3D printed video game props

Top 10 3D Printed Video Game Props - 3D Printing Blog

How about 3D printing video game props and using them in cosplay? Cosplay, a movement that unites costumes and role-playing with the possibility to have weapons and other props from video games in 3D printed form, allows all gamers and fans to step into their beloved character’s shoes and to wield dangerous guns, swords, and other weapons.

As a true game geek, you can’t have too many game props. If you have a 3D printer at home, you can simply download files and print them in a matter of hours. If, however, you don’t have one, there are many 3D printing hubs that provide pinting services for those who can’t afford to invest in their own 3D printer.

Stepping aside from the 3D printer and 3D printable files topic, we’ve compiled our favorite top 10 video games 3D printed props (not classified according to our preferences, but on a random principle) to inspire you and to show you that human imagination has no limits.

Prop # 1. 3D printed Warhammer 40k chainsword

This awesomely created chainsword from Warhammer 40k is not a simple 3D printed video game prop. It has a full working mechanism that makes it running. Although it is not able to cut objects in half, the plastic-made full-size chainsword looks like it can do more. It was created by Phillip Bennett from Games Workshop store.

The entire model consists of several separate parts that have been reproduced in PLA filament. It has a motor and some electronic components that put the chain into action.

Prop # 2. 3D printed blackhand Warhammer from World of Warcraft

World of Warcraft is a massively multiplayer online role-playing game. With thousands of gamers worldwide, the fantasy Warcraft universe is known to be the inspiration for many 3D modelers that have mastered the ability to recreate popular games characters for 3D printing.

This 3D printed blackhand Warhammer, although different from the one depicted in the video game, is awe-inspiring and will leave you all wanting to have one in your collection. Printed in 2 separate parts, the hammer head has 2 orange LED’s and a section for 2 AA batteries to light them. The hammer head is printed in translucent PETG while the rest – in PLA. The model is painted with simple acrylic paints, to give it a realistic look. It was created by the finish hobbyist Ceravyn.

Printed in 2 separate parts, the hammer head has 2 orange LED’s and a section for 2 AA batteries to light them. The hammer head is printed in translucent PETG while the rest – in PLA. The model is painted with simple acrylic paints, to give it a realistic look. It was created by the finish hobbyist Ceravyn.

Prop # 3. 3D printed articulated Warhammer 40k power fist

This project is the achievement of gsterley, an enthusiast without any modeling skills. But he is the proof that nothing is impossible. Having received a 3D printer for Christmas from his wife, he dedicated a bunch of time to sketch, model and print one impressive Warhammer 40k power fist. The fingers are functional and can easily fold to form the fist with the help of a clever pull string mechanism.

The entire Power Fist was printed in ABS. The creator used foam padding to snug the fist down his arm and make it wearable.

For the rest of the body, the creator used foam which was decorated with a skull, wings, and Latin lettering. The prop was then painted using paint brushes and airbrushing technique. The result is awe-inspiring. See for yourself.

The prop was then painted using paint brushes and airbrushing technique. The result is awe-inspiring. See for yourself.

Prop # 4. 3D printed AK-47 from Rust

Rust is a survival video game, tasking players to survive in the wilderness by crafting their own items using materials they gather or steal. So, it’s no surprise that avid Rust fans Pavel Konstantinov of MyMiniFactory and 3D artist Sergey Koleskin have partnered together to bring one into the real world. Although not functional, this weapon is the 3D printed and painted replica of envied by many of those who walk the dangerous territory of Rust.

AK-47 from Rust consists of 21 parts. The entire printing took the creators 40 hours. It was later painted so you can now admire a model that looks almost as though is being taken from the computer screen. The modeling of AK-47 weapon was received with huge enthusiasm by Rust fans, many offering money to make the project happen or throwing design suggestions.

Prop # 5. 3D printed pistols from the upcoming game, Overwatch

Although Overwatch has not yet been released, 3D designers and enthusiasts have found, yet again, a new rich source of inspiration to create awesome stuff. This time, it is about the iconic pistols that the in-game character Tracer is wielding while working her way to complete numerous missions. The Overwatch pistol 3D model was designed by Simone Fontana, consists of 22 parts, and it is easily assembled.

The model is painted in neutral colors. However, you can always use bolder colors to paint your own pistol according to your liking. Also, if you want to be true to the game, you will have to print two of these.

Prop # 6. 3D printed helmet from Star Wars: the Old Republic

Star Wars universe has no limits. And when it comes to cosplay, Star Wars is probably one of the most preferred franchises to take inspiration from. With a large pool of protagonists and antagonists, the Star Wars fandoms have unique and colorful characters. No wonder Star Wars is one of the most popular fandoms among cosplayers. So, it was nothing out of the ordinary when a new Star Wars inspired prop appeared on the market. These types of 3D printed items are highly appreciated among fans who can add them to their meticulously designed and created costumes.

No wonder Star Wars is one of the most popular fandoms among cosplayers. So, it was nothing out of the ordinary when a new Star Wars inspired prop appeared on the market. These types of 3D printed items are highly appreciated among fans who can add them to their meticulously designed and created costumes.

Sith Lord Aloysius Kalling helmet for 3D printing consists of 5 separate parts. To have the prep printed, the 3D modeler needed about a week and another two for post-printing processing. All credits go to the prop designer RuthlessFX.

Prop # 7. Peacemaker, Hellboy

Hellboy, like many other video games, infiltrates gamers in adventurous and dangerous missions, making them face evil and supernatural enemies. Packed with combat situations, with heavy attacks, the video game’s environment abounds in opponents and foes that must be defeated.

The gun is known in the video game as the “Good Samaritan” oversized pistol. In the game, the gun fires single shots with up to nine different types of ammunition. The 3D printable prop has a rotating and removable chamber, replaceable guns, and a flip down mechanism that permits to access the chamber in the way it is shown in the film. The parts can be printed on two print beds with almost no support. It was modeled by Christian C. of MyMiniFactory.

The 3D printable prop has a rotating and removable chamber, replaceable guns, and a flip down mechanism that permits to access the chamber in the way it is shown in the film. The parts can be printed on two print beds with almost no support. It was modeled by Christian C. of MyMiniFactory.

Prop # 8. Warhammer 40k Nerf Bolter 3D printed prop

This Warhammer inspired Bolter is something to behold. Started as a birthday present for a little boy from his aunt, this prop is something to dream of. And most certainly, many boys, little and old, have wished to have a Warhammer 40k Nerf Bolter replica in physical form.

The prop is nicely crafted, following the video game’s graphics. It the picture below it is shown in its finished and painted form. According to the artist, the painting of 3D printed model was done with paintbrushes only, and although it took extra time, the result is worth every second. Warhammer 40k Nerf Bolter was modeled and finished by Nerfeinstern, a props creator, and 3D artist.

Prop # 9. 3D printed AER9 laser rifle

Probably, no weapon in the entire Fallout universe is as useful as AER9 Laser Rifle proves to be. Capable of holding large ammunition, gamers can easily take down enemies from a distance. After the Pip Boy, the laser rifle is one of the most popular props for cosplayers.

The 3D printable prop, created by Yvo de Haas, is a highly detailed rifle, with room for internal electronics to make it functional. The project took a lot of time to complete, namely because the 3D modeler’s intention was to build a prop as close to the one used in the game as possible. Therefore, the gun has a reloading mechanism, enabling you to change batteries and a built-in laser that shoots when the trigger is pulled.

Prop # 10. 3D printed Eredin, King of the Wild Hunt helmet from The Witcher 3

3D printing proves every day that you can recreate anything with this technology. Luckily for cosplayers, their work has been simplified tenfold. No more wasting hours on end cutting and gluing cardboard or foam or any other material, painting and finishing a video game prop. Now, everyone with little courage can try their hand at 3D modeling. And with a large choice of open source 3D modeling software, the activity doesn’t mean to be costly.

No more wasting hours on end cutting and gluing cardboard or foam or any other material, painting and finishing a video game prop. Now, everyone with little courage can try their hand at 3D modeling. And with a large choice of open source 3D modeling software, the activity doesn’t mean to be costly.

The helmet of Eredin, the King of the Wild Hunt from The Witcher 3, is an impressive 3D creation, not only because it has been reproduced in 3D printing, but because of design, the helmet is very impressive and awe-striking. Due to the popularity and critical acclaim of the video game, it was a matter of time until one 3D designer, Stefano Anagnostopoulos, put his skills to work.

The 3D model was designed in Zbrush and 3D Studio Max and it took the modeler three days to complete, plus several more days for printing and post-processing. The result is a very close replica of the King of Wild Hunt helmet, with a rusty finish, that makes the perfect cosplay prop for the true fan.

Conclusion

3D printed video game props are acquiring popularity among game enthusiasts. As avid cosplayers, these ten inspiring props will not leave you indifferent to the capabilities of 3D printing technology. Put your own 3D modeling abilities to work and see what you can craft for yourself to make your next Halloween party a blast.

(Visited 6,990 times, 1 visits today)

Author

A 3D printing website where users can buy and sell 3D printer files.

Video Game Props - Etsy.de

Etsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

Find something memorable, join a community doing good.

(1,000+ relevant results)

09. 03.2022

03.2022

Content

- How to choose a 3D printer for miniatures

- Advantage of 3D printing for miniatures 9000 9000 FDM 9000 LCD/ DLP

- FDM

- LCD

Miniature figurines with amazing detail attract the eye. A little grotesqueness and slightly wrong proportions (otherwise it would be inconvenient to play or transport such a “little one”) are more than compensated by detailed elaboration and an abundance of small, at first glance, insignificant details. These are no longer just small table soldiers, but heroes with their own unique history.

Warhammer 40k 9 miniature soldier0044

Miniatures come in different sizes: from 6mm and more. The most popular today is the 28mm format. The creation of such figurines is really almost jewelry work.

The most popular today is the 28mm format. The creation of such figurines is really almost jewelry work.

A 3D printer will help not only in the production of miniatures, but also in related areas, such as the creation of figurines, details of game locations, or, for example, elements of dioramas. To understand the advantages of 3D printing over classical manufacturing methods, it is worth remembering how such models are usually made at home.

Advantage of 3D printing for miniatures

Not everyone was ready to shell out a substantial amount for the purchase of a set of table soldiers, and sometimes the necessary heroes simply were not on sale. Then baked and self-hardening plastics for modeling were used.

First you need to make a wire frame, so the finished figure will turn out to be more durable, and it will be much easier to keep all the proportions. The wire frame can be attached to the stand, which will make the miniature statue more stable, and it can be easily fixed in any position without fear of smearing small parts with your fingers.

Wire frame for miniature

Gradually, layer by layer, the volume of plastic increases on the frame. Each layer must be baked or dried well, depending on which plastic is used - self-hardening or baked.

Gradually, we begin to add small details and work out the details. In fact, this is a very painstaking process that requires perseverance and some sculpting abilities. For a convenient study of small details, you may need special stacks for modeling, but they can be successfully replaced with improvised tools.

Sculpting tool set

The result is such a miniature statue.

Miniature 28mm baked plastic

By the same principle, large table figures, or some elements of dioramas, can be made.

Sometimes a sculptor is more accustomed to working with plasticine. Then, after sculpting, the stage of preparation and casting of the figurine into a silicone mold is added. This method is suitable for small-scale production of a small desktop army.

Then, after sculpting, the stage of preparation and casting of the figurine into a silicone mold is added. This method is suitable for small-scale production of a small desktop army.

But it is necessary to properly prepare the figurine for casting. The finished "warrior", most likely, will have to be divided into several parts, so that it would be more convenient for the caster to remove the molds and make castings. During the cutting process, it is worth adding a few locks so that the finished castings can be easily assembled, like pieces of a puzzle.

Molded figurine against silicone mold

Some craftsmen have learned to cast metal copies. Such soldiers are usually made of low-melting metals (for example, lead) and cast in plaster molds. Sometimes a special silicone is used, but it is a little more difficult to achieve good shedding of a small product in a silicone mold.

Cast metal soldier

In addition to making figurines from scratch, some craftsmen remake ready-made miniatures. This is called conversion.

This is called conversion.

Conversion in miniatures is a refinement, stylization or alteration of a finished figure. Unfortunately, not every hobbyist has good sculpting skills, and this alteration helps to achieve good results regardless of artistic skills. The main thing is to act very carefully.

Conversion helps enthusiasts achieve amazing figurine detail, add some detail, change the pose, or create a new character that is not yet on sale.

Lord of the Astral Claws turned to Chaos

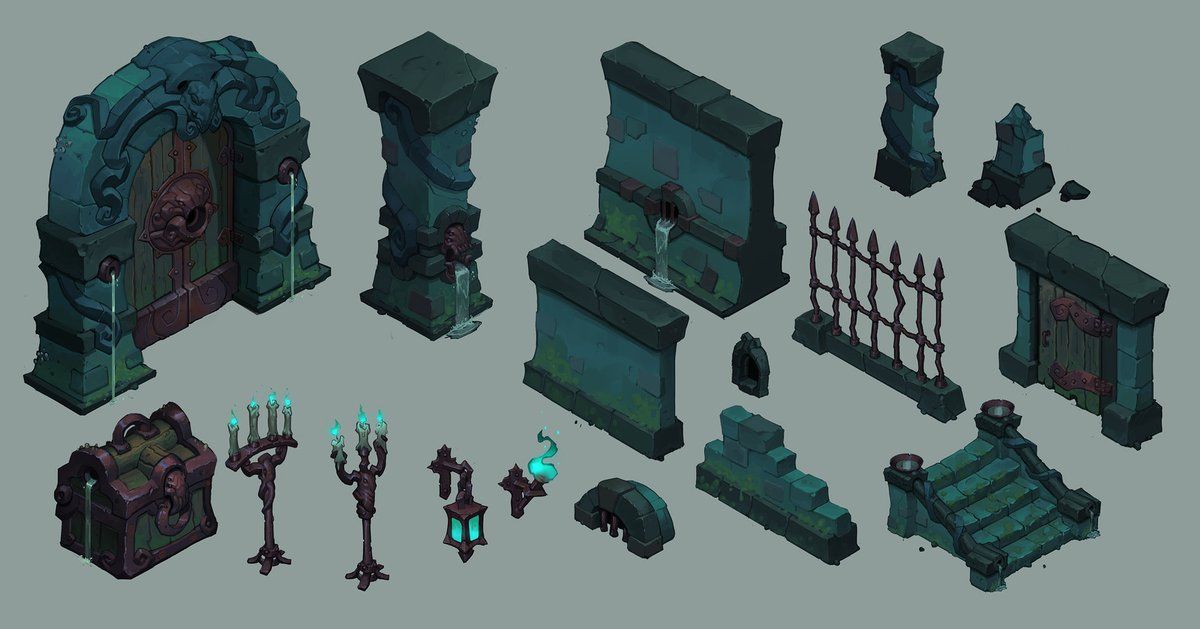

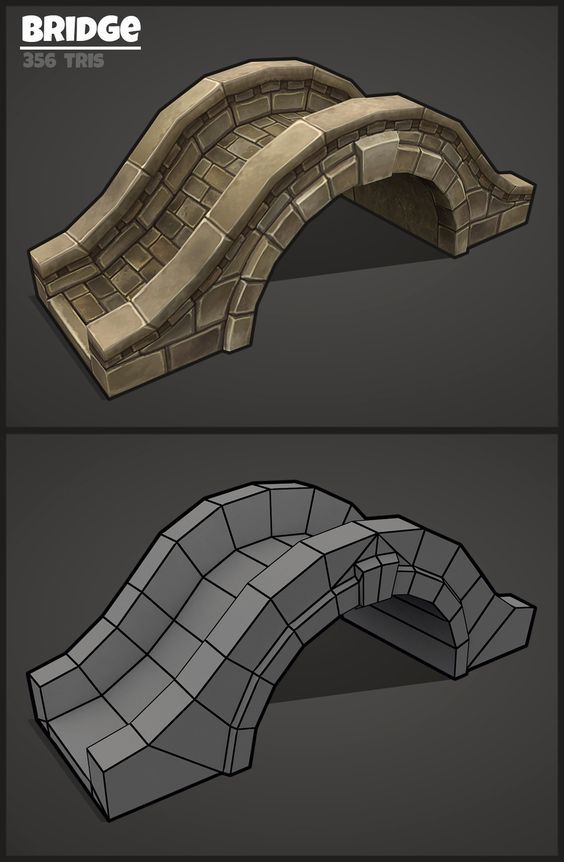

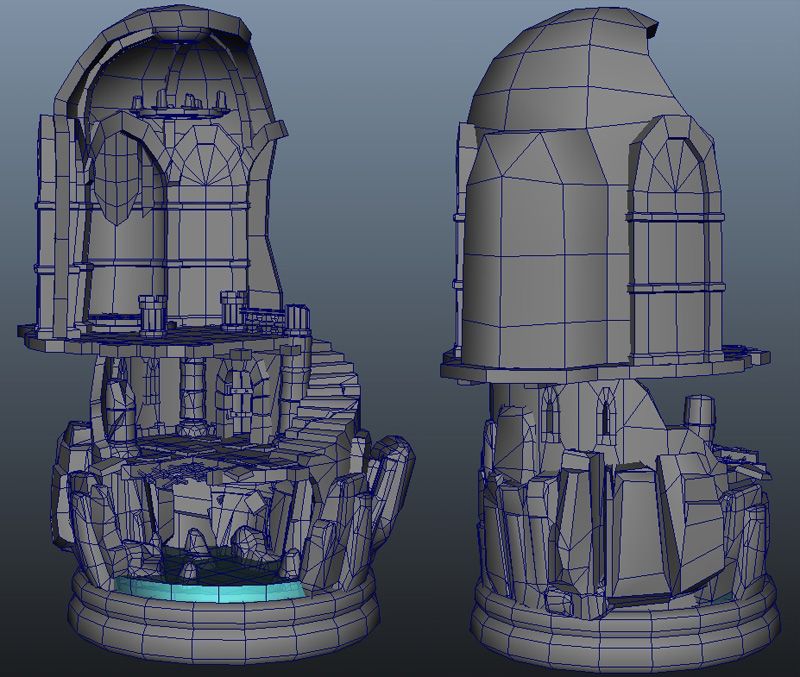

In addition to making the figures themselves, modelers create colorful locations to immerse themselves in the world of their favorite game. This is true not only for 28mm miniatures, but for example for DND games. Such voluminous locations allow you to immerse yourself in the world of your favorite game much better and make the game more exciting.

Game location for board game Warhammer40k

The creation of such locations is painstaking work, and both improvised and special equipment are used as material.

Role play location

A 3D printer allows you to produce miniature figures and game locations much faster. On the Internet you can find many paid and free models of 28mm figures from different universes or various elements of locations - houses, fences, mechanisms, etc. Adapting or slightly changing the finished 3D model for yourself is much easier than cutting and gluing a finished figure. And creative people with modeling skills are unlikely to have difficulties with the transition to “digital clay”.

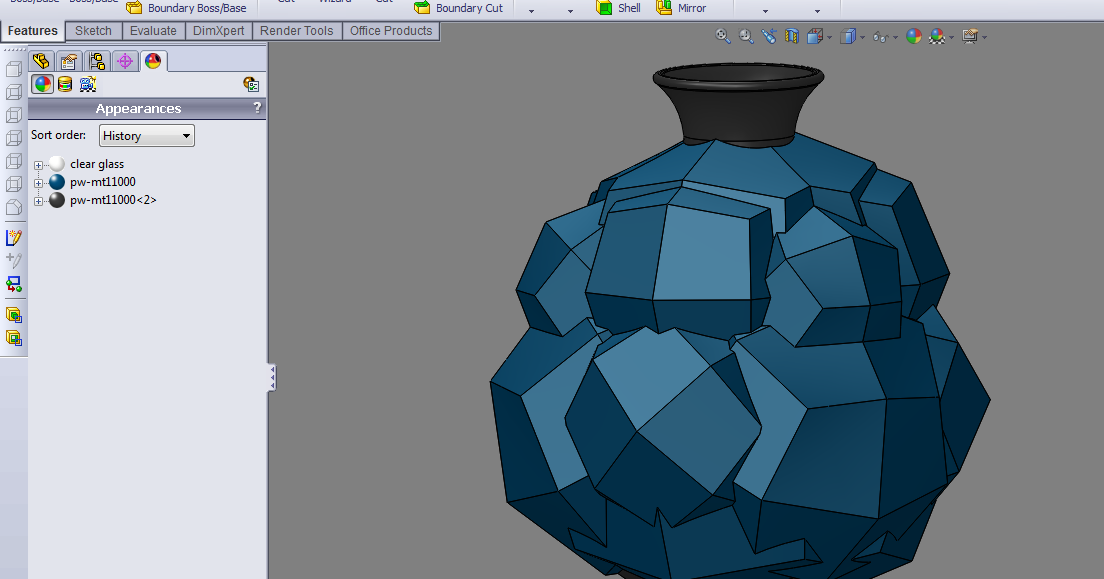

Warhammer40k universe 3D miniature model

And of course, dioramas are worth noting. This is a separate art form with a scene or location frozen in time. Dioramas come in different sizes, but each of them impresses with its detail and careful study.

Diorama based on the game STALKER

Each diorama is unique, so the craftsmen use improvised materials to make it. Everything is limited only by the imagination and ingenuity of the artist.

Everything is limited only by the imagination and ingenuity of the artist.

Diorama “Desert Hero”

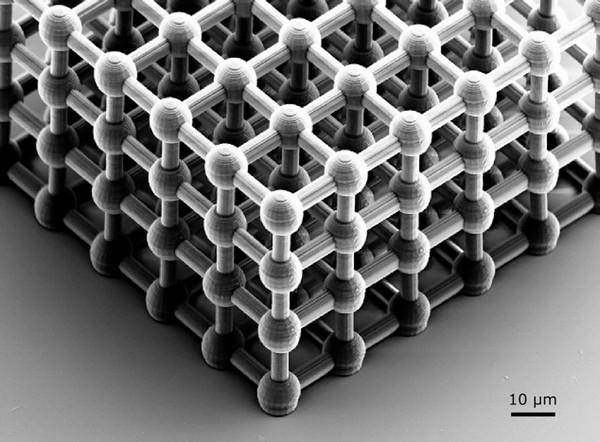

The main advantage of 3D printing is high detail and repeatability. If you need to make a small batch of miniatures, it will be much easier to print them than to cast, for example. Casting small items is a painstaking process that requires some skill and equipment. It is very difficult to achieve good pourability of small products the first time.

From model to finished figure

And for the manufacture of piece products, such as a diorama element, a 3D printer can replace many materials and tools for modeling. In addition, by using and combining different materials, it is possible to create models that are difficult or almost impossible to create manually. For example, using a special polymer, you can print optically transparent products that can imitate glass.

Which technology to choose

To begin with, it is important to determine the requirements for the printer - will it be used only for the manufacture of 28mm personal army or should it be a universal printing machine? It is important to understand what size the finished model will be, how detailed it should be, and how much time can be spent on post-processing.

Depending on this, it is worth deciding on the technology by which the 3D printer will work. You can choose one of two technologies - FDM or photopolymer printing (there are several technologies, but DLP and LCD printers are currently popular).

FDM

FDM 3D printers use a plastic filament as a material. In a heated extruder, the filament is melted and extruded through a thin nozzle, so layer by layer, a three-dimensional model is grown.

Working principle of FDM 3D printer

Layer thickness and nozzle diameter can be changed in some printer models. The minimum layer is usually 0.1 mm. In some models of 3D printers, a layer of 0.05 is available, but for printing with such a layer, it is important to choose the right many settings and the print speed will be quite slow.

Pros:

-

Large print area

-

Many different materials are available for every “taste and budget”

-

Inexpensive Consumables

Cons:

Of course, FDM printers are hardly suitable for making miniature figures, but they can be successfully used to print large souvenir figures, create game locations and some parts of dioramas.

LCD/DLP

The principles of operation of LCD and DLP printers are very similar. The material used is polymers that harden under the action of UV light. The only difference is that an LCD printer uses an LED matrix in conjunction with an LCD screen as a source of UV radiation, while a DLP uses a projector.

Working principle of photopolymer 3D printer

Pros:

-

The ideal surface of the finished figure

-

Many different materials available

-

High print accuracy even for the smallest items

Cons:

Photopolymer 3D printers are able to create miniature products that cannot be made using FDM technology. This technology will be an ideal choice for creating miniatures, small poster models, etc.

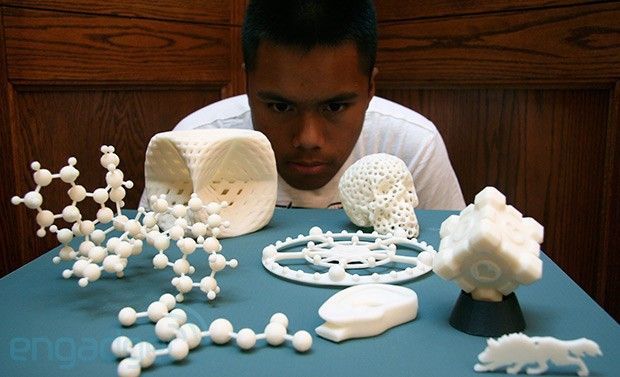

Print examples

Robot printed on Asiga Pro 4k

Figurine made with Phrozen Sonic Mini 4k

28mm 3D printed miniatures

3D Printed Halloween Miniature

3D printed play models

FDM Cube Thrower

Figure making process from 3D model to painting

Best Printer Ranking

FDM

Creality3D Ender 3 (Build Kit)

Features:

Print technology: FDM/FFF

Working area size: 220x220x250 mm

Number of extruders: 1

Max. extruder temperature: max. 255℃

extruder temperature: max. 255℃

Closed Camera: No

Heated table: Yes

Plastic type: ABS, PLA, PETG, Flex, Decorative plastics, others

A popular and unpretentious 3D printer that many makers liked. Creality3D Ender 3 is sold as a kit (assembly kit), but thanks to the detailed instructions, there should be no problems with assembly.

Wanhao Duplicator 6 Plus

Features:

Print technology: FDM/FFF

Working area size: 200*200*180mm

Number of extruders: 1

Max. extruder temperature: max. 260°C

Closed Camera: Optional

Heated table: Yes

Plastic type: ABS, PLA, PETG, Flex, Decorative plastics, others

Wanhao Duplicator 6 Plus is an updated version of the Duplicator 6. The new modification adds automatic calibration, printing resume after a power outage, and others. You can immediately purchase a printer with a closed case, this will allow you to easily print with composites. Wanhao Duplicator 6 Plus will become a trouble-free workhorse, and thanks to the “omnivorous” extruder, even a beginner will be able to print exotic materials without any problems, such as soft flexes or rubbers.

Wanhao Duplicator 6 Plus will become a trouble-free workhorse, and thanks to the “omnivorous” extruder, even a beginner will be able to print exotic materials without any problems, such as soft flexes or rubbers.

FlashForge Creator Pro 2

Features:

Print technology: FDM/FFF

Working area size: 200x148x150 mm

Number of extruders: 2

Max. extruder temperature: max. 240°C

Closed Camera: Yes

Heated table: Yes

Plastic type: ABS, PLA, PETG, Flex, Decorative plastics, others

FlashForge Creator Pro 2 is an almost professional dual extruder 3D printer. Thanks to the closed body, Creator Pro 2 has no problem even with composite materials, and two extruders allow the use of soluble support for complex models. Moreover, FlashForge extruders are independent, this allows you to print 2 mirror or identical models at the same time. This allows you to speed up the production of the same type of models. FlashForge Creator Pro 2 will not only be a good home printer, but also a great helper for a workshop or small production.

FlashForge Creator Pro 2 will not only be a good home printer, but also a great helper for a workshop or small production.

LCD

Anycubic Photon Mono 4K

Features:

LCD display resolution: 3840x2400 (4K)

UV wavelength: 405 nm

Working area size: 132x80x165 mm

Layer thickness: 0.01-0.15mm

Inexpensive, but fairly modern 3D printer with a 4K monochrome display. Anycubic Photon Mono 4K will be a good tool for printing miniature models.

Phrozen Sonic Mini 4K

Features:

LCD resolution: 6.1" 4K Mono LCD

XY positioning accuracy: 35 microns

UV wavelength: 405 nm

Working area size: 134x75x130 mm

Layer thickness: 0.01-0.30mm

The Phrozen Sonic Mini 4K is a compact high resolution 3D printer. It allows you to get accurate models even with an abundance of small details. Sonic Mini 4K is a good choice for those who need to print quickly and accurately.

Phrozen Sonic Mighty 4K

Features:

LCD resolution: 9.3" 4K Mono LCD

XY positioning accuracy: 52 microns

UV wavelength: 405 nm

Working area size: 200x125x220 mm

Layer thickness: 0.01-0.3mm

With a larger work area, the Phrozen Sonic Mighty 4K allows you to quickly produce large models or small batches of small items. Such a 3D printer will be a good help for a small workshop or a hobby circle.

Phrozen Sonic Mini 8K

Features:

LCD resolution: 7.1" 8K Mono LCD

XY Positioning Accuracy: 22 µm

UV wavelength: 405 nm

Working area size: 165x72x180 mm

Layer thickness: 0.01-0.3mm

Phrozen Sonic Mini 8K is one of the representatives of 8K photopolymer printers, which can still be counted on the fingers of one hand. The high resolution LCD-matrix allows you to print figures with amazing surface quality and amazing detail. Such a printer is suitable for demanding printers who care about accuracy and the perfect surface of the finished model.

Such a printer is suitable for demanding printers who care about accuracy and the perfect surface of the finished model.

Totals

3D printers are gradually showing themselves to be great helpers in many areas, not only in medicine and industry, but also in home hobbies. Thanks to 3D printing, it is possible to produce small figurines or elements of dioramas much faster, paying more attention to the elaboration of details, rather than painstaking modeling or the search for exotic materials.

And digitalization makes it much easier to share your work and finished models in the community or adjust them to your needs, for example, change the scale or adjust the pose.

Free Shipping

Add to compare

Item added to compare Go

| Manufacturer | Phrozen

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Anycubic |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Phrozen

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Phrozen

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | FlashForge |

Add to compare

Product added to compare Go

| Manufacturer | Creality |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Wanhao |

#Application

Share

all materials

3D technology for the sake of art.

Areas of application for 3D devices in the theater and museum

Areas of application for 3D devices in the theater and museum Not surprisingly, a 3D printer is a versatile tool for creating everything that can be made from plastic. Other 3D technologies - lasers, milling cutters, scanners, etc. - are joining the same line. However, have you ever thought that the scope of these devices is not limited to industry and trinkets for the soul?

And there are enough applications. And not only in theory, but those that are already being used in practice. Specifically, here we will talk about the use of 3D technologies in art - theater, museum, cinema.

Applications of 3D technologies in theater and museums

3D technologies are generally divided into two categories of use - scanners and object manufacturers. Let's start with the first.

3D Scan

These devices are used to convert a physical object into a digital format - an electronic 3D model. After that, the model is ready for use both in the creation of 3D games or films, and for prototyping on a 3D printer, for example.

There are many different scanners, both in design and in the principle of operation, but the most popular format is an installation with a rotating platform and a fixed reading device (laser, camera, etc.), which “reads” the shape of an object on the surface and writes it in the form of an electronic 3D models.

EinScan-SE 3D scanner

Props and props using 3D technologies

There are many 3D technologies for creating various objects and details. We wrote about different types of 3D printers here, but besides them, there are various CNC machines - lasers, milling machines, engravers, etc., so they can be used in any idea. You can safely use both plastic and metal powder, and if your heart desires, then make objects from wood, stone, metal using a blank on a CNC machine.

3D printer Wanhao Duplicator I3 mini

Specific examples of using 3D devices

The purpose of 3D devices is quite clear - digitization or creation of a real object. But let's not be unfounded - we look at the real use of these devices.

But let's not be unfounded - we look at the real use of these devices.

Theater

Costumes and props in theaters are not limited to cloth costumes and household items.

In the theater, the use of a 3D printer and other devices is beneficial and in demand, because, unlike cinema, it is impossible to use 3D graphics in theaters for obvious reasons, so making real props and props is a must. With the use of 3D devices, this process becomes faster and easier, and as a result, durable and no less high-quality things are obtained.

Yekaterinburg Puppet Theater has 3D-printed figurines

Cinema

Yes, cinematography often uses 3D graphics instead of creating real props, but no one will argue with the fact that real objects have always been and will look like in the frame is much more impressive and realistic than the elements of the environment and interaction drawn in the editor.

3D printed Iron Man suit

But no one has abolished 3D graphics, and that's where 3D scanners are used.

For example, in the film The Girl with the Dragon Tattoo, the stuntman's head was "replaced" by actress Rooney Mara using 3D scanning in the stunt scene.

The process of "replacing" the stuntman's head in the frame

Museum

In the museum business, objects of interest are exhibits. But the bust of Nefertiti and the statue of the Virgin Mary exist only in one copy, and you want to look at them, even copies. Here they show themselves on the good side of 3D technology.

Bust blank, machined from foam. Do not be embarrassed by the strange appearance, the model is still at the manufacturing stage 🙂

By the way, 3D scanners will be indispensable for prototyping exhibits, which will help create an accurate and high-poly electronic model, for example, a sculpture or a bas-relief.

CNC machines are good at making exact copies of objects. This is very handy when copying

Cosplay

Cosplay (eng. costume play) - the embodiment of any image from cinema, animation, video games, etc., that is, a repetition of the costume and appearance of the character, his behavior, facial expressions, etc.

costume play) - the embodiment of any image from cinema, animation, video games, etc., that is, a repetition of the costume and appearance of the character, his behavior, facial expressions, etc.

Cosplay is like theater. Here, too, props and acting are needed, but still, in cosplay, you need not only to create a costume, but to make it as similar as possible to the original source.

Awesome suit. The parts are made using a 3D printer, which is why they have such a realistic "factory" shape

What is the best equipment for creating props

In theater, cinema and cosplay, 3D printers will be the most in demand. On our website, we can get a decent option even with a small budget, for example, Creality3D Ender 3.

If you need to make smaller parts and the best quality and shape of the final model is important, the Anycubic Photon Mono photopolymer printer will suit you.

If you want to look for another option, then here is a link to the catalog 🙂

CNC machines are needed to process finished workpieces made of wood, metal, etc. To create bas-reliefs and similar decorative elements, we recommend taking a milling machine. A good option would be Scotle 6040.

To create bas-reliefs and similar decorative elements, we recommend taking a milling machine. A good option would be Scotle 6040.

3. Conclusion

The convenience and indispensability of 3D technologies in theater, museums and other areas of art is understandable and justified. With the help of various devices, you can create something entirely with high quality or simplify the process of hand-made. And some devices, like a 3D scanner, do make available what was impossible to do without the scanner itself.

We hope that your horizons have expanded and, perhaps, you will begin to actively use 3D technologies in one of the areas that we talked about above. As we have already said, the potential of 3D devices is huge.

Think, estimate the pros and cons, and if you decide to make a purchase, we will be glad to see you in our catalog. If you need advice, do not hesitate to contact our managers - they will help you choose the right option for you.

We wish you success and only good purchases on the site.