3D glass photo printing

Custom 3D Photo Crystal Gifts & Awards

Featured Products

-

Quick view

Pet Memorial Jeweled Puck

These beautiful laser etched crystals are perfect gift items. The jeweled puck measures 3" x 3" x 1.…

Now $69.00

Choose Options

-

Quick view

Heart Keychain Light

What a wonderful and affordable personalized gift.

The heart shaped photo crystal lighted key …

Now $39.00

Choose Options

-

Quick view

3D Heart

Our 3d crystal hearts are the perfect gift to express your love. Holidays like Mothers Day, Fathers …

Now $159.00

Choose Options

-

Sale

Quick view

Rectangular Pendant

Beautiful rectangular shaped cut crystal pendant, laser etched with the photo of your choice! Perfec…

Now $49.

00

00

Was $59.00

Choose Options

-

Quick view

Crystal 3D Diamond

Great for 3d portraits and 3d corporate logos crystal diamond shaped cubes have one corner cut flat …

Now $59.00

Choose Options

-

Quick view

Photo 3D Crystal Cube

Crystal Cubes are perfect for 3d portraits, memorial keepsakes or company product and logo promotion…

Now $59.

00

00

Choose Options

-

Quick view

Photo Crystal 3D Tower

Tower awards are tall rectangles that may be ordered with an optional black piano finish wood …

Now $189.00

Choose Options

-

Sale

Quick view

Photo Crystal Heart Ornament

The Heart shaped ornament measures 2.

5 inches in width and height. The faceted edges catch the ligh…

5 inches in width and height. The faceted edges catch the ligh…

Now $39.00

Was $49.00

Choose Options

-

Sale

Quick view

Photo Crystal Oval Ornament

The size of the oval ornament is 4 inches tall x 2.5 inches wide. The faceted edges catch the light …

Now $39.00

Was $49.

00

00

Choose Options

-

Quick view

Wide Iceberg

Solid optical crystals shaped to look like icebergs. They are perfect for almost every application a…

Now $139.00

Choose Options

-

Sale

Quick view

Heart Pendant

Beautiful heart shaped cut crystal pendant, laser etched with the photo of your choice! Perfect for …

Now $49.

00

00

Was $59.00

Choose Options

-

Quick view

2D Heart Paperweight

Heart shaped crystal measures 4"x4"x1" and is the perfect gift for Valentines Day or Anniversaries o…

Now $129.00

Choose Options

Reviews

Remembrance And Memorial Gifts | Crystal Prints

Sort By: Featured ItemsNewest ItemsBest SellingA to ZZ to ABy ReviewPrice: AscendingPrice: Descending

-

Quick view

3D Heart

Our 3d crystal hearts are the perfect gift to express your love.

Holidays like Mothers Day, Fathers …

Holidays like Mothers Day, Fathers …

Now $159.00

Choose Options

-

Quick view

Pet Memorial Jeweled Puck

These beautiful laser etched crystals are perfect gift items. The jeweled puck measures 3" x 3" x 1.…

Now $69.00

Choose Options

-

Quick view

Memorial 3D Crystal Cube

Crystal Cubes are perfect for 3d portraits, memorial keepsakes or company product and logo promotion…

Now $59.

00

00

Choose Options

-

Quick view

Crystal 3D Diamond

Great for 3d portraits and 3d corporate logos crystal diamond shaped cubes have one corner cut flat …

Now $59.00

Choose Options

-

Sale

Quick view

Memorial Rectangular Pendant

Beautiful rectangular shaped cut crystal pendant, laser etched with the photo of your choice! Perfec…

Now $49.

00

00

Was $59.00

Choose Options

-

Sale

Quick view

Memorial Heart Pendant

Beautiful heart shaped cut crystal pendant, laser etched with the photo of your choice! Perfect for …

Now $49.00

Was $59.00

Choose Options

-

Sale

Quick view

Photo Crystal Heart Ornament

The Heart shaped ornament measures 2.

5 inches in width and height. The faceted edges catch the ligh…

5 inches in width and height. The faceted edges catch the ligh…

Now $39.00

Was $49.00

Choose Options

Printing on glass without problems

Personal diaries

Subscribe to the author

Subscribe

Don't want

9

Many people wonder what kind of surface to choose for 3D printing. Most use mirrors, window glass, and as we know, they do not last long, as they crack from heat. Therefore, you have to order large quantities - although this is inexpensive, it is too troublesome. It is not always possible to print a model so that it does not come off the glass surface. I tried many ways to print on different surfaces and found what works best for me: copier glass and furniture glass, because they are perfectly even, withstand high temperatures and hide all the unevenness of the heating plate due to their thickness of 4 mm. I printed on them with a wide variety of plastics: ABS, PLA, HIPS, FLEX, SBS. For ABS plastic, you need to lubricate the table with Erich Krause glue stick.

I tried many ways to print on different surfaces and found what works best for me: copier glass and furniture glass, because they are perfectly even, withstand high temperatures and hide all the unevenness of the heating plate due to their thickness of 4 mm. I printed on them with a wide variety of plastics: ABS, PLA, HIPS, FLEX, SBS. For ABS plastic, you need to lubricate the table with Erich Krause glue stick.

[IMG ID=188707 WIDTH=402 HEIGHT=245][IMG ID=188708 WIDTH=439 HEIGHT=242]

To keep the model on it better, I treated the glass with an abrasive (40th grit, hardness above 5 on the scale Mohs). So the glass becomes dull and rough, but this does not affect the quality of the appearance of the model, smoothness is maintained. I like the fact that it is not at all afraid of temperature changes - I can safely wipe it with a damp cloth when the table temperature is 60-90C. For all the time of use, there was not a single case that the glass cracked. In order for the model to ideally stick to the glass, I smear the first layers on a cold table with a glue stick.

[IMG ID=188709 WIDTH=163 HEIGHT=163]

Printing starts by heating the hot end. The table heats up already in the process of printing a model. You should not smear glue on a hot table, as there is a high probability that the model will not stick well, plastic will click and at some point the model will completely come off the glass. If I print with ABS plastic, one layer is enough for about 3-4 prints, and there are no hints of peeling off. But: I print models with a skirt, the width of which is 10mm.

It is worth mentioning the minus of this glass, which does not appear immediately, or may not appear at all. If, after printing, the model itself comes off the glass, there is a possibility of getting shells on the surface (a piece of glass will break off along with the model). However, this can be avoided if you immediately tear it off the glass, without waiting for it to bounce off by itself. I didn't notice any other flaws. In general, printing on this glass completely satisfies me.

[IMG ID=188710 WIDTH=397 HEIGHT=220][IMG ID=188712 WIDTH=395 HEIGHT=221]

I hope this was informative for someone)

Subscribe to the author

Subscribe

Don't want

9

More interesting articles

Loading

11/28/2022

585

16

Follow author

Follow

Don't want to

My first normal typist (well, almost, especially after a serious application of hands) was a goat clone...

Read more

volock

Loading

11/18/2022

3688

12

Subscribe to the author

Subscribe

Don't want

Hello everyone. The workshop needed a small milling machine to cut wood and acrylic....

The workshop needed a small milling machine to cut wood and acrylic....

Read more

ski

Loading

17.04.2018

23769

91

Subscribe to the author

Subscribe

Don't want

Greetings!

Recently there have been several threads on bar splicing,

and to start...

Read more

Learn how to print glass of various compositions with a 3D printer

Swiss scientists have developed a 3D printing method that allows printing glass objects with a complex structure using different materials, but without using high temperatures during printing, which other methods do not allow. Article published at Nature Materials .

3D printing is most often used in two cases: when it is necessary to quickly create an object of the required shape without creating a streamlined production process for it with expensive molds and other equipment, or when it is necessary to produce a part with a complex structure that is more expensive to create by casting or other classical methods. For the second cases, engineers have long been developing printers that print not with polymers, but with other materials, including ceramics, glass, and even chocolate.

For the second cases, engineers have long been developing printers that print not with polymers, but with other materials, including ceramics, glass, and even chocolate.

However, glass, ceramics, and other similar materials are not suitable for 3D printing due to their high melting point. As a solution, some groups of scientists have suggested first printing the glass precursor blank and then high-temperature annealing so that the printer does not need to be adapted to the high temperature. Until now, such methods have only been demonstrated with silicon oxide, but now there is a more universal method.

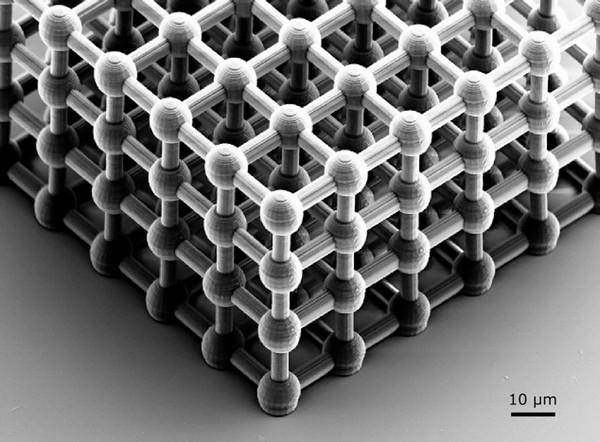

Scientists at ETH Zurich, led by Andre Studart, have learned to apply a similar principle to compositions of different oxides. The researchers used digital light processing (DLP), which uses a solution of photocurable polymer precursors that is illuminated in the right places with light, resulting in a solid object in the liquid solution.

The authors used various solutions consisting of an inorganic alcoholate precursor to create glass, a photoactive monomer, and a light absorbing agent. The compositions were selected in such a way that initially the components are in the solubility region of the system state diagram, but after photopolymerization they move into the region of incomplete miscibility. As a result, spinodal decomposition occurs and two phases (oxide precursor and polymer) are separated, forming a mutually continuous network structure.

The compositions were selected in such a way that initially the components are in the solubility region of the system state diagram, but after photopolymerization they move into the region of incomplete miscibility. As a result, spinodal decomposition occurs and two phases (oxide precursor and polymer) are separated, forming a mutually continuous network structure.

After polymerization, the object must be subjected to pyrolysis, in which the polymer part burns out, and the glass part remains, and at this stage the glass product turns out to be porous, with pores less than a micrometer in size. If it is necessary to obtain transparent glass, it must be additionally sintered until a solid and transparent structure is obtained. The transparency of the glass obtained after sintering is approximately 85 percent. Measurements showed that after sintering the relative density of such glass is 98 percent.

As an example, the researchers printed many complex structures, most of which are three-dimensional meshes with fine elements.