3D printer geared extruder

3D Printer Extruders - 3DJake International

Sort byRelevanceBestsellersCustomer ReviewsPrice, Low to HighPrice, High to LowNew arrivalsHighest Discount

-

E3D Hemera Direct Drive Kit - 1.75mm 2 Model types- Practical assembly

- Reliable extruder

- Unique heat sink

-

Creality Titan Extruder Upgrade Kit 3 Model types- Constant extrusion

- Efficient heat dissipation

- No clogging

-

BIQU h3 Extruder- Reduced weight

- Premium brass nozzle

- Unique cooling system

-

E3D Revo Hemera 2 Model types- Including a 0.

4 mm nozzle

- Dual gear extrusion

- Ideal for flexible materials

- Including a 0.

-

Micro-Swiss Direct Drive Extruder for Creality CR-10 & Ender 3 2 Model types- Dual drive gear

- Easy filament loading

- For flexible filaments

-

BondTech Metal Threaded Push-fit Connector 2 Model types- Inexpensive

- Easy installation

- With metal thread

-

BondTech Extruder BMG right- Dual-Drive

- Adjustable tension

- Versatile use

-

Micro-Swiss Bowden Dual Gear Extruder- Reliable and firm filament grip

- More accurate extrusion movements

- CNC precision gears

-

BIQU IDEX Upgrade Kit 2 Model types- Print twin models

- Multi-material

- More efficient

-

Micro-Swiss Direct Drive Extruder for Creality Ender 5 2 Model types- Dual drive gear

- Easy filament loading

- Perfect for flexible filaments

-

Phaetus Apus Extruder- With a Nema stepper motor

- Dual drive gear

- Stable extrusion

-

E3D Revo Hemera Upgrade Kit 2 Model types- Including a 0.

4 mm nozzle

4 mm nozzle

- Quick nozzle change

- Dual gear extrusion

- Including a 0.

-

Qidi Tech Extruder 5 Model types- Original spare part

- Available for different printers

-

Micro-Swiss Extension Cable for Direct Drive Extruders- 67 cm long

- Inexpensive replacement

-

Micro-Swiss CNC Extruder Plate for Wanhao i3- Made from Aluminium

- No adjustment work necessary

-

BondTech LGX PA12 Fan Shroud- For LGX extruders

- Compatible with the Artillery Sidewinder X1

- Compact design

-

E3D Revo Hemera Upgrade Full Kit 2 Model types- Incl.

4 Revo nozzles (0.25 mm, 0.4 mm, 0.6 mm, 0.8 mm)

4 Revo nozzles (0.25 mm, 0.4 mm, 0.6 mm, 0.8 mm)

- Quick nozzle change

- Dual drive gear extrusion

- Incl.

-

BondTech LGX Lite Large Gear Extruder- For 1.75 mm filament

- Raised filament handle

- Easy maintenance

-

Micro-Swiss NG Direct Drive Extruder for Creality CR-10 and Ender 3 series- 3:1 gear ratio

- Hardened steel dual gear drive

- Short filament path

-

BondTech LGX B for Anycubic Mega X 1 set- Easy installation

- Strong filament grip

- Compact and light

-

BondTech Drivegear Kit 1.75 mm 2 Model types- CNC machined

- Made of hardened steel

-

BondTech IFS Extruder for the Prusa Mini- Compatible with the filament sensor

- Hardened drive gears

- Adjustable tension

-

BondTech LGX Extruder 1 set- Larger drive wheels

- Multifunction interface socket

- Light and symmetrical design

-

Artillery Direct Drive Extruder Assembly 2 Model types- Original spare part

All prices incl. VAT.

VAT.

The 5 Best 3D Printer Extruders in 2022 – Clever Creations

3D printer extruders nowadays are as diverse as the printers themselves. You can find them in various shapes and sizes, with many extruders being specific only to particular 3D printers. A high-quality extruder will deliver consistent and predictable results that will help you get the best-looking 3D prints.

Direct and Bowden extruders are the two major types you can find in hobbyist FDM 3D printers. Each type has its benefits and is best suited for different situations.

In this article, we will explore these differences and go over top extruders that you can build or upgrade your 3D printer with. Read on to find out which is the best 3D printer extruder for your 3D printing workflow.

| 3D Printer Extruder | Extrusion System | Gear Ratio | Filament Size(s) | Price (~) | Best Offer |

|---|---|---|---|---|---|

| E3D Hemera | Direct / Bowden | 3. 32:1 32:1 | 1.75 mm | $118 | E3D |

| Bondtech BMG | Direct / Bowden | 3:1 | 1.75 mm | $89 | Amazon |

| E3D Titan | Direct / Bowden | 3:1 | 1.75 mm / 2.85 mm | $60 | E3D |

| Micro Swiss Direct Drive Extruder | Direct | 1:1 | 1.75 mm | $100 | Amazon |

| BIQU h3 | Direct | 7:1 | 1.75 mm | $90 | BIQU |

Image: Jona via Wikipedia, CC BY-SA 4.0

A 3D printer extruder is the part of an FDM 3D printer that melts and pushes out plastic filament to create the three-dimensional object. The extruder consists of various grouped parts.

The first group of components is called the cold end.

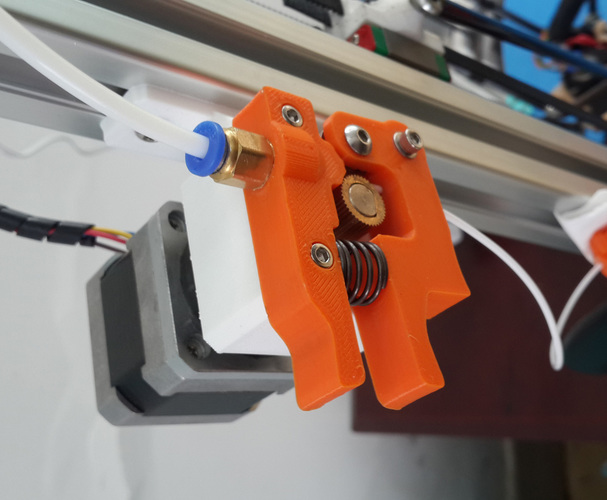

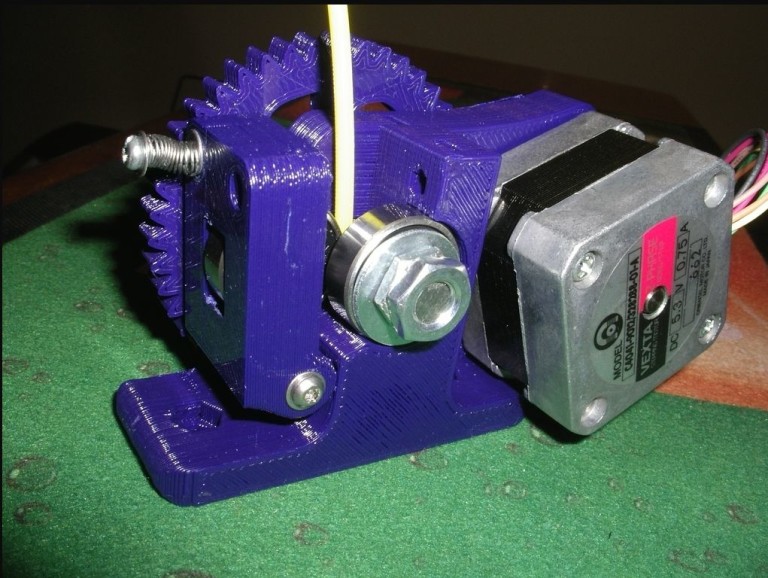

The cold end consists of a mechanism designed to pull your filament from one end and push it out of another while firmly grasping it. The majority of the 3D printer extruders utilize a system of gears and a pulley combined with a spring-loaded arm to accomplish this function.

The majority of the 3D printer extruders utilize a system of gears and a pulley combined with a spring-loaded arm to accomplish this function.

The second group is the hot end. It consists of various components, like the heat break, heater block, and nozzle.

The 3D printer filament is pushed through the heat break by the cold end until it reaches the heater block. The 3D printer filament is then melted by the heat produced by the heater and pushed out through a nozzle where it solidifies to create your 3D printed object.

The best 3D printer extruders will let you reliably 3D print at high speeds with various materials without affecting the print quality.

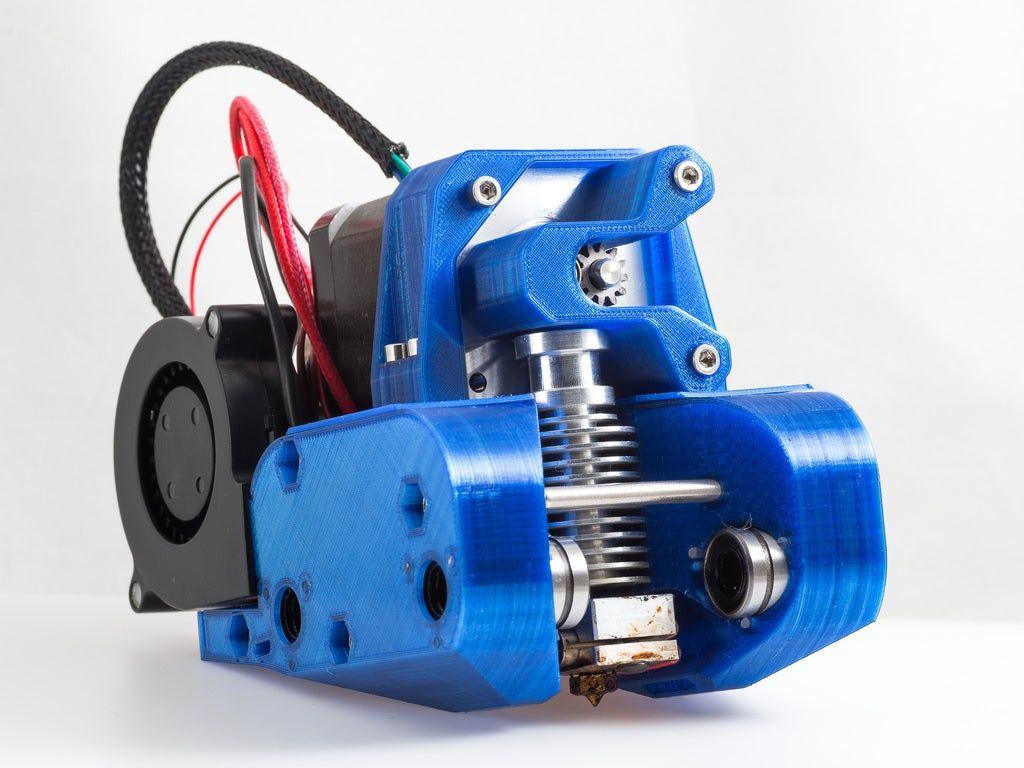

3D Printer Extruder TypesDirect Extruder

Image: Prusa3D

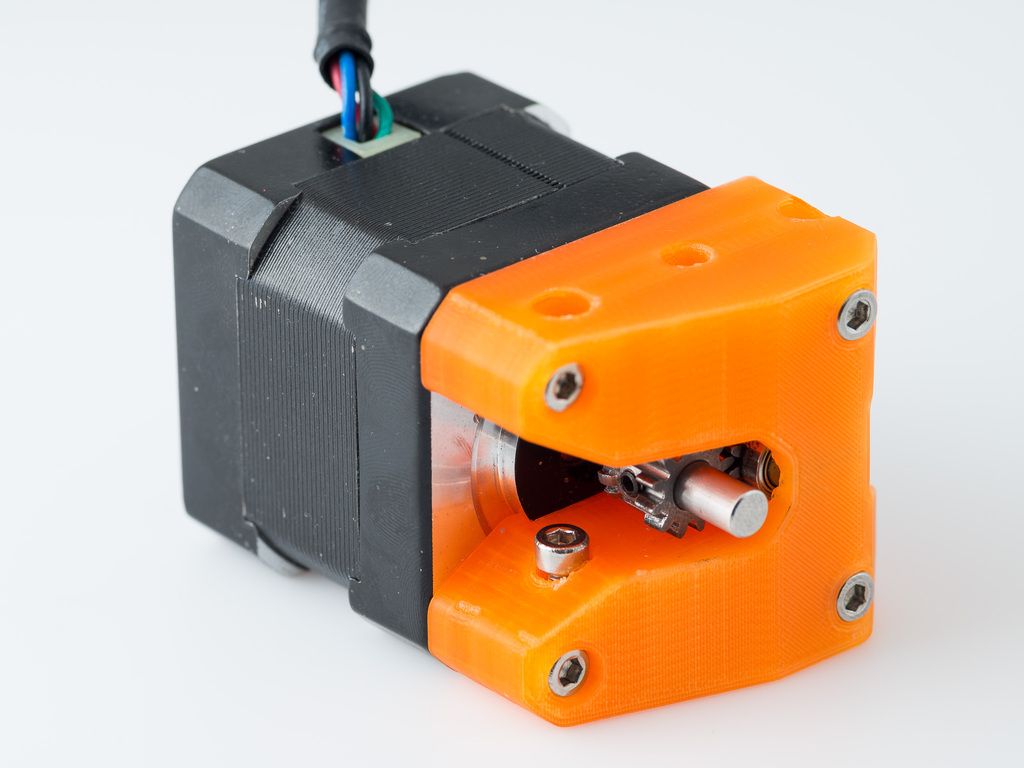

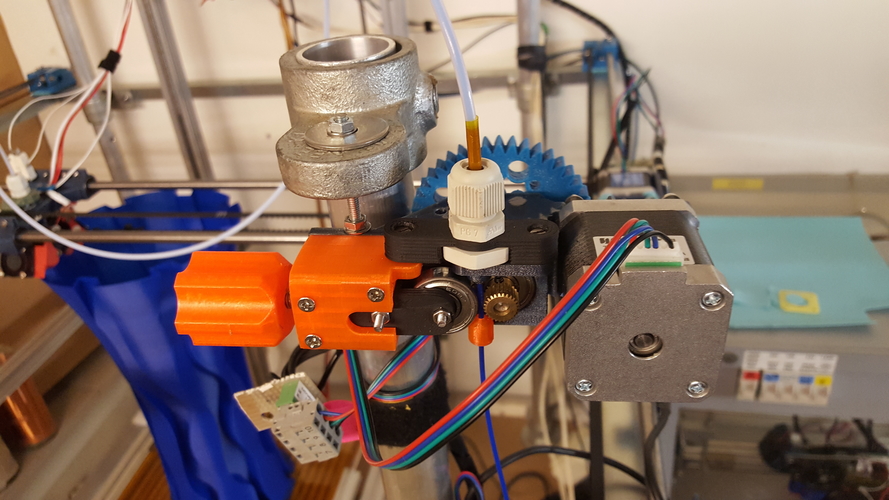

You can easily recognize a direct extruder system by looking at the 3D printer extruder. In a direct extruder setup, the extruder motor sits right on the top of the hot end and moves along with it. It allows for a short filament path, resulting in better retraction properties and better print quality.

Direct extruders are known to be compatible with flexible filaments, which are filaments that Bowden extruders (see the next section) have trouble with.

However, this kind of setup leads to a bulky hot end design. It increases the overall mass of the print head and forces you to print at lower speeds. And because the 3D printer extruder sits on top of the cold end of your printer head, it reduces the overall Z-height of your printer.

Pros:

- Good retraction control

- Consistent and predictable extrusion

- Wide material compatibility

Cons:

- Heavy print head, low print speeds

- Reduces maximum print height

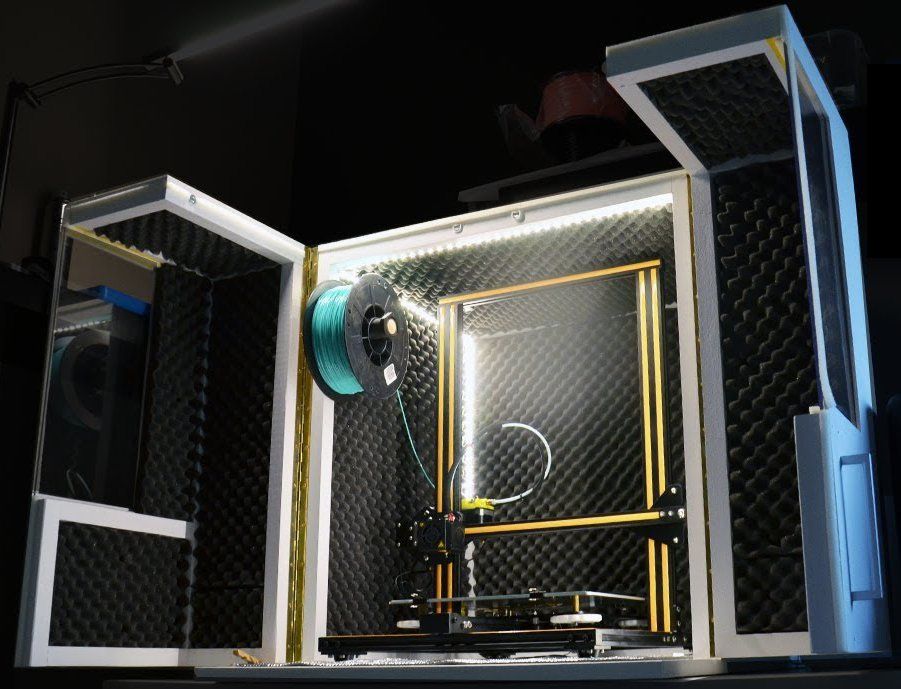

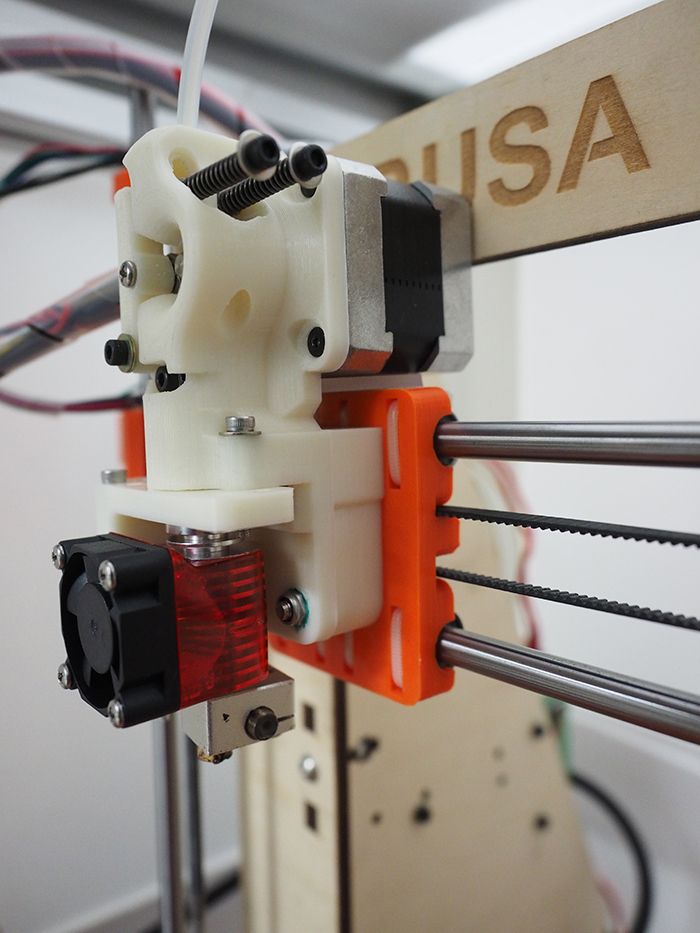

Image: jaybro187 via Reddit

Bowden extruders have their cold end mounted onto the 3D printer’s frame instead of above the hot end. The filament is then fed through a PTFE tube from the cold to the hot end.

This setup allows for a light print head and 3D printing at higher speeds without encountering print issues like ghosting and ringing

The lightweight design of a Bowden setup is best suited for a Delta 3D printer or dual extrusion 3D printer due to their unique construction and movement. However, you can find Bowden extruders in many budget 3D printers, as they allow for a simple print head design and increased print height.

One of their main downsides is that 3D printers with a Bowden extruder have a longer distance for the filament to travel. This can cause issues with retraction and lead to more stringing.

Pros:

- Lightweight and compact design

- Allows for fast print speeds

- Easy to access and fix issues

Cons:

- Needs fine-tuning of retraction settings

- Difficult to print with flexible materials

- Requires high power stepper motor

Image: E3D

Typical budget 3D printer extruders utilize a direct drive system. In a direct drive system, the filament drive gear is directly attached to the stepper motor shaft without gearing. This setup allows for a cheap and straightforward design.

In a direct drive system, the filament drive gear is directly attached to the stepper motor shaft without gearing. This setup allows for a cheap and straightforward design.

One downside, however, is that the extruder requires a high-powered stepper motor. On non-Bowden extruders, this means a lot of extra weight that has to be moved around. Not ideal.

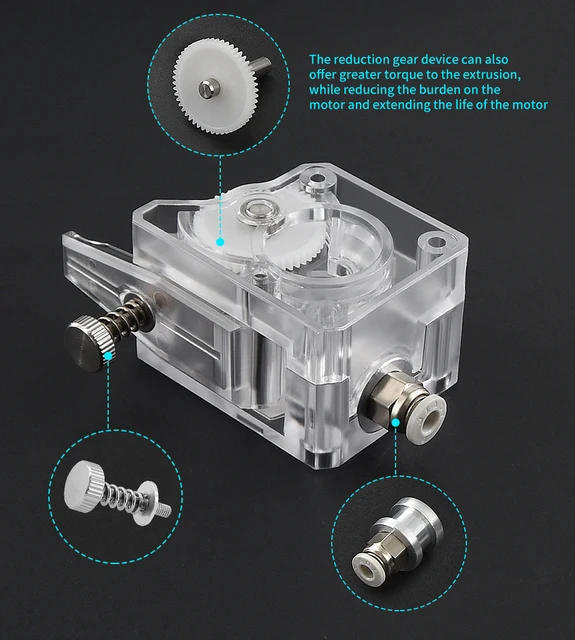

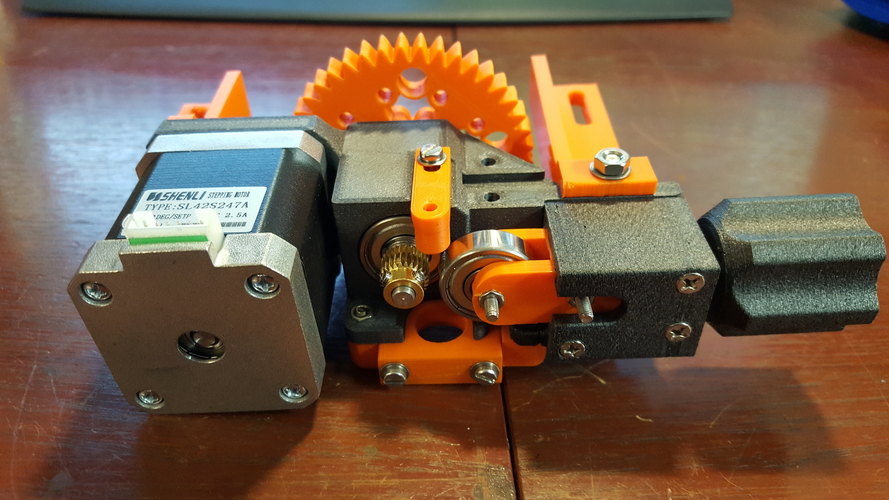

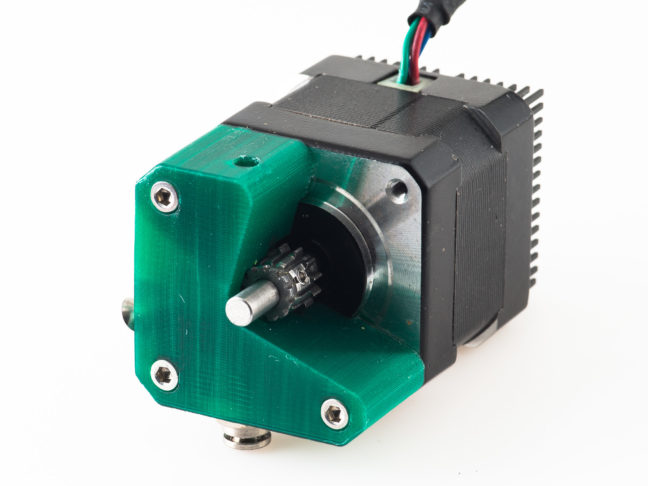

This is where geared extruders come into play. A geared extruder uses a gear mechanism to increase torque. This gives the 3D printer extruder a better grip over the filaments, resulting in a more controlled filament flow.

Because the gear system increases torque, a smaller stepper motor can be used. This results in a more lightweight and compact setup that is ideal for direct extruders.

Pros:

- Produces high torque

- Compact size

- Suitable for both Bowden and direct extrusion setups

Cons:

- Can be expensive

- Complicated internal mechanism

Because of their similar terminology, direct and direct drive extruders sometimes get mixed up. Here are some tips to tell them apart:

Here are some tips to tell them apart:

- A direct drive extruder has its drive gear mounted directly to the stepper motor shaft. It is the opposite of a geared extruder.

- A direct extruder has its cold end mounted directly above the hot end. It is the opposite of a Bowden extruder.

If a 3D printer extruder has its drive gear mounted to the stepper motor shaft and the cold end is installed directly above the hot end, it is both a direct and a direct drive extruder.

The Best 3D Printer Extruders in 2022

E3D Hemera

Best Direct Extruder

Check Price

AmazonE3DMatterHackers

The E3D Hemera is one of the most powerful extruders available on the market today. It uses a dual drive gear system that gives you almost 100 N of pushing force on the filament, allowing for high-extrusion rates without stripping the filament.

The high pushing force makes the Hemera a great 3D printer extruder for large 3D printers that require high flow rates. It comes with a T-slot mounting system that lets you easily design and mount the extruder on virtually any 3D printer. Moreover, it is compatible with the whole system of E3D hot ends and nozzles.

It comes with a T-slot mounting system that lets you easily design and mount the extruder on virtually any 3D printer. Moreover, it is compatible with the whole system of E3D hot ends and nozzles.

The E3D Hemera is available in both direct and Bowden extruder setups, making it difficult to find a 3D printer that it does not work with.

Regardless of whether you already use the E3D eco-system, the E3D Hemera 3D printer extruder is great if you are looking for a reliable and high-performance cold end.

Standout Features

- Over 100N of pushing force

- Optimized airflow circulation

- Wide printer compatibility

Technical Details | |

|---|---|

| Extrusion type | Direct and Bowden |

| Filament diameter | 1.75 mm |

| Gear ratio | 3.32:1 |

| Weight | 388 grams (Direct) 327 grams (Bowden) |

What We Like

- Excellent for printing flexible filaments

- Easy mounting system

- High flow rate

Could Be Better

- Bulky design

- Requires fine-tuning

Find E3D Hemera at

AmazonE3DMatterHackers

Bondtech BMG

Lightest Extruder

Check Price

AmazonMatterHackers

The Bondtech BMG extruder is a geared 3D printer extruder with a gearing ratio of 3:1. It is designed to be compact while still offering you excellent grip on the filament. The extruder weighs only 75 gms (0.16 lbs), making it one of the lightest extruders available.

It is designed to be compact while still offering you excellent grip on the filament. The extruder weighs only 75 gms (0.16 lbs), making it one of the lightest extruders available.

It has an adjustable tensioner system that lets you fine-tune the tension of the drive gears on the filament. It gives you complete control over the filament feed and is compatible with multiple materials. Its quick-release mechanism, too, is designed for fast material swaps bringing down your printer operation times.

The extruder comes with an SLS printed housing that guarantees strength and precision. Its most notable drawback is its lack of compatibility with 2.85 mm filaments, but considering that 1.75mm filament is the standard nowadays, that won’t be a problem for most users.

If you’re looking for a compact, lightweight solution for your delta or other high-speed printer, the Bondtech BMG is probably the best 3D printer extruder for you.

Standout Features

- Lightweight and compact design

- High gripping force

- SLS 3D printed extruder housing

Technical Details | |

|---|---|

| Extrusion type | Direct and Bowden |

| Filament diameter | 1. 75 mm 75 mm |

| Gear ratio | 3:1 |

| Weight (without stepper) | 75 grams |

What We Like

- Easily adaptable to any 3D printer

- Adjustable tensioner screw

- Suitable for printing abrasive filaments

Could Be Better

- Does not include Bowden adapter

Find Bondtech BMG at

AmazonMatterHackers

E3D Titan

Best Geared Extruder

Check Price

AmazonE3DMatterHackers

The E3D Titan is another compact geared extruder designed for fast printing speeds. It comes with a translucent case design that gives it a unique look and its durable materials make it a highly reliable extruder.

The Titan extruder comes with a 3:1 gear ratio, similar to the Bondtech extruder. One big difference is that the Titan is also compatible with 2.85 mm filaments, which makes it a truly versatile 3D printer extruder. Another difference is that the gears on the E3D Titan have a self-cleaning tooth profile, so you don’t have to worry about any ground-up filament getting stuck.

Another difference is that the gears on the E3D Titan have a self-cleaning tooth profile, so you don’t have to worry about any ground-up filament getting stuck.

You can expect high print quality at low layer heights and minimized issues during extensive retraction cycles. The Titan extruder is compatible with many RepRap 3D printers and is known for its simplicity and high-quality extrusion.

It is an excellent alternative to the Bondtech extruder, albeit a bit heavier. If you can stand the extra weight, the E3D Titan will give you excellent results at a comparatively lower price.

Standout Features

- Self-cleaning hobbed gear teeth

- Small form factor

- Lightweight construction

Technical Details | |

|---|---|

| Extrusion type | Direct and Bowden |

| Filament diameter | 1.75 mm and 2.85 mm |

| Gear ratio | 3:1 |

| Weight (without stepper) | 125 grams |

What We Like

- Easy filament changes

- Compatible with virtually any 3D printer

- Great for printing at low layer heights

Could Be Better

- Comes without mounting bracket

- Comes without Bowden adapter

Find E3D Titan at

AmazonE3DMatterHackers

Micro Swiss Direct Drive Extruder

Best Extruder for Ender 3

Check Price

AmazonMatterHackers

The Ender 3 is one of the most popular and widely used 3D printers. However, it comes with a Bowden extrusion setup that limits its material compatibility. The Micro Swiss extruder solves this by giving you a plug-n-play direct extruder system for the Ender 3.

However, it comes with a Bowden extrusion setup that limits its material compatibility. The Micro Swiss extruder solves this by giving you a plug-n-play direct extruder system for the Ender 3.

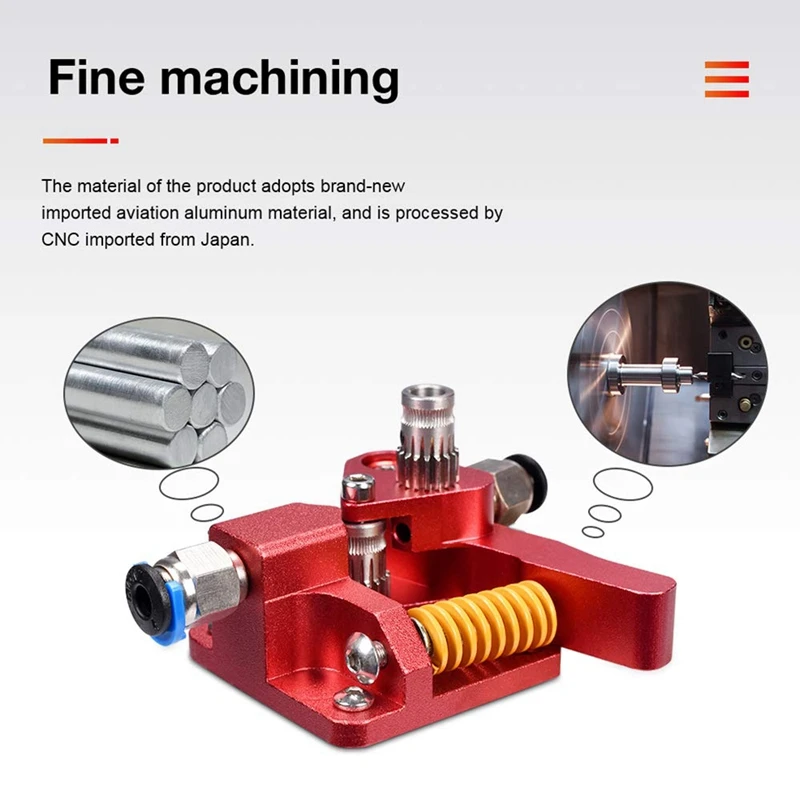

The Micro Swiss extruder setup comes with an all-metal hot end, brass nozzle and a bracket that lets you easily install the extruder on your Ender 3. It has a lightweight aluminum body, and CNC machined gears to allow precise and predictable extrusion. The spring-loaded tensioner arm lets you adjust the filament grip and enables you to load the filament quickly.

You get a detailed guide that helps you throughout the installation process, ensuring you get everything right. However, you’ll need to do some tweaking to get the best print results with this setup.

Overall, the Micro Swiss extruder is an excellent Ender 3 upgrade that lets you print with different filaments and helps you get an improved print quality.

Standout Features

- Plug-and-play design

- Adjustable filament grip

- Hardened tool steel gears

Technical Details | |

|---|---|

| Extrusion type | Direct |

| Filament diameter | 1. 75 mm 75 mm |

| Gear ratio | 1:1 |

| Weight | N/A |

What We Like

- Easy mounting system

- Dual drive train for better grip

- Constrained filament path

Could Be Better

- Bulky design

- Limited printer compatibility

Find Micro Swiss Direct Drive Extruder at

AmazonMatterHackers

BIQU h3

Check Price

AmazonBIQU

The BIQU h3 is a dual gear extruder system with a high-temperature hot end. It has a 7:1 gear ratio on the extruder, offering you a superior grip on the filament with a relatively small stepper motor.

You get stainless steel gears precisely machined to reduce filament jams and prevent hot end clogging issues. The extruder body includes a streamlined heat dissipation structure that directs the heat away from the nozzle, easily letting you print for extended hours at high temperatures.

It is designed to be fitted on most hobbyist 3D printers like the Creality, Anycubic, and Geetech machines. The BIQU h3 is a well-built hot end, and at a price of less than $100, it offers excellent value by giving you high-temperature printing capabilities with a direct extruder setup. It is ideal for users who want a good quality extruder-hot end set up at a budget price.

Standout Features

- Dual gear extrusion

- Optimized heat dissipation system

- High gear ratio

Technical Details | |

|---|---|

| Extrusion type | Direct |

| Filament diameter | 1.75 mm |

| Gear ratio | 7:1 |

| Weight | 211 grams |

What We Like

- Low cost

- Compatible with various budget 3D printers

Could Be Better

- Short cable wire length

- Not an all-metal design

Find BIQU h3 at

AmazonBIQU

What to look for when buying a 3D printer extruder?Direct or BowdenAs discussed earlier, both Bowden and direct extruder setups have their pros and cons. Direct extruders work with more materials and offer better extrusion quality. However, they do come with the extra mass on the print head and reduce maximum print times.

Direct extruders work with more materials and offer better extrusion quality. However, they do come with the extra mass on the print head and reduce maximum print times.

Alternatively, a Bowden setup results in a lightweight print head by fixing the cold end to the 3D printer’s frame. It allows for high-speed 3D printing without the mass of a direct extruder. Bowden extruders also increase maximum print volume.

The downsides of Bowden extruders are that it is hard to get good extrusion results with flexible materials, and you need a larger motor to overcome the increased friction in the filament path.

Because the path from the cold end to the hot end is longer, the filament has to travel a greater distance before it is finally melted and extruded. This often results in poorer 3D print quality.

If you have a Delta printer or want to 3D print at high speeds on a CoreXY 3D printer, a Bowden extruder system is ideal. An independent dual-extrusion system (IDEX) on dual extruder 3D printers also benefits from a Bowden setup’s lightweight and compact form factor.

On the other hand, if you regularly print with flexible materials and need a more reliable and consistent 3D printer extruder setup, direct-drive extruders will give you a consistent print quality. However, you will need to limit your print speeds, to avoid ghosting and ringing issues in your prints.

TorqueThe force required to drive your filament through the 3D printer’s hot end is referred to as torque. The amount of torque an extruder can produce is determined by its gearing and the size of its stepper motor.

Geared 3D printer extruders have a higher gear ratio, which results in more torque. A 3D printer extruder with a 3:1 gear ratio will produce 3 times more torque than an extruder with a 1:1 gear ratio (assuming the same stepper motor and drive gear).

If an extruder doesn’t have enough torque, the filament will slip, and you’ll see artifacts in your 3D prints.

A typical NEMA 17 stepper motor coupled with an ungeared extruder will give you a maximum of 8. 4N of torque. It is sufficient for basic 3D printing at 30-60 mm/s printing speeds.

4N of torque. It is sufficient for basic 3D printing at 30-60 mm/s printing speeds.

But you need to remember that a higher gear ratio comes at the cost of a lower maximum RPM of the extruder motor. In the case of extruders like the BIQU h3, the 7:1 gear ratio will give you a lot of pushing force, but with a lower maximum print speed.

In the end, it is all about balance. If you need a small extruder for your direct extrusion 3D printer, the Bondtech BMG and E3D Titan will help you get a better balance between print speeds and torque with their 3:1 gearing ratio.

Filament diameterTwo standard filament diameters are used in 3D printing: 1.75 mm and 2.85 mm (3 mm). While 3D printer manufacturers have started to standardize on 1.75 mm filament, there are 3D printers that still work with the 2.85 mm diameter.

When choosing the best 3D printer extruder for your needs, you need to make sure that the 3D printer extruder you’re buying is compatible with the filament diameter you want to use. Some extruders can work with both diameters, while others are only designed for a specific one.

Some extruders can work with both diameters, while others are only designed for a specific one.

In this roundup, the E3D Titan extruder is the only one compatible with both the filament diameters.

WeightThe weight of an extruder plays a crucial role in the 3D printer’s mechanics. It influences both the design and the maximum printing speed of the 3D printer.

A lightweight extruder will have less inertia and let you print at higher speeds, even in a direct extruder setup. A heavy 3D printer extruder will limit your printing speeds unless you are willing to sacrifice the quality of your printed models.

The Bondtech and the E3D Titan are some of the most lightweight extruders suited for both Bowden and direct extrusion systems. These will let you print at high speeds and deliver consistent print quality with minimal issues during the printing process.

Frequently Asked Questions

How many extruders can a 3D printer have?

There’s no one-size-fits-all answer to this question, as the number of extruders a 3D printer can have depends on the specific model and make of the printer.

However, most 3D printers on the market today generally have either one or two extruders. In the case of two extruders, the machine is called a dual extruder 3D printer.

Some high-end commercial printers may have more extruders (four or more), but for the average home user, most 3D printers will have either one or two.

The benefits of having more extruders include the ability to print with multiple colors or materials and to print faster. However, more extruders also mean that the printer is more expensive and difficult to maintain. Ultimately, it is up to the user to decide whether they need a printer with multiple extruders or not.

How much does a 3D printer extruder cost?

Prices for 3D printer extruders vary depending on the type and quality of the extruder. Generally, extruders range in price from around $50 to $200.

Some of the more expensive extruders are made with better materials and offer more precise control over the printing process, while cheaper extruders may be less reliable or produce lower-quality prints.

How long does a 3D printer extruder last?

You are unlikely to have to replace any extruder components with regular use, aside from the nozzle. You can expect to swap out the nozzle every 6 to 12 months for the best results, but more frequently if you often 3D print abrasive filaments.

Where is the extruder on a 3D printer?

On direct drive extruders, the extruder is mounted on top of the 3D printer hot end. On a Bowden extruder, it is often mounted on the frame of the machine to reduce the moving mass.

Is a direct extruder on a 3D printer better than a Bowden extruder?

Yes, a direct extruder is generally better than a Bowden extruder, especially for flexible filaments. A direct extruder is attached directly to the motor, whereas a Bowden extruder uses a drive shaft to push the filament through a tube to the hot end.

The main advantage of a direct extruder is that it has less resistance than a Bowden extruder, which means that it can push filament through faster and with more force. This is important because flexible filaments are prone to tangling and jamming, so it’s critical that the printer can push them through quickly and without any resistance.

This is important because flexible filaments are prone to tangling and jamming, so it’s critical that the printer can push them through quickly and without any resistance.

Even for non-flexible filaments, a direct drive extruder gives better results than a Bowden extruder. Assuming it has been properly calibrated.

Are all 3D printer extruders interchangeable?

3D printer extruders are typically not interchangeable, but an extruder upgrade is often possible with some modification. This does require a degree of skill and knowledge to complete successfully. Without proper skills and understanding, it is possible to cause serious damage to your 3D printer.

Can you convert a 3mm extruder to a 1.75 mm extruder?

Technically, it is possible to convert a 3mm extruder to a 1.75 mm extruder. However, it is not a simple process and will require some engineering skills. You will likely need to modify the hot end and the cold end feed mechanism in order to make them compatible with 1. 75mm filament.

75mm filament.

Additionally, you may need to adjust the printer’s firmware in order to get proper calibration and functionality with the new extruder. Overall, it is a complicated process that is unlikely to be worth it compared to simply swapping out the extruder and hot end with 1.75mm variants.

Conclusion

A high-quality 3D printer extruder can mean the difference between a good print and an excellent 3D print. If you are building a 3D printer or want to do an extruder upgrade, It is important to consider the different extrusion systems. Then choose the one that offers you the best print quality without sacrificing print speeds.

Considering all the criteria, the E3D Titan extruder is the overall best 3D printer extruder on the list. It is compatible with various 3D printers, has excellent material compatibility, and is well-known to deliver consistent and reliable print quality.

However, it is an old design and lacks some of the advanced features of the newer extruders. This is where the E3D Hemera and the Bondtech BMG extruder come out as great alternatives to the Titan. The E3D Hemera is one of the most powerful extruders with a unique and practical design. In contrast, the Bondtech extruder gives you the advantages of a lightweight 3D printer extruder setup.

This is where the E3D Hemera and the Bondtech BMG extruder come out as great alternatives to the Titan. The E3D Hemera is one of the most powerful extruders with a unique and practical design. In contrast, the Bondtech extruder gives you the advantages of a lightweight 3D printer extruder setup.

Let us know your thoughts on the list and if you’ve used any of these extruders. If there’s anything else you’d like to see in the article, feel free to comment below.

Light Orbiter Extruder for 3D Printer

top sellers

-

Bearing 604UU U604ZZ

U-bearing U604ZZ 604UU 4*13*4

35.00 UAH

-

Thermal mat for 3D printing 200 x 200 mm

3D printing thermal pad

150.

00 UAH

00 UAH -

Buy epo3d+ 3D printer

Epo3d+ Ukrainian FDM 3D printer on HIWIN rails. Thanks to reliable...

UAH 35,000.00

-

ABS granules

ABS granules for extrusion

400.00 UAH

-

PLA

PLA environmental plastic from Plexiwire. 100% advance payment....

UAH 375.00

-

Buy ABS plastic (ABS)

ABS plastic from Plexiwire.

100% prepayment. Free shipping...

100% prepayment. Free shipping... UAH 220.00

-

Mini motor reducer 12v 100 rpm

high torque mini electric motor. Its size...

150.00 UAH

-

Nozzle for 3D printer 1.75 mm, for E3D and MK8 hotends

3D printer nozzle 1.75 mm 0.2/0.3/0.4/0.5

35.00 UAH

-

PETG plastic for 3D printer

PETG plastic from Plexiwire. 100% prepayment. Free...

UAH 360.00

-

SHF-20 shaft support

SHF-20 shaft support is used for CNC

60.

00 UAH

00 UAH -

A4988 stepper motor driver

35.00 UAH

-

Buy epo3d 3D printer

Ukrainian epo3d 3D printer built on the basis of modern kinematics...

UAH 18,000.00

All best sellers

Information

Lightweight Orbiter Extruder for 3D Printer

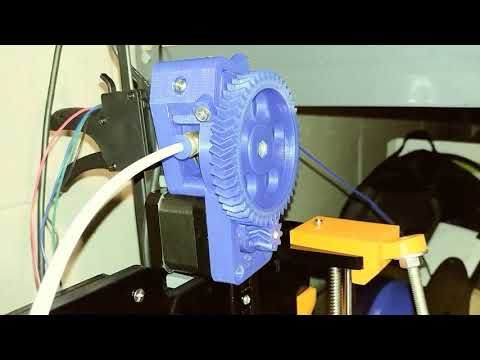

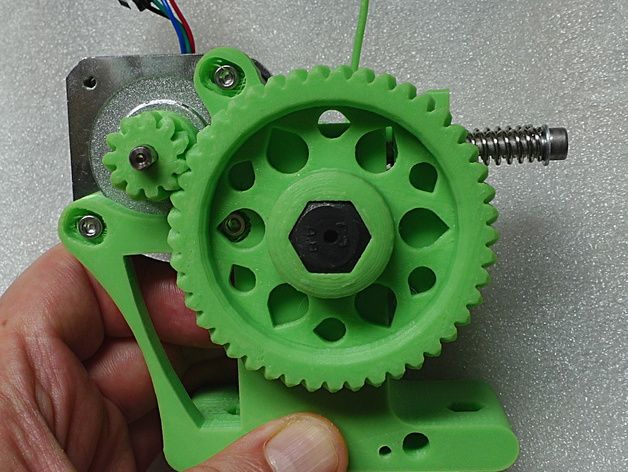

Home 3D printers are constantly being improved and upgraded, and light direct drive extruders have recently appeared. The Orbiter Extruder can set the pace for a newfangled type of particularly light direct drive extruder (DIRECT).

Weighing only 140 grams, this machine is equipped with a 7. 5:1 gearbox capable of pushing filament up to 200 mm/sec. What's more, the Nema 14's gear type and motor give it an overall body size that's smaller than any Nema 17-based extruder. The print samples shown on the Thingiverse project page are clean enough to speak for themselves. The best part is that the project is released as open source under a non-commercial Creative Commons Share-Alike license.

5:1 gearbox capable of pushing filament up to 200 mm/sec. What's more, the Nema 14's gear type and motor give it an overall body size that's smaller than any Nema 17-based extruder. The print samples shown on the Thingiverse project page are clean enough to speak for themselves. The best part is that the project is released as open source under a non-commercial Creative Commons Share-Alike license.

Although this little extruder has only been around since March, it seems to be a big hit with some 3D printer developers. The developers of E3D Toolchangers have also experimented with a planetary gear head. And the Annex-Engineering team just finished several new extruder designs, such as the Sherpa and Sherpa-Mini successors to the Ascender, all derived from the Nema 14 engine, similar to the one used in the Orbiter. Admittedly, with some similarities between the Annex and Orbiter designs, it's hard to tell who inspired whom. However, the result is that modern extruders are getting smaller: smaller stepper motors and a more compact gearbox for a lightweight design.

Equally interesting are the terms of the license: you can faithfully reproduce the design for yourself, provided you don't benefit from it, and you can remix it, but only if you share your creation with the producer. [lorinczroby] has also entered into an agreement with Blurolls Store, an AliExpress seller, where Blurolls sells pre-made versions and a portion of the proceeds is returned to [lorinczroby].

This is a good way to share great open source hardware. With this sales model, users don't have to worry about making mechanically complex parts themselves; they can just buy them. On top of that, the design remains open and subject to change as long as the remixers comply with the terms of the license. In a world where mechanical industrial designers worry about cloning their creations, sharing is a great alternative for others to apply and develop an author's work while sending a tip back.

We were looking for information about those who experimented with such an extruder and here is how one of the enthusiasts on “Tvingiverse” describes his observations:

https://www. thingiverse.com/thing:4223085/files

thingiverse.com/thing:4223085/files

stock gearbox without screw on Ender 3 pro

creality-ender-3

I am new to 3D printing. After a lot of searching for my specific problem (and of course not finding any answers) I decided to lend a hand.

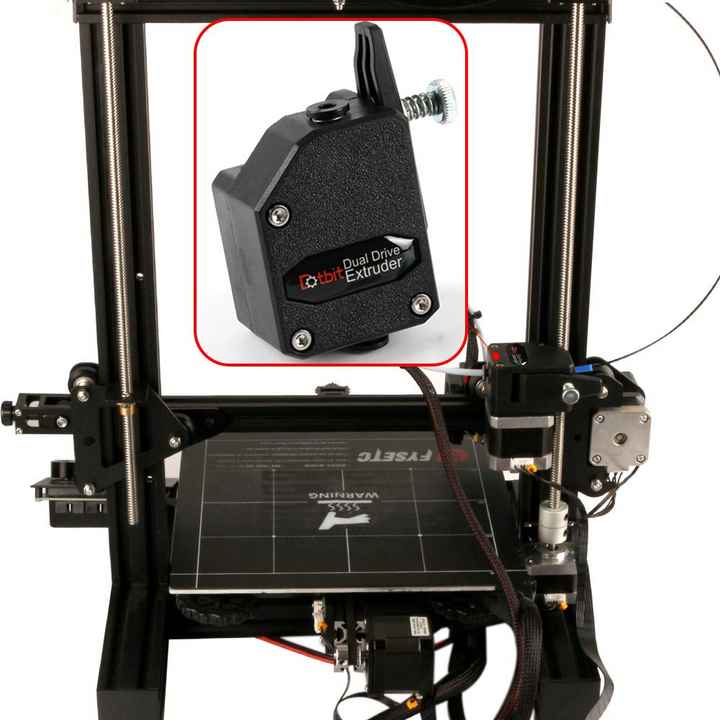

I bought a Creality Ender 3 Pro in November and saw beautiful prints a few days later I decided to upgrade the printer with a glass bed and an "Aluminum Dual Drive Extruder Kit".

The problem, as you might have guessed, is related to the installation of a two-stage extruder. I've watched a dozen YouTube videos and all of them have something I don't have - a screw in a spare gold gear for the extruder motor.

How can I install the Aluminum Dual Drive Extruder Kit if I remove the gear? Should I try to remove it by force? Please, if anyone has come across the same situation that there is no screw in the spare extruder motor gearbox and mange to take it out, please tell me. I'm adding a picture so you can see what I mean.

@ציון לוי, ♥1

Discussion

10 answers

▲ 1

If you do not see any worm screw on the Extruder six, it is quite likely that it was constantly pressed on the engine shaft . It is possible to remove the gear if you have something like a Dremel to cut it off, however be aware that this will be a permanent modification and that your warranty (if you have one) will be voided. If you do go down this path, be careful not to slam the dremel into the motor shaft, as this will most likely result in the new gear not seating properly.

If this is a new printer, I would recommend putting it together with a standard extruder assembly first and ordering a secondary extruder motor without pressing the gear onto its shaft. Then you could swap them and not have to worry about damaging the existing engine.

, @ craftxbox

▲ 1

This brass extruder gear is either press fitted (see other answer) or hot crimped onto the shaft. Brass has about twice the rate of thermal expansion than stainless steel, so you can heat up the gear when the shaft cools (e.g. stepper upside down with the shaft in water, heating the gear with a small lighter, a homemade aluminum foil shield can be used to protect the base stepper) to remove the gear.

Brass has about twice the rate of thermal expansion than stainless steel, so you can heat up the gear when the shaft cools (e.g. stepper upside down with the shaft in water, heating the gear with a small lighter, a homemade aluminum foil shield can be used to protect the base stepper) to remove the gear.

Grinding it would be easier (or even easier to buy a new stepper motor) as when you remove the gear the shaft is round so you need to grind a flat spot on the shaft anyway to make sure the extruder double gear can be tight screwed.

, @ 0scar

▲ 5

This is an older Ender 3 Pro, they came with those gears pressed in at some point, they are not meant to be removed which is a bad design decision. I would recommend buying a new motor than going through the hassle of removing it.

, @ Barrel

▲ 2

Heating it was useless in my case (I didn't have a blowtorch either), I was able to remove the gear with a Dremel and also flattened the small side for the screw.

However, to my extreme disappointment, I found that the actual shaft height was not high enough to reach the dual extruder's filament hole, and so I had to order another motor.

, @ Neo

▲ 5

I had the exact same problem with an Ender 3 Pro I bought a couple of weeks ago (March 2021) and I was able to remove the gear easily with a small gear/bearing puller.. .look on amazon and you will find a lot of choice.

The 3-arm puller works better as it is much more stable when pulling the gear (this is the one I have). Both work the same way; the arms/jaws attach to the bottom of the gear and the tip of the top screw pushes the motor shaft down.

, @ BCD

▲ 3

I had the same problem with gear pressed. With a WD40 and een center impact, the gear came off completely. The next problem was the shaft, which had to be short and perfectly round. With a small grinder (Dremel) I created a flat spot. I gently tapped the shaft on the bottom of the motor until it was sticking out of the top side enough. Now it works great with my dual extruder.

With a WD40 and een center impact, the gear came off completely. The next problem was the shaft, which had to be short and perfectly round. With a small grinder (Dremel) I created a flat spot. I gently tapped the shaft on the bottom of the motor until it was sticking out of the top side enough. Now it works great with my dual extruder.

, @ hensteb

▲ 0

Same problem here. I took it off by force using pliers and a hammer and then drilled a spot on the shaft with an ikea bit. So far everything is working fine.

, @ Eric

▲ 0

I had the same problem. Bought my Ender 3 Pro in July 2021 so not sure if the new or old versions have this issue. I solved the problem a little differently.

I couldn't get the gear out, it was too tight, so I put pliers on top of the gear and then hammered gear down instead of up. Then on top of that I put the gear that came with the dual drive on top of the old gear and screwed it in to match the position of the nozzle. After calibrating the electronic pitch, to my surprise, everything worked and the print was fine.

Then on top of that I put the gear that came with the dual drive on top of the old gear and screwed it in to match the position of the nozzle. After calibrating the electronic pitch, to my surprise, everything worked and the print was fine.

, @ Resat Ilgaz Demirel

▲ 3

I did this with a couple of open wrenches and some heat.

-

Heat the brass end of the gear with a butane torch or MAP gas torch

-

Vise the stepper motor

-

Position two public keys so that you can use the exposed part of one public key under the brass gear, while the second key is perpendicular to the first, below it (photos in the next article will help visualize).

-

Carefully tap the end of the first wrench to release the brass gear

-

Install the new gear, but you will need to grind a small flat on the stepper motor shaft to get the set screw to fit.

The idea is to make a lever out of a single wrench and use impact force to release the gear.

See this article for visuals: Installing Micro Swiss Direct Drive for Creality Ender 3 Pro with 9 Extruder Press Gear0009

, @ skelliam

▲ 1

I picked up a used Ender 3 Pro that I had to work with a lot. I found the same trouble: the extruder "gear" was pressed in, and the shaft was too short for the manual additional wheel. I had a similar motor (with the same connector) in my parts box, so after some effort with 1 I removed the gearbox and installed it on the new motor.

When I am in place, I have enough shaft to install the flywheel. Another note: the connector was the same, but the wiring was not. I had to unplug the windings and move a couple of pins to the female connector. Now it works great and everything is fine (pun intended?).