Xyz 3d printer da vinci mini filament

XYZPrinting Da Vinci Mini Review 2022

Heard about XYZPrinting Da Vinci Mini 3D printer? We did as well and decided to test one of them to see if they're worth it. Here are our findings!

By Justin Evans

4

See Price

So you’ve decided to get into the world of 3D printing. Where do you begin? There are printers for every possible requirement, and there’s a lot of jargon floating around that makes it hard to accurately compare different models. Relax – we’re here to help.

XYZPrinting is known for creating some of the best entry-level 3D printers around. Today, we’ll be looking for any strengths or weaknesses that the Da Vinci Mini might have– it’s a small printer, but it’s certainly capable. However, is it right for you and your needs? You’ll have to read on to find out.

| Filament Diameter | 1. |

| Extruders | 1 |

| Supported Materials | PLA |

| Connectivity | USB, WiFi |

| Printing Speed | 100mm/s |

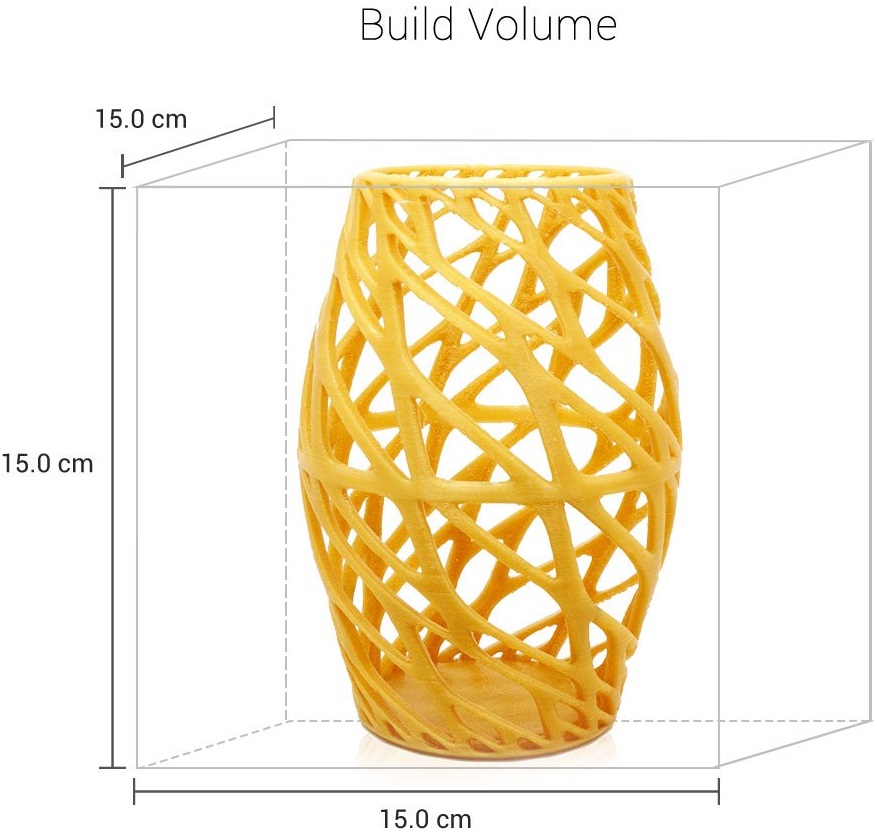

| Build Volume | 5.91 x 5.91 x 5.91” |

Table of ContentsShow

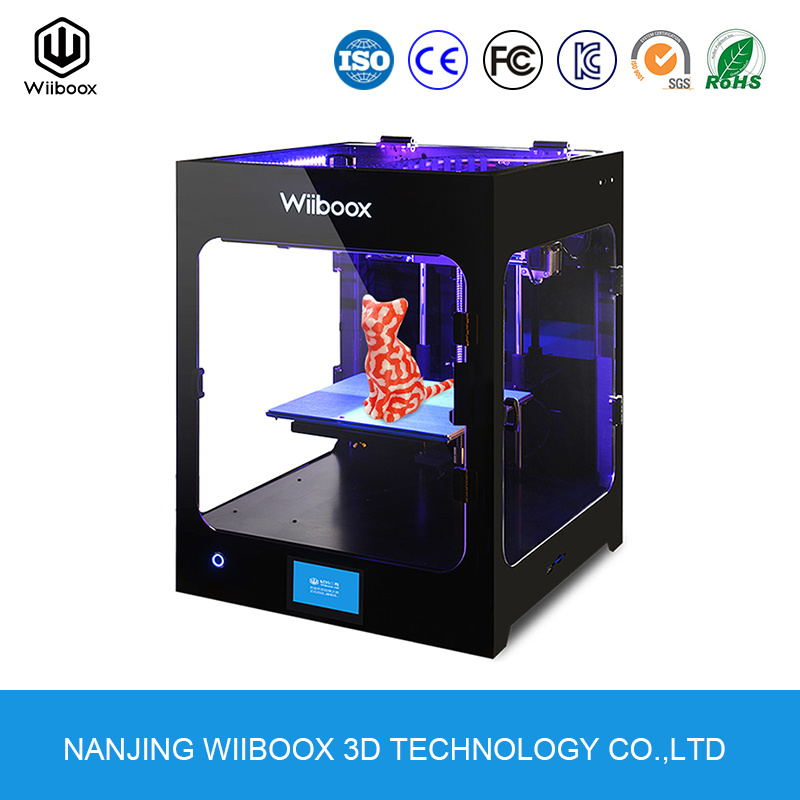

Design

The XYZPrinting Mini comes pre-assembled, so there’s no need to factor in build time. It’s a small-sized unit, perfect for sitting on your desktop, but this does mean that the build area is similarly restricted. Don’t get us wrong – you’ll be able to print decent-sized models, but nothing too huge.

Notice how there’s no enclosure? This means that it’ll be a little louder when you print, but all things considered, it’s still fairly quiet since the mechanical parts are mostly covered by the plastic frame. There are also implications for heat retention, but that’s not an issue, as we’ll explain later.

You get exactly what you’d expect from a low-end printer: there’s a single extruder and a maximum speed of 100mm/s. This is fairly standard and just means that you’ll take slightly longer to print. However, as the build area is only around 6” in each direction, you won’t be waiting hours unless you’re trying to print a large, solid cube.

Printing

There are three different speeds to choose from. As expected, the faster you print, the rougher the final quality. We found that the fastest setting resulting in significant stepping on curved surfaces, while if you allow it to take its time, your models look far better, but still not professional-level.

In an attempt to keep things as simple as possible for new users, XYZPrinting has limited the Mini to using PLA filaments. This removes the need for an enclosure but does restrict you somewhat in terms of the things you can build. Still, for beginners, PLA is more than enough to get you started.

The overall quality of the prints is too low for manufacturing, and the build volume too small for mass-production. However, it’s perfect for people looking to print things for their home or office. Better still, it takes any 1.75mm PLA filament – not just those made by XYZPrinting.

However, it’s perfect for people looking to print things for their home or office. Better still, it takes any 1.75mm PLA filament – not just those made by XYZPrinting.

Features

So what other features does the Mini have to make things easier for beginners? Well, instead of adding things, XYZPrinting has removed components. There’s no heated bed, for instance, and no built-in screen. You do have a USB connection, though, and WiFi functionality, which is almost unheard of in low-budget printers.

We were pleased to see that drivers are available for both Windows and Mac computers. On the other hand, there’s no Linux support. It supports four different file types, though, so you’re not really limited to using a particular modeling program, which is great.

Even the interface is simplistic. There’s a single button for starting a print and a status LED that lets you know how your print is going. All in all, it’s easy to use even if you’re not particularly tech literate. Let’s be honest – that’s never a bad thing.

Let’s be honest – that’s never a bad thing.

Cost

Here’s the thing: the Da Vinci Mini isn’t available in the United States. You can buy it from several European locations, though. It costs around $700, which makes it among the cheapest, most robust 3D printers we’ve covered. Of course, you’ll have to find a company to ship it over if you’re in the US.

Running costs are minimal. PLA is among the least expensive materials you can use, and since while third-party filaments aren’t supported, you can easily mod it to accept them. Large spools of PLA often cost less than $20 so really, your monthly material costs will depend on how often you print.

We think that this 3D printer is appropriately priced. It’s clearly intended for novice users, and the price point helps it stay affordable, unlike more advanced printers that offer user-friendly features. You’ll likely outgrow it in a year or two, but until then, it’ll serve you well.

Support

XYZPrinting’s support section provides customer help telephone numbers for 11 different countries. Best of all, each of these can talk to you in the native language or English. This is almost unheard of, and we’re genuinely delighted to see this level of help being offered for free.

Best of all, each of these can talk to you in the native language or English. This is almost unheard of, and we’re genuinely delighted to see this level of help being offered for free.

The limited warranty period is similarly outstanding. You’re covered from factory defects for up to two years at no extra cost, presuming you bought the printer from one of XYZPrinting’s recommended sellers. There’s no option to extend this warranty, though, which is a bit of a shame.

Customers can consult model-specific FAQs and tutorials in case they need any technical help. There are also different versions of the software, as well as documentation for each printer model here. All in all, it’s one of the most comprehensive support packages offered by any major 3D printing manufacturer.

Printrbot Simple Metal Review

XYZ da Vinci Mini 3D Printer

The da Vinci Mini offers a perfect entry point for beginners and students to explore 3D printing, thanks to simplified controls and a user-friendly workflow process.

- One touch button process for quick 3D printing

- Auto calibration provides instant bed leveling

- Small footprint, yet robust build volume

- Bundled with XYZmaker and XYZware

- Built-in Wi-Fi for connecting to the home, office, or classroom

- Accommodates safe, non-toxic PLA filament

Read the full description below

Notes from the Workshop:

With the XYZprinting STEAM program, students and beginners can quickly get acclimated to 3D printing in science, technology, engineering, math, and the arts.

XYZprinting’s da Vinci Mini is part of its Beginning line of products, ideal for young makers, students, and part-time hobbyists who require an easy and affordable way to get started with 3D printing. Using a seamless, one-touch control process, the da Vinci Mini features an automatic filament loading system, color coded indicator lights, and a simplified overall workflow for beginners. With its intuitive auto-calibration system, the da Vinci Mini performs instant bed leveling prior to each 3D print. It can connect wirelessly to computers in homes, offices, and classrooms, reducing the need for USB cable clutter.

With its intuitive auto-calibration system, the da Vinci Mini performs instant bed leveling prior to each 3D print. It can connect wirelessly to computers in homes, offices, and classrooms, reducing the need for USB cable clutter.

Made with a rigid plastic housing and supported by steel components, the da Vinci Mini 3D printer offers a stable, vibration-free extrusion process in order to ensure accuracy. The aluminum build plate helps promote surface adhesion in order to prevent warping and curling. All of the printer’s precision components have been carefully designed to ensure consistent and trouble-free 3D printing.

The da Vinci Mini’s build area measures 5.9” x 5.9” x 5.9”, allowing it to work with objects such as toys, small prototypes, jewelry, and more. The external drive system pushes filament toward the single extruder hot end, simplifying the process for beginners. The color coded LED interface changes according to the 3D printing conditions, providing a new way for users to interpret heating, printing, or potential filament feeding issues.

Important information about print material (filament) – again, in a positive way

- To be noted if print material is limited (e.g. only custom PLA spools).

- To be noted if the variety of print materials is impressive.

Anything else notable

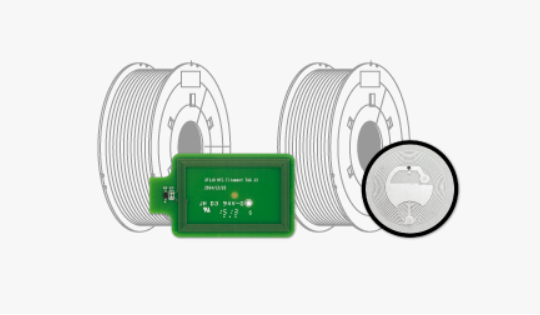

- The da Vinci Mini 3D printer uses proprietary filament rolls from XYZprinting, making them safe for younger consumers, students, and casual hobbyists.

- XYZprinting PLA filaments are non-toxic and free of heavy metals; extensively tested for safe and reliable 3D printing.

- XYZmaker and XYZware are bundled with the da Vinci Mini, providing streamlined 3D modeling and slicing capabilities that are easy and intuitive for classrooms.

- Can go into more technical information about the print chamber size, extruder model or temperatures, print bed material. Feel free to include actual specs (e.g. 17 microns, 12”, etc.)

The da Vinci Mini 3D printer is capable of printing between 100 micron (0. 1 mm) and 400 micron (0.4 mm). Users should be aware that the finer the resolution, the slower the overall print speed.

1 mm) and 400 micron (0.4 mm). Users should be aware that the finer the resolution, the slower the overall print speed.

The da Vinci Mini is available in two colors, orange and black, and red/yellow/blue. The red, yellow, blue color scheme is designed to complement the atmosphere of younger classrooms.

XYZprinting is a leading provider of affordable desktop 3D printers for homes, offices, and schools. Backed by a variety of 3D printers and accessories, the company strives to make 3D printing affordable and accessible to the masses.

| Technique | Additive Manufacturing |

|---|---|

| Printer Type | FDM (Fused Deposition Modeling) |

| Filament Compatibility | PLA (Polyactic Acid) |

| Construction | Plastic, Aluminum |

| Printer Weight | 22.7 lbs |

| External Dimensions | 20” x 18” x 15.5” (508 mm x 457 mm x 394 mm) |

| Print Bed | Aluminum Plate |

|---|---|

| Print Bed Max Temp | Non-Heated |

| Extruder Configuration | Single Extruder |

| Extruder Max Temp | 230 Degrees Celsius (446 Degrees Fahrenheit) |

| Motor | NEMA |

| Build Area | 5. 9” x 5.9” x 5.9” (150 mm x 150 mm x 150 mm) 9” x 5.9” x 5.9” (150 mm x 150 mm x 150 mm) |

|---|---|

| Build Volume (Approximate) | 205 cubic inches (3.36 Liters) |

| Layer Thickness Minimum | 100 microns (.1 mm) (Variable) |

| Layer Thickness Maximum | 400 Microns (.4mm) (Variable) |

| Input File Type | .STL |

|---|---|

| System Compatibility | Windows |

| Software Compatibility | XYZ Maker, XYZWare, XYZ printing STEAM |

| Power Compatibility | 100 – 240 VAC, 50 – 60hz |

|---|---|

| Manufactured In | Thailand |

Vendor: XYZ Printing

XYZ Da Vinci mini. The last three letters of the alphabet.

Together with the Ultimaker 2 Go, the guys from IGo3D sent me and this little one for review. The kid, made specifically for all sorts of TsMIT, that is, for children's creativity, therefore, should be as simple as slippers, but nevertheless be able to print honestly, so as not to be rejected by the young generation of makers who Marco Bruni brings up so diligently. True, offering his version of Prusa.

True, offering his version of Prusa.

Is he as screwed up as he is painted?

Let's do a little unpacking. A neat box with a picture of the printer and the model name.

Inside - a complete set of various necessary devices for printing.

This is a scraper/palette knife. If sharpened, it is convenient to pick off the part from the table. Although, I prefer a clerical knife.

USB cable - USB type B, for connection to a computer.

Sheet of paper tape. In general, there should be 3 of them. One is glued on, one is a spare, and another piece was on the Ultimaker table when it was delivered to me. Unheated table, designed for PLA printing only. The knights of the cold table will appreciate this miracle, costing less than $300. Particularly hard-nosed citizens manage to print on drygostols with nylon. As you know, everyone has their perversions.

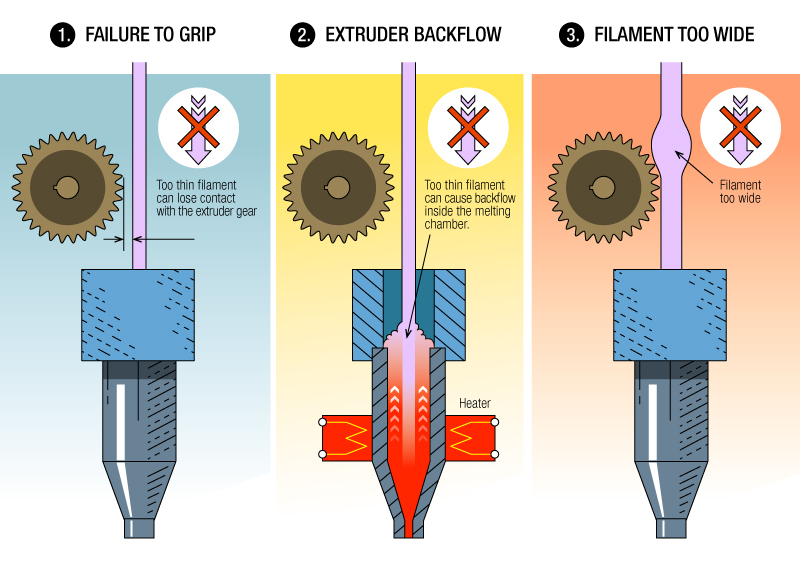

Interesting brush. Designed to clean the feed gear of the extruder from plastic chips, if it suddenly feeds poorly. I used this to wash baby bottles and nipples. :D

Such a funny aluminum record. As the manual says, it's a Leveling tool. The level, then, will expose them.

And spare fitting PC4-01.

Of course, the power supply, 24V and 2.5A.

The printer itself is so shiny and glamorous. Purebred pryuche-shaped drygost. I myself played enough of this at one time, I bought an acrylic dry-table on aliexpress at the dawn of sales on Ali. The printer is made in a beautiful glossy case of bright colors, which undoubtedly attracts the attention of children.

Of course, for the sake of caring for the environment, and minimizing the possible risks of electrical and thermal injuries - there is no heating of the table. Printing is offered with polylactide (PLA) only. All possible moving and rotating and heating parts are covered with protective casings and provided with warning labels.

Printing is offered with polylactide (PLA) only. All possible moving and rotating and heating parts are covered with protective casings and provided with warning labels.

Just the right time to stick a large sheet of paper tape from the ZIP on the table, for better adhesion of the plastic to the table.

The most important thing is the simplicity of the design. XYZ decided to go the easy route, like inkjet printers, using rolled aluminum in the form of a beam and a second rail. The first is the shaft. Belts are applied closed, thin.

Z-axis coupling made of pipes, with screw holes. No split joints. And just one pin.

The classic scheme for most inkjet printers is a stamped aluminum sheet, with shaft and motor mounts, attached to a molded plastic part, with bearings installed in Z. studs M5. Simple and no frills.

Head feed - classic bowden. Attached is a picture of how to refill the plastic. A little lower is a folding reel seat.

Attached is a picture of how to refill the plastic. A little lower is a folding reel seat.

We press the pressure lever from below and insert the plastic into the extruder.

Even with bearings. The coil rotates freely. This option is ideal for flex printing.

The carrier structure of the printer is based on an aluminum profile. Reliable, beautiful, easy to install.

Optical limit switches are located at the bottom of the housing for precise positioning of the extruder.

On the back, on the panel, there is a power connector and a connector for connecting to a computer.

The top of the printer is closed with a lid, with a slot for a Bowden tube, with a company logo.

The printer is quite compact, its table, when installed against the wall, does not rest against the wall. And it fits easily on the windowsill.

And it fits easily on the windowsill.

What about software?

The manufacturer supplies a simple and understandable software for children - slicer XYZware.

We connect the printer to the computer, select our printer, upload the model and print. Everything seems to be simple.

In addition to printer management and print preparation software, XYZ distributes its free 3D modeling software, XYZmaker.

Download utilities on the official website.

The printer, in addition to simulating a COM port, has a fully functional Wi-Fi.

Select our printer from the list.

Connect it via USB.

It is then defined in the program.

In the settings, you can set up a Wi-Fi connection and safely cut off the USB cable. Since they were already printed in IGo3D, 33 meters out of 100 remained from the complete coil. Not a lot. Okay, let's load what we have.

Since they were already printed in IGo3D, 33 meters out of 100 remained from the complete coil. Not a lot. Okay, let's load what we have.

In the thread menu, select boot.

Follow the instructions on the screen.

Here we either wait until he pulls the snot out of the nozzle and press ready, or wait until he spit out a little more of it (he knows the length of the tube) and turn off the flow himself.

Now let's calibrate the plane of the table. This can be done in the settings menu.

Select calibration.

We press the magic button, and a probe comes out from below, which will measure the surface of the table in 9 currents, in order to map the surface of the table. That is, when the table is curved, it will bypass this curvature and print smoothly.

And after measurements, he asks to remove the probe by pressing the button.

Excellent, surface calibrated. Now let's calibrate the offset.

This is the calibration of the optical limit switch in Z. It must be done if the first layer does not lie flat, that is, either the nozzle is imprinted on the table (and you need to press the button with the up arrows) or the thread from the extruder lies on the table freely and does not stick (then press down arrow). Each press makes a change in 0.05 mm increments. This is usually not required before the first print.

All calibrated, start printing.

To load and slice a model, it must be loaded into the program in STL or OBJ format.

For the test, I decided to print the head of some alien humanoid, which was shared with me here. With the thinnest layer of 0.1 mm and high speed.

Select settings. And press print. Slicing starts.

After that, you can save to your g-code format - 3w.

Regarding the size, you can scale it with standard tools.

I selected based on the amount of free time and the remaining filament.

Press print and the g-code file is transferred to the printer's internal memory.

Then it warms up the nozzle and starts printing. During printing, any actions with the printer are not available, only pause and stop printing.

Since I have less than a third of the reel left, I periodically got such messages.

Printing starts in Makerbot style - 2 lines are drawn on the edge to ensure plastic feed.

And then - the brim ordered in the settings.

The first layer is printed very thick and is not adjustable. But filling at high speed (which is not the maximum, but still about 70 mm / s) works out disgustingly. Outlines draw well. But it prints in a strange way, apparently very large jerks (Jerk) at small accelerations, so at first it moves smoothly and slowly, and then when switching to idle, it slowly accelerates, and in the end it just flies at high speed to the desired coordinate.

Outlines draw well. But it prints in a strange way, apparently very large jerks (Jerk) at small accelerations, so at first it moves smoothly and slowly, and then when switching to idle, it slowly accelerates, and in the end it just flies at high speed to the desired coordinate.

Conclusions

We must pay tribute to the developers, they minimized the cost of the printer so much that from there is the maximum that can be pulled out to the organs - steppers, limit switches and an extruder with a cooler. All.

Regarding noise - it prints comparable to inkjet MFPs and the like, there is a rattling backlash of plastics, a few melodies of steppers. In principle, this is what everyone is striving for, to make a super-cheap printer and get the main profit from consumables. But, not only in the Russian Federation, this idea seems ridiculous, filament counter resetters are already being sold on Ebay.

If you judge by the ease of working with a printer specifically for children, then this is the undoubted leader, everything is intuitively simple, and no intervention with a screwdriver is required. There is no need to understand how a stepper motor works and how to determine the sequence of its connection to the printer board, you do not need to understand the firmware settings and learn the basics of C ++. Just turn it on and follow the instructions on the screen.

There is no need to understand how a stepper motor works and how to determine the sequence of its connection to the printer board, you do not need to understand the firmware settings and learn the basics of C ++. Just turn it on and follow the instructions on the screen.

The print quality is quite decent for this price category, and the presence of an auto-level table is an undeniable advantage over all sorts of plush-shaped designs in the form of a whale for twice the cost of this baby.

This is the head. The printing is accurate, for this kinematics it is a masterpiece.

No wobble, the plastic feeds evenly and neatly.

As you can see, the biggest mistake of the company is the lack of blowing of the part, despite the fact that the print is blocked only by PLA. But despite this, many hanging elements turned out just gorgeous.

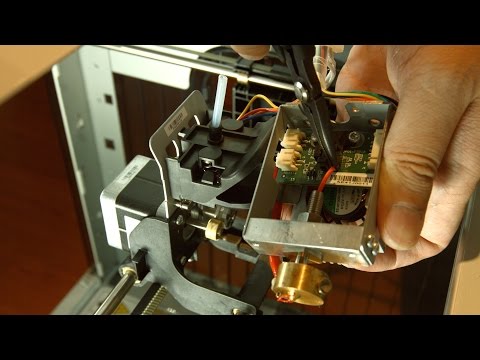

And now the guts.. .

.

And inside it has one board of its own design.

Accurate wiring, there is only one ground for the entire printer, and it is displayed on the frame from the profile.

The heart of the printer is a 32-bit processor from Atmel. Approximately, as in Arduino Due. With support for 1 device with SD / eMMC memory, one USB and ethernet port occupied by Wi-Fi.

Memory - Kingston 4 GB, eMMC. The g-code file is loaded there after slicing. It is likely that after the start of printing, you can generally cut off the cable from the PC and printing will not stop. This is probably why, during printing, there are no flow and speed settings.

Toshiba drivers, micro-stepping up to 1/32.