that weight to 250 grams.

Now you may be thinking; “surely such a simple guess couldn’t be accurate?”. And you’d be right. But as an estimate goes, the Fermi approximation is a great way to reach an accuracy of within one order of magnitude or one power of 10 of the actual answer. So, the actual helmet could only be 100 grams, or it could be 400 grams, but you can be sure that you wouldn’t needmore than one 1 kg spool of filament for it. And that is what we needed to estimate: How many spools of filament you would need for the project.

So, the actual helmet could only be 100 grams, or it could be 400 grams, but you can be sure that you wouldn’t needmore than one 1 kg spool of filament for it. And that is what we needed to estimate: How many spools of filament you would need for the project.

As a pro-tip, we would recommend you steer clear of using a geometric volume as fine way to calculate weight of the 3D print.

Firstly, most 3D prints are of a unique shape and unless you are brilliant at math, their volumes would need to be estimated by simplifying the design to Minecraft-style cuboids.

You are already uncertain of the final details of the 3D print, so you’d be making multiple guesses as to the volume of the resultant cuboids. This increases the uncertainty as the complexity of the 3D print increases.

Secondly, a volumetric approach usually would fail to account for the support structures, failed prints and other technical losses that you may face, so more often than not, you would wind up under-estimating your project requirements.

Lastly, it is human nature to make conservative guesses when faced with the unknown. In terms of estimating the required filament, this would invariably mean that the person guessing the volumes of the various parts would also under-estimate.

Since not running out of filament for the duration of the project is the entire goal of the estimation, the end-result of the geometric volume approach is time spent doing nothing worthwhile in most cases. However doing so may give a better estimate on how many spools of filament to inventory over time.

Since 3D printing is an additive manufacturing process there is very limited material waste involved. With a 1 KG spool of filament, you would probably 3D print ~990 grams or so of the material.

Factors that affect this of course, is the quality of the filament. If the filament keeps breaking or keeps getting jammed, this would reduce the effective amount of filament you could 3D print with.

The other factor is the age and degradation of the 3D printer itself which would lead to increased jams, more failed prints, and more process loss at the hot end.

The biggest contributor to wasted filaments is not the hardware nor the filament, but complex 3D print design, improper filament storage or incorrect 3D printer settings is what lead to excessive waste of material.

Support structures are arguably the bigger contributors to willful wastage of materials when it comes to complex 3D prints. Support structures can be avoided by either breaking the complex design into multiple simpler units and then attaching them in post-processing, or by incorporating the support structure into the 3D print itself; grids, interlocks, beams and scaffoldings have been a part of architecture for centuries, so consider incorporating one or more of them in your next project.

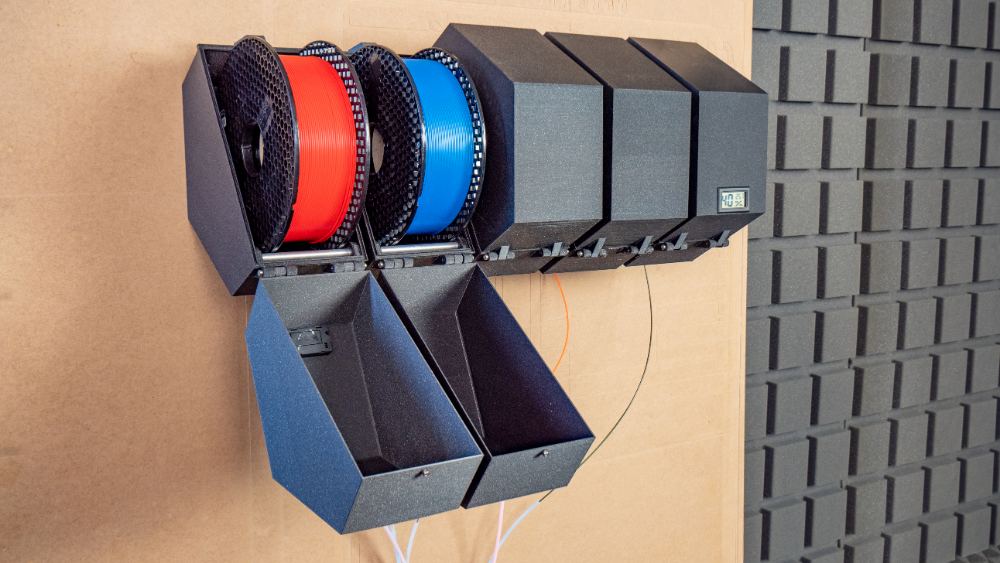

Improper filament storage is perhaps one of the biggest reasons that leads newcomers to have to buy new spools frequently. Remember, proper storage of 3D printer filaments is somewhere dry, away from sunlight, properly spooled (not tangled), and preferably in an airtight container.

Failed prints are another major culprit that waste precious filament. The best way to minimize the risk of failed prints is to learn about your material and the optimal 3D printer settings with a few test prints before doing any actual 3D printing. Learning from others’ mistakes is the best way to avoid making those same mistakes yourself.

Tags: 3D printingFilamentMaterialsPLA

How Long Does a 1KG Roll of 3D Printer Filament Last? – 3D Printerly

I’ve been 3D printing this same roll of 1KG PLA for a while now and I was thinking to myself, just how long does a 1KG roll of 3D printer filament last? There are clearly going to be differences from person to person, but I set out to find out some average expectations.

The average 1KG spool of filament lasts users just over a month before it needs replacing. People who 3D print on a daily basis and create larger models could use 1KG of filament in a week or so. Someone who 3D prints a few small objects from time to time could stretch a 1KG roll of filament for two months and more.

There’s some more information below which is relevant to answering this question such as the amount of common objects you can print and how to make your filament last longer. Keep reading to find out!

If you are interested in seeing some of the best tools and accessories for your 3D printers, you can find them easily by clicking here (Amazon).

How Long Does a 1KG Roll of Filament Last?

This question is quite similar to asking someone ‘how long is a piece of string?’ If you have a long list of items that you have been wanting to print and they are of a bigger size, infill percentage and you want large layers, you can go through a 1KG roll pretty quickly.

The timing for how long a roll of filament will last really depends on how often you are printing and what you are printing. Some will tell you a roll of filament lasts them a few days, others will tell you one 1KG roll lasts them a few months.

Some big projects such as costumes and props can easily use over 10KG of filament, so 1KG of filament won’t last you barely any time at all.

If you have one big print, you could technically use up a whole 1KG roll of filament in just one day, with a big nozzle such as a 1mm nozzle.

It depends on your flow rates and the models you are printing. Your slicer software will show you exactly how many grams of filament it will take to complete.

The piece below is almost 500g and lasts around 45 hours of printing.

When the same piece has the nozzle size changed from 0.4mm to 1mm, we see a drastic change in the amount of printing hours to just under 17 hours. This is around a 60% decrease in the printing hours and the filament used even increases from 497g to 627g.

You could easily add settings which use tons more filament in less time, so it’s really about your flow rates out of the nozzle.

If you are a low volume printer and like to print smaller items, a spool of filament can easily last you a month or two.

A high volume printer on the other hand, who likes to print bigger objects will go through that same filament in a few weeks or so.

A lot of people are involved in the D&D (Dungeons and Dragons) game, which are primarily made up of miniatures, terrain and props. For each print, it can easily take around 1-3% of your 1KG spool of filament.

One 3D printer user described that in 5,000 hours of printing in the past year, they had gone through 30KG of filament with near constant printing. Based on those numbers, that is 166 printing hours for every KG of filament.

This would measure up to about 2 and a half 1 KG rolls per month. It is a professional field that they are in so it their large filament consumption makes sense.

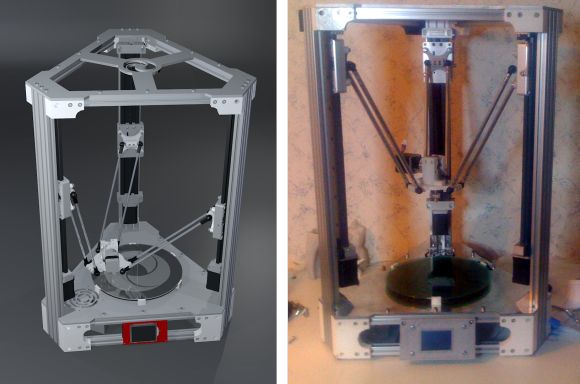

Using a bigger 3D printer like an Artillery Sidewinder X1 V4 (Review) compared to a Prusa Mini (Review) is going to make a big difference in how much filament you use. When you are limited in your build volume, you have no choice but to print smaller items.

A 3D printer with a large build volume leaves more room for ambitious, larger projects and prints.

How Many Things Can I Print with 1KG Spool of Filament?

For a rough picture on what it can print, you would be able to print somewhere between 90 calibration cubes with 100% infill or 335 calibration cubes with just 5% infill.

Some extra perspective, you could print around 400 average sized chess pieces with a 1KG spool of filament.

If you measure how long your 3D printer filament lasts in printing hours, I’d say on average you could get around 50 printing hours.

The best way to determine this would be to download some slicer software such as Cura and open a few models that you can see yourself printing. It will give you direct estimates for how much filament will be used.

This chess piece below in particular uses 8 grams of filament and takes 1 hour and 26 minutes to print. That means my 1KG spool of filament would last me 125 of these pawns before it ran out.

Another take away is that 1 hour and 26 minutes of printing, 125 times would give me 180 printing hours.

This was at a speed of 50mm/s and increasing it to 60mm/s changed the time from 1 hour 26 minutes to 1 hour 21 minutes which translates to 169 printing hours.

As you can see, a fairly small change can decrease 11 printing hours, technically making your 3D printer filament last less time but still printing the same amount.

The goal here is not about increasing or decreasing printing hours, but being able to print out more objects for the same amount of filament.

The average for a miniature is less than 10 grams per mini so you could print over 100 minis before your 1KG spool of filament will run out.

You could also technically account for prints that fail, since there’s always potential for that to happen and be of no use to you. If you’re lucky most of your failed prints happen at the initial first layers, but some prints can go wrong a few hours in!

Check out my post on Great Ways to Stop 3D Prints Moving While Printing, so your prints fail a lot less!

How Do I Make My 3D Printer Filament Last Longer?

The best way to make your rolls of filament last longer is to slice your objects in such a way that it uses less plastic. There are several ways to cut down on plastic production which over time can save you a substantial amount of filament.

There are several ways to cut down on plastic production which over time can save you a substantial amount of filament.

Many factors affect how long a roll of filament lasts, such as the size of your prints, infill density %, use of supports and so on. As you’ll realize, a 3D printed part such as a vase or pot uses very small amounts of filament because the infill is non-existent.

Play around with the settings to lower your filament usage per print to make your filament last longer, it will take some trial and error to really get good at this.

Find Ways to Reduce Support Material

Support material is widely used in 3D printing but models can be designed in such a way where it doesn’t require support.

You can also make use of 3D printing software to efficiently reduce support material. You can create custom supports in a software called Meshmixer, the video below by Josef Prusa goes into some nice detail.

I found out about this awesome feature by researching the Best Free 3D Printing Software, which is an epic list of slicers, CAD software and more.

Reduce Unnecessary Skirts, Brims & Rafts

Most 3D printer users will use a skirt before each print, and this makes a lot of sense so you can prime your nozzle before printing. You can remove the number of skirts you set if you do more than 2, even one can be enough a lot of the time.

If you don’t already know, skirts are the extrusion of material around your print before it gets to printing the actual model, though skirts use such a tiny amount of filament it doesn’t matter.

Brims and rafts, on the other hand, can usually be reduced or removed altogether in many cases, as they do use up more filament. They can be very useful for certain prints, so balance out the savings with the benefits carefully.

If you can figure out where you can remove them, you can save a lot of filament in the long run and a nice amount for each 1KG roll of filament.

Make Better Use of Infill Settings

There’s a massive trade-off in using high infill percentages versus 0% infill and it will allow your filament to go a long way.

Most slicers will default to an infill of 20% but many times you’ll be fine with 10-15% or even 0% in some cases. More infill doesn’t always mean more strength, and when you get to very high infill settings, they can even start to become counterproductive and unnecessary.

I printed a 3D model of Deadpool with just 5% infill using the Cubic pattern, and it’s pretty darn strong!

Infill patterns can definitely save you filament, the honeycomb, hexagon, or cubic patterns are usually good picks to do this. The fastest infills to print are going to be the ones that use the least material and the hexagon infill is a great example.

You’ll not only save material and time, but it’s a strong infill pattern. The honeycomb pattern is widely used in nature, main example being the honey bee.

The honeycomb pattern is widely used in nature, main example being the honey bee.

The fastest infill pattern is probably the Lines or Zig Zag and are great for prototypes, figurines or models.

Print Smaller Objects or Less Often

This is an obvious way to make your 3D printer filament last longer. Simply scale your objects down if they are non-functional prints and don’t necessarily need a larger size.

I understand wanting larger objects but you have to understand there will be a trade-off, so keep that in mind.

For example, if you only print items that use up 10g of filament at a time and you print twice a week, a 1KG roll of filament would last you 50 weeks (1,000 grams of filament/20g per week).

On the other hand, if you’re into projects that use up 50g of filament at a time and you print every day, that same filament is going to last you just 20 days (1000g of filament/50g per day).

Another simple way to make filament last longer is to print less often. If you print a lot of non-functional items or a bunch of items that collect dust (we’ve all been guilty of this) maybe dial it down a bit if you really want to make your filament roll to go a long way.

If you print a lot of non-functional items or a bunch of items that collect dust (we’ve all been guilty of this) maybe dial it down a bit if you really want to make your filament roll to go a long way.

Imagine over one-year span, you managed to save 10% of filament using certain techniques, if you use 1KG of filament per month and so 12KG of filament per year, a 10% saving would be just over a whole roll of filament, at 1.2KG.

You might think there are drawbacks of doing this such as making weaker parts, but if you use proper methods you can actually strengthen parts as well as save filament and printing time.

How Much Filament Do You Need for a Print?

How Long in Meters/Feet) is a 1KG Roll of Filament?

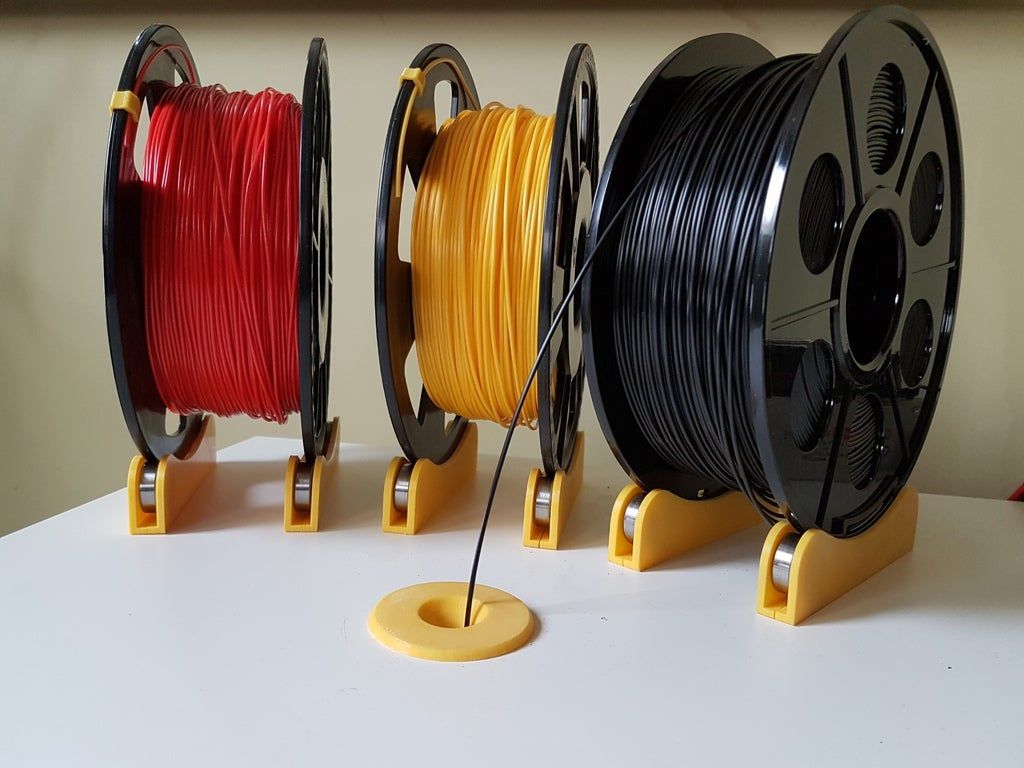

According to Rigid Ink, based on PLA having a density of 1. 25g/ml a 1KG spool of PLA would measure up at around 335 meters for 1.75mm filament and 125 meters for 2.85mm filament. In feet, 335 meters is 1,099 feet.

25g/ml a 1KG spool of PLA would measure up at around 335 meters for 1.75mm filament and 125 meters for 2.85mm filament. In feet, 335 meters is 1,099 feet.

If you wanted to put in a cost per meter of PLA filament, we have to assume a specific price which I can say on average is around $25.

PLA would cost 7.5 cents per meter for 1.75mm and 20 cents per meter for 2.85mm.

If you love great quality 3D prints, you’ll love the AMX3d Pro Grade 3D Printer Tool Kit from Amazon. It is a staple set of 3D printing tools that gives you everything you need to remove, clean & finish your 3D prints.

It gives you the ability to:

- Easily clean your 3D prints – 25-piece kit with 13 knife blades and 3 handles, long tweezers, needle nose pliers, and glue stick.

- Simply remove 3D prints – stop damaging your 3D prints by using one of the 3 specialized removal tools.

- Perfectly finish your 3D prints – the 3-piece, 6-tool precision scraper/pick/knife blade combo can get into small crevices to get a great finish.

- Become a 3D printing pro!

Threads in 3D printing

Dear friends, welcome!

This article would like to highlight the appearance of threads in printing. I will try to note the main factors influencing the appearance of threads.

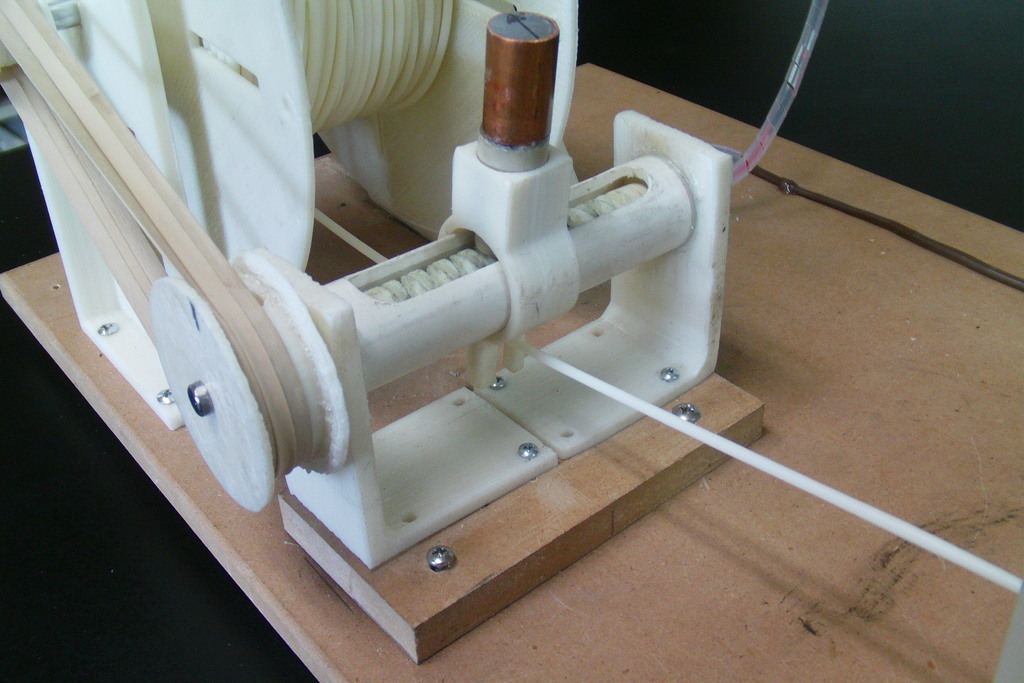

1) Idling speed and acceleration. The idle run consists of the following stages - first there is a retract, then the movement of the extruder, then again a retract. The plastic is spontaneously squeezed out precisely during the idle time, forming various kinds of defects. Now imagine an example if the idling takes zero seconds. Under this condition, the plastic will not have time to spontaneously extrude. Therefore, the higher the speed and acceleration, the less time the idling lasts, which means there will be fewer threads. But speed and acceleration are limited by the motor driver, the motors themselves, and the rigidity of the printer frame.

Therefore, you can try to slightly increase the speed and acceleration with each print, but at the same time make sure that the motors do not overheat, otherwise microsteps may be skipped, which will lead to print rejects.

2) Idling path. Different slicers process parts according to different algorithms, which means that the idling trajectory may differ. Some slicers build more rational extruder motion than others. Therefore, you can try to prepare the same part in several slicers and stop at the option that will be more rational.

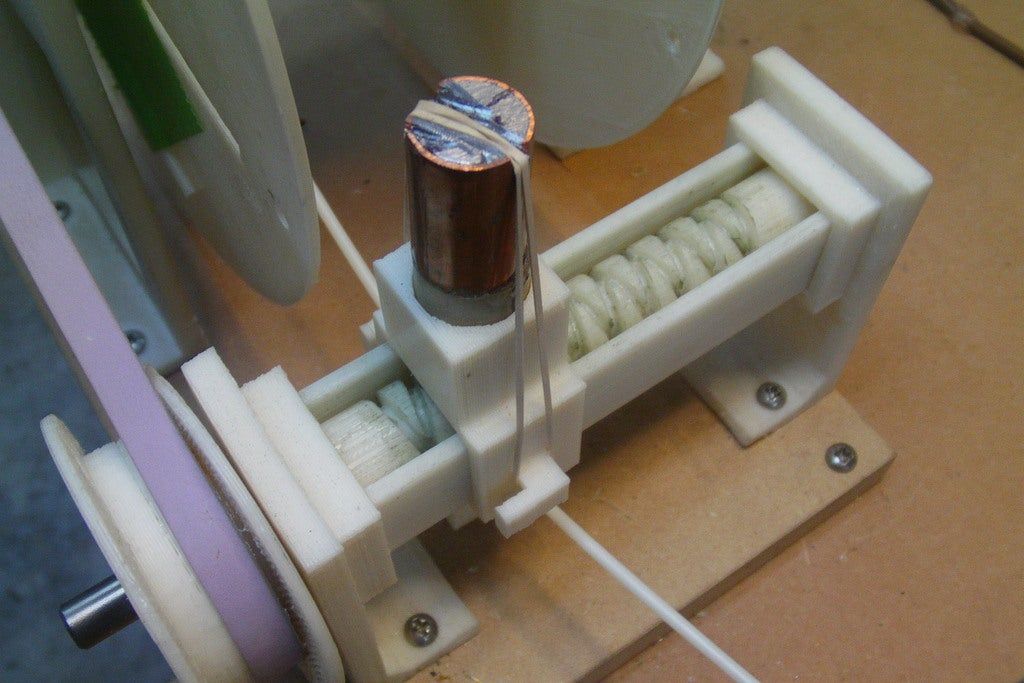

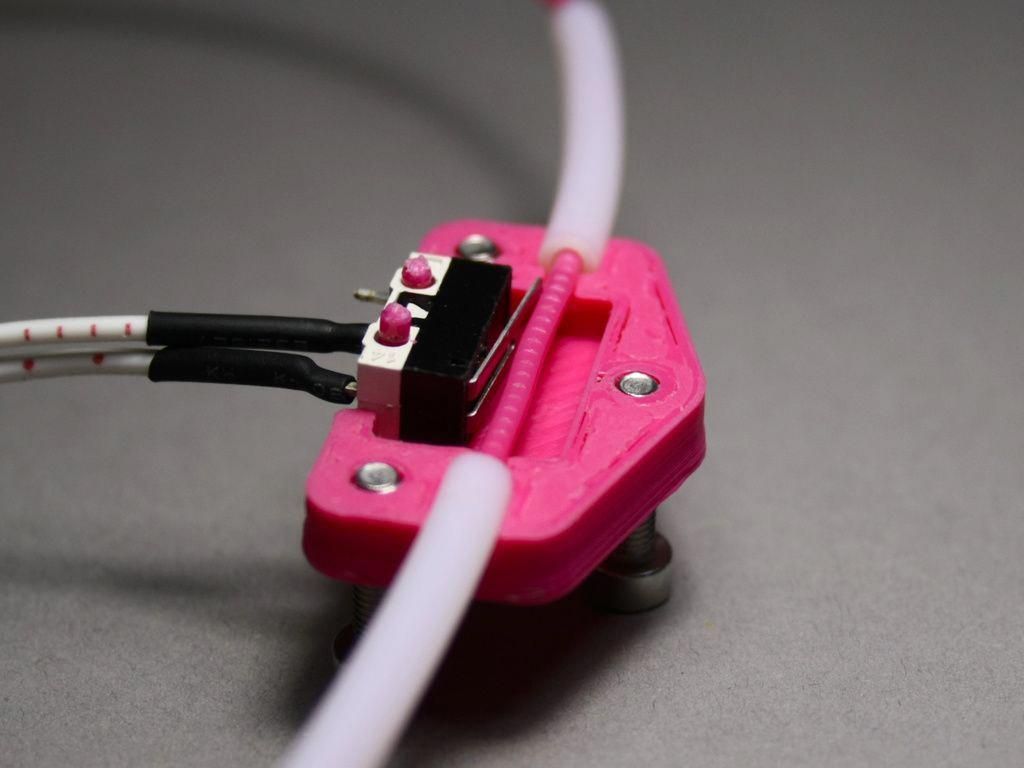

3) Feeder dependent, i.e. from the plastic supply system. Printers most often have one of two options: "bowden", i.e. far-distance or "direct", this is when the "feeder" is located near the extruder. Under the same printing conditions with direct, there will always be fewer threads than with bowden. But this does not mean that you can always switch from Bowden to Direct. It may also be that your printer will not be able to work with "direct" for one reason or another. The transition to "direct" must be considered with each printer individually.

The transition to "direct" must be considered with each printer individually.

4) Retract setting, i.e. plastic rollback - its task is to remove the residual pressure in the extruder during idling. Without retract, the threads will appear more intensely. For most printers, the values are as follows - for direct, the range is from 1 to 6mm, and for bowden, from 4 to 12mm. (the amount of retract also depends on the diameter of the nozzle).

5) Plastic quality. If you are constantly printing only budget plastics and are unhappy with the result, then try to buy plastic in a higher price category, and more importantly, with good reviews. And then compare the print quality. But the main thing - from different manufacturers, compare the same types of plastic - you should not compare, for example, ABS from one manufacturer, and PLA from another.

6) Plastic drying. By the way, this applies to almost all plastics, not just nylon. If you have unnamed or cheap plastic in your hands, it is recommended to dry it after opening it, because. it is not known whether the plastic was dried before packaging.

it is not known whether the plastic was dried before packaging.

7) Nozzle diameter. The larger the diameter, the more plastic will spontaneously squeeze out during idling. There is nothing you can do about it, it just needs to be taken into account when choosing a nozzle diameter.

8) Extruder temperature. If you heat the extruder to the upper limit of the recommended range (indicated on the plastic that is being printed), then the fluidity of the plastic will be higher, and it will be more easily extruded from the nozzle. Plastic manufacturers give a temperature range for a reason. If you set the print speed to high, then the extruder temperature should be in the upper limit of the range. But if the print speed is low, then there is no need to heat up the extruder much, otherwise filaments may appear due to overheating of the plastic.

Therefore, you can try to reduce the temperature of the extruder as follows - during printing, every couple of minutes, reduce the temperature by 5 degrees over and over and watch the print closely. If the threads disappear, remember the temperature and stick to it. But if the temperature is greatly lowered, then the plastic will not be able to extrude at all. Don't overdo it.

If the threads disappear, remember the temperature and stick to it. But if the temperature is greatly lowered, then the plastic will not be able to extrude at all. Don't overdo it.

9) Dependence of temperature on the type of extruder. There are many different models of extruders. For example, consider the E3D V6 and E3D V6 Volcano extruder. The E3D V6 Volcano has an extended nozzle and an extended aluminum block. And this means that the zone where the plastic is in the molten state is larger, so it can push through a larger volume of plastic per unit of time. As a result, this extruder will be able to print at higher speeds than the regular E3D V6. But here you need to understand the following - if you have a "powerful" extruder, and you print at low speeds, then the plastic will overheat, which will lead to the appearance of threads. Therefore, for powerful extruders, it is better to set the temperature in the lower limit of the recommended range. And on the contrary - for an extruder that cannot heat up a large amount of plastic, the temperature should be kept in the middle or at the upper limit of the recommended one.

The conclusion here is the following - for different models of extruders, different printing temperatures are needed.

10) Free travel distance. If you are printing multiple parts at once, try to space them closely to reduce the dry travel distance. Well, if a solid part is printed, with individual elements at a great distance from each other, in this case, you can try to change the location of the part in space so that there are fewer idle moves.

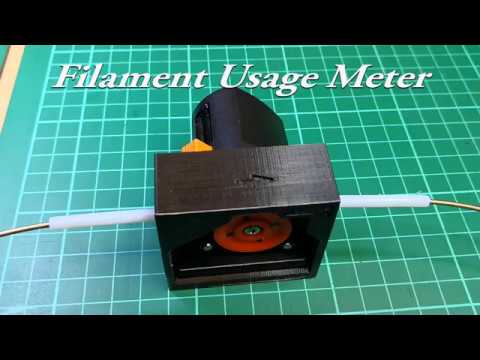

11) File analysis before printing. When your G-code is ready, do not be lazy and meticulously analyze it before printing, because. at the verification stage, you can detect unwanted elements that can create various kinds of defects, including the appearance of threads. By the way, in whatever slicer I prepare the file, I almost always check the finished code with the help of “Repetier-Host”, because it shows all the movements that can lead to certain defects.

12) Plastic type. All plastics have both strengths and weaknesses. For example, PETG plastic has a high tendency to filament. ABS, on the other hand, has a low predisposition to threads, but it will have to concentrate on the problem of shrinkage and a low degree of sintering of the layers.

For example, PETG plastic has a high tendency to filament. ABS, on the other hand, has a low predisposition to threads, but it will have to concentrate on the problem of shrinkage and a low degree of sintering of the layers.

Therefore, before printing, familiarize yourself with the pros and cons of the plastic with which you plan to print.

13) Using the "Lift Z" function. When enabled, a gap will be created between the extruder and the printed part. It is needed so that during idle the extruder does not cling to the outer walls of the part. This feature can significantly reduce the number of threads. But it should be used if the printer has a powerful driver and a motor along the Z axis, as well as a screw with a thread pitch of at least 8mm. This is necessary to achieve high speed and acceleration on the Z axis. Well, if you try to use this function at low speeds, the problem will only get worse and there will be more threads, because. idle time, taking into account "Lift Z", will increase significantly. The idling time with the "Lift Z" function consists of: movement along the Z axis + retraction + idling + retract + movement along the Z axis.

The idling time with the "Lift Z" function consists of: movement along the Z axis + retraction + idling + retract + movement along the Z axis.

Therefore, you can try to experiment with this function and see the result.

14) Problems with the extruder. Imagine a situation where you put a large retract, but a large plug of melted plastic formed in the thermal barrier between the nozzle and the Teflon tube. In such a situation, no matter how big you put the retract, this plug will not disappear, but will remain in its place. And, therefore, the retract will not be able to completely relieve the pressure in the system. Therefore, keep your extruder clean and in good working order.

15) Problem with the driver on the motor in the feed system (motor on the feeder). It's a rare phenomenon, but it's still there. I've run into a problem where the driver only spins the motor in one direction, regardless of the command, whether it's spinning one way or the other -- the motor only spins in one direction.

And in practice it looks like this: the motor advances the plastic during printing, and at the moment of idling, when a retraction should occur, the motor sharply squeezes out additional plastic (because the driver rotates the motor in only one direction).

As a result, although this phenomenon is rare, it still took place in my practice.

Thank you for your attention, I hope the material was useful, I wish you all the best!

What is 3D printer filament and how to choose it?

December 3, 2021

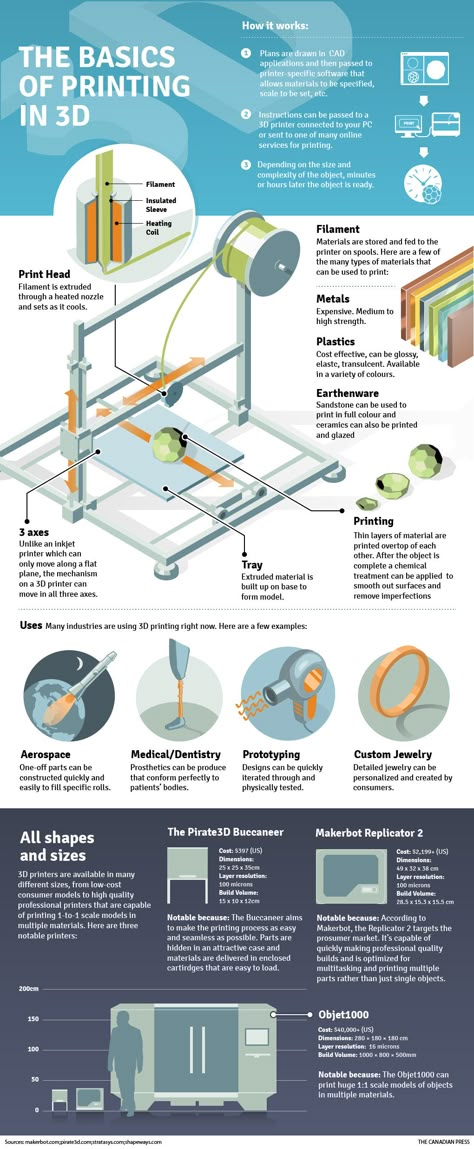

To print objects on a 3D printer, he needs the appropriate material. 3D printers typically use special plastics that have different properties depending on their composition. These plastics are called filaments. And because of their shape, in the form of a thin thread, everyone is used to calling them that way. And you yourself choose which filament for a 3D printer to buy in order to get the desired result.

It is important to understand that during the printing process, the filament is heated, melted and extruded through the 3D printer's extruder nozzle. There are many 3D printing filaments used in printing today, from standard plastic filaments to metallic imitations or wood or flexible filaments.

There are many 3D printing filaments used in printing today, from standard plastic filaments to metallic imitations or wood or flexible filaments.

It's important to choose the right filament for your 3D printer. Using filament with the wrong diameter or settings will inevitably result in printing failure or damage to the printer. This can be avoided if you understand which filament is best for your printer and your part. All 3D printers have a unique set of temperatures, speeds, and features that you must also consider in order to buy the right filament.

Each filament has its own set of characteristics both in terms of appearance and physical properties. Each offers its own set of features that you need to know to optimize your printing. You also need to consider what properties are needed for the object you are printing. Will the material be used indoors or outdoors? Should the part move and flex, or should it be absolutely rigid? What forces will be applied to the object? What post-processing methods will be applied to the finished 3D print? It depends on what thread you need to buy.

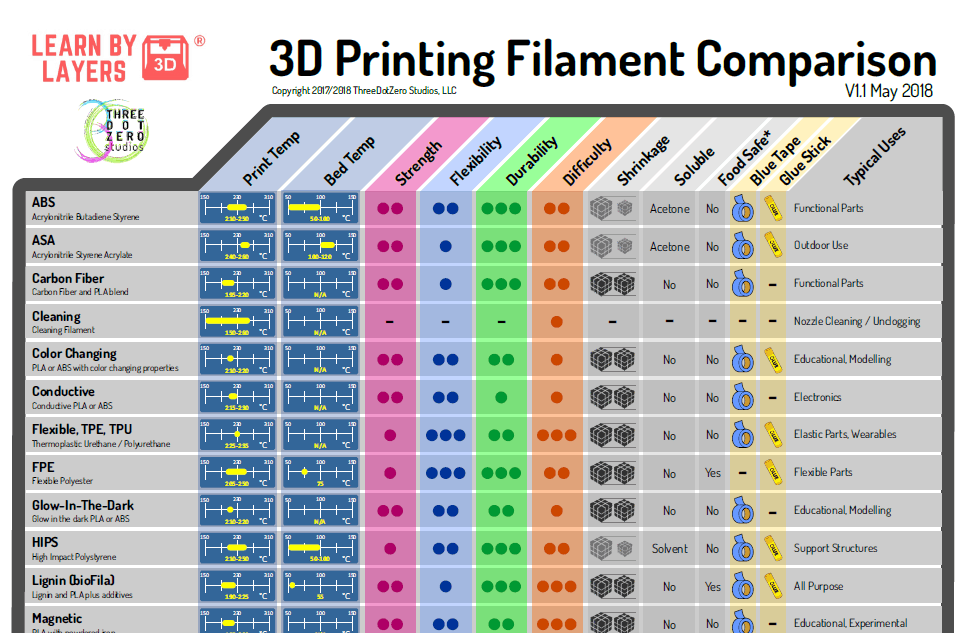

Of the many threads available, some are more popular than others. These are such filaments as ABS, PLA and PET/PETG.

ABS is popular because it is durable and impact resistant. It's this strength and moderate flexibility that makes it a great choice for 3D printing. In addition, it is easy to extrude from the nozzles of the printer, so it is easy to work with and can be bought anywhere.

PLA (polylactic acid) is a special type of thermoplastic made from organic materials such as corn starch and sugar cane. The main benefits of PLA are that it is safer and easier to use and does not contain toxic fumes to worry about. Compared to ABS, PLA allows you to print more aesthetically pleasing 3D parts, thanks to its unique luster and smooth appearance.

PET, also known as polyethylene terephthalate, is a stable and harmless plastic, odorless and fully recyclable. In its raw state, the thread has no color and is crystal clear. After exposure to cold or heat, the material quickly becomes opaque.