Idex 3d printers

Independend Dual Extrusion 3D Printers

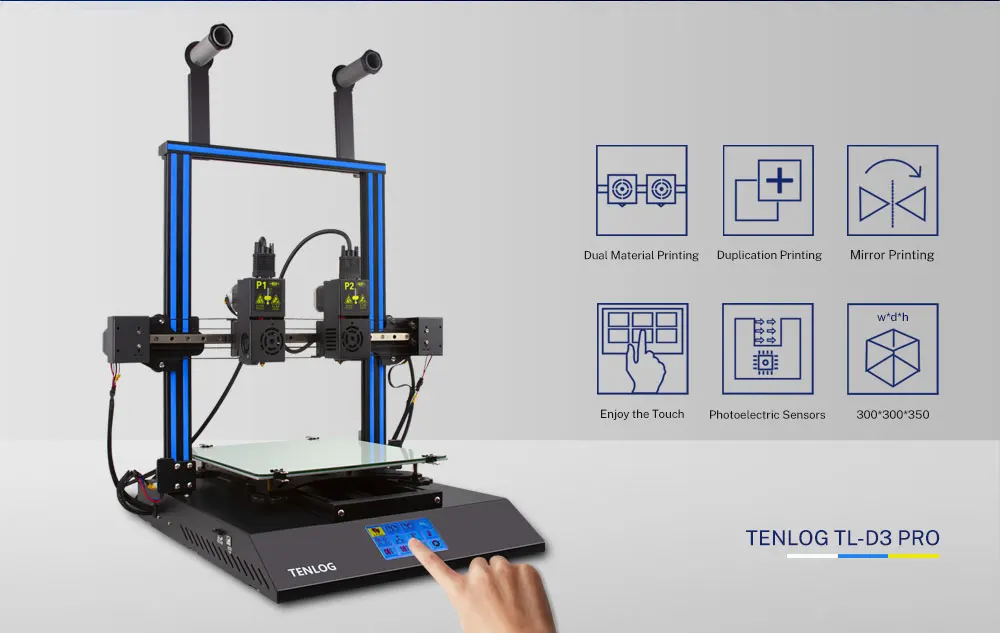

What is Independent Dual Extrusion 3D printing? Independent Dual Extrusion (IDEX) means that the 3D printer consists of two separate tool head carriages which allows independent, simultaneous movement during printing. The separate tool heads prevent the residue drip often found in traditional single toolhead configurations. With both hotends working simultaneously, capacity is double that of a conventional desktop 3D printer. This translates into double the productivity with the same investment of other 3D printers.

Guides & Articles

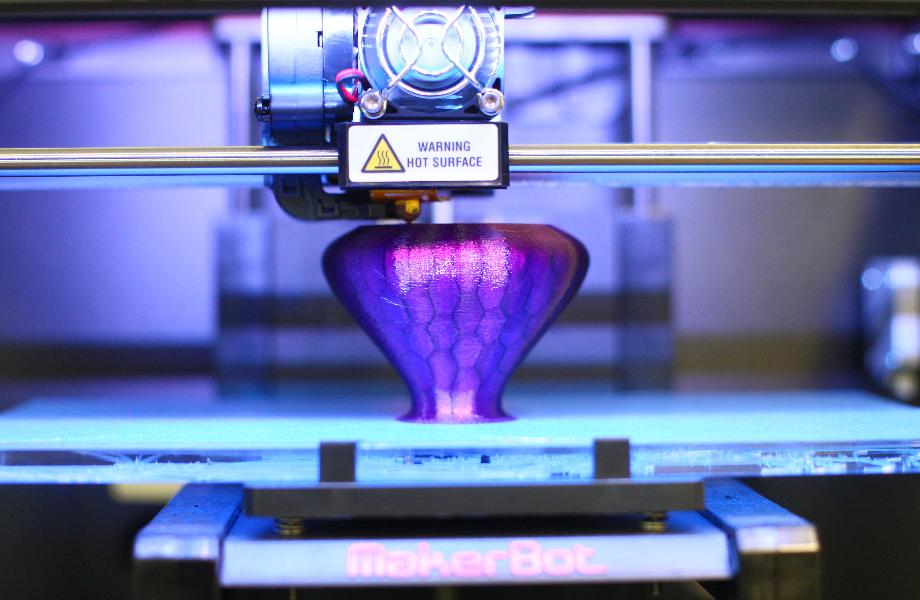

What is 3D Printing?

3D printing is a process where physical, three-dimensional objects, parts, or models are made layer-by-layer from Computer-Aided Design, or CAD, and digital files.

Anatomy of a 3D Printer

Get an understanding of how 3D printing works, from the inside and out. This guide will walk you through each of the critical components of a 3D Printer, answering the question: "How does a 3D printer work?"

The Top Ten Tips For Getting Started With 3D Printing

We were all noobs at one point! Here the ten best tips for getting started with 3D printing - whether it's your first time 3D printing or you need to brush up on the basics, this guide will help you out!

3D Printer Troubleshooting Guide

Use this guide to help you identify and solve the most common issues that may occur while 3D printing.

How To Calibrate Your 3D Printer's Extruder

This quick and informative guide will help you calibrate your extruder perfectly, resulting in accurate, quality prints.

3D Printing 101: How to Succeed with a Perfect First Layer for Every 3D Print

The first layer of your 3D print is the foundation of everything that comes after, which makes it such an important part of the 3D printing process.

How To Get The Best 3D Printed Parts By Understanding Extrusion Settings

Melting is a critical concept to 3D printing, and yet it hasn’t received a lot of in-depth attention. This article will teach you how to extrude your filament properly so it flows smoothly. Make filament jamming, delamination, and weak parts things of the past.

3D Printing Essentials: How to Succeed with Every Bed Surface Solution

Matching 3D printing filaments with the proper bed surface material is an important part of the 3D printing process. Read more to find out the best path to success.

Read more to find out the best path to success.

3D Printing Essentials: Filament Loading

Proper filament loading and unloading is a necessary part of 3D printing without trouble. Read on to learn the essential method you should be following.

3D Printing Essentials: Bed Leveling

For some, levelling a 3D printer's bed can be challenging, but it doesn't need to be. Read this essential guide to see what it takes to do it right.

Quick Tips: How To Get Started With Batch 3D Printing

Utilizing 3D printer time most efficiently is much easier once you start batch printing parts to maintain 3D printer uptime and minimize downtime.

IDEX Technology - BCN3D

What is 3D Printing?

3D Printing Technology, technically acknowledged as Additive Manufacturing (AM) or Rapid Prototyping, is a manufacturing process in which layers of material are built up to create a solid object.

Learn more

What is FFF technology?

At BCN3D we design and manufacture desktop FFF 3D printers. Fused Deposition Modeling (FDM), or Fused Filament Fabrication (FFF), is an additive manufacturing process that deposits a thermoplastic material layer-by-layer in order to build a part. This technology manufactures strong, durable and dimensionally stable objects with a great accuracy.

Among the multiple 3D Printing technologies in the market, FFF is the most widely spread because of several reasons. First of all, both the hardware and material are affordable, requiring a low initial investment. Secondly, there is a large range of materials available (such as Nylon, TPU, PET-G or ABS, among others), so the technology is suitable for multiple applications and markets. Finally, the design criteria needed and equipment operation are simple enough, especially compared with other 3D Printing technologies, so there is no need for specialized operators or complex training.

Learn more

What is IDEX technology?

Download White Paper “IDEX Technology: Doubling Productivity While Halving Costs”

The BCN3D printers are equipped with a unique double extrusion architecture: the independent double extrusion system (IDEX), the only extrusion system capable of printing with two heads independently.

Reliable dual extrusion 3D printing with IDEX technology

Because of the manufacturing strategy, sometimes it is required to build auxiliary support structures for those models with overhangs shallower than 45° from the horizontal plane.

In the case of printers that only have one extruder instead of a dual extruder system, once the model is printed, it is necessary to perform a manual and time-consuming operation to remove the supports. This process affects the quality surface between the model and the supports and also increases the chances of breaking the part. In addition, depending on the geometry of the model it can be impossible to totally remove the supports by hand.

In addition, depending on the geometry of the model it can be impossible to totally remove the supports by hand.

However, BCN3D proposition uses IDEX architecture to counteract the described disadvantage. IDEX architecture is the most reliable and neat solution on the market when it comes to dual extrusion technology. This is because the two extruders work independently when printing water-soluble supports or multi-material parts. While one extruder is printing the second one is parked, preventing the drip of molten plastic into the part. Conventional dual extrusion printers have both extruders together, which may result in filament threads left on the piece.

IDEX technology: Same investment, double productivity

IDEX is the only extrusion system capable of printing with two heads independently. This system allows enabling Duplication and Mirror printing modes capable of printing two pieces at a time. Double printing capacity means double productivity, all with the same investment. Unlike any other dual extrusion machines on the market, when you acquire a BCN3D machine, you get one printer but you double your productivity. All thanks to the IDEX technology.

Unlike any other dual extrusion machines on the market, when you acquire a BCN3D machine, you get one printer but you double your productivity. All thanks to the IDEX technology.

BCN3D Epsilon W27: BCN3D

3D printersfrom BCN3D

Starting price 615 000 ₽ - starting price 615 000 ₽

Starting price

615 000 ₽

615 000 ₽ - 615 000 ₽

Current price 615 000 ₽

| /

Savings 0 ₽ Savings -615.000 ₽ nine0003

Available on request

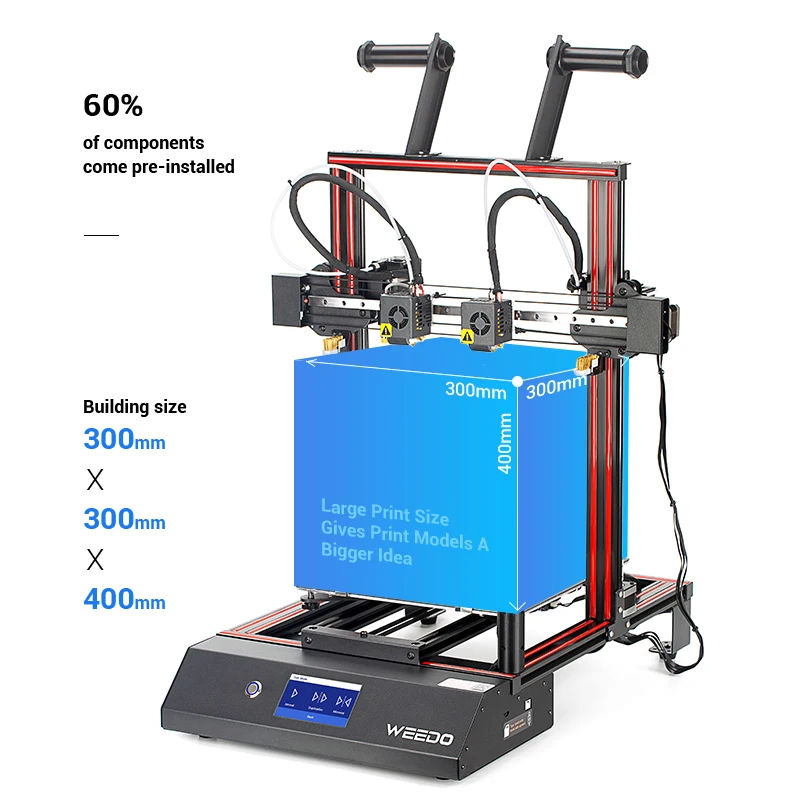

Epsilon W27 is a powerful professional 3D printer designed to create solid parts from industrial grade materials

3D printing properties | |

| Print technology | Printing with plastic thread (FDM/FFF) | nine0032

| Application | Prototyping, Prototyping, Design, Architecture, Mechanical engineering, Medicine, Business, Large print area, Industrial 3D printers, Advertising, Engineering, Professional |

| Maximum print size (LxWxH), mm | 420x300x220 |

| Platform | nine0034 Heated glass platform|

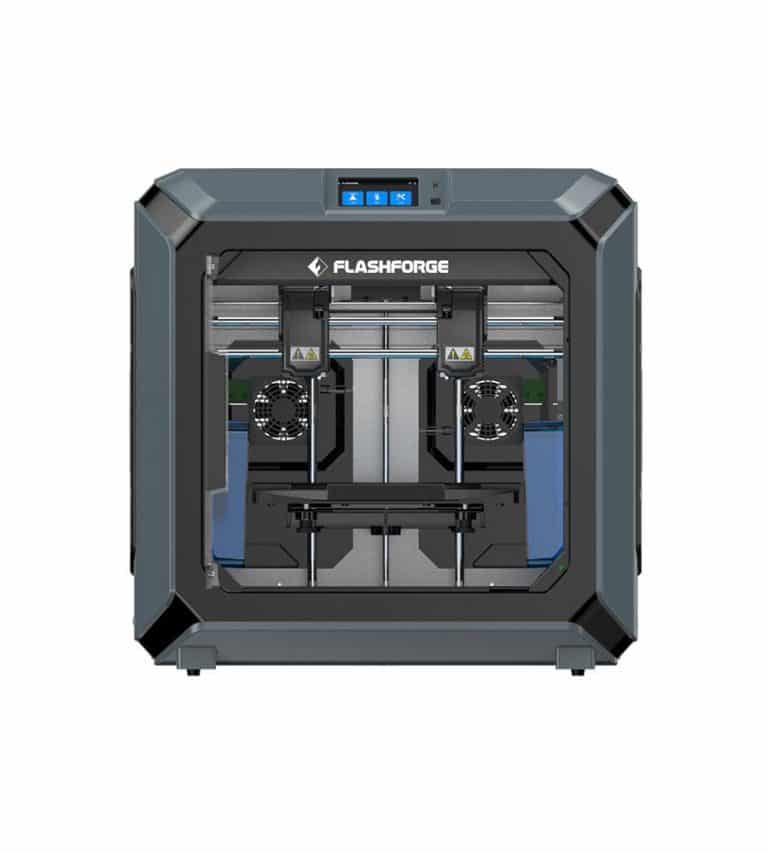

| Number of printheads | 2 |

| Thread diameter | 2. 85 mm 85 mm |

| Media | ABS, PLA, Special materials |

| Layer thickness | nine0034 0.05 mm|

| Extruder operating temperature | 300 °C |

| Platform operating temperature | 120°C |

| Printable file formats | STL, OBJ, AMF |

| How to download a project | nine0034 USB, Wi-Fi, Ethernet|

Shield | |

| Screen type | LED |

Power supply | |

| Power consumption | 840 W |

Dimensions | |

| Width | 690 mm |

| Height | 750 mm |

| Depth | 530 mm |

| Weight | nine0034 33 kg|

Epsilon W27

Epsilon W27 is a powerful independent dual extruder (IDEX) professional 3D printer designed to create solid parts from industrial grade materials with its heated chamber and fully enclosed bodySafety first

The BCN3D Epsilon W27 3D Printer is equipped with a HEPA filter that protects the working environment from potentially harmful particles when 3D printing using industrial materials. nine0003

nine0003

Key Features

Bondtech™ Extruder Equipped with Bondtech™'s high-tech Dual Drive for more control, sharper detail and superior performance for any type of filament.

Epsilon W27 can be paired with the new Hotend X ,

designed for seamless printing using fiber-filled media for stronger parts (sold separately). nine0003

Materials for BCN3D Epsilon W27

- In stock

BCN3D PAHT CF15 2.85mm 750g

- In stock

BCN3D PETG 2.85mm 750g

- In stock nine0002

BCN3D PVA 2.

85mm 500g

85mm 500g - In stock

BCN3D PP GF30 2.85mm 700g

- In stock

BCN3D TPU 2.85mm 750g

- In stock nine0002

BCN3D ABS 2.85mm 750g

- In stock

BCN3D PLA 2.

85mm 750g

85mm 750g -

BCN3D PLA 2.85mm 2500g

- nine0002

BCN3D PETG 2.85mm 2500g

-

BCN3D ABS 2.85mm 2500g

-

BCN3D PA 2.

85mm 750g

85mm 750g -

BCN3D PP 2.85mm 700g nine0030

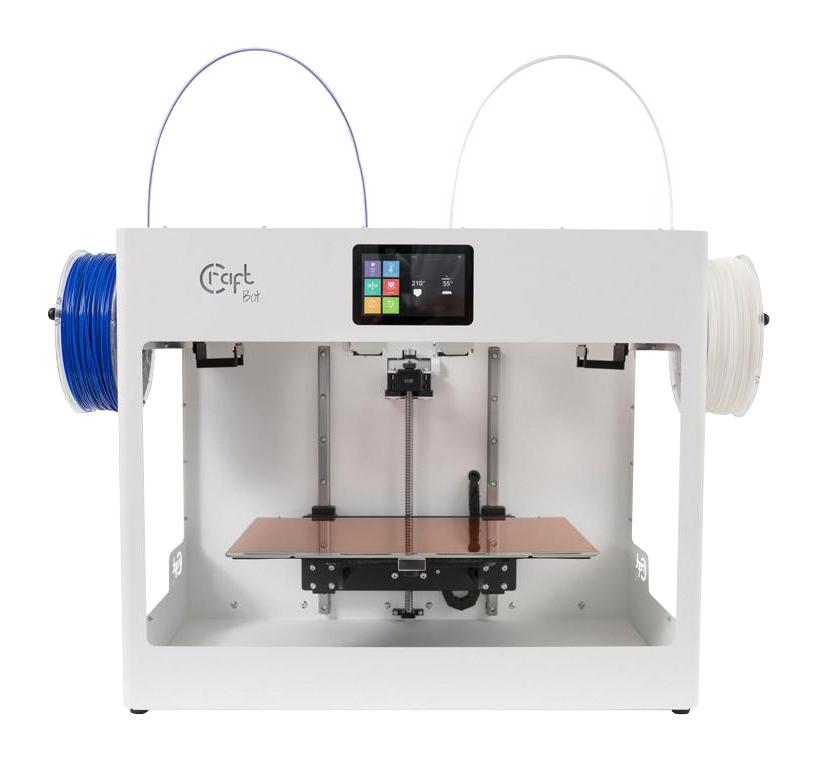

BCN3D Sigma

3D Printer Overview Thedual extruder 3D printers have an absolutely terrible reputation. While the ability to 3D print in different materials and colors is inspiring, most beginners face a lot of challenges.

So when 3D printing in two colors does not cause problems, it causes even slight surprise. By the way, this 3D printer has been leading many top quarterly reports on the popularity of 3D printers from 3D Hubs for several quarters. nine0003

BCN3D Sigma designed and manufactured in Barcelona, Spain. Of course, like any model, the Sigma has its drawbacks, but this is a really great model.

And the great thing is that BCN3D Sigma is 100% open source. So both the software and the design and documentation can be used and modified under the General Public License. Well, let's move on to the review.

Benefits of BCN3D Sigma

- Excellent 3D print quality;

- Robust, thoughtful design; nine0193

- Easy and quick set up;

- Automatic calibration;

- Quality knots;

- Magnetic 3D printing table;

- Simple and efficient 3D printing media supply system;

- Innovative open sorce solution with two independent extruders;

- Supported by most slicing software, including Cura and Simplify 3D.

BCN3D Sigma Disadvantages

- Large;

- There are bugs in the touchscreen; nine0193

- Difficult to predict print times with dual extrusion;

- Noisy like an average printer, not quiet;

- Not enough WiFi connection.

Brief preliminary verdict

BCN3D Sigma's main slogan is: "3D printing with two independent extruders should not be a problem. " Considering how elegantly all the problems of dual extrusion were solved, we can say that this is a really successful model. In addition, all solutions are open source, with good documentation, so kudos to the developers. nine0003

" Considering how elegantly all the problems of dual extrusion were solved, we can say that this is a really successful model. In addition, all solutions are open source, with good documentation, so kudos to the developers. nine0003

BCN3D Sigma also excels when printing with a single extruder. Good workspace size, easy operation, unique design, in general - a lot of advantages.

Among the shortcomings, it is worth highlighting the lack of WiFi, some minor bugs in the firmware, a large amount of waste during 3D printing due to the work of two extruders. But overall, these shortcomings are minor and the BCN3D Sigma is a really good 3D printer that is comfortable and enjoyable to work with. nine0003

Brief information about the appearance of BCN3D Sigma

The history of BCN3D Sigma is quite interesting. The developer company BCN3D Technologies is not, in fact, a company. This is a special department in the Fundació CIM - a non-profit educational foundation at the Polytechnic University of Catalonia (English - University Polytechnic of Catalonia).

The development team is rooted in the ReRap movement. For about 20 years they have been researching the possibilities of 3D printing and finally decided to share their developments with a wide open source audience. nine0003

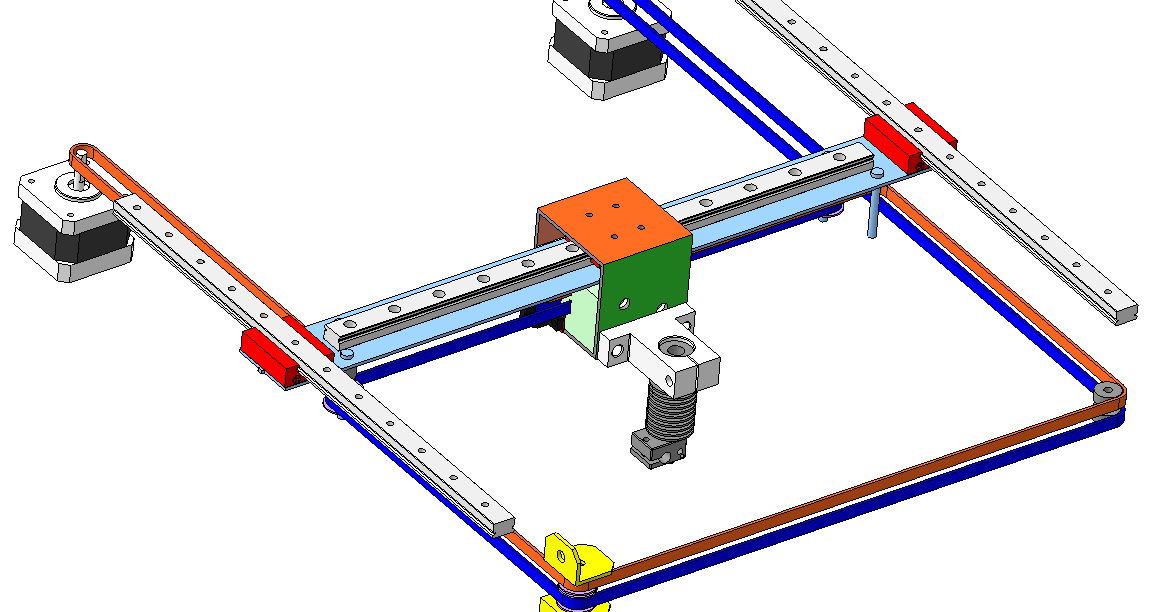

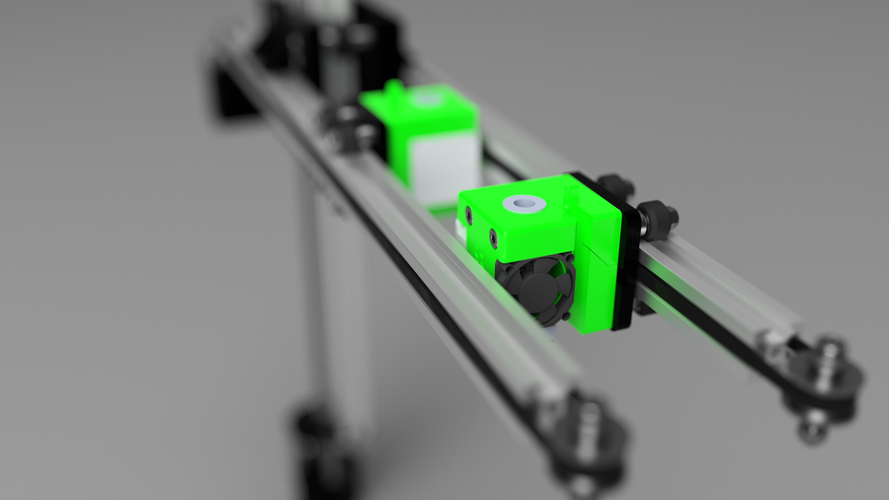

The first model was the BCN3D+ DIY 3D Printer, which came in separate pieces for self-assembly. After that, the team started experimenting with dual extrusion and by trial and error introduced a new approach - Independent Dual Extrusion (English - Independent Dual Extrusion - (IDEX)).

In earlier designs, both extruders were placed on the same moving carriage, which made them heavy, bulky, and prone to errors during 3D printing. The IDEX system involves the separation of extruders and installation on two independent carriages that move independently of each other. Thanks to this, by the way, the quality of 3D printing with one extruder does not fall. nine0003

This is a really simple and ingenious solution. During testing, the BCN3D Sigma produces really high-quality prints, whether you use one or two extruders.

And this is not the only impressive feature of this model. The printer has a range of elegant features that make it easy and enjoyable to use.

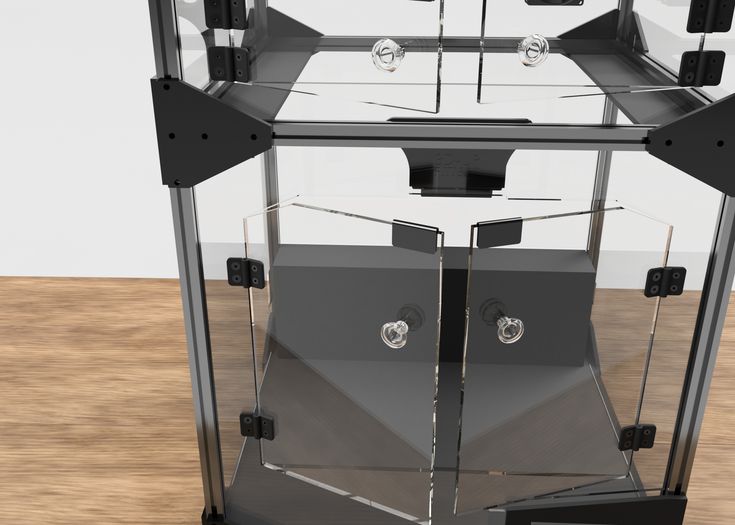

Design and features

The BCN3D Sigma frame is made from powder coated aluminium. The frame measures 465mm wide, 440mm deep and 680mm high. The dimensions are explained by the design with sharp corners and a semi-open frame. The top and front parts are open, and plastic transparent inserts are installed on the two sides. nine0003

Working space 210 x 297 x 210 mm. This volume is above average for desktop 3D printers. The resolution of 3D printing is in the range of 50 to 300 microns.

Printing table - PCB Heatbead on which the glass is mounted. The glass is held on by magnets. Thanks to this elegant solution, the table is easy to clean after 3D printing. Perhaps you assume that over time, under the influence of heat, the magnets will weaken? But this problem is also solved thanks to the grooves in which they are flush with the heated surface. nine0003

nine0003

3D printing table and IDEX mounted on movable carriages. The table moves along the X axis (vertical), and both extruders along the Y and Z axes (horizontal axes). The BCN3D Sigma has an SD card slot, but, unfortunately, no WiFi module is provided, so all control is carried out using the touchscreen display. The touchscreen is responsive, but a little unusual to the touch.

The filament for printing is located within the body of the Sigma, which is another reason for the large dimensions of this model. Each spool is located at the bottom of the 3D printer. The filament is fed from the bottom of the printer into a guide tube in one of the two printheads. The path is long enough and it is not clear what will happen if the material breaks. But during the tests, this did not happen, so it will remain a mystery. nine0003

Unboxing and setup

The BCN3D Sigma costs around €2,295. This price range is somewhere between the industrial and hobby markets. However, it cannot be said that this is a truly industrial model with complex settings.

Using the quick setup guide, which is available in English and Spanish, you can set up your printer and start your first 3D print in just 15 minutes. More detailed documentation and printable materials are available online. nine0003

There is no assembly step as such. It is enough to carefully take the Sigma out of the box, remove the protective films and you are ready to set up. Also included is a box with tools, cables and instructions. In addition, the kit comes with a special spray for better adhesion of the printing table.

Setup consists of 6 steps: place the glass on the print table; install two spools with printing materials, and feed the material itself into the feed mechanism; install guide tubes for each of the materials and attach them to the hotend cables; install "cleaning rubber bands" for hotends; insert the SD card and connect the power cable. nine0003

The next step is to calibrate using the touchscreen - step by step instructions are provided for this - and prepare the model for 3D printing using a slicing program on your personal computer. BCN3D offers a special version of Cura, but you can use any other software of your choice.

BCN3D offers a special version of Cura, but you can use any other software of your choice.

In general, the time from the moment of unpacking to the start of 3D printing is really short - about 15 minutes.

3D Printing Materials

BCN3D Sigma uses 2.85mm filament. This 3D printer model works with a wide range of materials, so you won't be limited to ABS or PLA plastics. nine0003

White and black Colorfila PLA plastics were used in our tests, but ABS, HIS, PVA, TPE ColorFabb and many other exotic materials can be used.

I'd like to note once again that double extrusion is really a strong point of BCN3D. First, you can use two colors for aesthetic purposes, but there are other interesting options - for example, use PLA and PVA (pictured below) or ABS with HIPS. Use PLA or ABS as the base material for 3D printing, and the other two for support structures that you can dissolve when the print is complete. nine0003

Thanks to the use of soluble materials paired with common plastics, you will not be limited in the design and configuration of your products. Sigma will enable you to print almost any model with high quality, without bugs and lengthy post-processing.

Sigma will enable you to print almost any model with high quality, without bugs and lengthy post-processing.

Software

BCN3D Sigma can work with many slicing programs. Including Cura and Slic3r (free software) and Simplify3D (paid). In fact, it does not matter which program you use, since the end goal is the same - convert the STL file into layers based on the 3D print resolution settings you set, add a structure support if necessary, and convert the resulting data to G-code for print. During our review, the Simplify3D program was used. nine0003

Simplify3D is easy to use and has a huge amount of options and settings. Open the program on your PC and a virtual printing table will appear on the screen. On the left side of the window there is a menu with which you can import your models and specify the necessary processing settings. The easiest and fastest option is to choose from the presets: High Quality Print, Medium Quality Print, or Fast Low Quality Print. nine0003

nine0003

You can specify the type of material used and the settings will automatically pull up to optimize 3D printing. You can choose from several styles of interior detailing available. You can manually add a structure support. Also, if you are having problems with the first layer during printing, you can add an extra mesh to the base of the model.

During dual extrusion, it is important to understand that you actually have two STL files that overlap each other. Simplify3D has a special assistant that helps during setup, correctly aligns and groups 3D models. nine0003

Once the model is ready, simply export the file and copy it to an SD card, install the card in the dedicated slot on the Sigma and select it from the print menu.

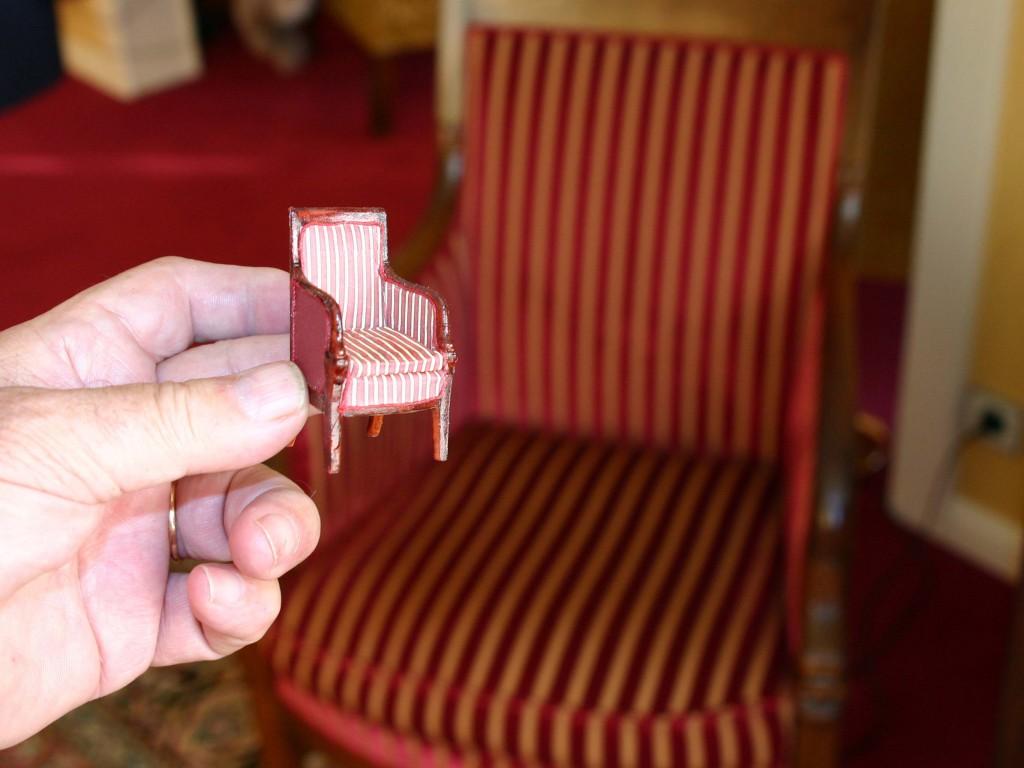

Test 3D printing results

We printed about a dozen 3D models on BCN3D Sigma. Some were printed at high resolution (50 microns), one at fast print settings (250 microns), and the rest at 200 microns (since resolution affects layer height, the lower this value, the better the 3D print result). nine0003

nine0003

BCN3D Sigma printed most of the test models perfectly. The print quality with a single extruder is excellent. We 3D printed the Hubs Marvin mascot, 3DBenchy and the Rook tour on high quality settings. The result made us very happy.

Now let's move on to 3D printing with two extruders. The results are great too. Using a resolution of 200 microns, we printed a frog, a lizard, and a traffic cone.

Some post-processing is still needed, since the constant change of the printing extruder still makes itself felt. But in general, the models turned out great. Since the quality settings are not the highest, the print surface was visible. You can, of course, reduce the height of the 3D printing layer and this will affect the quality for the better, but the 3D printing time will also increase. Basically, we didn't do it. nine0003

The only model that disappointed us was the 3DBenchy in two colors. Printing with low settings was successful, but in general the quality of the model is clearly inferior to the similar one with low quality settings, but using one color.

Some features (and disadvantages) during operation

While observing the operation of the 3D printer during dual extrusion, we noted several points. Firstly, automatic calibration (a process where the sensor checks and subsequently sets the level of the table relative to the coordinate axes) works very well. nine0003

During operation, the extruder continues to feed a small amount of filament when not in use. This is probably done in order to maintain the temperature even when it is "resting", but the waste container fills up quickly enough and it may not even be enough if you print medium-sized models.

The touchscreen does not show the time required to complete 3D printing. Instead of time, you are shown an estimate as a percentage. This is not the most useful information. It would be desirable, of course, to receive an assessment in time. nine0003

By the way, over time there is another bug. For example, Simplify3D estimated the required 3D printing time at 12 hours, but in fact we printed in 16 hours. In principle, it cannot be said that this is a BCN3D Sigma problem, since the software can be wrong here. But in any case, we noted it.

In principle, it cannot be said that this is a BCN3D Sigma problem, since the software can be wrong here. But in any case, we noted it.

The most annoying thing we encountered during the tests was the freezing of the touchscreen display during 3D printing. We managed to use the display only after the end of 3D printing. Probably, the company can solve this problem with a new firmware. nine0003

Noise and fumes levels are not particularly different from the average desktop 3D printers. 56 decibels is not much, but still loud enough. The instruction manual provides standard language for using this 3D printer in a well-ventilated area.

Leads

The BCN3D Sigma is a large, half-open 3D printer suitable for both hobby and professional use. This model is highly customizable. Its ease of setup is comparable to the Ultimaker 2 series.

Sigma can print both large and small 3D models with fairly high detail. There is almost no difference between printing with one and two extruders, and the IDEX system is a fantastic innovation for the open source community.