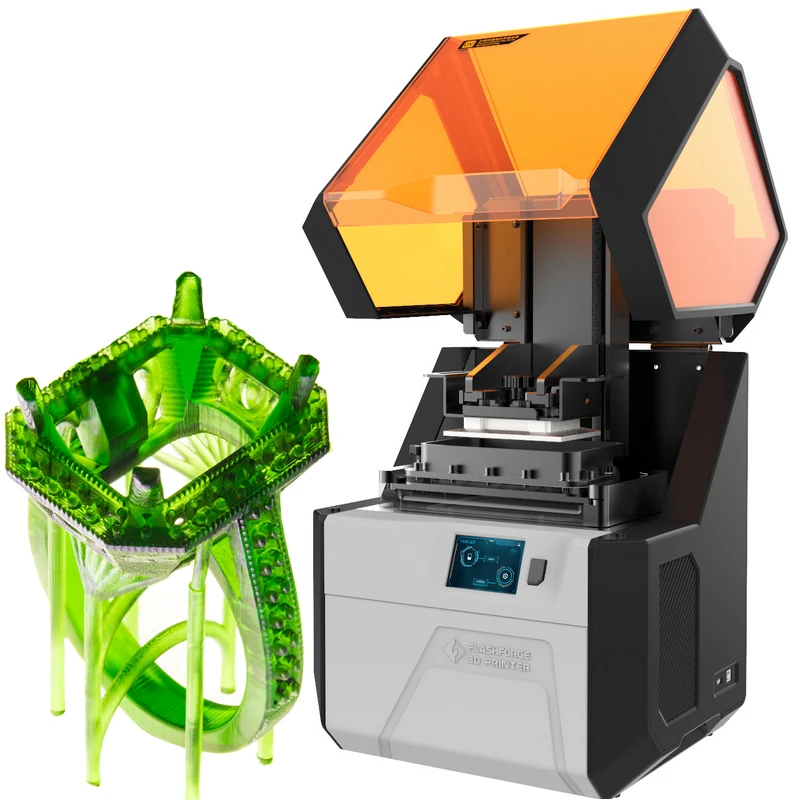

Hunter dlp 3d printer

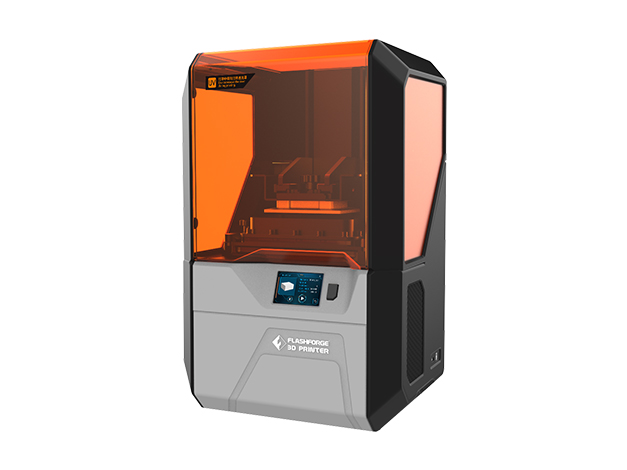

FlashForge Hunter S Dental 3D Printer – FlashForge USA

Skip to contentFLASHFORGE HUNTER S DENTAL 3D PRINTER

Digital Dentistry Solution

Digital Dentistry Solution

FlashForge Hunter S Dental 3D Printer provides speed, reliability, accuracy, and low operating costs to denture manufacturers, dental laboratories, and clinical use.

Reliability, High Accuracy, and Efficiency

FlashForge Hunter is an advanced 3D printer with Texas Instruments DLP® technology, featuring the latest technology in additive manufacturing. Compatible with third party resins (details below), Hunter S offers flexibility and low operating cost to your dental business. Easy to swap aluminum resin tray with pre-installed vat film for maximum efficiency when switching between print jobs and resins.

Compatible with NextDent and Dentona Dental Resin

FlashForge Hunter S is fully compatible with NextDent and Dentona dental resins making it much easier to manage your resin inventory without starting a new inventory of proprietary resins.

- Shorten working hours. Improve more than 50% production efficiency

- Compatible with multiple third party materials. Providing a rich printing experience

- High precision, showing more details

Hunter S Dental Applications (Printed with NextDent Resins)

Ortho Flex

Transparent 3D print material for Splints and Retainers

Crowntec

Permanent Crown material

C&B MFH (Micro Filled Hybrid)

Balancing opacity and translucency perfectly

Denture 3D+

Print Denture Base applications

Gingiva Mask

Flexibility in printing model parts

Cast

Residue-free combustible 3D printing material

SG (Surgical Guide)

Design and print high-precision transparent drilling template

Model 2.

0

0High-precision dental model prints

Try-In

Biocompatible printable material for Try-In

Ortho Clear

Aesthetically pleasing 3D print material

Ortho IBT

Flexible material for orthodontic applications

Tray

High-quality material for 3D printing trays

SPECIFICATIONS

- Principle: DLP (Digital Light Processing)

- Build Volume: 144 x 81 x 180 mm (5.69 x 3.2 x 7.1 in)

- Printing Speed: 10-30mm/h

- Screen: 3.5-inch colorful IPS touch screen

- Net Weight: 23 kg (50.7 lbs)

- Printer Dimension: 360 x 320 x 560 mm (14.2 x 12.6 x 22 in)

- Power: 100-240VAC, 50-60Hz, 1A

- Software: FlashDLPrint

- Connectivity: USB / Ethernet / Wi-Fii

We Recommended

FlashForge FHD 1500 Dental Resin 1 Liter - Transparent (Clear)

Check it out

FlashForge FHJ 2100 Resin 1 Liter - Wax Resin

Check it out

FlashForge Castable Wax Resin 1 Liter - Standard

Check it out

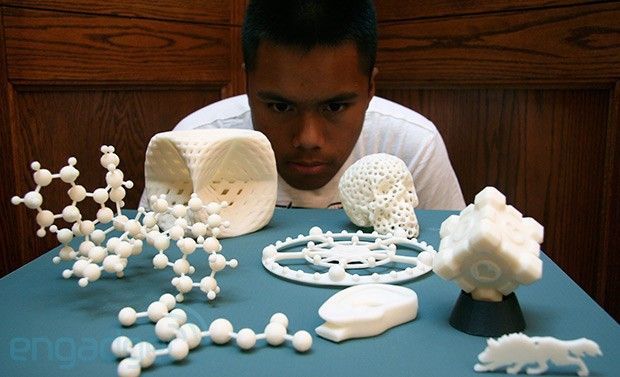

Flashforge Hunter DLP 3D Printer for Dental and Jewelry Industry Durability & Fine Details Guaranteed.

Flashforge Christmas Sale: Up to 60% off! Get an extra Christmas gift when order US$200+.

loading

Share the product to

Worry-free warranty

Dedicated support

Fast shipping.Free shipping for items available at USA/UK/AU/EU warehouses.

- Overview

- Parameter

- In the Box

Main features:

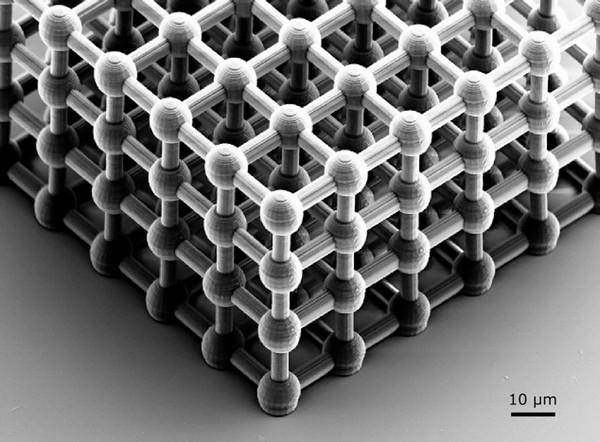

- High precision 3d printing based on DLP (Digital Light Processing) technology, meeting dental & jewelry industry’ accuracy requirements.

- Self-developed 1920*1080 resolution light engine: well-distributed light intensity, print parts, and accessories with high precision and fine details.

- Special Precision Compensation Algorithm: gray compensation & correction algorithm ensures smoother surface and higher dimensional accuracy.

- 3.5-inch touchscreen: professional quality 3d prints start from clicks, offer an intuitive user experience.

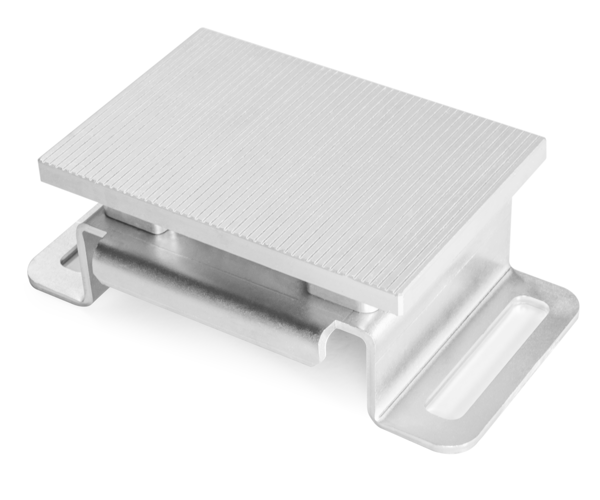

- Removable aluminum resin VAT and FEP Films contribute to minimal resin waste, long durability, and low maintenance costs.

- Compatible with multi-brand photopolymer resins, multiple preset resin 3d printing modes for specific brand resins.

- DLP Printer slicing software FlashDLPrint lets you prepare 3d models for quick and accurate dental & jewelry application printing.

- Multiple 3d model transfer options: USB cable, USB stick, WiFi.

- Bonus 1 bottle of Photopolymer Resin(500g).

High Precision

Layer Height 0.025mm/0.05mm/0.1mm/0.2mm.

Outstanding Surface Quality

Print 3D objects and parts with smooth surface and lovely appearance.

Higher Printing Speed

Print intricate work efficiently.

Multi-field Application

A variety of materials can be applied in multiple fields.

Compatible with Multi-brand Resin

Hunter adopts Flashforge's self-developed Full HD 1920*1080p resolution light engine with a life expectancy of 50000 hours, print intricate work efficiently.

Print Finished Ring

By using an extraordinarily accurate Z-axis LM guide actuator module, Hunter enables an accuracy of up to 20 microns, builds 3d objects and parts with smooth surfaces and a lovely appearance. With layer thickness from 0.025mm to 0.2mm, Hunter fulfills 3d printing dental and jewelry accuracy requirements.

Through advanced light intensity control, this light engine realizes sustained and stable LED intensity, eventually helps to achieve better DLP 3D printing quality in a shorter time.

Special Precision

Compensation Algorithm

Gray compensation & correction algorithm ensures smoother surface and higher dimensional accuracy of the printed objects and parts.

Gray Compensation Algorithm

Distortion Correction Algorithm

Hunter equips with a simple smart touchscreen that lets you process professional 3d printing within a few fingertips. You can trigger & cease printing, preview model & printing status, calibrate Z-axis, carry out general settings all through this control panel.

Supports WiFi connection, big files can be transferred quickly.

- Printing TechnologyDigital Light Processing(DLP)

- Light Source405 nm LED

- Layer Thickness 0.025-0.05mm

- Build Volume 120*67.5*150mm

- Print Accuracy ±0.05mm

- Build Speed10 mm/h

- Positioning Accuracy 1920×1080 pixel

- MaterialPhotopolymer Resin

Mechanical & Dimension

- Screen3.

5’’ color IPS Touch Screen

5’’ color IPS Touch Screen - Product Dimensions560*360*320mm

- AC InputInput: 100V-240VAC, 47-63Hz Power: 65W

- Support Formats3MF / STL / OBJ / FPP / BMP / PNG / JPG / JPEG; GX / G

- Compatible operating systemWin XP / Vista / 7 / 8 / 10, Mac OS, Linux

- Power65 W

- Net Weight17.8 kg

- Gross Weight22 kg

Electrical

- SoftwareFlashDLPrint

- ConnectivityUSB cable, USB stick, WiFi

Others

- Touch screen language Simple / Traditional Chinese / English / French / Japanese / Spanish

- Certification CE / FCC / RoHS

Product accessories

3D Printer X1

Photopolymer Resin X1

Power cable X1

Power adapter X1

USB Cable X1

Rinse Bucket X1

Soft Cloth X1

Vat Film X1

Vinyl Gloves X1

Brush X1

Metal scraper X1

Plastic scraper X1

Accessories Kits X1

Spare Screw Kits X1

Quick start guide X1

After-sales service card X1

Spare Screw Kits:

Hexagon Socket Head Cap Screws, Flat Washer, Spring Washer

Accessories Kits Contents:

Hexagon Wrench (2. 5mm*1/3mm*1/5mm*1), Phillips Screwdriver, USB Stick, Plastic Tweezers

5mm*1/3mm*1/5mm*1), Phillips Screwdriver, USB Stick, Plastic Tweezers

Your questions will be answered by the users who have purchased this product

May not be greater than 255 characters.

Read All Reviews

FAQ

No questions.

3D File Predator Mask Jungle Hunter STL File

follow me

FACEBOOK: https://www.facebook.com/groups/1797954133626126/?ref=bookmarks

ISTAGRAM: cody3d1 https://www.instagram. com/cody3d1/

TWITTER: https://twitter.com/Cody3D

ARTSTATION: https://www.artstation.com/cody3d/store

YOUTUBE video: https://youtu.be/MONGITKvJi8

Predator Mask Jungle Hunter STL - OBJ file for 3D printing

as a whole The model consists of 1.8M dots

all files have been decimated to polygons but without loss of detail, this makes the light files suitable for each computer

dimensions approximately W 27 Cm D 17 Cm H 34 Cm

W 10 inches D 6.6 inches H 13 inches

dimensions are for an adult of average height.

however, the dimensions can be changed with each slicer,

in this case you will find the file of the whole model, which you will need to understand how much to scale each individual part

Thickness of the mask varies from 5mm to 10mm

all files are ready for optimal printing

The 3D model has been designed to produce a clean print result, without taking into account the consumption of printing materials, however, you can rotate or scale freely,

each part of the model in the most convenient way for you.

Each file has been checked and fixed with Netfabb

Parts of the model are already positioned for 3D printing

Compatible with every slicer - Simplify3D, Care, Slic3r, etc. ...

All parts of the model have been cut out so they can be printed vertically for higher print quality

The Predator

The Predator is a 1987 American science fiction action film directed by John McTiernan and written by brothers Jim and John Thomas. [ 4] The first installment in the Predator franchise, the film stars Arnold Schwarzenegger as the leader of an elite paramilitary rescue team on a hostage rescue mission in guerrilla-held territory in the Central American rainforest, who encounter the deadly Predator (Kevin Peter Hall), a skilled , a technologically advanced alien who hunts and hunts them down.0003

[ 4] The first installment in the Predator franchise, the film stars Arnold Schwarzenegger as the leader of an elite paramilitary rescue team on a hostage rescue mission in guerrilla-held territory in the Central American rainforest, who encounter the deadly Predator (Kevin Peter Hall), a skilled , a technologically advanced alien who hunts and hunts them down.0003

The film "Predator" was written in 1984 under the working title "Hunter". Filming took place from March to June 1986, with creature effects designed by Stan Winston; the budget was about $15 million. 20th Century Fox released the film on June 12, 1987 in the US, where it grossed $98.3 million. Initial reviews were mixed, but the film has since been considered a classic of the action genre.

The success of Predator launched a franchise of films, novels, comics, video games and toys. The film spawned three direct sequels: Predator 2 (1990), Predators (2010) and The Predator (2018), as well as the upcoming prequel Prey (2022). [5] Crossover with the Alien franchise led to the Alien vs. Predator including Alien vs. Predator (2004) and Aliens vs. Predator: Requiem (2007).

[5] Crossover with the Alien franchise led to the Alien vs. Predator including Alien vs. Predator (2004) and Aliens vs. Predator: Requiem (2007).

"wikipedia"

Recommended settings for printing

each part has been cut vertically to print better, so for the top parts,

it is recommended to print with a 4-5 obturator

Quality

Layer Height: 0.1mm*

Initial Layer Thickness: 0.3mm

Bottom/Top Pattern: Lines

Horizontal Expansion: 0.04mm (when entering 0.04mm index 3D Printer perceives the model as a monolith, i.e. as having no hidden layers).

*For the best print quality, we recommend using a layer height of 0.1 mm. However, this will double the print time.

As a provider of STL files, our goal is to ensure that files are error-free and printable in the most accurate way possible. That is why we test print only the most difficult segments

model parts.

Model parts have been tested and printed in PLA. If you need advice on where to buy filaments, check out our partner site.

If you need advice on where to buy filaments, check out our partner site.

Speed units:

Filling speed: 30 mm/s

Outer sheath speed: 30 mm/s

Inner sheath speed: 20 mm/s

Top/bottom speed: 20 mm/s

Support speed : 50 mm/s

Travel speed: 150 mm/s

Skirt speed: 30 mm/s

Number of slow layers: 4

Infill:

Infill pattern: Grid

Distance between lines: 1.5 mm

Infill overlap: 20%

Infill layers: 0

Placement: All over

Eave angle: 30°

X/Y spacing: 0.7 mm

Peak spacing: 0.2 mm

Bottom spacing: 0.2 mm

Stair step height: 0, 5 mm

Joint Spacing: 0.7mm

Area Smoothing: 0.6mm

Tower Usage: Verification

Pattern: Grid

Line Spacing: 1.5mm

profile, video, photo or audio in any form or forum now or in the future is NOT allowed without my written consent.

Any action to promote or profit in any way (for example, monetary or social) from the use of my profile, video, images or audio in any form of my profile is a violation

my privacy and subject to prosecution..jpg) BY VIEWING IT: You acknowledge and agree that you will not host, upload, publish, transmit or make available in any way the content of this

BY VIEWING IT: You acknowledge and agree that you will not host, upload, publish, transmit or make available in any way the content of this

page, including images and downloadable video streaming recording. This is intended and presented only as a one-time, single-view live presentation.

Punishments for copyright infringement: By reproducing, reprinting, or distributing the copyright owner's work without permission, you violate or have violated the following

his or her rights under the Copyright Act. The copyright owner can sue for damages ranging from $250 to $150,000 or imprisonment for one year.

FlashForge Hunter 3D printer. Read article

Hunter 3D printer from the Chinese manufacturer FlashForge is the hero of this article. The model prints using DLP technology, and this is already a significant advantage over models that print using SLA technology. First of all, the advantage concerns printing speed, since SLA printers do not illuminate the entire layer at a time, but form it gradually. DLP printers have a special built-in projector that illuminates the entire layer.

DLP printers have a special built-in projector that illuminates the entire layer.

FlashForge manufactures very good and affordable FDM printers that have received extremely positive reviews. "Hunter" intrigued and, by the way, did not disappoint, but let's not spoil it...

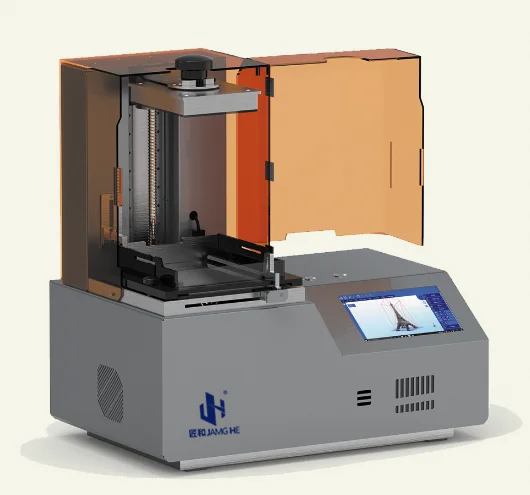

FlashForge Hunter 3D printer - exterior

The first impression of the Hunter is very good. Its appearance is somewhat reminiscent of a spaceship from science fiction films, especially if the lid is open. The cover is transparent, allowing you to observe the printing process, but at the same time it is safe for the eyes.

The dimensions of the 3D printer are 36x31x56.5 cm, that is, it is quite compact and can be installed on any desktop. There is a print pause function, that is, a pause. This is convenient for evaluating intermediate results. When you press pause, the platform will rise and reveal the printer to your gaze.

FlashForge Hunter has the following specifications:

| Ratio | Value |

| Power | |

| File formats | STL |

| Net weight | 17. 8 kg 8 kg |

FlashForge Hunter is most interesting for the projector. It was developed by the company's engineers with a deliberate optimization of the device for 3D printing with photopolymer resins. The projector has a resolution of 1080p, and the operating life is about 50 thousand hours.

FlashForge also provided something like projector feedback. Thanks to this, it is possible to make adjustments to the intensity of illumination. Thus, stability of work, high levels of detailing, as well as printing accuracy are ensured.

The surface of the platform is ribbed. Despite the fact that the grooves are not very deep, nevertheless, the model adheres to the surface so well that it is sometimes difficult to remove it.

A trapezoid is used in the Z direction, which is already well known. Due to this, the platform has a rigid fixation, there are no backlashes.

The tub is complex, consisting of a replaceable film and a lens. The tray is attached to the printer with two screws, as well as slightly spring-loaded metal clips.

The tray is attached to the printer with two screws, as well as slightly spring-loaded metal clips.

You can control the "Hunter" using the screen with a responsive touch. The design of the menu, and the interface itself, impressed me and very much reminded me of the menus of fantastic games.

Hunter is equipped with a WiFi module and also has up to 7GB of internal memory. This allows models to be downloaded directly to the device's disk so that you do not need to constantly use a flash drive.

Using the Happy 3D application and the WiFi module with Hunter, you can keep in touch with your phone or tablet. The application is very simple, it allows you to model simple objects and send them to print.

Soft

Guess which slicer FlashForge Hunter uses? That's right, the well-known FlashPrint, and this pleases, since this software is very convenient, functional and simply intuitive. In the settings, "Hunter" is selected and the model is loaded. The developers have even provided several pre-made profiles that are customized for some resins. Thanks to this, the first launch of Hunter is simple, convenient and affordable even for a “teapot” in 3D printing.

The developers have even provided several pre-made profiles that are customized for some resins. Thanks to this, the first launch of Hunter is simple, convenient and affordable even for a “teapot” in 3D printing.

You can make a profile for any other resin. The program offers a wide range of settings. This includes the banal ones - layer thickness, exposure time, and extended ones - the size of the wall thickness, the filling density indicator, etc. Well, the standard functions of this software are at full disposal, that is, you can cut the model or convert individual images into a three-dimensional bas-relief.

3D printing

As soon as you unpack the Hunter, you will surely be pleased that the equipment is delivered assembled, that is, it does not need assembly or calibration. You just need to open the lid, fill in the resin, peel the model and 3, 2, 1 "START" - go ahead 3D printing.

The Hunter 3D Printer comes pre-configured and calibrated. But if in the course of work there is a need for calibration, then the menu has such an opportunity. First, first lower the working platform “to zero”, then you need to go to ZMove and set the parameter for raising or lowering the platform in relation to the bath. The received values are saved. That's the whole calibration.

But if in the course of work there is a need for calibration, then the menu has such an opportunity. First, first lower the working platform “to zero”, then you need to go to ZMove and set the parameter for raising or lowering the platform in relation to the bath. The received values are saved. That's the whole calibration.

When printing is in progress, the Hunter cover can be opened. In this case, printing will be automatically paused and the platform will rise. This is very convenient when you need to make sure that the model is securely fixed. Attention! You can use a simple opening of the lid, but the manufacturer recommends that you first pause the process to avoid errors and incorrect illumination, because all this can affect the print result.

The package bundle of the FlashForge Hunter 3D printer is impressive, the manufacturer has made sure that everything you need is at hand. So, the Hunter package includes:

3D printing results

Talk, talk, but we need results that can be realistically evaluated. Printing was carried out using Fun To Do Snow White - a regular resin with a set of pigments. I must say that "Hunter" prints very quickly, it takes only 2 seconds for one layer. In this case, you can choose a layer thickness of 25 or 50 microns, which is reflected in the print speed.

Printing was carried out using Fun To Do Snow White - a regular resin with a set of pigments. I must say that "Hunter" prints very quickly, it takes only 2 seconds for one layer. In this case, you can choose a layer thickness of 25 or 50 microns, which is reflected in the print speed.

Various rings were printed from the material, including those with images and inscriptions on the outer and inner surfaces, an overlay for a weapon, pendants, a detail of a figurine, a miniature chest with treasures and various crowns - all to evaluate and illustrate the capabilities of the "Hunter" as much as possible. ".

As for consumables, we can say that FlashForge Hunter is basically omnivorous. Any photopolymer with a wavelength of 405 nm can be used. The choice in this case is very large and you can find a resin that will meet all the requirements.

Hunter 3D printer is designed for use in jewelry and dentistry. In these industries, increased requirements for high accuracy and detail. And FlashForge Hunter coped with these tasks 100%. The device is compatible with all types of resins, including biocompatible and moldable ones. This allows it to be used very widely, including for creating high-precision mechanisms, prototype parts.

And FlashForge Hunter coped with these tasks 100%. The device is compatible with all types of resins, including biocompatible and moldable ones. This allows it to be used very widely, including for creating high-precision mechanisms, prototype parts.

To sum up…

FlashForge Hunter is a decent DLP printer that did not disappoint. The model is very well thought out, made qualitatively and soundly. The developers did their best, providing for all aspects of working with a 3D printer, making them as convenient and simple as possible.

Advantages of FlashForge Hunter, to summarize all of the above, are as follows:

- simple, uncluttered software;

- easy operation and adjustment;

- high print speed;

- printing several models at once without changing the print speed;

- low cost of ownership compared to SLA printers.

I must say that Hunter's working area is not the largest, but for those industries for which the device is designed, or rather jewelry and medicine, this is quite enough.