24 hour 3d printed house

3D Homes That Take 24 Hours and Less Than $4,000 to Print

3D Homes That Take 24 Hours and Less Than $4,000 to Print Search iconA magnifying glass. It indicates, "Click to perform a search". Insider logoThe word "Insider".US Markets Loading... H M S In the news

Chevron iconIt indicates an expandable section or menu, or sometimes previous / next navigation options.HOMEPAGEScience

Save Article IconA bookmarkShare iconAn curved arrow pointing right.Download the app

New Story and Icon's first 3D-printed home model.- Last March, the 3D printing company Icon produced a 350-square-foot tiny home that cost $10,000 and took just 48 hours hours to build.

- The company was confident that it could print a larger structure in just 24 hours for even less — around $4,000 — since the printer wasn't running at full speed.

- A year after its prototype was released, Icon is now selling an upgraded version of its 3D printer.

Thanks for signing up!

Access your favorite topics in a personalized feed while you're on the go.

Thanks for signing up!

Access your favorite topics in a personalized feed while you're on the go.

Printable homes represent the latest wave in construction, but they're not always cheap or easy to build.

In March, New Story, a housing nonprofit based in San Francisco, and Icon, a construction-technology company that designs 3D printers, defied these stereotypes by producing a $10,000 tiny home in just 48 hours.

Icon called the structure "the first permitted, 3D-printed home in America."

Read more: A French family just became the first to permanently live in a 3D-printed home

At 350 square feet, the house was far cheaper than the average tiny home, which has a price tag hovering at around $25,000, but can often reach six figures. Before using 3D-printing technology, it took New Story eight months to build 100 homes, each costing about $6,000.

Before using 3D-printing technology, it took New Story eight months to build 100 homes, each costing about $6,000.

While the prototype was being developed, Icon's printer, known as the Vulcan, was running at only 25% speed. That gave the companies confidence that they could build a 600- to 800-square-foot home in just 24 hours for $4,000 or less.

When it comes to producing an average-sized home — around 2,000 square feet — the savings aren't quite as stark. A year after releasing its $10,000 prototype in Austin, Texas, Icon told the Wall Street Journal that printing a 2,000-square-foot home would cost around $20,000.

More remarkable is the fact that the company's upgraded printer, the Vulcan II, is now available for purchase, and could soon be used to produce affordable homes in places like Austin and Latin America.

Icon's first 3D model offers a glimpse of what the machine could produce in the future. Take a look.

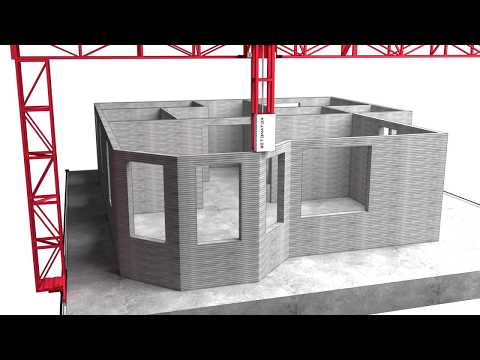

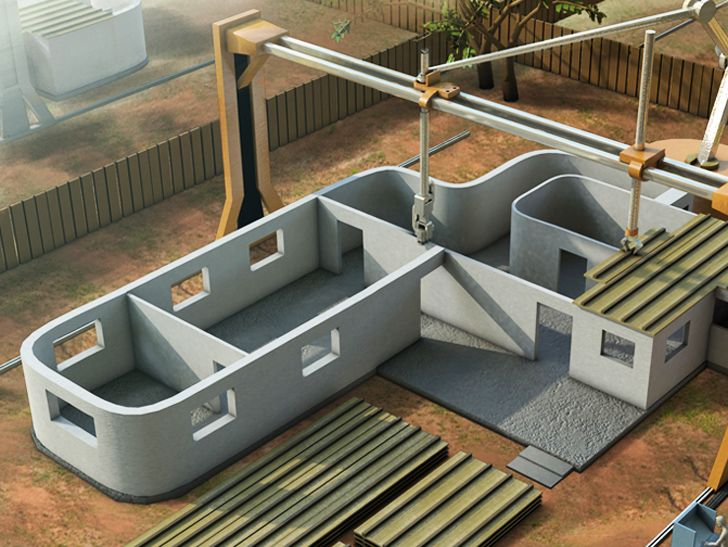

The Vulcan II can produce a home seamlessly onsite, without having to piece together individual units.

New Story/BANDD Designs

New Story/BANDD Designs The printer churns out layers of cement, which amass to form the walls of the home. Non-printed fixtures like doors and windows are installed later.

The Vulcan II is capable of producing walls that are up to eight-and-a-half feet tall and up to 28 feet wide.

It's also made to withstand rural weather conditions, meaning it could operate during a power shortage or without access to potable water.

New Story/BANDD DesignsThe home's cement mixture is also able to withstand extreme weather conditions.

The New Story prototype features a living room, a single bedroom and bathroom, and a small office space.

New Story/BANDD DesignsFamilies in El Salvador could move into the 350-square-foot homes this year, following seismic and safety tests.

New Story/BAAND DesignsIcon and New Story plan to produce more than 100 homes in El Salvador, a country whose rough terrain and frequent floods have made housing construction difficult.

New Story is seeking $1 million to print the homes, CNN reported last year.

From there, they hope to provide safe homes to some of the 1.3 billion people around the world residing in slums.

Icon will begin shipping its upgraded printer in April.

New Story/BANDD DesignsAn Austin-based developer called Cielo Property Group is planning to use the printer to build affordable homes in the area.

The next stop? It could be 3D-printing in space.

New Story and Icon's first 3D-printed home model. New Story/BANDD Designs

New Story/BANDD Designs Icon is researching how its printing technology might be used to build space habitats. As the company put it: "It sounds crazy, but it would be a lot crazier to fly sheet rock and 2x4's to Mars."

Read next

Features BI Innovation 3D PrintingMore. ..

..

3D Printed House Was Built in Just 24 Hours, and We Want to Live in It

3D Printing Has Made Incredible Feats, but Can It Also Answer the Housing Crisis?

What if you could build a house in just 24 hours? Actually, you don’t have to. This 3D printing machine can do that for you.

This 3D printing machine can do that for you.

3D printing has inspired some remarkable designs over the last decade. From engineers to fashion designers, anyone has used 3D printing to bring their ideas to life, meanwhile saving time and money. Innovators are also harnessing the power of 3D printing to solve worldwide problems ― think 3D printed organs and recyclable cars.

But what about using 3D printing to solve another problem: housing?

The first 3D-printed, on-site house

Apis Cor wanted to prove that not only could they print a house using a 3D printing machine but that they could do it in less than 24 hours. Together with PIK companies, they printed the first on-site house in Stupino, Russia. Unlike other 3D printed houses, the machine printed the house as a whole rather than component parts.

The yellow, three-pronged, tycoon-shaped house is just 38 m2 and one story tall. The unusual shape of the house was purposeful. Apis Cor wanted to show the machine’s flexibility and diversity in formats available.

Inside, there’s a hall, bathroom, living room and compact functional kitchen complete with modern Samsung appliances. It also has a washing machine that lets you add forgotten laundry and detergent to a running load without starting over (score!). If that’s not cool enough, you can also control it remotely via your smartphone.

Extreme conditions, meet smart solutions

The team used concrete as the printing “ink” to construct the house, which presented a challenge. The build took place in 2016 during the coldest time of the year, where temperatures average 17-26°F. Although the machine can operate at temperatures below -31°F, the concrete mixture only works above 41°F.

Apis Cor solved this problem by pitching a large tent around the machine to control the temperature. With new materials like geopolymers, companies can soon print houses any time of the year.

After the walls were printed, the team applied insulation and a roof to withstand the snowy winter. They touched-up the house with eco-friendly, weather-resistant paint and climate-control windows.

They touched-up the house with eco-friendly, weather-resistant paint and climate-control windows.

What are the saving – if any – of 3D printing houses?

In total, the build cost $10,134 equal to approximately $275 per m2. A square printed house using more standard materials would have cost just $233 per m2. Additionally, 3D printing houses erases the risk of human error during construction.

Typical construction cost for anything from houses to hotels can range from $810 to $2,650 per m2, according to Mortgage House. And that’s on the low end of construction costs. Furthermore, building a standard cottage house can take up to 2 months to complete.

Apis Cor believes this house in Stupino is a big leap to a new evolutionary stage. Going forward, they hope that this build can convince others worldwide that 3D printing is a reality in the construction market.

An answer to the housing crisis?

We’ve seen 3D printed human organs, musical instruments and cars that function equally to their non-3D-printed counterparts. Now, companies can create unique 3D printed houses in less than 24 hours no matter the weather.

Now, companies can create unique 3D printed houses in less than 24 hours no matter the weather.

For the housing crisis worldwide, this offers an innovative and achievable solution for lack of housing. As 3D printing advances and becomes more popular, countries can use this technology to meet the demands for more affordable housing in any climate. And, they can build the houses faster than ever before.

3D printing technology for residential buildings becomes a reality in 24 hours

From space exploration to robotics and medicine, 3D printing has huge potential in all areas, but especially it is starting to make a real impact in the world of affordable housing. The latest example of this is a slightly augmented project for the homeless in Texas, USA, which began with the construction of a stylish new 3D-printed administrative block in just one day.

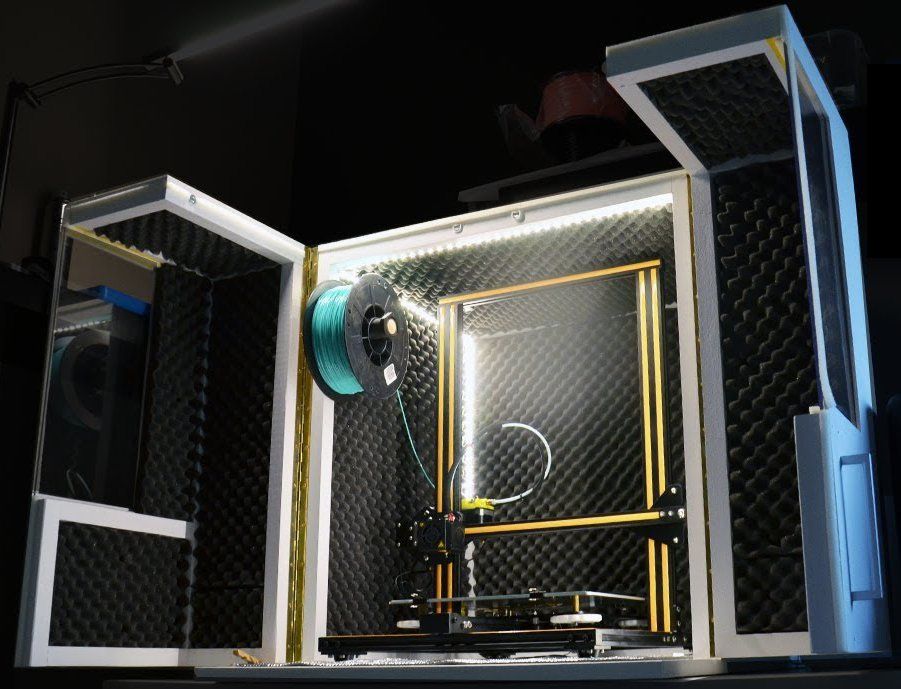

The construction company behind the new 3D printed homes goes by the name ICON. The company presented its first prototype during the Texas media conference SXSW 2018, and after that it set about building an entire village - the world's first 3D-printed neighborhood, in a poor area of South America. Its Vulcan II 3D printer is designed to build simple boxes of houses, while the installation of roofs, doors and window openings is carried out by builders. The company is able to build housing much cheaper and more efficiently, and its concept shown at SXSW took just 48 hours to complete and cost just $10,000.

Its Vulcan II 3D printer is designed to build simple boxes of houses, while the installation of roofs, doors and window openings is carried out by builders. The company is able to build housing much cheaper and more efficiently, and its concept shown at SXSW took just 48 hours to complete and cost just $10,000.

The Village of 3D Printed Homes aims to instill hope for a secure future for low-income people whose income does not exceed $200 a month, while promoting this concept of affordable housing solutions around the world.

Participation in a new project in Austin, Texas called Community First! Village was the next step for ICON. The project is led by local non-profit organization Mobile Loaves & Fishes for the homeless and will include more than 500 homes on 20 hectares when completed. In this social settlement of more than five hundred houses, additional addresses will appear - six objects made using the 3D construction method. Designed by Texas-based Logan Architecture, Icon will print three houses at once for the first time to showcase their build efficiency and focus on cost reduction. According to the company, all six houses will be rented out before the end of the year, but construction of the 46 sq. m. welcome center building is already completed at this stage. m for the future village, which was printed in just 27 hours. These 3D houses are among the affordable ones and will be ready to move in in just a few weeks.

According to the company, all six houses will be rented out before the end of the year, but construction of the 46 sq. m. welcome center building is already completed at this stage. m for the future village, which was printed in just 27 hours. These 3D houses are among the affordable ones and will be ready to move in in just a few weeks.

How does it work?

The façade of the building is erected on the Vulcan printer developed by the company. The device prints walls with a mortar of concrete that retains its shape as it cures. Such technology allows them not to collapse. After erecting the facade, the builders install the necessary infrastructure, a wooden roof and windows. It takes a little more than 24 hours to fully build a finished house, depending on the building area, the maximum figures of which are about 75 square meters. The company installed the first such house in the American city of Austin.

This development has a number of advantages, such as relative cheapness, construction time, and the ability to build houses in conditions with limited resources and harsh climatic conditions. In addition, the walls of the building have an air gap that retains heat in cold weather. The estimated cost of building a dwelling is $4,000.

In addition, the walls of the building have an air gap that retains heat in cold weather. The estimated cost of building a dwelling is $4,000.

The second generation of this printer, the Vulcan II, is designed specifically for the production of reliable one-story buildings - quickly, inexpensively and with great variability. The printing area has been increased to 186 square meters. m, the width of the walls is adjustable for different sizes of panels. You can transport the printer in a special trailer; no assembly is required before starting work.

As ICON assures, anyone who has been instructed will be able to operate this printer. All functions are intuitive and displayed on the tablet screen. The printer itself is 3.5 meters high and 10 meters wide. It prints walls up to 2.5 meters high on a foundation up to 8.5 meters wide. It prints a part 0.3 high and 0.6 m wide at a speed of 1.5 - 2 meters per second.

Especially for the operation of the machine, the company has developed and patented a recipe for concrete-lime material Lavacrete. It has passed all strength tests and is recognized as safe for residential construction.

It has passed all strength tests and is recognized as safe for residential construction.

This is not the first attempt at 3D printing living spaces. Recall that in the spring of 2017, researchers from the Massachusetts Institute of Technology presented a similar construction technology.

Not only American startups are going to solve the problem of affordable housing with printing. A similar project is planned in India. Tvasta promised the first printed houses this year. Indian technology takes more time: the startup plans to print the components of a 30-square-meter house in about three days, and assemble it “under the roof” within a week.

Source: New Atlas

Read an article about the first 3D printed houses?

3D printing has been used in construction for several years. In this article, you will learn about the first real houses printed on 3D printers.

3D printing of houses is still quite new to the layman.![]() While construction 3D printing technologies have been developed for many years, only a few "real" projects have already seen the light of day. We are still far from technology taking over conventional construction methods. But with each new project, she is getting closer to becoming mainstream.

While construction 3D printing technologies have been developed for many years, only a few "real" projects have already seen the light of day. We are still far from technology taking over conventional construction methods. But with each new project, she is getting closer to becoming mainstream.

There are many benefits to 3D printing. For example, the cost of a 3D printed house can be much lower. And it will take much less time to build.

In order to draw a line under what has already been achieved in this area and show some interesting projects, we have devoted an article to the "first" and the best. These projects will always remain milestones in the construction 3D printing industry as they set the stage for future advances in the field.

Germany's first 3D printed house

Germany is a country often associated with cutting-edge engineering, so let's start our list with Germany's first ever 3D printed house.

The house itself is located in Beckum, a city that is partly located in North Rhine-Westphalia, next to Holland and Belgium. This is the first 3D printed house to be fully certified to official building codes. This project will give way to many other 3D printed construction projects in Germany as well as the rest of Europe.

This is the first 3D printed house to be fully certified to official building codes. This project will give way to many other 3D printed construction projects in Germany as well as the rest of Europe.

The project is the result of a collaboration between German construction company Peri and Danish construction 3D printing firm COBOD. Peri is a large corporation that operates not only in Germany, but throughout the EU. Its portfolio includes many products, including scaffolding and formwork solutions that every construction site needs.

Peri followed the construction 3D printing segment for many years before acquiring a stake in COBOD in 2018. Now they are pushing the technology together and further. The construction of the house in Beckum began two years after the acquisition of the share.

For 3D printing at home, a BOD2 modular 3D printer from COBOD was used. The printing itself took just over 100 hours.

• Built: (started) September 17, 2020

• Commissioned: summer 2021

• Where: Beckum, North Rhine-Westphalia, Germany

• By: Peri, COBOD

First occupied 3D printed home in the US

Several homes have been printed in the US, but this home is the first officially occupied home, according to CNN. Its creators: the construction company Alquist and the humanitarian organization Habitat for Humanity Peninsula.

Its creators: the construction company Alquist and the humanitarian organization Habitat for Humanity Peninsula.

From a distance, you might think that this is an ordinary house. However, when approaching it, the layered structure of the concrete walls becomes noticeable. After all, 3D printing creates an object in layers.

Surprisingly, the 111.5 square meter concrete structure of the house (was printed in about 12 hours, significantly faster than traditional construction methods would allow.

The house was reportedly bought by April Springfield, who lives there with her son and dog She bought the house through Habitat for Humanity's housing program, and given that the nonprofit's goal is to help solve the global housing crisis, it makes sense to use 3D printing to create affordable homes that will make many people's dreams of home ownership come true.0003

• Built: 2021

• Commissioned: December 22, 2021

• Where: Williamsburg, Virginia, USA

• By: Alquist 3D, Habitat for Humanity Peninsula, Greater Williamsburg

The first five-story 3D printed house

This project, made by the Chinese company WinSun, is a real record holder. It is a 3D printed five-story residential building with a height of 10 meters - the tallest 3D printed building so far.

It is a 3D printed five-story residential building with a height of 10 meters - the tallest 3D printed building so far.

The house is located in Suzhou Industrial Park in Jiangsu province in eastern China. It stands next to a mansion that was also built by WinSun using a concrete 3D printer.

Looking at WinSun designs, you can't help but notice that they don't look like they've been 3D printed. Usually 3D printed structures are gray in color, the layer lines are clearly visible. But WinSun adds color and makes walls smoother. Nowhere is it stated how the company achieves the smoothness of the walls, but we assume that the workers smooth them by hand. WinSun projects are not like the ones we're used to.

• Built: Winter 2014

• Commissioned: Not specified

• Where: Suzhou, Jiangsu, China

• By: WinSun

First 3D printed biodegradable house

Can you guess that there is rice in the walls of this house?

Most 3D printed buildings are made from concrete mix. But this project is different from the rest. With the aim of creating housing solutions with little to no environmental impact, Italian company WASP 3D printed Gay's house using soil and agricultural waste.

But this project is different from the rest. With the aim of creating housing solutions with little to no environmental impact, Italian company WASP 3D printed Gay's house using soil and agricultural waste.

WASP developed the sustainable blend in collaboration with Ricehouse, a company that specializes in using natural and agricultural materials such as clay and rice in construction.

The house is named Gaia in honor of the ancient Greek goddess of the earth. In fact, 25% of the mixture contains local soil, 10% hydraulic lime, 25% rice husks and 40% crushed rice straw (a by-product of rice production at harvest).

An innovative solution not only in terms of material, but also in the design of the walls themselves. The specific corrugated structure was used to provide ventilation on warm days as well as insulation on cold periods, virtually eliminating the need for air conditioning.

Gay's house is small - about 20 square meters. The wall printing took only 10 days, while the estimated materials cost is just under $1,000.

• Built: not specified

• Put into operation: October 7, 2018

• Where: Massa Lombarda, Ravenna, Italy

• By: WASP, Ricehouse

AirBnB's first 3D printed home

The perfect weekend getaway.

You can find many different types of accommodation on AirBnB, but what about a 3D printed home?

The so-called Fibonacci house is the first 3D printed house to be offered for booking through AirBnB. Considering that it is located in rural British Columbia, it will be a wonderful place to stay.

Although the Fibonacci house looks small, it has a lot to offer vacationers. About 35 square meters is enough to accommodate up to four people.

The concrete walls of the house were designed and printed by Dutch 3D printing firm Twente. 20 concrete parts were produced offsite in just 11 days. The material was produced by Laticrete. The parts were later transported and assembled at their current location.

• Built: 2020

• Commissioned: Not specified

• Where: Kootenays, British Columbia, Canada

• By: Twente Additive Manufacturing

First 3D printed houseboat

Prvok is not only the first 3D printed house in the Czech Republic, but the world's first floating 3D printed house on a pontoon.

The project was implemented by the start-up company Scoolpt. The concrete structure of the houseboat took only 22 hours to print.

Approximately 43 square meters of living space divided into bathroom, bedroom and living room with kitchen. Weight isn't usually discussed in the context of houses, but given that this one is on water, it's interesting to note that Prvok weighs 43 tons.

The house is equipped with a built-in recirculating shower and tanks for drinking and municipal water and has a service life of at least 100 years.

• Built: June 2020

• Commissioned: August 18, 2020

• Where: Prague, Czech Republic

• By: Scoolpt

Europe's first 3D printed residential house

Not every 3D printed house has visible line layers.

More often than not, 3D printed houses are demos made to show what the technology can do. For most of them there is no information about the actual residents. But in 2017, the couple did move to live in a 3D printed house located in Nantes, France. Thus, the house of "Yanov" became the first of its kind, which was inhabited in Europe.

Thus, the house of "Yanov" became the first of its kind, which was inhabited in Europe.

The house is a project of the University and the Laboratory of Digital Sciences of Nantes. An interesting aspect of the project is the special technique used in its construction by BatiPrint3D. Instead of 3D printing a concrete structure, the robotic arm created wall shells using polyurethane, a material used for insulation. Later, these membranes were filled with concrete.

It took a total of 54 hours to print. It took a little over 4 months to complete the construction. Mainly due to the fact that the rest of the components were created using conventional means. House area - 95 square meters.

• Built: 2017

• Commissioned: March 2018

• Where: Nantes, France

• By: University of Nantes, Nantes Digital Science Lab

India's first 3D printed house

This building was built in a couple of days.

India's first ever 3D printed house was completed back in 2020. The project was carried out by construction startup Tvasta, founded by graduates from the Indian Institute of Technology Madras. In fact, the institute's Chennai campus was chosen as the location of the building.

The project was carried out by construction startup Tvasta, founded by graduates from the Indian Institute of Technology Madras. In fact, the institute's Chennai campus was chosen as the location of the building.

The significance of this project lies in its possible impact on the solution of the housing crisis worldwide and in India in particular. The ability to build such a house within a few days and at a low cost cannot be underestimated.

House 55.7 sq.m. with a spacious layout, one bedroom, combined kitchen and living room.

The concrete structure of the house was 3D printed off site and the parts were later transported and assembled on campus. The foundation, meanwhile, was built using the conventional method of pouring concrete into the ground.

• Built: 2020

• Commissioned: Not specified

• Where: Chennai, India

• By: Tvasta Construction

Africa's first 3D printed house

Back in 2019, in the Moroccan city of Ben Guerir, Spanish firm Be More 3D created Africa's first 3D printed house. The project originated during the team's participation in the Solar Decathlon in Africa. This is an international competition during which teams design and build solar-powered houses.

The project originated during the team's participation in the Solar Decathlon in Africa. This is an international competition during which teams design and build solar-powered houses.

Be More 3D printed house 32 sq.m. in about 12 hours, took first place and received the title of the most innovative startup.

Be More 3D didn't stop building in Africa and later created the first 3D printed house in Spain and developed its own concrete 3D printer in partnership with several corporations from the automation and materials industries.

• Built: 2019

• Commissioned: Not specified

• Where: Ben Guerir, Morocco

• By: Be More 3D

First 3D printed home for sale in the US

Last on our list is the first 3D printed home for sale in the US.

This house was printed in the same place by SQ4D, a company specializing in the development of robotic building systems. The building was printed with SQ4D's Arcs concrete extrusion system and has a 50-year warranty on the printed structure.