How to choose 3d printers

How to Choose a 3D Printer?

Throughout the last decade, 3D printing has become widespread, expanding from strictly industrial applications to small businesses, schools, and hobby workshops. Increased competition on the market also means that choosing the right 3D printer can be more difficult than ever.

We would like to help you with the whole thought process, not by recommending any particular printer, but rather by guiding you through the topic so you can make your own choice, in accordance with your demands and preferences.

Table of contents:

- Technology and application

- Choosing an FFF printer

- FFF printer construction

- Print material (filament)

- Print quality

- Print speed

- Print volume

- Using the printer: noise, ventilation, necessary space

- Choosing an SLA printer

- SLA printer construction

- Print material (resin)

- Print quality

- Print speed

- Print volume

- Using the printer: noise, ventilation, necessary space

- Aspects common for both technologies

- Safety

- Technical support

- Professional use and/or frequent printing

- Price

- Where to get further information?

Technology and application

3D printing has a wide array of applications. Some of them require special printers, able to print from metal, biomaterials, or with a huge print volume. We are going to focus just on regular, “desktop” printers, affordable for an ordinary customer. However, that doesn’t mean such printers are only suitable for simple tasks and hobby purposes. On the contrary, many of them are frequently used for business, in science, or medicine, sometimes even arranged into print farms, i.e. dozens or even hundreds of printers together.

Keep in mind there are many differences even among this category of printers. For various applications, some options might be more suitable than others. Later in this guide, we will also mention some factors you should take into account if you plan to use your printer professionally (or basically for any heavy-duty purpose).

By the way, if you don't have any particular use in mind yet, and just think 3D printing sounds fun, do not worry. There is plenty of inspiration available on the internet, as ready-made 3D models for download. Of course, the process of choosing the right printer is going to be a bit more difficult if you don’t have clear preferences yet.

There is plenty of inspiration available on the internet, as ready-made 3D models for download. Of course, the process of choosing the right printer is going to be a bit more difficult if you don’t have clear preferences yet.

Before we delve deeper into this topic, you should choose which of the two popular 3D printing technologies is more suitable for you, as the differences can be significant:

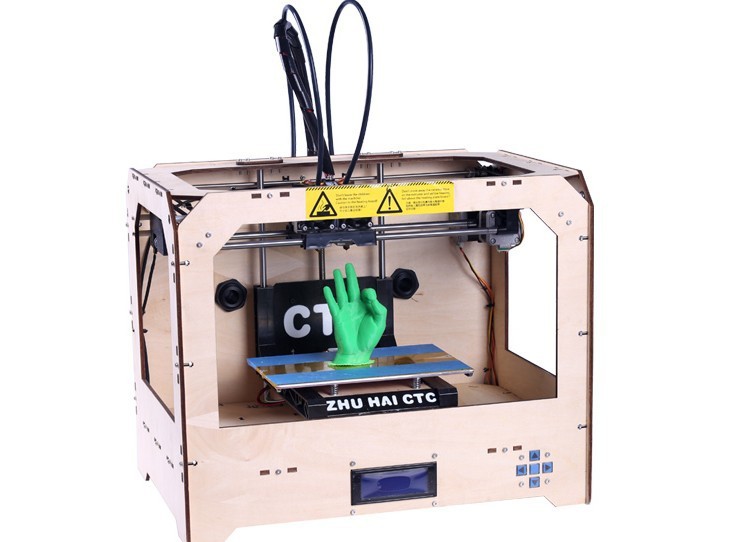

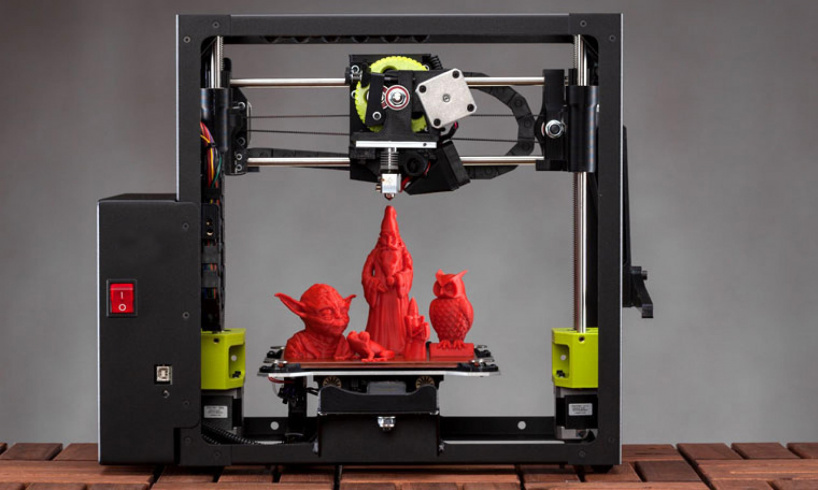

FFF (sometimes called FDM) technology prints from a melted plastic filament, extruded from a nozzle. Imagine a large and very precise hot glue gun, carefully layering the material, that is quickly cooled down to form a solid object. It is by far the most popular 3D printing technology.

Its main advantages are a larger print volume, easier use, and manipulation with the print material (filament) - which is available in many different colors and materials with various functional qualities.

The main disadvantage is visible print layers, which might be bothersome, especially on small and detailed prints.

SLA technology (also called MSLA or DLP - more on the terminology later in the chapter on SLA printer construction) prints from a liquid resin, hardened by a UV light source.

Some examples of SLA prints.The main advantage is the ability to print much smaller and more refined details than the FFF technology. The newer SLA printers are also very fast.

The main disadvantage is a smaller print volume and more difficult manipulation with the print material (sticky liquid, often with unpleasant odor). Fresh prints need some additional care - first, the uncured resin has to be washed away, and then the prints need more UV light exposure to cure completely.

A collection of both SLA prints (the orange tower and cyan bust) and FFF prints. The chess pieces have a chemically smoothed surface (overcoming the visible print layers).

More information on the basic terminology is available for example in our e-book Basics of 3D Printing. It’s available here for a free download.

SLA and FFF technology are very different from each other, therefore, we will consider them separately first. In the last few chapters, we will go through some aspects common for both technologies (price, technical support, etc.).

Choosing an FFF printer

FFF printer construction

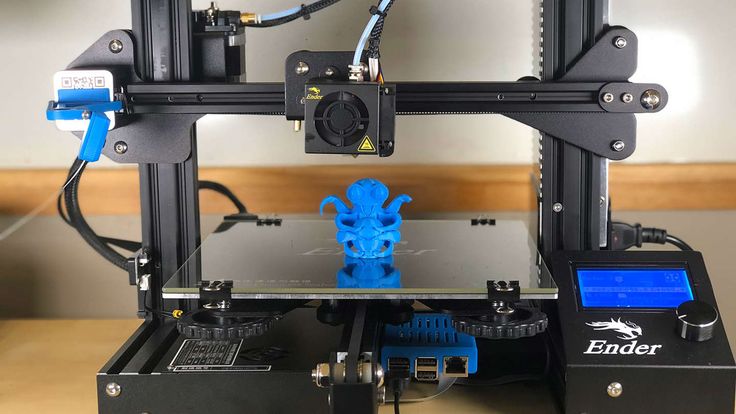

Each FFF printer has two basic components: a print head with a nozzle that extrudes the melted filament. The extruded material builds up, layer by layer, on a print bed.

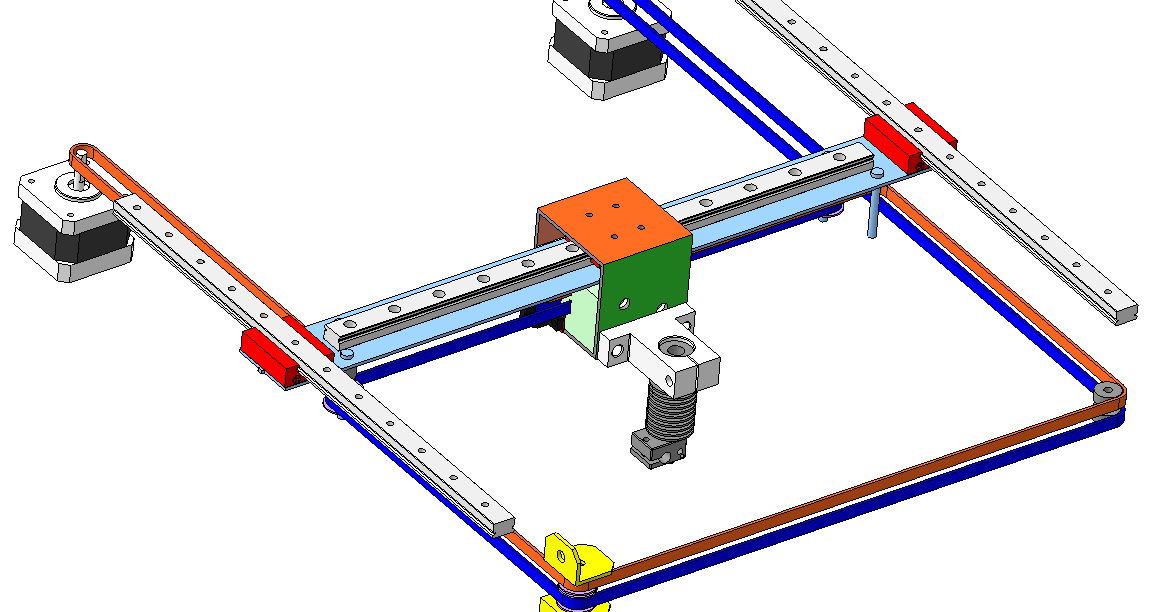

A new object is just being finished on the print bed of the Original Prusa i3 MK3S.The FFF technology has more subcategories, each of them having different means of moving these two components against each other. By far the most common is the cartesian construction: the print bed usually moves forward and backward, the print head moves above the bed, sliding on vertical and horizontal axes, up-down and left-right. There are other construction types as well (named delta, corexy, polar, etc.), that have completely different patterns of movement: for example, the print bed might be static, rotating, or moving up and down.

There are other construction types as well (named delta, corexy, polar, etc.), that have completely different patterns of movement: for example, the print bed might be static, rotating, or moving up and down.

We won’t discuss the different constructions and their pros and cons here, as it is a complicated topic worth a standalone article. At least a basic description is available in our e-book Basics of 3D Printing. If you don’t want to study this topic in detail yet, don’t worry, you can choose your new printer just fine by considering other parameters.

As for the print bed, it can be manufactured from various materials, for example from glass, but modern printers usually have a removable steel sheet with a special coating. Print bed heating is a very important feature.

An example of the removable print sheet (Original Prusa i3 MK3S).

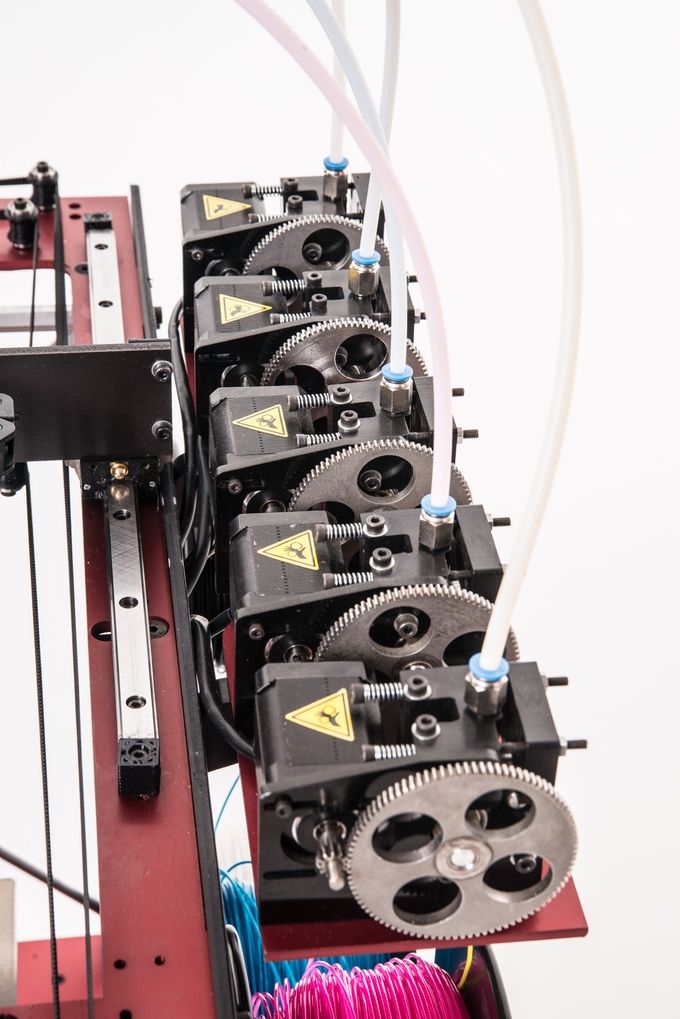

As for the print head, there are two main construction variants. The first variant is called direct or direct drive, where the drive gears responsible for pushing the filament into the nozzle are located directly in the print head. The whole print head is then usually called the extruder. The second variant is Bowden, where the drive gears are placed separately (in a component called extruder). This results in a lighter print head. The filament travels between the extruder and the print head through a Bowden tube.

An example of the Bowden variant: the white Bowden tube connects the extruder and the print head (Original Prusa MINI).As for some “premium” FFF printer features, let’s mention for example:

- filament sensor, if the printer runs out of filament, the sensor lets you insert a new spool before resuming the print. Without the sensor, the printer would just continue printing empty, resulting in a failed print.

- “power panic”, i.e. protection against power loss (adds the possibility of resuming the print when the power is back on)

- various means of remote control of the printer (wifi, bluetooth, etc.)

Obviously, the appearance of the printer is going to impact our decision, the same as with any other product. Try to distinguish purely aesthetic factors from those that affect the printer’s function and ease of use. For example, a closed design (the whole printing mechanism is inside an enclosure) looks more professional, which often means more expensive (but often with worse value). However, the closed design does have an actual impact on the print quality, when printing large objects and/or special materials, because it helps maintain a stable temperature. The open design looks more “DIY”, but also makes accessing the printer’s mechanism much easier, for maintenance or possible mid-print interventions.

We will give you more examples of how the various features mentioned above affect the printer’s speed, print quality, etc., in the following chapters.

By the way, you can customize your printer’s appearance and give it a really personalized look. If the printer is open source, usually, there are printable parts available, with various modifications shared by the community.

An example of a custom modification: a four-legged "MINI Base" add-on for the Original Prusa MINI.Print material (filament)

Now let’s look at the printer features from the aspect of print material.

There is a wide choice of filaments available for FFF printers, with diverse physical qualities (tenacity, chemical or temperature resistance, etc.).- Special materials are usually harder to print with. One of the factors is the minimal necessary nozzle temperature.

In most cases, you need to reach temperatures of 200-300 °C (392-572 °F). Make sure your printer is able to meet the requirements of the materials you are planning to use.

In most cases, you need to reach temperatures of 200-300 °C (392-572 °F). Make sure your printer is able to meet the requirements of the materials you are planning to use. - For most of the print materials, a heated print bed is also necessary. It decreases the risk of the printed object warping or even detaching from the print bed. The print bed surface also plays its role, as special coatings increase the adhesion.

- A closed design (enclosure) of the printer also helps to maintain a stable temperature. Even an “open” printer can be put into an enclosure, there are various DIY solutions for that, for example using a photo studio light tent, or an IKEA Lack table).

- The direct drive printers make printing of some materials (especially TPU/TPE, soft, flexible materials, often called just “flex”) much easier. These printers are also less prone to problems caused by a low-quality filament (that could get stuck in the bowden tube because of uneven diameter or bumps on its surface).

On the other hand, bowden printers, thanks to a lighter print head, have more fluent movements and suffer less from vibration-induced print defects. Therefore, it is difficult to clearly say which construction solution is better.

On the other hand, bowden printers, thanks to a lighter print head, have more fluent movements and suffer less from vibration-induced print defects. Therefore, it is difficult to clearly say which construction solution is better. - Some materials (for example those containing metal particles or carbon fibers) are abrasive - replacing a regular nozzle with a hardened one is recommended.

By the way, multi-color (or even multi-material) printing is possible with the FFF technology. There are various solutions, more expensive printers may have multiple nozzles or print heads (extruders).

There are upgrades that let you switch colors even on a regular, single-nozzle printer (for example, the MMU2S upgrade for our Original Prusa i3 MK3S+).To a certain extent, simple multi-color print is possible with almost any FFF printer - you just pause the print job and replace the filament manually.

More information on various filament materials is available in our Knowledge Base.

Print quality

The topic can be split into these two aspects:

a) The level of “resolution”, i.e. how fine details is the printer able to render. This depends on the minimal print layer height and the nozzle diameter. Changing the nozzle (make sure this is possible with the printer of your choice) from the most common 0.4mm diameter to, for example, 0.25mm, will bring very noticeable improvement of details. However, it will also make your printer much slower - so the right choice depends on your priorities.

Different nozzle diameters.b) Absence of print defects, like shifted layers, uneven or “wavy” surface, etc. This is a matter of printer construction quality, both regarding the individual components and their assembly.

- Some manufacturers claim awesome values of the minimal print layer height (as little as 0.02 mm), however, realistically, the results are also limited by the nozzle diameter and by the general character of the FFF technology (extruding hot plastic is never going to be absolutely precise).

- The choice of filament also affects print quality. Some materials don’t render details that well and/or are more prone to print defects.

- To maintain the initial advantage given by a well-built printer, regular maintenance is needed (tightening loose belts, lubricating bearings, updating the firmware, etc.)

- 3D model optimization before printing helps a lot (even simple things, like how the model is oriented on the print bed, go a long way quality-wise).

- The appearance of the finished prints can be radically enhanced with post-processing techniques like filling, sanding, various methods of smoothing the surface, etc.

Print speed

- To a large extent, there is an indirect proportion between print quality and speed. For example, if you need simple prototypes or functional parts, you can sacrifice the details for quicker printing, by mounting a larger diameter nozzle (say, 0.

6mm instead of 0.4mm) or by different software settings, for example, a larger print layer height.

6mm instead of 0.4mm) or by different software settings, for example, a larger print layer height.

- You can also directly increase the speed of the printer’s moving parts, however, this will also increase the risk of print defects. For example, faster movements will cause vibrations, filament won’t have enough time to cool down and harden, etc.

- It is difficult to compare different printers simply by stats given by the manufacturers unless you can see what quality can the printer achieve at that given speed. Also, the exact speed depends on a particular 3D model, as some printers might deal better or worse with certain shapes.

- In the end, the most effective way of speeding things up is, again, optimization before printing: not wasting time with printing unnecessary supports, too dense infill structure, etc. You can learn all the tricks later, for example from our online beginners’ courses.

Print volume

The option of large-scale printing is one of the main advantages of FFF technology.

A comparison of the maximum print volume of the Original Prusa printers.However, when looking for a printer with a huge print volume, consider the following:

- With most materials, the maximum print size will be limited by warping caused by thermal differences between the print layers, anyway.

- Basically, the only material suitable for really large prints is PLA (i.e. the most common material, with average physical qualities - it is relatively brittle and not very heat resistant).

- To a large extent, the issues with warping can be reduced with a closed design (or placing the printer inside an enclosure), that maintains a stable temperature.

- The larger the printer, the more stable and well-built it must be to maintain print accuracy and quality.

- Usually, it is quicker (and also more reliable) to print large objects as multiple parts on more printers at once.

The parts can be glued, snap-fitted, or screwed together afterwards. Therefore, the maximum print volume doesn’t have to be the most important factor when choosing your printer.

The parts can be glued, snap-fitted, or screwed together afterwards. Therefore, the maximum print volume doesn’t have to be the most important factor when choosing your printer.

- Printing really large objects can take several days, a failed print then means a significant waste of time and material. There are two features worth gold in this regard: the filament sensor and power panic (power loss protection), both mentioned above.

Using the printer: noise, ventilation, necessary space

- If your printer will be placed in your office or living room, noise is going to be an important factor. FFF printers can be rather noisy, because of their ventilators, stepper motors, and all the movements along their axes. A good modern printer can have an average noise level of 50 dB, older or cheaper model 65 dB. It seems it’s not such a big difference, but it’s exactly over the threshold when we start to perceive the noise as really distracting when working on a computer, etc.

The level of noise is also influenced by the printer settings and its maintenance (for example lubricated/worn bearings).

The level of noise is also influenced by the printer settings and its maintenance (for example lubricated/worn bearings). - Don’t forget that apart from the space occupied by the printer itself (with some leeway on all sides) you need some space for the spool holder and also for storing and manipulating all the material, tools, and finished prints.

- Some of the more advanced materials (for example ASA or ABS filaments) emit unpleasant odors during printing. Therefore, the printer should be placed in a ventilated room, but at the same time, not drafty (that would increase troubles with materials prone to warping, coincidentally, that also includes ASA and ABS).

- Keep in mind that even odorless materials (PLA, PETG) might emit plastic microparticles - in a poorly ventilated space, these could reach harmful concentrations.

Choosing an SLA printer

SLA printer construction

All SLA printers print from a liquid resin hardened by UV light. However, there are multiple subcategories of this technology, depending on the source of the UV light and the way of its distribution (so the resin hardens only at the right place and moment). We will describe just one of those subcategories, the MSLA (Masked Stereolithography). To simplify things, we refer to it only as SLA. MSLA is by far the most common subcategory of all the SLA printers and many people perceive these names as synonyms. Again, a short description of some of the other subcategories can be found in the Basics of 3D Printing.

However, there are multiple subcategories of this technology, depending on the source of the UV light and the way of its distribution (so the resin hardens only at the right place and moment). We will describe just one of those subcategories, the MSLA (Masked Stereolithography). To simplify things, we refer to it only as SLA. MSLA is by far the most common subcategory of all the SLA printers and many people perceive these names as synonyms. Again, a short description of some of the other subcategories can be found in the Basics of 3D Printing.

The basic components consist of a tank filled with liquid resin. The tank has a transparent bottom, made of an FEP foil. Underneath the tank, there is a display, with a UV reflector beneath. The display projects silhouettes of the individual print layers on the FEP foil, these act as masks letting the UV light through only where necessary. A platform travels up and down, submerging to the resin tank, so each printed layer sticks to it, detaching from the FEP foil at the same time, making the bottom of the tank ready for the following print layer. An illustrative picture is available in the Basics of 3D Printing.

A platform travels up and down, submerging to the resin tank, so each printed layer sticks to it, detaching from the FEP foil at the same time, making the bottom of the tank ready for the following print layer. An illustrative picture is available in the Basics of 3D Printing.

Better SLA printers also have a tilt mechanism - the print layers stuck to the platform are not detached from the FEP foil by a direct upward movement, but with a slight swing of the resin tank, which makes the process much more gentle and reliable.

Print material (resin)

- As for the printer compatibility, unlike with filaments, there are no temperature requirements, the only factor is a UV light wavelength, that causes that particular resin to harden. A vast majority of the available SLA printers (and thus the widest choice of resins) use the 405 nm wavelength.

- There is a relatively wide selection of resins with various physical properties, from basic (usually called “tough”), through flexible, high-tenacity types, to special materials used in medicine, jewelry making, etc. However, the overall choice is smaller than with filaments, resins have worse functional parameters in general (basic variants are quite brittle), and last but not least, resin costs at least twice as much per kilogram than filament.

- Multi-color or multi-material printing is not possible with SLA technology.

Print quality

- Similar to the FFF technology, the main factor responsible for the detail quality is the print layer height setting. Another important factor is the display resolution.

- Some printers support anti-aliasing, a setting which makes the visible print layer edges smoother.

- Monochromatic display (that is slowly becoming a standard for all better SLA printers) renders sharper details.

Also, it has much better longevity than a regular color (RGB) display.

Also, it has much better longevity than a regular color (RGB) display.

- Despite being able to print much more delicate details, the SLA technology is surprisingly simpler than FFF, at least regarding the printer’s mechanics. Instead of complicated movements in all three directions, there is just a platform going up and down. Nothing has to be heated up, the print material doesn’t travel anywhere. However, to make a good SLA printer is not that easy, as the technology is much more sensitive to any minor errors and inaccuracies. In the end, the quality of construction plays an even bigger role than with FFF, to ensure pinpoint mechanical movements, uniform dispersion of the UV light all over the print area, etc.

- Again, the print quality can be enhanced by thorough preparation and optimization before printing, as for the 3D model orientation, placing print supports, etc.

This preparation is more demanding than with FFF and there is a bigger risk of print defects or outright print failure.

This preparation is more demanding than with FFF and there is a bigger risk of print defects or outright print failure.

Print speed

- First of all, the print speed depends on the choice of the print material. Various types of resin have different curing times (in the order of seconds per print layer). The basic resins of any brand need a similar time, but special materials might require twice as much or even more.

- UV reflector and display are also very important: the more UV light the reflector emits, and the more the display lets through, the faster the curing process is. Printing with a monochromatic display is much faster than with an RGB display (even 4 times faster!).

- Note that the total print time is affected also by the speed and efficiency of the mechanical movements of the printer (platform moving up and down and print layers detaching from the resin tank bottom).

The earlier mentioned tilt mechanism helps a lot in this regard.

The earlier mentioned tilt mechanism helps a lot in this regard. - Interestingly, because the whole bottom of the resin tank can be cured at once, the total printing time is given only by the printed object’s height, its width and length doesn't matter (as long as it fits into the print area, of course). Ten identical models would print in the same total time as just one.

Print volume

- The print volume size of affordable SLA printers currently matches the size of a tablet or a larger phone (plus approximately 15 cm of height). That means it is much smaller than with regular FFF printers.

- More affordable larger-volume SLA printers are slowly entering the market, however, there is not much competition on the market yet and some of these printers might have questionable value, with too many corners cut regarding print quality and reliability.

Using the printer: noise, ventilation, necessary space

- In general, SLA printers are quiet, only the ventilators and the platform movement might emit perceptible noise.

- Resins have odors, how strong and unpleasant depends on a particular type and brand. There are odorless (or rather low odor) variants, too. Better printers have an air filter, but don’t expect it to always be 100% efficient - ventilation is a must.

- SLA technology needs more working space around the printer. The finished prints have to be peeled off the platform, washed from uncured resin with isopropyl alcohol, and finally cured with more UV light. There are curing and washing stations available for some printers, which will make these tasks much easier.

- Make sure the printer has easy calibration and controls.

- The platform and resin tank should be easy to remove - you will have to do this after (almost) every print.

- Also, the display and the FEP foil should be easy to replace.

- Is the printer easy to clean in case of some resin spills (that will happen, sooner or later)?

- Is the printer lid easy to open? Does it stay open on its own (not always the case with cheap printers)?

- Why do we list so many things that sound quite self-evident or not so important? Well, the thing is, dealing with liquid resin can be so tricky and annoying on its own, that you will really appreciate smooth operation with no extra complications caused by the printer!

Aspects common for both technologies

Safety

- The same as with any other electric appliance, there are strict safety regulations regarding cables, connectors, power source, etc. Especially the heating components of the nozzle and the print bed on the FFF printers must meet the highest standards, so they don't pose a fire hazard.

- Firmware is of the same importance as hardware. It should include various safeguards, especially against overheating.

Even though it sounds absurd, there are certain cheap printers on the market with these safeguards intentionally turned off by the manufacturer (they have to be reinstalled by an update).

Even though it sounds absurd, there are certain cheap printers on the market with these safeguards intentionally turned off by the manufacturer (they have to be reinstalled by an update). - However, we must add that part of the responsibility is always on the user, as for the regular maintenance - the same as with an automobile. For example, you have to check for loose or damaged power cables.

Technical support

- Of course, in the end, everything is breakable 🙂 Even a top-notch printer will need reliable, 24-7 technical support.

- It is always better to be able to contact the manufacturer directly, instead of just a vendor.

- The printer should be user-serviceable to some extent (for example, you should be able to clean or replace a clogged nozzle yourself). Is there proper documentation and comprehensible manuals?

- The user community is important. Keep this in mind when choosing an unusual/rare printer, you might have a hard time looking for advice later.

- Does the manufacturer support even its older printer models? Are there long-term firmware updates, bug fixes, hardware upgrades?

Professional use and/or frequent printing

Keep in mind that the most important quality of a (semi)professional printer is neither speed, superb details, or ability to print special materials, but simply its reliability. When you work with firm offers and deadlines, you can hardly tell your clients “sorry, my printer is just acting up today” or “I’ll have to charge you three times for material because I had two failed prints”.

- Are replacement parts readily available? How much do they cost? How quick a service repair would be?

- As even the most reliable printer breaks sometimes, consider splitting risks with two less expensive printers instead of one (of course, not sacrificing quality or reliability, but for example print volume), or one main printer and one smaller as a backup.

.jpg)

- The print preparation (calibration, preparing print bed) should be easy and not too time-consuming. Of course, this is important for all users, but twice as much if you print almost nonstop and have to meet deadlines.

- Easy controls also mean you can delegate the tasks to less experienced colleagues.

- Some options of printer remote control will be handy.

Price

This aspect is listed as the last one in this guide, on purpose - it makes no sense to consider price before you really make sure what do you need your printer for and what features and advantages it should have.

- Make sure you know what you pay for - what features are you really going to utilize?

- Don’t forget the value of your time. When choosing between cheaper and more expensive options, it is often a question of what is more valuable for you: your time or your money. A working middle-aged person would probably see this differently than a student.

Even a poor, low-quality printer can sometimes be tuned and upgraded into a half-decent machine, however, it depends on how much time and effort are you willing to invest. Sadly, in most cases, you’ll have to invest time and money, anyway, paying the cost of various upgrades and spare parts. In the end, you often spend even more, just with costs spread into a longer period.

Even a poor, low-quality printer can sometimes be tuned and upgraded into a half-decent machine, however, it depends on how much time and effort are you willing to invest. Sadly, in most cases, you’ll have to invest time and money, anyway, paying the cost of various upgrades and spare parts. In the end, you often spend even more, just with costs spread into a longer period. - Note that, as with any other goods, sometimes you pay just for brand and design. There are printers on the market that cost more than 5000 USD and yet feature more obsolete solutions than printers sold for 1/10 of their price.

- You can save costs by choosing an assembly kit instead of a completely assembled printer. In such a case, you don’t have to make any concessions to quality, just do some work instead of the manufacturer. There is an added bonus, too - you’ll get to learn how your printer works, which will make later maintenance much easier.

However, there is also some risk of defects caused by your own errors during assembly, therefore it is very important to choose a kit with good, thorough instructions.

However, there is also some risk of defects caused by your own errors during assembly, therefore it is very important to choose a kit with good, thorough instructions. - An interesting choice is picking multiple less expensive printers instead of spending the whole budget on a single machine. That means splitting the risks, and also brings an option of faster printing by splitting a large model into parts and printing them at once.

- Don’t forget the operating costs! It makes no sense to acquire an expensive printer and then feed it with a low-quality material. A cheap filament often causes clogging and various print defects. Also, keep in mind the extra cost of some special materials you might need for your projects.

- Avoid manufacturers that force their customers to use only their brand of material! Such filament or resin might cost multiples of the regular price. For example, a regular SLA printer resin is usually sold for 70-90 USD per kilogram.

However, a resin of the same quality, sold in the form of a branded and chipped cartridge, costs more than 200 USD!

However, a resin of the same quality, sold in the form of a branded and chipped cartridge, costs more than 200 USD! - A similar problem exists with spare parts. There is always a wider (and less expensive) choice for printers with an open source license.

Where to get further information?

As the amount of 3D printers on the market has grown, so did the sources of information. Here are just a few examples of popular Youtube channels and online magazines, where you can look for reviews and other 3D printer related content:

3D Printing Nerd

Thomas Sanladerer

CNC Kitchen

All3DP

3D Printing Industry

Make: Magazine

Now for some general tips from us:

- Obviously, it is optimal to rely on advice from someone you know in person, with verifiable 3D printing experience.

- There are various workshops, labs, and maker spaces, where 3D printers are available for trying out.

- If you are considering a purchase of an Original Prusa printer, we suggest looking at a map on the PrusaPrinters.

org website. You can find users in your vicinity who could help you or even show the printer at work (on the map, you can filter those offering “Show and Tell“).

org website. You can find users in your vicinity who could help you or even show the printer at work (on the map, you can filter those offering “Show and Tell“). - As for the information from the manufacturer himself... obviously, everything they (or, we :-)) say could be just marketing a should be taken with a grain of salt. On the other hand, manufacturers are responsible and accountable for giving accurate information regarding technical specs, compatibility, etc.

There is a worldwide 3D printing community, made of people always eager to help. However, when sifting through all the advice, consider the following:

- Are the sources really independent and unbiased? (even with no selfish intent, someone is just an avid fan of a certain brand, etc.)

- Do they really own that particular printer, did he try it, just theoretically consider trying it, or just repeat the opinions of somebody else?

- How long do they own the printer? (People are most eager to share advice in euphoria just after they made their own purchase, without experience about the long-term reliability of the product, etc.

)

) - Have you seen their prints? (Quality is relative, what someone describes as perfect might be unacceptable for someone else.)

- “The XY printer is the best for learning the basics!”. XY usually stands for some dubious printer that needs tweaking and/or replacing most of its parts before the first successful print or hitting it with a hammer, whatever comes first. We believe that for efficient learning (unless you want to learn frustration tolerance), it’s better to choose the exact opposite: a decent, reliable printer, that lets you discern your own mistakes from the faults of the hardware, and doesn’t make you hate 3D printing right from the start... 🙂

- Another peculiar kind of advice goes like “you can buy this printer, but it won’t be any good unless you immediately replace the rods, the bearings, the firmware, use my excellent slicer profiles, etc.” Tweaking your printer is a lot of fun, for a lot of us, it’s actually more important than printing itself 🙂 However, it’s not a good idea to do it right from the start.

First, give a chance to the factory settings and original components, before looking for their improvement. After all, if the printer comes from a decent manufacturer, these settings were probably tested on a much larger scale than any single user could do.

First, give a chance to the factory settings and original components, before looking for their improvement. After all, if the printer comes from a decent manufacturer, these settings were probably tested on a much larger scale than any single user could do.

How to Choose an FDM 3D Printer? 2022 3D Printer Buying Guide

Investing in a FFF (also known as FDM) 3D printer is an important business decision. At its core, choosing a 3D printer means the printer that fulfills the requirements of your application the most cost effectively. When looking to purchase a 3D printer, a business should be informed of the following:

- The business’ application’s 3D printing needs

- The 3D printer’s build volume

- The filaments needed for the business’ application

- Dual extruder 3D printers

- How a business should budget for a 3D printer

- The cost to operate the printer

- Easy to use printer

However, businesses should also become informed of a 3D printer’s quality and safety features, as these could be additional measurements of a professional 3D printer. Businesses should also be aware that 3D printing software and support from a 3D printer manufacturer can affect their 3D printing experience, learning curve, and 3D printing production.

Businesses should also be aware that 3D printing software and support from a 3D printer manufacturer can affect their 3D printing experience, learning curve, and 3D printing production.

This guide will discuss what you need to consider when determining which 3D printer is right for your business.

Step 1a: Determine Whether You Need an In-House 3D Printer or a 3D Printing ServiceSome common reasons why companies need 3D printing include making manufacturing more efficient, producing customizable parts, and performing small-batch manufacturing. Read “Why Businesses Need 3d Printing” for a more comprehensive description of why businesses need 3D printing.

If your business has decided that it can benefit and implement 3D printing into its operations, it will need to decide whether to opt for an in-house 3D printer, or a 3D printing service. If your business did not need 3D printing before, it could indicate that you may not need an in-house 3D printer just yet. Your intended application or goal for 3D printing can help determine whether purchasing a 3D printer is the right option for you.

Your intended application or goal for 3D printing can help determine whether purchasing a 3D printer is the right option for you.

For example, if the project’s goal is to print a few parts, it may be more beneficial to outsource this task to a 3D printing service capable of producing the parts you need rather than purchasing a 3D printer.

However, if your business aims to increase production or create product models for your business then it would be better if you purchased a 3D printer. In addition, if your goal is to start a 3D printing business, then it would be necessary to purchase a 3D printer.

Step 1b: Understand Your 3D Printing ApplicationUnderstanding your 3D printing application is crucial because it will help determine which type of 3D printer and which 3D printing technology will work best for you. One way to start understanding your 3D printing application includes keeping in mind your industry and your intended use for the 3D printer.

Common industries that incorporate 3D printing into their operations include:

- Automotive

- Education

- Entertainment

- Manufacturing

- Medical

Common 3D printing applications include:

- End-use parts

- Jigs & Fixtures

- Prototyping

- Production

- Model Making

For example, KIDO Sports CO, Ltd. is a motorcycle helmet manufacturer who used 3D printing in their prototyping to edit and test new helmet designs cost-effectively before mass-producing the designs. This resulted in more accurate, customer-oriented helmets for their clients. Read the full story of KIDO Sports’ 3D printing application here.

Read about other 3D printing applications across different industries here.

Step 2: Make Sure the 3D Printer Has the Right Build Volume for Your ApplicationA 3D printer’s build volume refers to the size of the parts it can produce. Different build volumes are suitable for different types of projects and applications.

Different build volumes are suitable for different types of projects and applications.

A desktop 3D printer like the E2 has a single extrusion build volume of 330x240x240 mm (13×9.4×9.4 inches) and is an excellent option for projects that require smaller parts whose size will not increase over time. Desktop 3D printers are excellent options for schools and small-batch manufacturing.

The Bolton School Junior Boys use an E2 desktop 3D printer because the machine is small enough to fit on a desk, yet has a large enough build volume to produce different projects. Printing with the E2 helped students learn interdisciplinary design and production in art, design, and technology courses. Read Bolton’s 3D printing experience with the E2 here.

In comparison, a large-format 3D printer like the RMF 500 has a build volume of 500x500x500 mm (19x19x19 inches) for single and dual extruder printing. The RMF large format 3D printer produces high-performance end-use parts with repeatability, making it an excellent option for small batch manufacturing.

There are many instances when a business needs to print a part whose size is not practical to produce on a desktop 3D printer or a large format 3D printer. Or a business may currently have projects that are smaller, but will need to produce larger parts in the near future. Looking for a 3D printer with a more flexible build volume is helpful in these situations. For example, the dual extruder 3D printers in the Pro2 Series and the Pro3 Series.

The Pro2 Series includes:

- Pro2 with a build volume of 305x305x305 mm (12x12x11.8 inches)

- Pro2 Plus 3D printer with a build volume of 305x305x605 mm (12x12x23.8 inches)

The Pro3 Series includes:

- Pro3 with a build volume of 300x300x300mm

- Pro3 Plus with a build volume of 300x300x605mm.

A 3D printer with a build volume like the printers in the Pro2 and Pro3 Series give businesses the flexibility to print parts of different sizes.

Step 3A: Make Sure the 3D Printer Processes the Filaments You Will Need

The right 3D printer for your business will be able to support the right filament for your application.

The right 3D printing filament for your application depends on a variety of factors, including the following:

- The type of part that will be printed

- How that part will be used

- The conditions that part will be under (for example: whether it needs to perform well in high heat, or have high strength)

- The desired result for what the project is trying to achieve

- The quality of the part needs to be (Keep in mind that price can be an indicator of the quality of the filament)

Depending on the type of work that needs to be done, a business may need a printer that can process a variety of filaments, or may only need a printer that specializes in a few types of filaments.

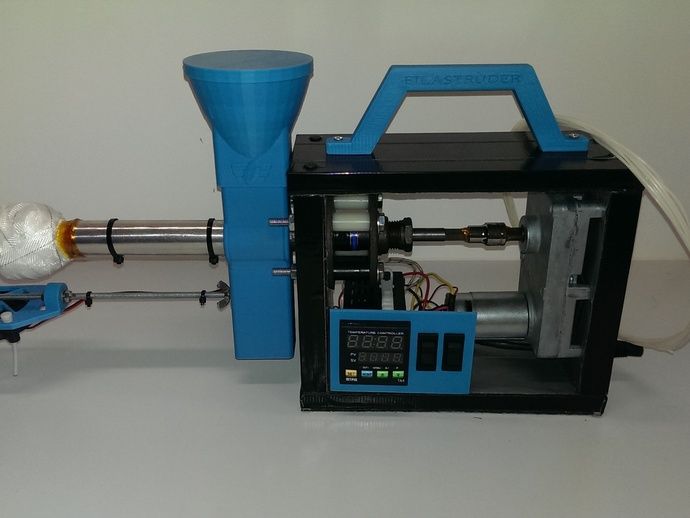

For example, the E2CF is an IDEX desktop 3D printer with features that make carbon fiber 3D printing easier. At the moment the E2CF is compatible with PA12 CF, which is a carbon fiber reinforced filament. A business whose 3D printing application will remain focused on producing carbon fiber printing could benefit from a 3D printer such as the E2CF.

At the moment the E2CF is compatible with PA12 CF, which is a carbon fiber reinforced filament. A business whose 3D printing application will remain focused on producing carbon fiber printing could benefit from a 3D printer such as the E2CF.

There are printers capable of printing with a wide range of filaments. For example the E2, Pro2 Series, and Pro3 Series can process the following: PLA, ABS, HIPS, PC, TPU, TPE, NYLON, PETG, ASA, PP, PVA, Glass Fiber Infused, Carbon Fiber Infused, Metal Fill, Wood Fill. A business can benefit from purchasing a printer capable of printing a variety of filaments in the following types of situations:

- Current projects require multiple filaments

- Parts that require a support structure during printing

- There is uncertainty whether future projects will require different types of filaments

Finally, ISO certifications are available for filaments. For example, biodegradable materials that offer sterilization capabilities are distinguished by the FDA. A 3D printer manufacturer that possesses ISO certifications (ISO9001, ISO14001) can indicate the quality of your filaments and printers.

A 3D printer manufacturer that possesses ISO certifications (ISO9001, ISO14001) can indicate the quality of your filaments and printers.

When researching a printer’s filament capability confirm whether the 3D printer can support third-party filaments, because it usually affects the material’s cost and availability of various materials. A 3D printer manufacturer with an Open Filament Program (OFP) makes it easy to choose from a wide variety of filaments with the best quality and top performance for your printing needs.

An Open Filament Program is a collaboration between the manufacturer and several selected certified filament manufacturers to identify and pick top-performing filaments that are highly compatible with the 3D printer manufacturer’s printers. This ensures that materials are certified by the manufacturer.

Since filaments listed in an OFP are compatible with the 3D printer, they can be easily installed into the printer’s settings. This is much easier than buying a filament from another brand and setting it up yourself. It is a time-consuming process and the quality of the results will depend on the user’s experience.

When searching for a 3D printer, you will notice that 3D printers feature either a single or dual extruder to perform single or dual extrusion printing. Some businesses may find that a 3D printer with a single extruder can perform the 3D printing project to the standards required of their application. However, most businesses may find that a dual extruder 3D printer better suits their needs. These printers perform advanced functions and processes making them an important asset in a variety of applications such as prototyping, production, manufacturing, and RnD.

Dual extruder 3D printers can also perform dual-color printing and dual material printing. Dual material printing allows you to produce parts with breakaway support in a material different than that of the part. Breakaway supports give you the freedom to create more intricate and complex designs and geometries.

Sometimes only one material is necessary to produce a part and if it is necessary to print the part with breakaway support, it is possible to print the part and breakaway support in the same filament. However, if the part and support are printed in the same material, the support may be difficult to remove or it can cause damage to the final print.

For example, if a part and its break-away support are printed in carbon fiber, the break-away support will be hard to remove.

Carbon fiber if you use its own material to support it, it will be hard to remove. Break away support saves you time and effort. It also gives you the freedom and geometry to make more things.

Step 5: BudgetThere is a price range for different level printers. Pricing on a 3D printer can range from as low as $200 to a million. Printers under $1,000 can generally satisfy the needs and requirements of hobbyists. Professional 3D printers well suited for business applications usually start at $3,000. While a business’ 3D printing needs can be met with a $3,000 professional printer, having a budget of at least $5,000 gives a business more options and flexibility when purchasing a printer.

Several factors contribute to the cost of a 3D printer, such as:

- The type of 3D printer

- The 3D printer’s build volume

- The quality of the 3D printer

Many options of FDM 3D printers are priced within a $5,000 budget. For example, a dual extruder 3D printer, like the Pro2 is $3,999. A desktop 3D printer with IDEX, like the E2, is $3,499. And a desktop IDEX 3D printer for carbon fiber printing, like the E2CF, is $4,499.

When shopping for a 3D printer it is important to understand that a printer’s price is not the only cost associated with purchasing a 3D printer. 3D printers have direct and hidden costs.

Direct Costs:

- 3D Printer Price

- Materials

- Equipment

- Labor Costs

Hidden Costs:

- Consumables

- Slicing Software

- Training & Electrical Resources

- Electricity costs

- Machine operator

Because of direct and hidden costs, it is advisable to maintain two budgets when shopping for a 3D printer. The first budget is for the actual 3D printer. The second budget is the yearly budget for the function and maintenance of the printer. A common mistake businesses make when purchasing their first 3D printer is to spend the whole budget on the actual printer, leaving no room for maintenance or consumable costs. Consumables include replacing the filament used in 3D printing and the cost of replacing machine parts due to wear and tear during the 3D printing process. Examples of machine parts that receive a lot of wear and tear including nozzles, hotends and, Buildtak or other printing surfaces.

Depending how often a business is printing consumables can cost $1,500 a year, and this needs to be considered when budgeting for a machine.

For general purposes, a 5K-10K budget is enough for purchasing a high quality 3D printer. However, when the task is too demanding, i.e. big parts, metal parts, etc, a larger budget is necessary to accommodate the demand.

At times businesses may have different 3D printing options that fit their application needs. For example, a business may require a metal part and may initially look into SLM for direct metal 3D printing. SLM is an high cost system that uses a high powered laser that melts and fuses an expensive metal powder to build a metal part. However, indirect metal 3D printing is also capable of producing a metal part that fits the business’ needs, and a business can choose indirect metal 3D printing over CNC and SLM. For example, Metalfuse from Raise3D is a metal 3D printing system that can operate at 10% or 20% of the cost of SLM because it does not use a high powered laser or metal powder as a material. This option may not work for every business because the final 3D printed part from an indirect metal 3D printer will have less density than that of an SLM printer. Less density results in a loss of mechanical strength, but not all applications require such high mechanical strength. For example, SLM printed parts can have a density of 99% and above, and the Metalfuse achieves 97% density.

97% density can meet the requirements of most applications. Another factor to consider is the maximum size that can be built with indirect metal 3D printing. Generally, because of the debinding and sintering process, the part can not be too large. Make sure an indirect metal 3D printing option like Metalfuse can produce metal parts in the size required by the business application. Contact Raise3D to discuss if Metalfuse indirect metal 3D printer can suit your needs.

When choosing a 3D printer for an application, selecting the most cost-effective option gives the business flexibility to invest in more 3D printers. In general, investing in creating an in-house printing farm of several different 3D printers is advantageous to a business. The types of 3D printers included in the farm can range across the most cost-effective and the most capable. Therefore, a single printer does not need to be used for all the applications a business requires. It is possible to have several types of printers for different applications. In addition, a 3D printer may not be able to fulfill all the requirements of an application. If a business needs to invest in additional manufacturing equipment beyond a 3D printer, then choosing the most cost-effective printer will leave flexibility in the budget for other manufacturing equipment.

Printing metal parts can be used as an example to help explain this point further. If a business requires metal parts for an application, then SLM or an indirect metal 3D printing process OR CNC, like Raise3D’s Metalfuse, is necessary to produce those parts. If the business chooses Metalfuse is a much lower cost system than SLM, but a relatively higher cost by the dollar amount. However, it may not be necessary to produce the part in metal before deciding and achieving the final design of the metal parts. A business can use another 3D printer, like the Pro3 Series, to prototype the part in plastic to finalize the design before producing the part in metal. By prototyping the prototype using a more cost-effective printer for the task, like the Pro3 Series, the more cost-effective printer will lower the business’ overall expense and get to the final part quicker. Therefore, a single printer does not need to be used for all applications, and a single printer is not necessary for the same application, because different printers may be more cost-effective for different stages of production.

3D printing is not an instant process. Depending on the type of project, it can take over 10 hours to finish a print job. Some materials, such as resin, require post-processing, adding to a project’s timeline. Purchasing multiple 3D printers gives engineers on the team more access to a printer, meaning no one has to wait for a machine to be ready to use. This maximizes workflow and increases production, resulting in an advantage over competitors.

Investing in multiple printers saves time, and shortens a business’ production cycle. Shortening production cycles gives a business the ability to react to clients and new situations quicker. Having a slow response to urgent matters and clients can result in a loss of revenue and a loss of confidence in a company. For example, a business might be prototyping with a client who constantly updates its needs. Since the client’s needs change frequently, a business could lose the client’s confidence if it can not accommodate the new changes efficiently.

When the COVID-19 pandemic began, the supply chain for most businesses was impacted. It prompted many businesses to look for ways to have more control over their operations. Owning a 3D printer allows businesses to produce what they need in-house, removing the dependency and time spent waiting on a third party and shipping. During this time, businesses that owned a 3D printer had more control over their operations. However, businesses that invested in multiple 3D printers saved more time and were able to serve customers better because they eliminated the time spent waiting for a project to finish printing before beginning a new print job.

For example, a business with a $10,000 budget can purchase one Pro3 Plus professional 3D printer, priced at $7,249 with a build volume of 10 × 11. 8 × 23.8 inch/ 255 × 300 × 605 mm. If a business does not need a printer with a larger build volume, like the Pro3 Plus, then it should leave room in the budget for operational costs, filament, and consumables like hotends.

A business can purchase:

- Pro3 priced at $5,249

With a Pro3, a business can have a printer with features to improve the overall 3D printing experience. - E2 priced at $3,499

If the business is producing batches of smaller parts, then it could consider purchasing several E2IDEX 3D printers to boost productivity. - E2CF, priced at $4,499.

A business also has the option to purchase the E2CF for high strength parts in a carbon fiber enhanced composite filament.

The above 5 steps guide businesses interested in purchasing 3D printers on how to break down their research for searching and budgeting for the right 3D printer. However, there are other equally important factors that businesses should give equal importance to when evaluating 3D printers.

1.

Choose a High Quality 3D PrinterWhen purchasing a 3D printer, businesses should pay close attention to the printer’s quality. The price of a 3D printer is not the most reliable measure of a printer’s quality.

Visit the manufacturer’s website or read the buyer reviews to learn if the printer has received any industrial awards and recognition. Manufacturers of high-quality printers share the certifications, awards, and recognition their products receive on their websites.

For example, Raise3D shares on its website that the Raise3D factory is ISO certified. This means that all their products are made in factories that possess the IOS9001 and ISO14001 certifications. To put it simply, it means these printers are made with good components.

ISO9001 certification is defined as the international standard that specifies requirements for a quality management system (QMS). Organizations use the standard to demonstrate the ability to consistently provide products and services that meet customer and regulatory requirements. Companies that possess this certification are recognized for creating, implementing, and maintaining a Quality Management System.

An ISO14001 certification states that an organization is required to identify and have access to all applicable legal requirements related to its environmental aspects. ISO 14001 is an internationally agreed standard that sets out the requirements for an environmental management system. It helps organizations improve their environmental performance through more efficient use of resources and reduction of waste, gaining a competitive advantage, and the trust of stakeholders.

2A. Choose a High Quality Slicing SoftwareWhile a high-quality 3D printer is capable of producing a quality print, it executes the model based on a series of commands given to it in the printing file. The printing file makes a difference in the quality and success rate of a print. For example, if someone printed the same model using identical machines but different templates, the final printing results can have different results: a good quality print, a lower quality print, or even a failed print. Therefore, a high quality printing file is necessary for the printer to execute the model you need. Businesses that use a high quality slicing software with advanced features, and an optimized algorithm will be more likely to produce a high quality printing file.

Load the 3D model to the slicing software to begin preparing the printing file. A common choice for the code format used in the printing file is GCode. Code format, like Gcode, is the series of commands that dictates to the printer how to execute the model based on the settings in the slicing template.

Note: When exporting the 3D model, remember to make sure the chosen file format is compatible with the slicing software, and 3D printer. STL and OBJ are the two most common file types that modeling software can export and slicing software and 3D printers can import.

Examples of the settings that can be controlled in the slicing template include:

1. print speed

2. nozzle temperature

3. bed temperature

4. infill percentage

5. infill pattern

6. retraction settings

7. print order prioritization

Creating high quality instructions in the printing file during this step is critical to a print’s success rate. This is because 3D printing produces an object layer by layer, depending on the layer thickness set in the template, the file is cut into an x-amount of layers, and the number of layers equals the model height divided by the layer thickness, which is where slicing comes from. However, different printing methods finish each layer differently. FDM/FFF printing the hotend is controlled to move from one spot to another spot, drawing lines of a certain width and thickness. The thickness of these lines is the Layer Height. The width of these lines is the Nozzle Height. This line will finish the layer, and then the next layer is built on top of the existing layer. How well the slicer is able to prepare the file for printing each layer, and how well each layer is sliced is the foundation of a print having a good success rate. A good, high quality slicing software with good starting templates and open to a variety of setting adjustments to fine tune printing templates for the best results is essential for producing a high quality printing file.

ideaMaker is a free, easy-to-use slicing software developed by Raise3D. This slicer can import STL, OBJ, 3MF, and OTLP files and export GCode. In addition to processing these files, ideaMaker can process pre-existing templates, and templates uploaded to ideaMaker Library (open software template where users can contribute and download designs from different users) from other users.

An example of one of ideaMaker features is Automatic Support.

1. Automatic Support

This user-friendly slicer can automatically generate support structures and features an auto-repair tool that can highlight and correct any areas of the model that need repair. Users can edit the automatically generated supports by adding or removing supports from the part. ideaMaker also offers features to fine-tune the model before printing such as the ability to cut, duplicate, and change the file size.

ideaMaker’s advanced features allow users to customize and optimize settings for their model. Examples of its advanced features include:

- Modifiers

ideaMaker’s modifiers allow users to specify settings changes within specific regions of the model. This means users do not need to use the same settings for the whole structure, and can only customize the sections that require it. For example, if a part needs to be strong within a certain area without such advanced modifiers, users may need to print the entire part solid and use additional material.However, ideaMaker’s modifiers give users the ability to specify the exact area that needs to be strong, rather than being forced to make the entire part solid and use extra material.

- Adding Texture

Users can skip lengthy CAD processing and easily create different iterations of the same STL model by applying different patterns to the selected model’s surface. It works by creating a concave or convex surface on the designated model according to the values of an image’s greyscale. Users can try out an unlimited amount of images for many appearance options. This easy-to-use feature gives those still learning modeling skills the possibility of customizing the surface of a 3D printable object with a texture.

ideaMaker is compatible with filaments such as PLA, ABS, ASA, PETG, TPU, PP, and PC. There are pre-set templates for the E2CF to process PA12CF and its support material for carbon fiber printing. The E2 desktop 3D printer can also run GCode from this template. In addition to processing a wide range of filaments, ideaMaker is compatible with Raise3D’s Open Filament Program (OFP). OFP is a collaboration between Raise3D and several filament manufacturers to identify which filaments work best on Raise3D printers.

ideaMaker’s range of features makes it a useful slicing software to users of different levels of 3D printing experience. This high quality slicing software also connects to the rest of Raise3D’s suite of 3D printing software, ideaMaker Library, and RaiseCloud, resulting in a sophisticated 3D printing software ecosystem.

2B. Choose a 3D Printing Management Platform

RaiseCloud is a cloud-based 3D printing management platform developed by Raise3D. With RaiseCloud users can remotely operate and monitor the printer from their mobile device accessing files, webcam streams, the status of their print job, and more.

The ability to operate remotely is a valuable asset for businesses. For example, since RaiseCloud features a webcam stream of the print job, having a person on-site to monitor the print job is no longer necessary, lowering the cost of labor.

Operating remotely also gives businesses the ability to react quickly to unexpected changes. For example, COVID-19 made working remotely necessary, and businesses had to suddenly alter how they operated. Businesses that had RaiseCloud were able to continue their 3D printing operations and continue production. In comparison, businesses without a printer management software like RaiseCloud needed to spend time figuring out and setting up remote operations, causing production delays.

RaiseCloud also manages users and printing tasks while keeping teams synchronized, improving workflow management which is useful for businesses that require multiple 3D printers. For example, a business with multiple printers needs to manage the sequence of print jobs to make sure when a printing task finishes, the next task can begin without losing time. With RaiseCloud, businesses can create a queue of printing tasks, and assign these tasks to printers, making sure that time is not lost on any project.

RaiseCloud pairs with ideaMaker, completing Raise3D’s 3D printing ecosystem. The Raise3D ecosystem results in a better 3D printing experience while producing high quality prints.

3. Choose a 3D Printer with Fail Safe FeaturesWhen 3D printing, there can be certain occurrences that can cause a print to fail or to be damaged. Two common examples are if the filament runs out during printing, or if there is a power outage during printing.

- Filament Runs Out

If the filament runs out during printing, the part can break or snap in the middle, and can not be repaired. The print job will need to be restarted. However, professional, high quality printers will include features to alert users before the filament runs out during printing. For example, Raise3D printers feature filament run-out sensors on their extruders that can sense and alert when the filament is about to run out.

- Power Outage

A power outage or an accidental unplugging of the printer will cause the printing process to stop. In this situation, after power is restored, the printer will not be able to continue printing from where it left off unless it has some features that address power outages. For example, Raise3D printers feature power loss recovery, meaning the printer can pause and save its place during a power outage and resume printing when power is restored.

- Automatic Detection

Since some businesses want to be mindful that the 3D printers are fully enclosed, the business may want the option to pause printing if the printer’s door or lid is opened. Printers like the Pro3 Series, E2CF, and E2 provide businesses the option to enable a feature called Automatic Detection. If a business enables Automatic Detection, printing will pause if the printer’s door or lid is opened. If the business does not enable Automatic Detection, then the printer will continue printing even when the printer’s door or lid is opened.

A 3D printer with support from the manufacturer or reseller (whose sales network offers good support), is easier to communicate with, and offers educational resources to learn how to use the printer is invaluable. Receiving support results in a smoother, better 3D printing experience and it shortens the learning curve enabling businesses to start printing quicker.

For example, Raise3D offers a Support Center with a Ticket System to answer your technical questions. We also provide an online demo studio where you can connect with us, and schedule presale or sale demo sessions. Our online educational resources include manuals, guides, and a learning center, RaiseAcademy. We share educational videos and live streams on Raise3D’s Youtube channel.

8 nuances worth paying attention to

Sooner or later, everyone will learn about 3D printing. And only a few lucky people, imbued with the opportunities that 3D printing opens up, catch themselves thinking that they want to purchase a 3D printer. The desire gradually develops into a serious decision and the search for the right option begins. And here the potential buyer is faced with the fact that he does not fully understand what to choose among the whole variety of 3D printers. We will try to answer this question in as much detail as possible. What to look for, and how to make a choice? We want to offer a small checklist of the nuances that you need to pay attention to when choosing a 3D printer. You need to decide for yourself for what tasks you will use this technique? What features should a 3D printer have to solve your problems?

Tip 1 : Decide on 3D printing technology

The first step is to decide on the technology of 3D printing. There are two main paths here. If you are faced with the task of manufacturing high-precision and miniature products, such as jewelry, then 3D printers using SLA or DLP technology are suitable for you. Such printers are specially designed for the manufacture of high-precision models. 3D printing in these printers occurs using a laser beam that illuminates the photopolymer resin. Hence the accuracy of the models. Prominent representatives of this segment: Form 2 3D printer or B9 3D printercreator If you are faced with a wider range of tasks, and functionality, part size, and low manufacturing cost are more important, then an FDM printer will suit you. 3D printing on this equipment involves layer-by-layer melting of plastic. If according to SLA printers everything is clear. The scope of their application is jewelry, dentistry, high-precision prototypes of small parts. Then we will dwell on FDM printers in more detail. There is a lot more variety of different options for implementing printers.

Nuance 2: Evaluate your needs

Of course, you always want to get all the best and with maximum opportunities. Do you need all this to solve your current problems? What can be cited as an example? For example, the size of the working area of the FDM 3D printer. There are printers on the market with a large print area (1m x 1m x 1m), and with a very small one (100mm x 100mm x100mm). But for most tasks, a certain standard has already developed. This is the printable area within 200 x 200 x 200 mm. With slight fluctuations in size in one direction or another. Most 3D printers have exactly this size of the working area. This volume is enough to solve 95% of any tasks. But options are possible ... If you plan to manufacture small parts, then a smaller size will probably be enough for you. But if your work will be related to manufacturing, for example, a master model for casting, or large prototypes, then only then it makes sense to pay attention to a printer with a large print area. In other cases, the size of the print area larger than the standard is nothing more than a nice bonus. But as they say, you have to pay for everything. Therefore, most often it makes sense to focus on the “standard” print area. And even if the part you need to print is larger than the working area of your 3D printer, you can always cut it in a special editor, and then print 2 parts of the model and glue them together.

Nuance 3 : Decide on the complexity of the products

You should decide for yourself how complex models you will print on a 3D printer. If you plan to manufacture complex prototypes, or complex art models, then you need a 3D printer that can print with two materials. This is necessary so that your printer can print supports from soluble material. If the models are not the most complex, then you can get by with one extruder and save the budget. A complex model is a model with a large number of elements suspended in the air, or a model whose elements have angles of more than 30 degrees.

Point 4: Decide on the list of materials to be used.

Another important point. You must immediately determine for yourself a list of possible materials with which you are going to print. This primarily applies to materials with a high degree of shrinkage, such as ABS and Nylon. In order to print with such materials, a heated table is clearly required in a 3D printer. And it is very desirable to have a closed case to provide a thermal circuit around the model. If you plan to print only with PLA plastic. You don't need a heated table. But still it is better that the printer has a heated table. Now the difference in the cost of printers with a heated table is practically the same as the cost without it. But you get a universal solution with which you can perform the full range of tasks facing a 3D printer. One more moment. Ability to print with flexible materials Quite a number of 3D printers face the problem of printing with flexible materials. Of course, printing with various Flexes and Rubbers is very interesting at first glance. But the use of these materials in life is not very common. Usually, for most people, this happens like this: A couple of models are printed, and the understanding comes that this is not a fast and rather complicated process. And this is where the acquaintance with flexible materials ends.

Therefore, it makes sense to demand such an opportunity from the printer if printing with such materials is very necessary.

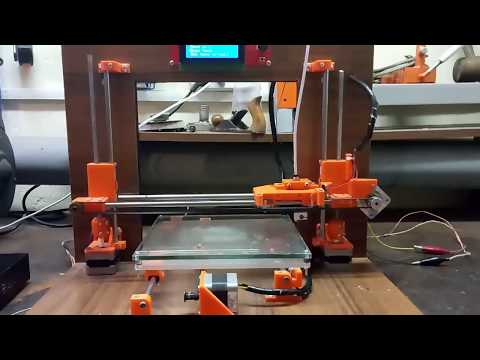

Nuance 5: Construction and kinematics

Next, you need to pay attention to the design of the 3D printer. Even if you are not a great specialist in technology, you can immediately see that some printers have an open design. And others are closed. As they like to be called in the Russian-speaking community "cubes". What does the appearance say? Printers with an open design, usually have kinematics with a horizontally moving table (based on Prusa 3D printers). This kinematics has some inherent flaws. Such as, not the highest print speed and possible print quality problems associated with the complexity of the settings. First of all, this is the so-called wobble. Also, the lack of a closed case can cause print quality problems with high shrinkage plastics (ABS, Nylon). The main advantage of printers of this design is their price. It is usually lower. But as you know, you have to pay for everything. In this case, the worst performance. The so-called "cubes" today, is the main design, which is represented by leading manufacturers on the market. Such printers are built according to the lifting table scheme. And they lack most of the shortcomings that are inherent in printers from the previous group. “Cubes” usually have a closed body, which allows the highest quality printing with plastics with a high degree of shrinkage. Closed case printers are more rigid. This results in better quality printing. The kinematics of moving the print head is represented by various designs. They have their pros and cons. But most of them have advantages over moving table printer circuits.

Nuance 6: Diameter and changeable nozzle

Most 3D printers on the market come with 0. 3-0.4mm nozzles. This is enough to solve the vast majority of tasks facing a 3D printer. Some of the printers have the ability to install a nozzle of a different diameter, others do not. As we wrote above, the need to print with nozzles with a diameter other than 0.3-0.4 mm arises very infrequently. This mainly concerns, or personal experiments, or some very specific tasks. If you do not plan to do this, then this opportunity is not so necessary. What do we mean by specific tasks? This is especially true for printing large items, where it is very important to reduce the printing time. This can be achieved by using large diameter nozzles. For example, with a diameter of 0.6-0.8 mm, or even a diameter of 1 mm. For printers with a large printable area, the ability to change nozzles is already a vital necessity. Therefore, here, as in the case of a heated table, the ability to change nozzles is a good bonus. It is not mandatory, but very useful if you do not have to pay extra for it.

Nuance 7: Print thickness

It is important to understand that most models on a 3D printer are printed with a layer of 0. 1-0.2 mm. These are the optimal values that allow you to achieve quality and acceptable print speed. There are a certain number of printers that allow you to print with a layer of less than 0.05 mm, and get very high quality prints. But then there is the problem of a sharp increase in print time. And if such print quality is important to you, then it probably makes sense to turn your attention to 3D printers, which we talked about at the very beginning of the article. These are 3D printers using SLA or DLP technology.

Nuance 8: Extruder type

Today there are two main types of extruder. This is a direct extruder in which the bar feed motor is located in the printhead itself. And the so-called Bowden extruder, where the plastic feed motor is located on the body. And the plastic itself is fed to the extruder through a fluoroplastic tube. What are the advantages and disadvantages of each type of extruder? Bowden extruder, due to the lack of a motor on the print head, has less weight. And therefore, it has greater positioning accuracy, which affects the print quality. And a higher speed of movement, which, accordingly, has a positive effect on the speed of printing. But it has one drawback. It is usually difficult to print with flexible plastics on a Bowden extruder. Such as Rubber or Flex. All its positive features, this extruder reveals when using plastic with a diameter of 2.85-3.00 mm. But this type of plastic is less common than the now standard plastic with a diameter of 1.75 mm. And therefore, users of printers with such plastic are often deprived of the opportunity to use new types of materials. Which are primarily produced in the most common form factor of 1.75mm. The direct extruder usually doesn't have such big problems with flexible plastics. Easier to set up, but due to the greater mass of the print head, it is inferior to the Bowden extruder in terms of speed and positioning accuracy. What to prefer? This is the user's choice. We just wanted to talk about the pros and cons of these extruder types.

Of course, there are many more nuances when choosing a 3D printer. But we think that even our small list will force you to look and study some points that you may not have thought about more closely. And it will save you time and money when choosing a 3D printer. 3Dtool company has extensive experience in the 3D equipment market. We work with leading Russian and foreign manufacturers, offering high-quality equipment for a reasonable price. Our service center is staffed by highly qualified specialists who are able to solve any problem in the shortest possible time, and all offered 3D printers come with a 1-year warranty.

In our assortment you can always find 3D printers for your tasks:

1) Budget 3D printers

2) 3D printers for business

3) Large area 3D printers

4) SLA and DLP 3D printers

Do you have any questions?

Call: +7 (495) 324-07-90 (Moscow) and 8 (800) 775-86-69 (toll-free in the Russian Federation) or write to the mail: sales@3dtool. ru and our employees will be happy to give you a detailed consultation on any topic of interest.

Which 3D printer to choose for home and hobby