Huge 3d printers

Large Volume 3D Printers | MatterHackers

Bring your most ambitious prints to life with these large-volume 3D Printers! From the enormously large Modix 3D Printers to flexible & industrial-grade 3D printers from brands such as Raise3D, MakerGear, or BCN3D; MatterHackers has the right large-volume 3D printer to fit your needs.

Available for purchase as kits or ready to ship fully assembled, these large-volume 3D Printers will enable you to print BIG and explore product development and prototyping without the need to invest in costly, full-scale additive manufacturing systems.

Guides & Articles

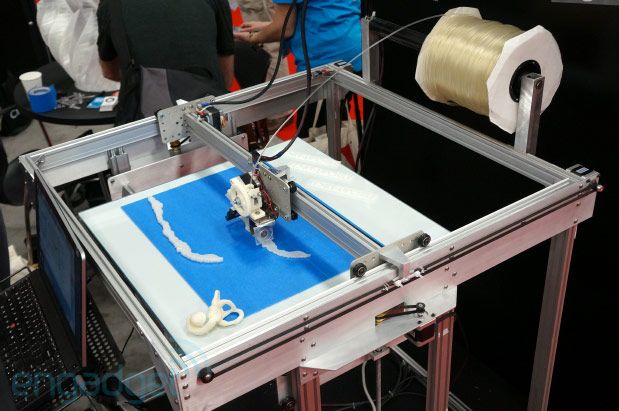

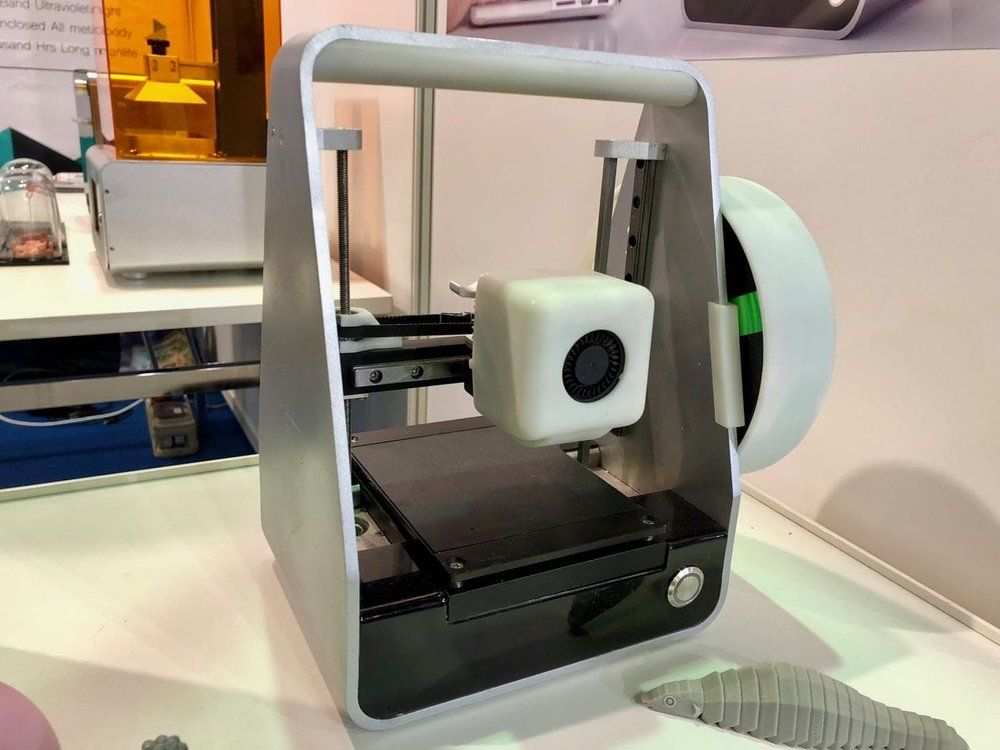

What is 3D Printing?

3D printing is a process where physical, three-dimensional objects, parts, or models are made layer-by-layer from Computer-Aided Design, or CAD, and digital files.

Anatomy of a 3D Printer

Get an understanding of how 3D printing works, from the inside and out. This guide will walk you through each of the critical components of a 3D Printer, answering the question: "How does a 3D printer work?"

The Top Ten Tips For Getting Started With 3D Printing

We were all noobs at one point! Here the ten best tips for getting started with 3D printing - whether it's your first time 3D printing or you need to brush up on the basics, this guide will help you out!

3D Printer Troubleshooting Guide

Use this guide to help you identify and solve the most common issues that may occur while 3D printing.

How To Calibrate Your 3D Printer's Extruder

This quick and informative guide will help you calibrate your extruder perfectly, resulting in accurate, quality prints.

3D Printing 101: How to Succeed with a Perfect First Layer for Every 3D Print

The first layer of your 3D print is the foundation of everything that comes after, which makes it such an important part of the 3D printing process.

How To Get The Best 3D Printed Parts By Understanding Extrusion Settings

Melting is a critical concept to 3D printing, and yet it hasn’t received a lot of in-depth attention. This article will teach you how to extrude your filament properly so it flows smoothly. Make filament jamming, delamination, and weak parts things of the past.

3D Printing Essentials: How to Succeed with Every Bed Surface Solution

Matching 3D printing filaments with the proper bed surface material is an important part of the 3D printing process. Read more to find out the best path to success.

Read more to find out the best path to success.

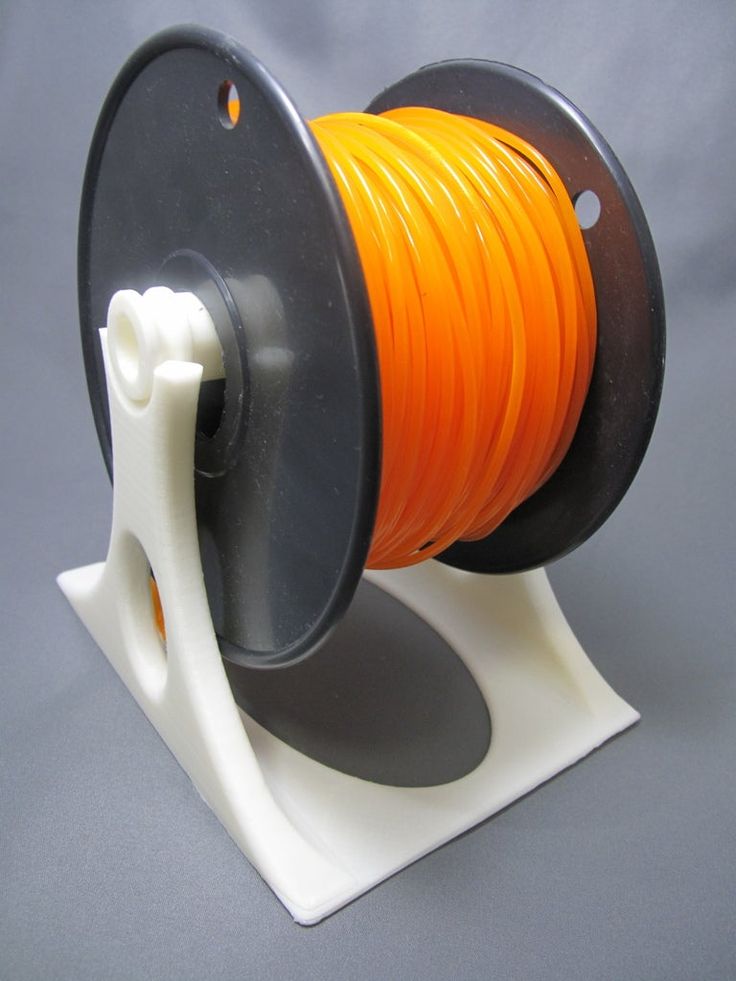

3D Printing Essentials: Filament Loading

Proper filament loading and unloading is a necessary part of 3D printing without trouble. Read on to learn the essential method you should be following.

3D Printing Essentials: Bed Leveling

For some, levelling a 3D printer's bed can be challenging, but it doesn't need to be. Read this essential guide to see what it takes to do it right.

Quick Tips: How To Get Started With Batch 3D Printing

Utilizing 3D printer time most efficiently is much easier once you start batch printing parts to maintain 3D printer uptime and minimize downtime.

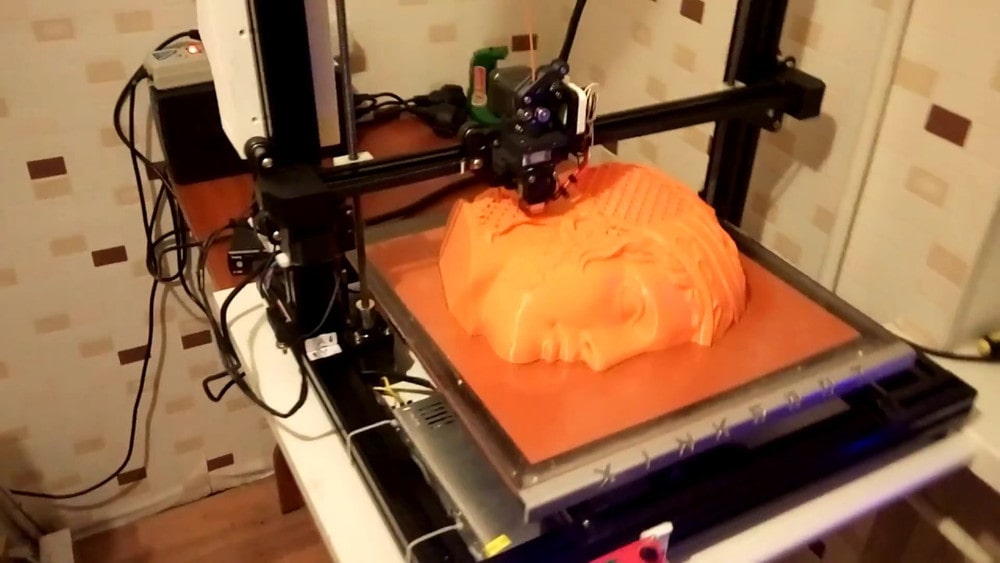

WHY SHOULD I SELECT A LARGE-VOLUME 3D PRINTER?The number of available large-volume 3D Printers is growing every day. Whether you are just getting started with 3D Printing, consider yourself an experienced hobbyist, or are a professional looking to take that next step into the world of large-scale production there is a large-volume 3D Printer to fit your needs.

Large-volume 3D Printers can range in price from as low as $500, such as the Creality Ender 5 Plus, while some can be as expensive as $15,000, such as the absolutely massive Modix Big-180X.

There are many other additional factors to consider when discussing the costs associated with large-volume 3D printers. It's important to thoroughly take into consideration things such as the type of 3D Printer Filament Or 3D Printer Resins you are planning to print with, the type of HotEnds and Nozzles required, as well as any other accessories such as Build Surfaces & Fume Extractors.

HOW LARGE CAN I PRINT?The Modix 3D Printer line easily takes the lead when it comes to print volume. Large, highly upgradable, and available exclusively as kits these printers are exceptional options for achieving ridiculously large prints.

- Modix BIG-40: 400mm x 400mm x 800mm, starting at $5,600

- Modix BIG-60 V3: 600mm x 600mm x 660mm, starting at $4,500

- Modix BIG-120X: 1200mm x 600mm x 640mm, starting at $7,550

- Modix BIG-120Z: 600mm x 600mm x 1200mm, starting at $7,450

- Modix BIG-180X: 1800mm x 600mm x 600mm, starting at $15,150

- Modix BIG-Meter: 1010mm x 1010mm x 1010mm, starting at $13,150

Creality3D Ender 5 Plus 3D Printer

- Home

- Store

- 3D Printers

- FDM 3D Printers

- FDM 3D Printers Under $1000

With a massive build volume, a striking design both new and classic, and a feature set designed for the huge prints you can make on this 3D printer, Creality3D's Ender 5 Plus is a powerful printer at an affordable price. Like many of Creality3D's printers, the Ender 5 Plus comes partially assembled, and can be up and running in minutes.

Like many of Creality3D's printers, the Ender 5 Plus comes partially assembled, and can be up and running in minutes.

- Massive build volume

- Striking design

- Feature set designed for huge prints

- Powerful printer at an affordable price

- Comes partially assembled

- Can be up and running in minutes

- Great for classrooms, tinkerers, or just makers looking to add a big new printer without breaking the bank

Remove from wishlist Add to wishlist loading...

Available Add-ons (3)

Show More Addons

Product No. M-3AG-VNU1

| List Price: | $600.00 |

|---|---|

| Price: | $509.52 |

| Price: | $... |

This item cannot be shipped to a PO Box or APO/FPO/DPO address.

Notify me when this is available

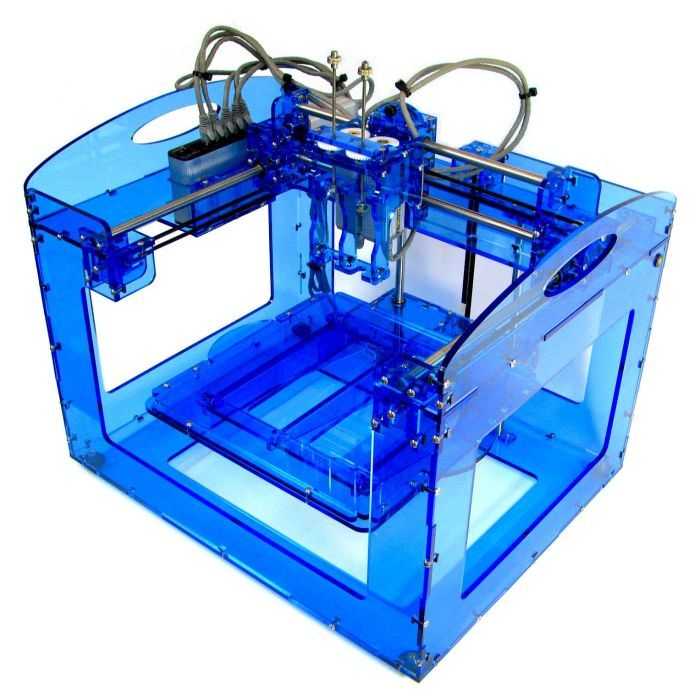

The Classic Sturdy Frame Reinvented for the EnderThe Ender 5 series has been designed from the ground up to improve upon the Ender 3 series in almost every way, and the most dramatic improvement is the large, box-shaped frame that vastly improves stability and allows for a much larger build volume than that of its predecessors.

The extruded aluminum rails that form this eye-catching cube reinforce the Ender 5 Plus' structure along each axis, and is the foundation of Creality's Double Axis Control System. This vastly reduces any vibrations during 3D printing by allowing the Y motor to control the gantry on each side simultaneously, allowing for more reliable, solid print quality, and impressively quiet 3D printing.

BL Touch Comes Standard for Flawless Bed Leveling on Every 3D PrintBefore every 3D print begins, the Ender 5 Plus takes stock of its huge print surface by employing the BL Touch auto-bed-leveling sensor. This sensor probes the print bed at multiple points, establishing a detailed mesh of the surface, and empowering your 3D prints to adhere easily along the ever-important first layer. Manually adjusting the bed with pinpoint accuracy is a thing of the past!

The Ender 5 Plus Keeps Going So You Don't Have ToTo take advantage of such a massive build volume, and 3D print the huge parts and objects you need, the Ender 5 Plus has been designed to allow long prints to keep going, so you can let the printing go on without spending any time worrying. Interruptions are a part of life, but with these quality-of-life features, it's like it never happened.

Interruptions are a part of life, but with these quality-of-life features, it's like it never happened.

With the built-in Filament Sensor, the Ender 5 Plus will immediately pause your 3D print, so no part of your model is lost. Simply feed in new filament and resume the print.

The Power Failure Resume feature is another life-saver. By continuously saving where the printer is in your print's gcode, the Ender 5 Plus is able to pick up where it left off after being interrupted. Even if the power goes out--once it's restored, printing is too.

Tech Specs- Build Volume: 350mm x 350mm x 400mm (13.8" x 13.8" x 15.7")

- Nozzle: Brass 1.75mm x 0.4mm (can be swapped out for 0.3mm or 0.2mm)

- Extruders: 1

- Max. Nozzle Temp: 260℃

- Heated Bed Temp: 110℃

- Bed Type: Tempered Glass

- Display: 4.

3" Monochrome

3" Monochrome - Power Consumption: 110V input, 24V, 21A output

- Frame: Aluminum

- Printer Weight: 40 lbs.

- Printer Size: 632mm x 666mm x 619 mm (24.9" x 26.2" x 24.4")

Large Area 3D Printer

Create functional plastic items up to 2.5 meters!

Learn more

Discovery 3D Printer is a range of industrial 3D printers made in Spain for creating large-sized products and prototypes using FFF/FDM technology.

Discovery 3D Printer additive machines produce objects from high-strength thermoplastics and are designed for industries ranging from shipbuilding and automotive to architecture and medicine.

Problems solved

Replacement of spare parts or lost parts in engineering, shipbuilding, oil and gas and energy enterprises

Production of small and medium series of products as an alternative to injection or molding of plastic parts automotive, shipbuilding and oil and gas industries

Creation of objects of exterior and interior design and design products for construction, production of facing materials

Production of functional prototypes for R&D and design bureaus in mechanical engineering, shipbuilding and aircraft construction

Production of large-sized wax or burnt master models for metal casting and metallurgy or trolleys)

Looking for a 3D printer for your needs?

Leave a request for a personal consultation!

Solutions catalog

3D printers

3D printer DISCOVERY 3D Printer 2021

Compact solution for 3D printing of large-sized products

Read more

3D printer Super Discovery Compact

Combination of compactness and high performance of the performance

Learn more

Super Discovery 3D Printer Hybrid

Advantages of granule and filament printing in one machine

More details

Super Discovery 3D Printer 3D Printer

Large build chamber and print speed up to 6 kg/h

More details

Super Discovery 3D Printer Workstation 3D Printer

3D large format printer combination: unique 2 in 1 combination and milling systems

More details

Your unique 3D printer

Do you need to print a product larger than 6 meters?

We will develop an individual solution with any build chamber for your needs. tasks - for printing products of any size!

tasks - for printing products of any size!

Choose the right solution for you - compare specifications by model

Compare 3D Printer

Solutions catalog

3D Printing Consumables

Do you have questions about 3D printing media?

Set them to our experts online!

Discovery 3D Printers work with all thermoplastics, including:

- PLA / PLA

- biodegradable polymer provides a smooth and gliding surface products. Designed to obtain detailed and ready-to-use objects

- ABS / acrylonitrile butadiene styrene

- impact-resistant material is able to withstand heavy loads and high temperature, resistant to heat, moisture and various alkalis

- PET / polyethylene terephthalate

- is a hard and strong material with high abrasion resistance.

Excellent suitable for making gears, carriages and guides

Excellent suitable for making gears, carriages and guides - PA / polyamide

- hard engineering plastic with excellent mechanical properties characteristics. Widely used in various industries

- ASA / acrylonitrile styrene acrylate plastic

- analogue of ABS, characterized by increased weather resistance, minimal shrinkage and high impact strength

- Nylon

- is elastic, wear-resistant and remarkably durable. Good suitable for printing functional parts and mechanisms

- HIPS / polystyrene

- Lightweight, alkali and acid resistant polymer. deserved popular in traditional manufacturing due to its impact resistance

Advantages of Discovery 3D Printer Solutions

ISO 9001 certified products

3D printers with the largest build chamber in the world

Ability to design a custom printer

The only 3D printer on the market with an integrated CNC system for finishing milling a part after printing

Accelerate the creation of new products thanks to the dual extrusion system

Repair and replacement of products faster and more economically than contractors

Ability to use a large number of third-party materials

Self-leveling platform function for automatic compensation of irregularities

Case Studies

FDM Airbus Spare Parts 3D Printing

| Industry: | Aircraft industry |

| Equipment: | Super Discovery 3D Printer |

| Material: | CFRP SABIC LNP™ THERMOCOMP™ AM EZ006EXAR1 |

Created a strong mold for autoclave forming parts with a sealed surface and a low thermal expansion coefficient.

3D printed car bumper

| Industry: | Automotive |

| Equipment: | Super Discovery 3D Printer |

| Material: | ABS with carbon fiber |

Prototype car bumper printed, measuring 1800 x 600 x 4500 mm and weighing 12 kg.

Large format 3D printed chair

| Industry: | Design |

| Equipment: | Super Discovery 3D Printer |

| Material: | 3D850 |

Printed design armchair measuring 45 x 50 x 95 cm and weighing 18 kg.

3D printed architectural statue

| Industry: | Architecture |

| Equipment: | Super Discovery 3D Printer |

| Material: | ABS with cellulose fiber |

The solid statue is printed and is 1. 87 m high and 45 kg in weight.

87 m high and 45 kg in weight.

3D printing of railway components

| Industry: | Railway industry |

| Equipment: | Super Discovery 3D Printer |

| Material: | plastic |

The front part of a tram for CAF was made in one printing session.

Helicopter seat 3D printing

| Industry: | Design |

| Equipment: | Super Discovery 3D Printer |

| Material: | ABS with carbon fiber |

Printed helicopter seat measuring 120 x 70 x 45 cm and weighing 20 kg.

3D printed internal combustion engine

| Industry: | Engineering |

| Equipment: | Discovery 3D Printer 2021 |

| Material: | Premium PLA |

Prototype of an internal combustion engine was created, the dimensions of which were 100 x 60 x 50 cm and the weight was 5. 5 kg.

5 kg.

3D printed exclusive piece of furniture

| Industry: | Design |

| Equipment: | Super Discovery 3D Printer Workstation |

| Material: | ABS |

A custom and exclusive chair created without the need for any further finishing.

Architectural 3D printed in durable ABS with cellulose

| Industry: | Design |

| Equipment: | Super Discovery 3D Printer Workstation |

| Material: | ABS |

A street sculpture has been made that fully implements the initial decorative idea of the project.

Dior boutique window dressing

| Industry: | Advertising |

| Equipment: | Super Discovery 3D Printer Workstation |

| Material: | plastic |

Huge bottles 3D printed for exclusive display at Dior's flagship stores.

FDM Cap Prototype

| Industry: | Design |

| Equipment: | Discovery 3D Printer 2021 |

| Material: | 3D850 |

Prototype cap printed at 29 x 19 x 4.5 cm and weighing 146 g.

A prototype of a modular toilet has been printed, measuring 2200 x 1700 x 1200 mm and weighing 250 kg. At the same time, the weight of the product was reduced by almost 50%.

3D printed marine ventilation grille

| Industry: | Shipbuilding |

| Equipment: | Super Discovery 3D Printer |

| Material: | ABS with carbon fiber |

Ventilation grill printed 59 x 89 x 4. 5 cm and weight 3500 g.

5 cm and weight 3500 g.

Printed motorcycle part measuring 42.5 x 16.5 x 4.5 cm and weighing 165 g.

Prototype printed with support measuring 10 x 9 x 2.5 cm and weighing 18 g.

Created a square mold that measures 10 x 10 x 2 cm and weighs 67 g.

Printed fender for a wheel measuring 55 x 16 x 20 cm and weighing 645 g.

3D printed and post-processed a high-strength mold for wind turbine blades.

3D printed car wheel

| Industry: | Automotive |

| Equipment: | Super Discovery 3D Printer |

| Material: | ABS with carbon fiber |

A wheel for a car was made, the diameter of which was 440 mm, and the weight of the product was 5 kg.

3D printed designer vase

| Industry: | Design |

| Equipment: | Super Discovery 3D Printer Workstation |

| Material: | ABS with carbon fiber |

Printed vase in ABS for excellent interlayer adhesion and minimal warping.

Geometric 3D printing

| Industry: | Design |

| Equipment: | Super Discovery 3D Printer Workstation |

| Material: | ABS with carbon fiber |

Pyramid printed with an 8mm extruder with a smooth surface thanks to the built-in milling system.

More projects and examples of 3D printing in production - in the blog 3D experts

Go to blog

Useful materials

Webinar on 3D printing large objects with complex geometry

- How can 3D printing help you optimize production?

- Features FDM-technology for printing products up to 2.

5 meters

5 meters - Benefits of using 3D plastic printing

- Real cases

Large Format Plastic 3D Industrial Printing Brochure

Benefits of FDM Technology, Overview of Equipment and Consumables, industries and implementation examples - this and much more in one material!

About the manufacturer

CNC Barcenas / Spain

is one of the leaders in the European market for large format 3D printing.

The company specializes in the production of industrial 3D printers Discovery 3D Printer for printing large-sized products and prototypes based on FFF/FDM technology.

discovery3dprinter.com

Take a closer look at Discovery 3D Printer solutions - take a virtual tour of companies!

3D TOUR OF COMPANY

About us

iQB Technologies is a Russian distributor of 3D printers, consumables, 3D scanners and software from the world's leading manufacturers.

We develop complete 3D solutions, provide printing services and scanning, as well as training specialists in the use of 3D technologies in their work.

iQB Technologies is the exclusive distributor of Discovery 3D Printer solutions in Russia.

3D printers are available for order

in this section .

iqb.ru

Why order a 3D printer from iQB Technology?

The best prices for this class of equipment

Training on how to use 3D printers

A wide range of integrated solutions: 3D printer + 3D scanner + software

Provision of services for the implementation, maintenance and repair of 3D equipment throughout Russia

Participation in public procurement and tenders

Still have questions?

Our experts will advise you free of charge on Discovery 3D Printer solutions

Frequently Asked Questions

Which technology to choose: the method of fusing granules (FGF) or polymer filaments (FFF / FDM)?

What are the kinematics and mechanics of the Discovery equipment?

In this respect, all Discovery equipment differs from budget additive solutions. The products are based on the kinematic diagram of a CNC machine. Gears, pulleys, lead screws, no belts. HIVIN rail guides are used. The entire structure is made with European quality from advanced products in the machine tool industry.

The products are based on the kinematic diagram of a CNC machine. Gears, pulleys, lead screws, no belts. HIVIN rail guides are used. The entire structure is made with European quality from advanced products in the machine tool industry.

What consumables can be used with Discovery products?

Any material (other than PEEK and PEKK) sold in bars or pellets. First of all, thanks to the heating of the table to 175 ° C and vacuum fixation, as well as due to the installed nozzles made of hardened steel.

How is such a large print platform heated?

A matrix of separate equidistant heaters is built into the platform from the bottom side; these modules provide uniform heating of the surface of the printing platform. The maximum recorded temperature difference over the entire area is 3°C.

How to speed up printing on such large dimensions?

There is a special method for properly emptying the internal volume, which you can learn more about from our technical experts. This procedure will have very little effect on the strength and elasticity of the print object, but will still reduce the time by up to 60%.

This procedure will have very little effect on the strength and elasticity of the print object, but will still reduce the time by up to 60%.

It is important to consider that with a large range of large-sized products, it is better to consider Super Discovery 3D Printer or Super Discovery 3D Printer Workstation with a capacity of up to 11 kg / h (depending on the material used).

Is it possible to upgrade this equipment for a specific enterprise?

Yes. Most of the Discovery machines can be upgraded for a specific production project. This is possible, since the equipment was designed for the tasks of Production 4.0, and our specialists will help to integrate it correctly.

What is the warranty for this equipment?

24 months, which is 1.5 - 2 times more than analogues from Europe, Russia and China. Permanent customer support is provided directly by the vendor or iQB Technologies specialists.

How to get a high quality product so that it can be handed over as a final product?

3D printing is basically a high quality preform process. If you need to get the final product, it is suggested to use milling or turning equipment, manual machining, priming, painting or varnishing.

This is often not necessary as the product is not visible.

full name *

Company *

E-mail *

Telephone *

Message

3D printers with large print area

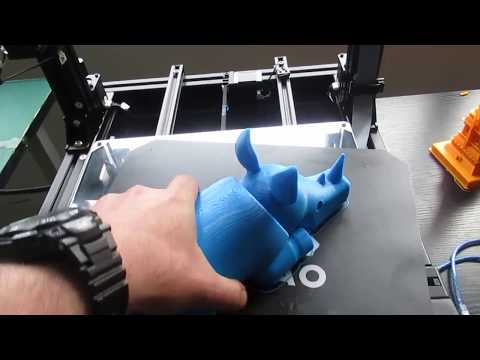

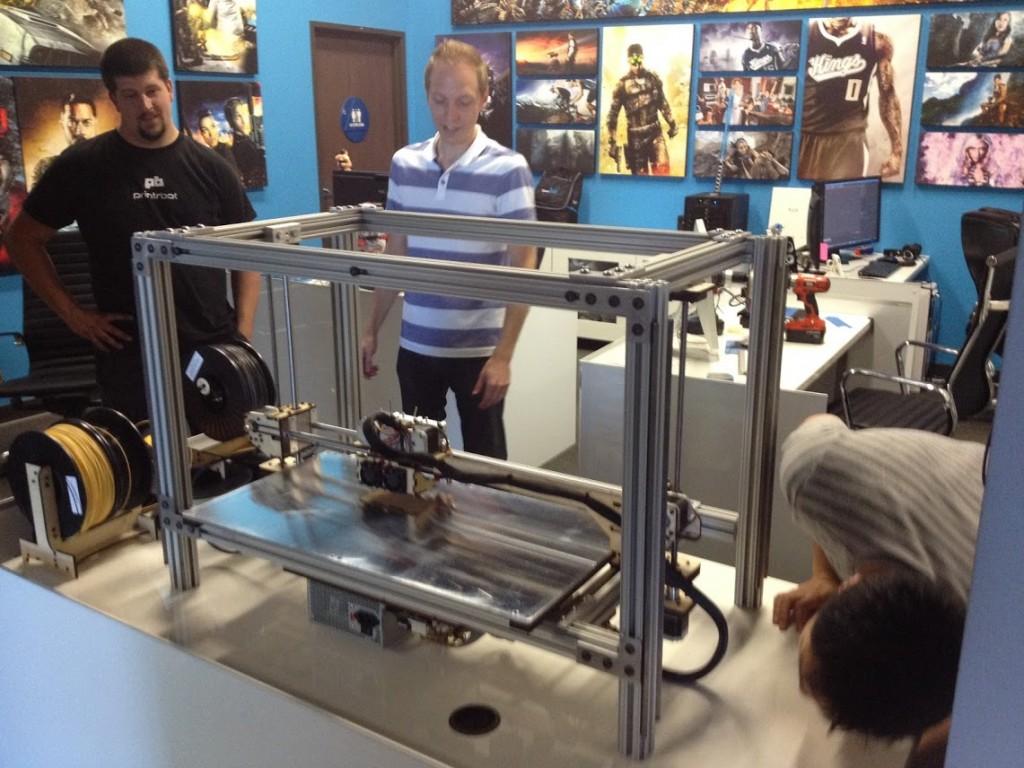

Our company is engaged in the development and production of large 3D printers according to your specifications One of the latest printers has a print area of 0. 5x1.0x1.0 meters. That's right, its print area is half a cubic meter. At the same time, a large 3D printer prints with popular polymers with low shrinkage - PLA, PETG, SBS and various composite plastics. Composite materials for 3D printing are polymers with a filler, usually carbon fiber is introduced as a filler. This is done to improve the characteristics of the material and reduce the shrinkage of printing large objects.

5x1.0x1.0 meters. That's right, its print area is half a cubic meter. At the same time, a large 3D printer prints with popular polymers with low shrinkage - PLA, PETG, SBS and various composite plastics. Composite materials for 3D printing are polymers with a filler, usually carbon fiber is introduced as a filler. This is done to improve the characteristics of the material and reduce the shrinkage of printing large objects.

The range of applications for large printers is very wide. This includes the printing of various types of large fixtures and holders for various industries, this is the printing of burnt models for casting into ceramic molds, the creation of large-sized prototypes in the development and production of cases, parts and other large objects. This is the creation of structural custom elements for the final assembly - for example, printing bumpers, fairings, consoles, panels and other elements to create a unique car design. Widely large 3D printers are used to print design elements, master models for making molds, creating molds and tooling when working with XTS for subsequent casting of alloys.

What are the dimensions of large area 3D printers?

Before designing and manufacturing a large 3D printer to suit your requirements, we first discuss issues related to the type of polymers used - this determines whether you need an enclosed or open printer. Then the dimensions of the print area are specified. We can produce professional printers with print area sizes up to 2.0x2.0x2.0 meters, larger areas are discussed separately. Every 3D printer comes with a warranty. If necessary, our specialist will install the printer and initial training on how to work on it.

For several years, our company has been creating custom-made 3D printers according to the individual requirements of customers. What is it for? Some need a specific print area, others need high quality and accuracy, others need reliability, and others need strictly defined dimensions of the printer.

We also produced industrial 3D printers with a large print area for various types of experimental tasks, for example, for a new granular extruder, which is still being developed. It all depends on the desire of the customer and the tasks facing him in the production of printed products. Someone needs large forms, someone needs to print with experimental high-temperature materials.

It all depends on the desire of the customer and the tasks facing him in the production of printed products. Someone needs large forms, someone needs to print with experimental high-temperature materials.

First, let's dispel the myth - there are no universal large 3D printers. A printer that prints large art objects, such as sculptures or molds for later use, is fundamentally different from a printer that prints structural materials into parts ready for practical use. If you need accurate and beautiful printing of artistic models, then we will manufacture a custom-made 3D printer in Moscow, which will have an open case and will print with common plastics like PLA, PETG, SBS. It is also suitable for printing various forms and toolings that are not used at medium and high temperatures. If you need a printer that prints with engineering plastics, then this is a completely different device - this is an enclosed printer with a thermal chamber. In this case, it is possible to reliably print with high shrinkage resins such as ABS, HIPS, PA6, PA12 nylons.

A very important point when designing a large 3D printer is to take into account the type of extruder, heater, nozzle and printable area used. These parameters determine how accurate and uninterrupted printing will be. In addition, these components directly affect performance. When testing the developed machine, the printing parameters are individually selected - speed, extrusion, profile settings for popular slicers.

For example, we recently built a printer with a printable area of 1x1x1.4 meters using a pellet extruder. Why did we use pellet extruder? Because the customer wanted a print output of 1 kg/h. During testing, we achieved a speed of 1.3 kg / h when printing with a layer of 3mm and a nozzle of 6mm. At the moment, the device we have created is actively used for its intended purpose when printing huge decorative vases. More than a hundred kilograms of granules have already been used, and this is only for 1 month.

Contact us and we will consult in detail on the manufacture of a large custom-made 3D printer according to your requirements, we will select the most suitable configuration for you.

Which industries use large 3D printers?

Machine-building industry - for a long time 3D printers are used for the manufacture of various types of equipment of large sizes. It's that kind parts that are used to fix manufactured products on conveyors in various types of technological processes and in CNC processing. At production of prototypes, not only for fitting, but also quite functional details. In the manufacture of molds and molds. In the injection molding industry production of molds from CTS for subsequent pouring with the required alloy.

Design. In this industry, everything is limited only by the imagination. designer. Large printers print household items, vases, furniture, sinks, bathtubs, fixtures and more. Wide choice of materials and post-processing methods allows you to create finished products without intermediate stages.

Architecture. Printing and restoration of fountains, sculptures, bas-reliefs. You can put an extruder on a large 3D printer that prints ceramics and receive extraordinary sculptures.