3D printer calibration prints

Top Ten Calibration Prints for Your 3D Printer

Get the most out of your 3D printer with these calibration tests which are designed to reveal small adjustments you can make to get your 3D prints to really shine.

Updated on November 9, 2022

by

MatterHackers

With this set of 3D models, you can fine-tune your 3D printer to optimize your it's capabilities and get the best 3D printed parts possible. Let's dive in!

Jump To:

- Vertical Surface Test

- Horizontal Finish Test

- Dimensional Accuracy Test

- Overhang Test

- Bridging Test

- Negative Space Test

- Retraction Performance Test

- Support Material Test

- Full Bed Dimensional Accuracy Test

- Z Wobble Test

- Squareness Test

- Download Calibration Models

Vertical Surface Test

This test is designed to look for "ghosting" or “ringing,” where features echo and ring out along vertical surfaces.

As the print head makes a quick movement, it can oscillate, which creates a ring effect.The oscillations diminish on longer lines and the vertical surfaces clear up until a sharp turn is made again. Ghosting can come from a lack of rigidity like a loosely mounted hotend or a wobbly frame, springy belts, printing at high speeds with a heavy direct-drive print head, a bed that isn't rigidly mounted, or firmware settings for acceleration or jerk that are too high for what the printer can achieve.

Some printers can handle high jerk and acceleration, where others will falter and show significant error because of it.

Vertical Surface Test

Horizontal Finish Test

With three different sections - flat, slope, and domed - you are able to see any sort of artifact or ridges from where the perimeters start and end. The more noticeable these points, the lower the score.

Cleaning this up depends on slice settings about perimeters, like start and end overlap, overlap percentage, and where the seam (start/end point of each outer perimeter) is located.

Horizontal Surface Test

Dimensional Accuracy Test

When you're printing coasters and keychains, it doesn't really matter if a part is 0.2mm too wide, but for multi-part prints that need to fit together, the accuracy of each part is very important to keep things fitting properly. Slots for connector pieces can be just fine off of Printer A but too tight to use from Printer B, or holes for nuts and bolts are supposed to allow for easy installation, but require unnecessary force to assemble.

The second level of this pyramid is supposed to be 20mm wide and deep, and loses points based on the average deviation from 20mm; if the average deviation is between 0 and 0.1mm, a full 5 points is earned. If the deviation is between 0.1mm and 0.2mm, 4 points are earned, and so on.

If you get a bad score, you should run through a calibration sequence for your extruder, making sure that your e-steps are accurate. You can find a helpful guide on how to do that here.

Dimensional Accuracy Test

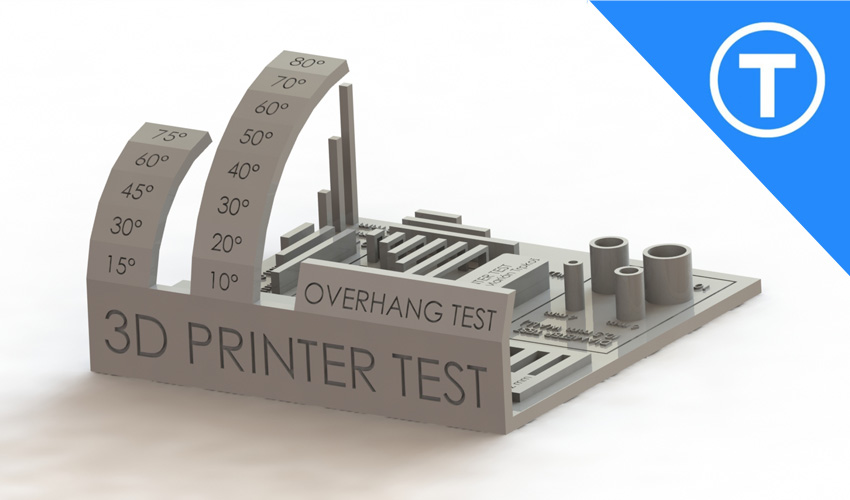

Overhang Test

This test is designed to see how well the printer can cool down the hot plastic as it is extruded; the better the cooling, the cleaner the bottom surface is. Printing speed does affect cooling, so the lower the print speed, the more time for freshly laid down filament to cool before the next layer is ready.

A small print with high print speeds is going to need much more cooling than a large print at slow speeds since material will have only a very brief amount of time to cool enough to solidify.

It is important to consider that the type of fan used for layer cooling (axial vs radial) and the direction your fan outlet is facing will impact how well an overhang is printed, so it would be wise to print this test rotated every 90 degrees to see if some faces fair better than others. You might even consider a new ducting for the cooling fan to try and direct the airflow toward the part.

Drooping, curling, and hanging filament all lower the score, especially when the lower angles have difficulty.

Overhang Test

Bridging Test

Most slicers have the ability to detect bridging, which is where filament needs to cross an unsupported span. Usually the slicer will turn up the layer cooling fan, slow down the print speed, and change how the this section is printed so the span is efficiently crossed with long strands rather than small zigzags.

This bridging test piece tests a bridging condition, but most models won’t have bridges this obvious or long. You can expect to see some minor bridging over holes in the side of a model, over grooves, or over slots for inset nuts.

You get 1 point for each clean bridge.

Bridging Test

Negative Space Test

Much like the dimensional accuracy test, it's important that negative space is accurately replicated. When you're trying to insert screws cleanly without drilling it out or threading the plastic, it's important to know how much extra space you need to model into your part to accommodate. In general, when I need to insert an M3 bolt, I'll model a 3.2mm hole to make sure it slides in easily.

In general, when I need to insert an M3 bolt, I'll model a 3.2mm hole to make sure it slides in easily.

In general, if you precisely calibrate the steps/mm for the extruder, start and end overlap, and seam alignment, you can push out all 5 pins without much force. If there's difficulty removing any of the pins, there’s still something that needs to be calibrated out to achieve tighter tolerances. One point is earned for every pin that can be pushed out.

Negative Space Test

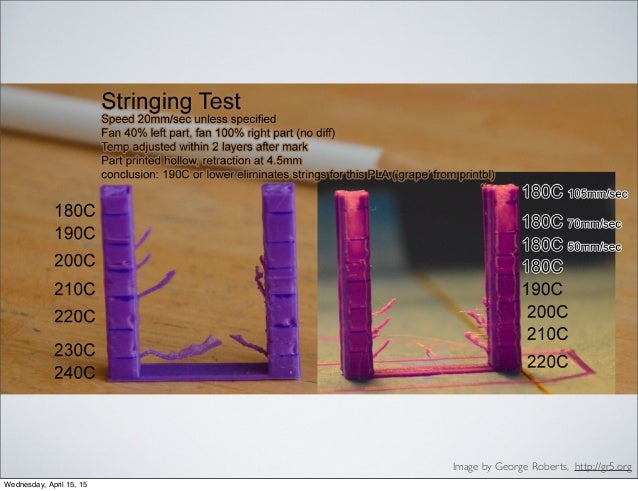

Retraction Performance Test

This test is hard to quantify the difference between a 4 and a 5, but the main thing this is looking for is retraction optimization. This is one of the toughest slice settings to calibrate due to just how many factors affect retraction, like the number of retraction settings, and even things like layer cooling, print speed, extruder style, or even your extruder's ability to extrude and retract without chewing the filament.

Retraction Test

Support Material Test

Whether you're using a dedicated support material like PVA or HIPS or you're using a single extruder printer and using the same material as your support material, it's important to have your support settings calibrated. Same material supports are printed with what's called an "air gap" where the print head rises above the print to create a slight gap between the roof of the support and the bottom of the printed part, giving the filament extra time to cool and droop onto the supports, preventing them from permanently adhering to each other. That air gap is something that needs to be optimized; too small and the supports adhere to the finished print, too large and the bottom surface will be really stringy and droopy until it can recover.

Same material supports are printed with what's called an "air gap" where the print head rises above the print to create a slight gap between the roof of the support and the bottom of the printed part, giving the filament extra time to cool and droop onto the supports, preventing them from permanently adhering to each other. That air gap is something that needs to be optimized; too small and the supports adhere to the finished print, too large and the bottom surface will be really stringy and droopy until it can recover.

Dedicated support materials produce a bottom surface finish almost as clean as the top surface, because they are printed without an air gap since they can be dissolved away. The test model has separate sections for intricate supporting and a flat bottom surface, because an air gap optimized for one may not be enough for the other.

Support Test

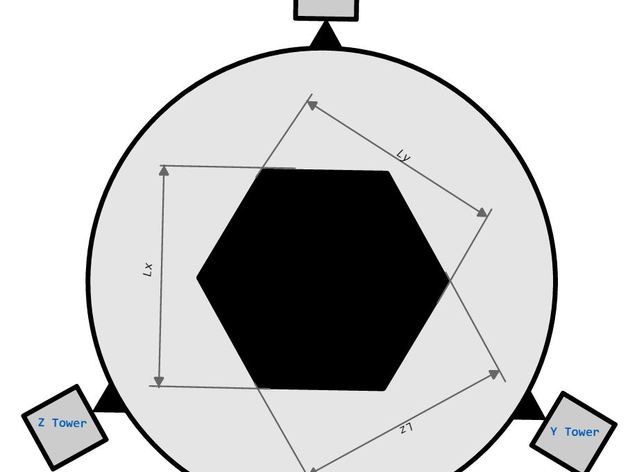

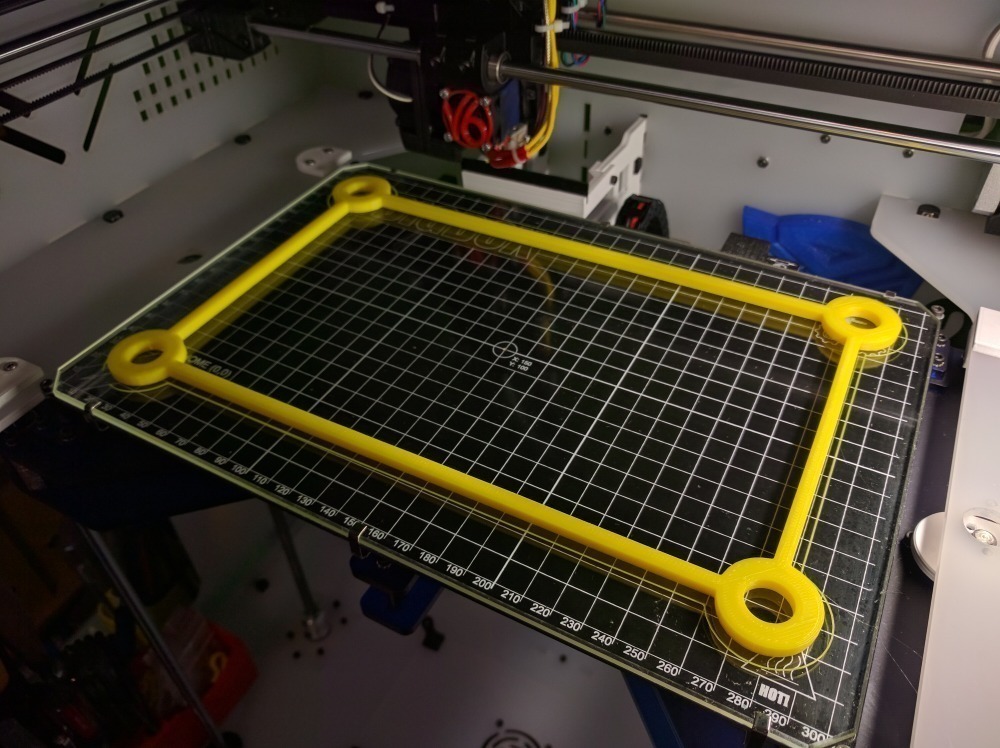

Full Bed Dimensional Accuracy Test

While the dimensional accuracy test checks the accuracy of a fairly small part, this test checks accuracy across the entire bed. A small error in the dimensional accuracy test will compound into a larger discrepancy across the bed, which is 10 times longer than the first test. The smallest difference in expected vs actual measurement just means that any multi-part prints are going to skew depending on the orientation the part was printed in.

A small error in the dimensional accuracy test will compound into a larger discrepancy across the bed, which is 10 times longer than the first test. The smallest difference in expected vs actual measurement just means that any multi-part prints are going to skew depending on the orientation the part was printed in.

Full Bed Dimensional Accuracy Test

Z Wobble Test

Unlike every other test, which uses a scale to grade the proficiency of the 3D printer, this test is simply a pass or fail. The tower has a wide brim to make sure it is well adhered to the bed, and to ensure that any sort of issue in the walls of the tower comes from the printer's structure, and not because it tipped off of the bed. If there is any wobble, it should be cyclical and repeat with a period identical to the pitch of the lead screw attached to the Z axis. If the lead screw had an 8mm pitch, then you should see the pattern repeat every 8mm.

A key thing to watch out for is to make sure that your Z axis is properly constrained and not over constrained. Properly constrained means you have smooth rods, linear rails, or extrusions with V-slot wheels making sure that the Z axis only moves on Z and doesn't shift around. Rods, rails, and wheels should be tensioned or secured so that they don't wiggle or move when the Z axis is raising or lowering. Over-constrained is something like installing bearings at the top of the leadscrews in a support bracket. This is actually counter intuitive, because no lead screw is perfectly straight and adding that bearing causes a deflection in the lead screw. There should in general only be two part interacting with the lead screw: a coupler that attaches it to a motor (or be part of the motor) and a lead screw nut, anything else is overconstraining it and can hurt print quality more than help.

Properly constrained means you have smooth rods, linear rails, or extrusions with V-slot wheels making sure that the Z axis only moves on Z and doesn't shift around. Rods, rails, and wheels should be tensioned or secured so that they don't wiggle or move when the Z axis is raising or lowering. Over-constrained is something like installing bearings at the top of the leadscrews in a support bracket. This is actually counter intuitive, because no lead screw is perfectly straight and adding that bearing causes a deflection in the lead screw. There should in general only be two part interacting with the lead screw: a coupler that attaches it to a motor (or be part of the motor) and a lead screw nut, anything else is overconstraining it and can hurt print quality more than help.

Z Wobble Test

Squareness Test

This test was developed to make sure that the printer's X and Y axis are assembled square with each other; this test will determine if the printhead moves on X, does it move a marginal amount on Y as well, or vice versa. Using an angle gauge, you will measure each of the five squares and determine how far off each corner is from 90 degrees. The further off from 90, the lower the printer's score.

Using an angle gauge, you will measure each of the five squares and determine how far off each corner is from 90 degrees. The further off from 90, the lower the printer's score.

Squareness Test

These are the top ten ...really 11 prints because there's just no way to cut out any one of these, they all serve a very specific purpose that without them you're missing some element of troubleshooting and calibrating your 3d printer to perform at its absolute best. And these are the tests that we run to make sure that the printers that we work with are running at their best as well, so I hope that with these calibration prints you’re better equipped to help calibrate your own 3D printer and getting it to perform at the best that it absolutely can.

All of these calibration prints, collected by Make, can be found in one place on Thingiverse here:

https://www.thingiverse.com/thing:2755063

Happy calibrating!

Article Tags

- 3D Printing

- Firmware

- 3D Design

- MatterControl

- Press Releases

- Small Business

- Automotive

- E3D

- Jewelry Making

- Engineering

- Entertainment Industry

- MatterControl Touch

- ESD Materials

- NylonX

- BCN3D

- Open Source

- Crafty Pen

- Digital Fabrication Anatomy

- How To

- Hardware and Upgrades

- Tips and Tricks

- Weekend Builds

- Top Ten

- Education

- Tech Breakdown

- Women in 3D Printing

- Project Ideas

- Advanced Materials

- Reference

- Pulse Dual Extrusion

- Product Spotlight

- Aerospace

- Jobs

- Military & Government

- Multi-Tool Machines

- Getting Started

- Healthcare

- How To Succeed With Any 3D Printing Material

- Creality3D

- Architecture

- 3D Printer Reviews

- Hacker of the Month

Related Products

View all related productsCalibration - Collections - glitchpudding

by glitchpudding, last updated

Stop, calibrate, and listen. Calibrate your 3D printer with these test prints.(3D printing disasters by tbuser, ravix, and gtg711r.)

Calibrate your 3D printer with these test prints.(3D printing disasters by tbuser, ravix, and gtg711r.)

68274 116563

656 1104

30 71

105 205

7504 11523

170 267

1754 3662

4260 7513

9664 15449

202 399

752 1330

173 281

10 models for 3D printer calibration.

Set up your printer

Set up your printer Before you start printing on a 3D printer, you need to test it. For this, special models are most often used to diagnose and calibrate the device. Next, we will list the top 10 models for calibration, in our opinion.

3D Benchy

Among all 3D printing tests, the flagship is 3D Benchy. This model is a boat that can test everything from protrusions to extrusion. If you want to test your 3D printer, then the benches will help you determine the optimal settings for the ideal result. On Thingiverse, more than three thousand users posted photos with their samples, and the boat itself was printed by more than a hundred machines and no fewer materials.

Model reference

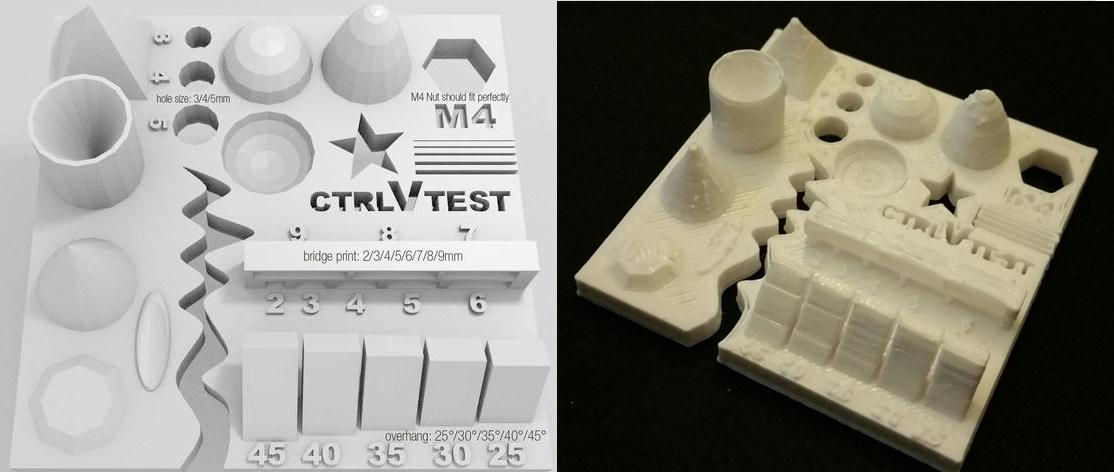

All-In-One

A very interesting model, which is called “all-in-one”. Everything is represented in the model: canopy, bridge, string, temperature and belt tension test, extrusion. This is an ideal model for testing the device at several levels at once. A manual is included with the model to help you troubleshoot any issues you find. On Thingiverse, more than 75 users have posted test results on different 3D printers and different materials.

A manual is included with the model to help you troubleshoot any issues you find. On Thingiverse, more than 75 users have posted test results on different 3D printers and different materials.

Model Reference

XYZ Calibration Cube

Very simple and fast model for testing. This is a cube with a side of 20mm. It helps to gain dimension by adjusting the steps in millimeters. Also, the model allows you to test extrusion, vibration, temperature. This cube was printed simply by countless 3D printers and a variety of materials.

Model Link

Cali Cat

Nice little calibration cat or just Cali Cat is a simple model that allows you to test the accuracy of the device, as well as detailing, lugs, bridges, vibration and extrusion. And all this in just one hour. More than 2.5 hundred users have submitted their test results on the service.

Model Reference

Phil A. Ment

The MatterHackers Mascot is a Phil A. Ment test model. It was originally intended for manufacturers. The description mentions the fact that Phil has several functions. And they were originally designed specifically for 3D printers. The model has small inserts, relief details, cylinders of vertical and horizontal orientation, ledges. In addition, the model contains chamfers, bridges and fillets. And this miracle is performed by a domed helmet. The record size on the service is 5,1397mm. A total of 84 models were published.

Ment test model. It was originally intended for manufacturers. The description mentions the fact that Phil has several functions. And they were originally designed specifically for 3D printers. The model has small inserts, relief details, cylinders of vertical and horizontal orientation, ledges. In addition, the model contains chamfers, bridges and fillets. And this miracle is performed by a domed helmet. The record size on the service is 5,1397mm. A total of 84 models were published.

Model Link

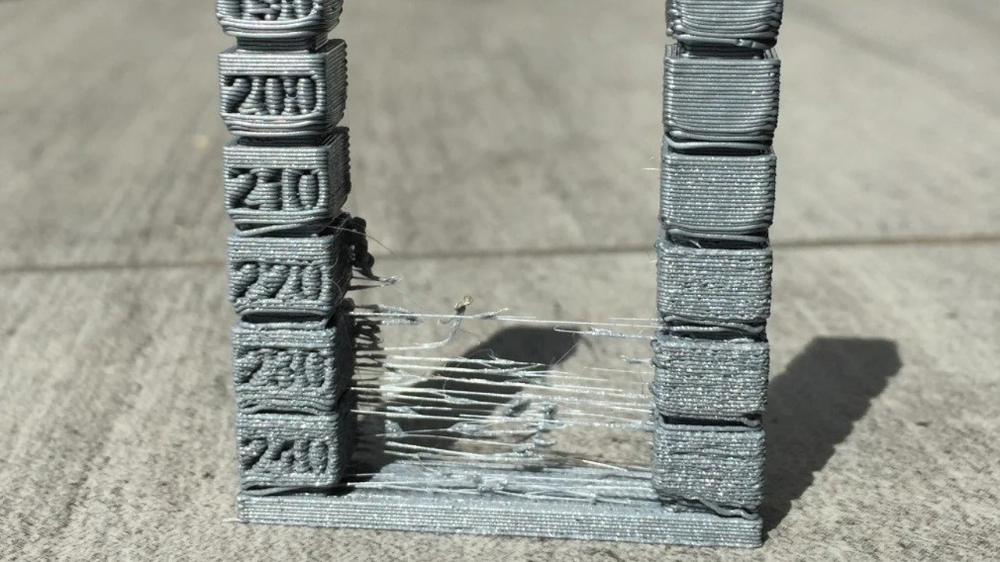

Calibration Temperature Tower

You can use this model to adjust the heat of your 3D printer. You can also test for different materials at what temperature the print comes out better.

NEW model Autodesk

This is a new model, or rather not even a model, but a whole procedure that will allow 3D printer manufacturers to show all the capabilities of devices to Kickstarter supporters. And of course, calibrate. The test was developed by Andreas Bastian and is a consolidated STL file that is able to test the system for the following indicators:

- authorization;

- alignment;

- accuracy;

- bridge, etc.

The model has it all. For example, if the 3D printer is set up well, then the horizontal function will be performed with a minimum of problems.

Model Link

PolyPearl Tower

If you want to test curves, cuts, bridges, cuts, then this model can be a great solution. In the description for this test model, the name "torture tower with a twist" appears. It is worth trying to use it for calibration.

Model Link

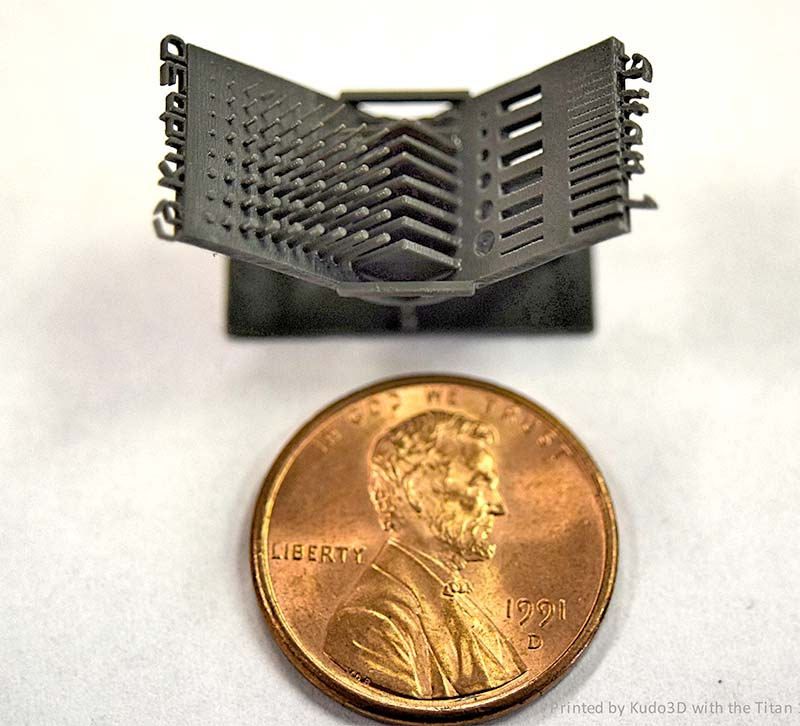

Rapid Screening

This model is a very quick test to check temperature, cooling, and retract function. Among the advantages of the model is its cost-effectiveness. The model will weigh only 0.23g. With its help, you can immediately remove the "strings".

Model Reference

Parametric Calibration Object

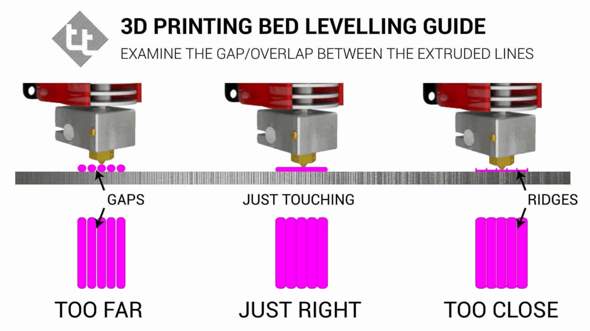

A particular difficulty in calibrating a 3D printer is lowering the stage level. With this model, you can draw the right conclusions to improve the first layer of printing, and as a result, get better prints.

Model reference

temperature test tower, test models

Calibration is the presetting of a 3d printer. Without this process, high-quality printing is impossible. To facilitate the setup procedure, special calibration models have been developed that allow you to load the printer as much as possible, diagnose and calibrate it.

What is a 3d printer calibration cube?

The Calibration Cube is a special model for testing the operation of a 3d printer. It is necessary to identify problems before the equipment is put into operation. Using the calibration cube, you can find errors in the printer settings and fix them. Also, such models allow you to identify physical problems of the device, for example, insufficient airflow or deformation of the extruder.

Top 10 test cubes for 3d printer

The test cube is a simple and lightweight model that prints quickly. Its main purpose is to help you test and tune your equipment. The following are the 10 most common calibration models.

The following are the 10 most common calibration models.

Calibration Temperature Tower

The temperature tower has a scale that shows the printer's ability to print at various temperatures with a single filament. The model clearly displays the quality of tensions, jumpers, overhangs at different temperatures. Also, by the finished product, one can judge the capabilities of the device to print curved surfaces with a specific plastic.

This model allows you to see the possibilities of materials that were not previously used or were used only in one temperature regime.

IMPORTANT. For each labeled element, you must set the temperature in the slicer or manually in the G-code.

3D-Benchy

Considered the flagship of all tests for 3D printing. With this model, you can check almost everything from protrusions to extrusion. "Bench" helps to determine the settings for the ideal operation of the printer.

XYZ Calibration Cube

This is a 20 mm cube. The model is an indispensable participant in the testing of any new 3d printer. With the help of a cube, it is convenient to adjust the steps in millimeters, dial the dimension, test the vibration level, temperature and extrusion quality.

All-In-One

The All-In-One (or all-in-one) test model can detect most problems in just one print. To make sure that the equipment and all its parts work correctly, you need to set the smallest layer height in the printer settings (most often it is 0.1 mm, but sometimes 0.05 mm) and an infill level of about 33%.

After the model has been printed, the following measurements should be made to check the correct operation of the printer:

- Dimensions of the object. The base should be 50 by 50 by 4 mm. The measurement is made with a caliper.

- Hole diameter. The test model has 3 holes for 3, 4 and 5 mm.

The measurement is carried out using a caliper or drill.

The measurement is carried out using a caliper or drill. - Nut size. An M4 nut should fit perfectly. You need to insert it into the hole. This will require a little effort.

- Smooth surface of small parts. You need to make sure that the numbers, cone and pyramid look nice and smooth.

- Prints round objects. It is necessary to check that the wave and the hemisphere are beautiful and smooth. You should be aware that not all 3D printers process rounded parts equally well. For example, they can be divided into polygons.

- Distance between walls. The model has 0.1 / 0.2 / 0.3 / 0.4 / 0.5 mm. But the results may vary depending on the slicer settings and the nozzle used.

- Protrusion: 25° / 30° / 35° / 40° / 45°. The accuracy will depend on the correctness of the selected cooling mode.

- Flatness. There should be no curvature on flat areas.

Cali Cat

This is a simple calibration model designed in the shape of a cute cat. It allows you to check the accuracy of the machine, as well as the performance of extrusion and vibration. With it, you can determine the detail of the printer, the quality of the protrusions and bridges. Printing takes only 1 hour.

It allows you to check the accuracy of the machine, as well as the performance of extrusion and vibration. With it, you can determine the detail of the printer, the quality of the protrusions and bridges. Printing takes only 1 hour.

Phil A. Ment

MatterHackers is a popular portal for additive manufacturing. He created his own version of the model to test the printing of a printer. This is a small figurine of an astronaut.

She has several elements that are designed to test the quality of 3D printing. These are jumpers, fillets, small relief details, inserts, overhangs, chamfers, cylinders of various directions and a domed helmet. A feature of this model is that it allows obtaining representative information for various dimensions of the printed product.

PolyPearl tower

This calibration model is relatively new. It is designed to test the printer and filament to the limit. The starting point for the creation of PolyPearl was the ship Benchy. But "Benchy" is suitable only for the entry level. With the development of devices and filaments, it has become insufficient. Most modern printers with PLA settings are already capable of producing quality Benchy prints. Therefore, a more complex model was invented - PolyPearl Tower.

But "Benchy" is suitable only for the entry level. With the development of devices and filaments, it has become insufficient. Most modern printers with PLA settings are already capable of producing quality Benchy prints. Therefore, a more complex model was invented - PolyPearl Tower.

"Express stringing"

When printing objects with complex geometry without knowing the capabilities of equipment and filament, you may encounter an error, which in English is called stringing (from string - string) or "spaghettification". In Russian, it is simply called "snot". Plastic begins to reach for the extruder. In this case, thin fibers are formed in the air.

This phenomenon is caused by the fact that during the idle movement of the extruder, some of the molten plastic begins to flow out of the nozzle. To prevent this, the retraction function is used, that is, the retraction of the filament at idle. It is necessary to take into account the properties of the plastic, the temperature of the extruder and the speed of its movement in order to correctly set the level of retraction.

The "Express Stringing" test pattern is used specifically to verify that this setting is correct. If there are no plastic fibers between the vertical pyramids, then all parameters are selected correctly. If there are threads, then you need to change some parameter.

NEW model Autodesk

Andreas Bastian has developed a validation process to help 3D printing equipment manufacturers better customize their devices and demonstrate the capabilities of their printers. With a single consolidated STL file, you can check the resolution, size alignment, and accuracy of your printer. For example, if the alignment is incorrect, the performance of the "bridge" functions will be poor. Because of this, the seal will be stiff and saggy.

Parametric calibration object

Lowering the stage level is especially difficult when setting up the device. Using the parametric model, you can understand what needs to be done to improve the print quality of the first layer.