10 crazy things 3d printers can make today

The 10 Strangest 3D Printed Objects

Here’s a riddle for you: What’s more amazing: Technology? Or what can be made with technology?

Apply that riddle to any number of topics: medicine, the internet, nuclear armament, or engineering, and you’re in for an afternoon of philosophical pondering. But, as far as 3D printing is concerned, there’s a very clear answer to the riddle.

While 3D printing technology is amazing, the things that have been created using 3D printing are far more incredible. Let’s discuss the 10 strangest things that have been 3D-printed. But first, let’s briefly review what has been going on in the 3D printing world.

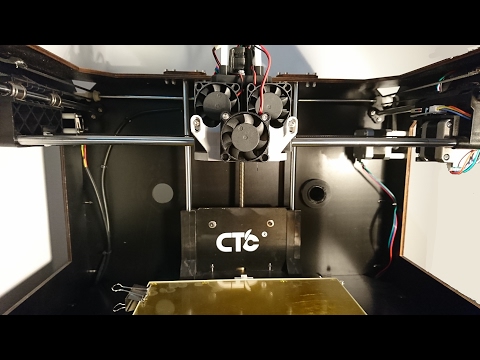

How does 3D printing work?

Have you ever made a sandwich? It’s simply an act of stacking layers of ingredients. The first layer is a slice of bread. The second layer is a coating of mustard. The third layer is a slice of lunch meat, and then there’s a layer of lettuce, and then tomatoes, and so on, so forth.

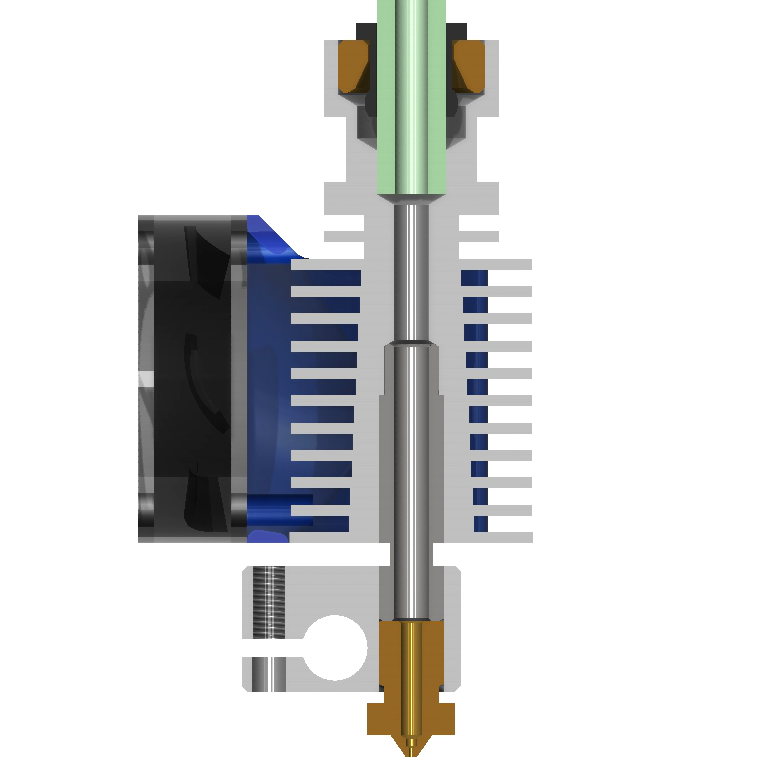

3D printing works in the same way. A 3D printer creates a physical object by stacking layer after layer of a particular substance. Each layer is poured as a liquid. Once the liquid dries or hardens, the next layer is poured on top. There are other 3D printing methods, but they work in roughly the same way.

A 3D printer works off of a computer-aided design (CAD). A CAD is basically a digital model of whatever’s going to be 3D printed. The CAD provides the exact specifications of the object so the 3D printer knows what the shape and size of each layer will be. Before you 3D print an object, you’ll first have to use a design-optimized computer to create a CAD of the object.

Are there limits to 3D printing?

Yes and no. Most of the limitations of 3D printing have to do with two things: size and substance.

On a regular printer, you can’t print a document that’s larger than the printer itself. Similarly, you can’t 3D print anything that’s larger than the 3D printer. But that hasn’t stopped some of the more ambitious individuals. An entire high-rise building has been 3D printed (we’ll get to that, soon). Obviously, the building wasn’t constructed entirely within the machine. But each portion of the building was 3D printed and then assembled onsite.

But that hasn’t stopped some of the more ambitious individuals. An entire high-rise building has been 3D printed (we’ll get to that, soon). Obviously, the building wasn’t constructed entirely within the machine. But each portion of the building was 3D printed and then assembled onsite.

One of the trickier obstacles to overcome is the choice of material that’s used to print. The material must be something that can be melted and fused into a solid shape. Engineers are always working to develop 3D printers that can print using new kinds of substances, and there are now 3D printers that can print metal objects. There still isn’t a 3D printer that prints wood, but they’ve gotten close. Hilariously, there are 3D printers that can print food (yeah, we’ll get to that, too).

With enough creativity, you can overcome some of the limits of 3D printing technology and create some truly remarkable things.

Useful 3D-printed objects

3D printing technology has been around since the 1980s. Originally, it was used to create scale models of manufacturing prototypes or assembly line parts, and that’s still largely what it’s used for today. Machine parts and scale models are commonly built using 3D printers.

Originally, it was used to create scale models of manufacturing prototypes or assembly line parts, and that’s still largely what it’s used for today. Machine parts and scale models are commonly built using 3D printers.

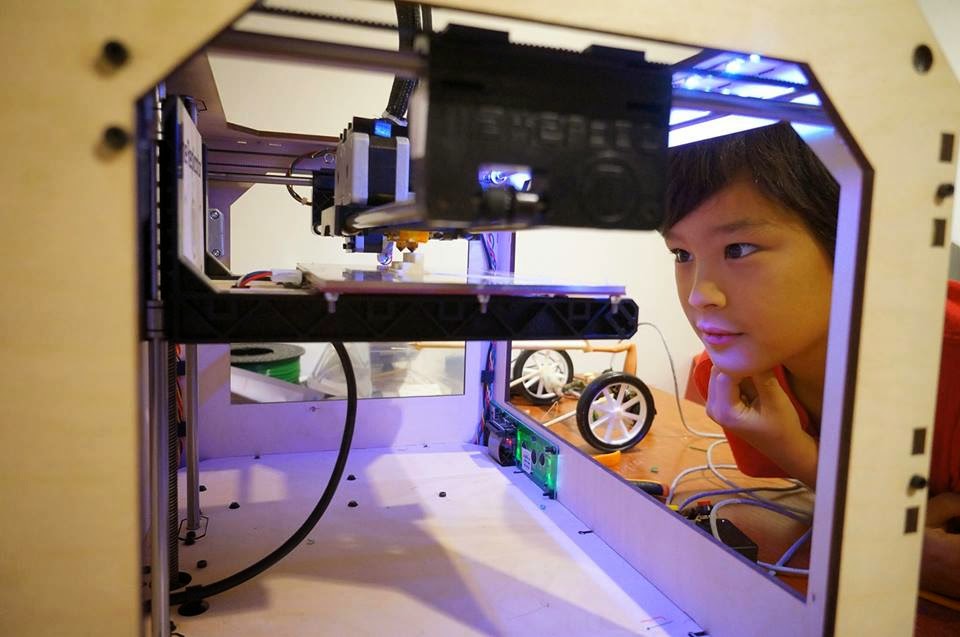

But in the last decade, 3D printers have become much more accessible to consumers. Media interest in 3D printers has also encouraged broader experimentation in lots of different industries, and these days both amateurs and professionals alike are printing unique 3D objects.

Strangest 3D-printed objects

Let’s discuss some of the weird objects that have been 3D printed. Some of these objects are actually quite useful. Others are not. But all of them are wonderfully weird. Here are 10 very bizarre things that have been crafted with 3D printers.

1. Mouse ovaries

Researchers at Northwestern University in Chicago created the first artificial mouse ovaries using a 3D printer. [1] Okay, so mouse ovaries aren’t technically useless - they’d be very useful for any infertile mouse. But ovaries aren’t the first thing you’d expect to be 3D printed, right?

But ovaries aren’t the first thing you’d expect to be 3D printed, right?

The mouse ovaries were created by 3D printing layers of gelatin. Then they were surgically implanted in seven infertile mice. Of the seven mice that received implants, three mice successfully gave birth to litters of pups.

There are human implications to this discovery, of course. The researchers hope that someday, they’ll be able to print artificial human ovaries for cancer patients and others who are infertile.

2. Food

Speaking of mice: researchers at University College, Cork in Ireland 3D-printed objects using cheese. [2] They filled a 3D printer nozzle with Easy Cheese and printed “cheesy” designs with it, including a small bear. The designs were mostly flat because aerosol cheese isn’t the most stable printing substance.

There are other types of foods that have been 3D printed, too, one of the most famous being 3D printed chocolate. If you think that chocolate rabbits are neat, you should see some of the nifty chocolate designs that have been made with 3D printers.

Chocolate makes for a great 3D printing substance because it can be layered while it’s melted then easily hardened. There are several companies that sell 3D-printed chocolate, including chocolate behemoth Hershey. [3]

They’ve also 3D-printed pizza. A printer was equipped with three nozzles that dispensed liquid dough, tomato sauce and cheese. In under five minutes, the pizza dough was ready for baking. Researchers said they were able to accurately control the crispiness of the bread thanks to the 3D printer.

Here are some other cool foods that have been 3D-printed:

- Quiches

- Croutons

- Candies

- Cereal

So what’s on the horizon for 3D-printed food? For one, restaurants and bakeries will be able to print large quantities of stylized foods and pastries. But the hope is that people will be able to prepare food in their own homes without having to cook. Very futuristic, indeed. “Computer...Tea. Earl Grey. Hot.”

3. Skin

Researchers at the University of Toronto created a handheld 3D printer that could apply skin cells on a pig. The pig had its cells harvested, and the cells were grown to a larger quantity. Once researchers had enough cells, they used the cells as the printing substance.

The pig had its cells harvested, and the cells were grown to a larger quantity. Once researchers had enough cells, they used the cells as the printing substance.

The 3D printer was rolled over the pig’s wound “like a white-out tape dispenser.” Success! The skin cells successfully attached to the open wound area. Scientists think that in the future, this technology could be used to replace skin grafts. It would make it much easier to treat victims with open wounds - especially burn victims. [4]

The science of printing living tissues is known as bioprinting. Researchers have printed:

- Artificial bone

- Artificial blood vessels

- Artificial bladders

Scientists are hoping they’ll be able to finally end the long - and sometimes fatal - wait for organ transplants. [5]

4. Bikini

Textiles are notoriously difficult to print, but a company called Continuum Fashion has created a number of cool 3D-printed fashion items. Their standout fashion piece is the 3D-printed bikini. You can hit the beach and go swimming in style and comfort.

You can hit the beach and go swimming in style and comfort.

Continuum printed the bikini using a material called Nylon 12, which is strong, flexible, and waterproof. The bikini has an awesome texture, too. It’s composed entirely of interconnected beads, a testament to the intricate kinds of designs that can be printed.

The company also produces a line of 3D-printed women’s shoes. [6]

5. Mini Power Drill

You’ve got to see it to believe it. A man in New Zealand created the world’s smallest power drill with a 3D printer. The drill measures 17 x 7.5 x 13 mm, and is equipped with a 0.5 mm drill bit. And it works! The drill is powered by a hearing aid battery and utilizes a miniature motor and headphone-cable wiring. [7]

Should we call this the world’s smallest drill, or the world’s cutest drill?

6. Microscopic race car

There’s a bizarre creation courtesy of researchers at the Vienna University of Technology. They created a 3D printer that can create near-microscopic objects. To demonstrate its abilities, the researchers printed a tiny race car that’s just about the width of a hair follicle. [8] It’s not quite built to tackle the Monaco Grand Prix, but it would make a perfect vehicle for lice.

To demonstrate its abilities, the researchers printed a tiny race car that’s just about the width of a hair follicle. [8] It’s not quite built to tackle the Monaco Grand Prix, but it would make a perfect vehicle for lice.

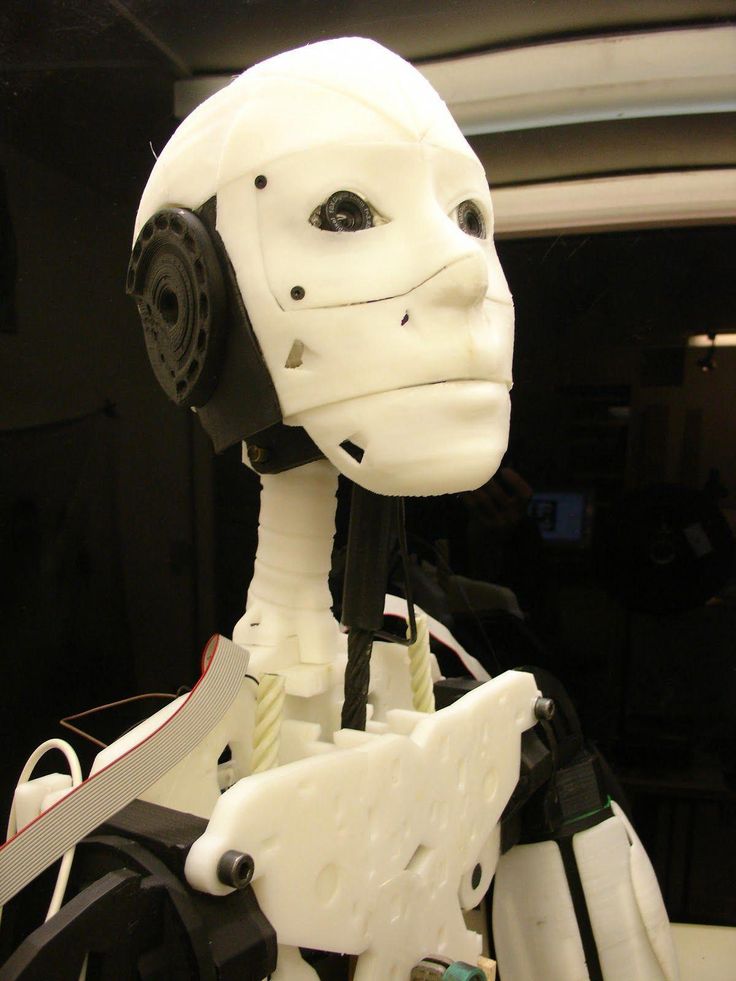

7. Wall-climbing robot

South Korean scientists used a 3D printer to build a robot that can climb walls. The robot mimics the movement of a gecko and is capable of climbing up vertical walls with the help of adhesion pads. The robot’s body was 3D-printed using a material called Polyamide 12. [9]

Another cool robot was 3D-printed at the University of California, San Diego. This robot has three legs and can navigate rough terrain, like sand and rocks. 3D printing was integral in building the robot. In order to crawl over rough terrain, the robot needed to be constructed of softer, more flexible materials than what most robots are made of. The researchers were able to 3D-print the robot’s soft and hard surfaces together. [10]

8. Unborn babies

Thanks to 3D printing, expectant parents can hold their baby before it pops out of the womb. A Russia-based company uses ultrasound scans to create a 3D-printed model of the unborn child. Umm… cute?

A Russia-based company uses ultrasound scans to create a 3D-printed model of the unborn child. Umm… cute?

In actuality, the models aren’t made to be baby shower gifts. They help doctors evaluate the health of the developing child. The models are a bit surreal. They’re highly detailed and capture the smallest facial features of the unborn baby. [11]

Imagine the comedic possibilities of using an unborn baby model at a gender reveal party.

9. Buildings

Buildings aren’t strange (unless we’re talking about some contemporary architecture). But constructing a building with a 3D printer is strange. How on earth can a 3D printer construct something so gigantic?

Concrete is the main substance that’s used by a 3D printer to print a home. A crane lifts the printer nozzle above the ground and maneuvers the nozzle as it places layers of concrete. Some 3D printers can also layer insulation materials.

Most 3D-printed buildings don’t adhere to building codes, so they’re either built as temporary structures or they’re built very small. But construction firms are optimistic that they’ll be able to build more advanced structures as the technology progresses. [12]

But construction firms are optimistic that they’ll be able to build more advanced structures as the technology progresses. [12]

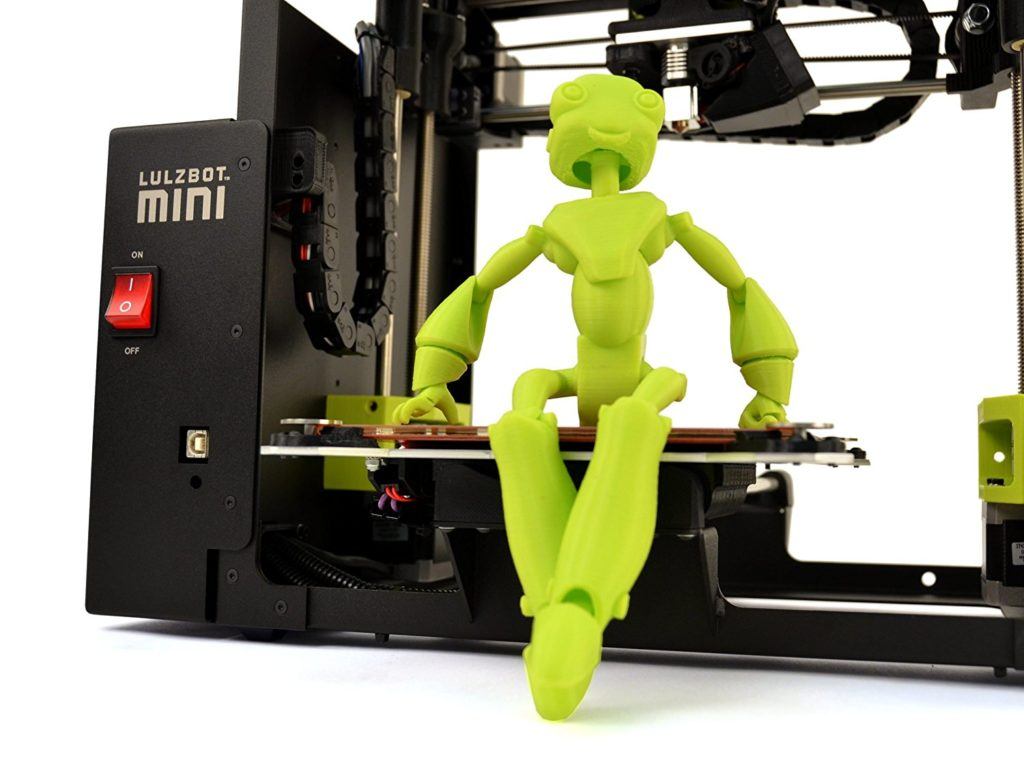

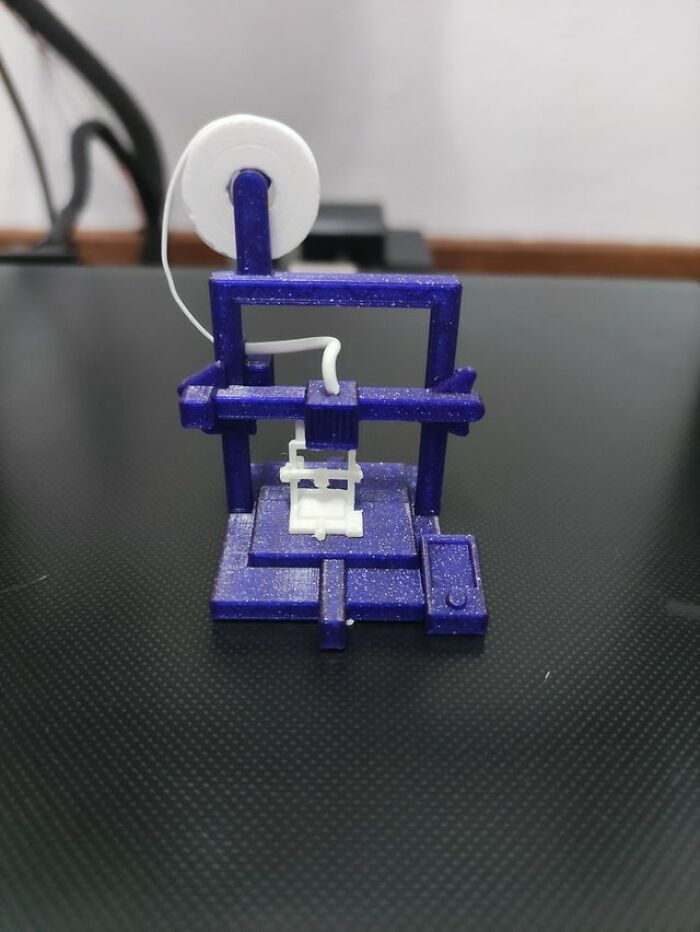

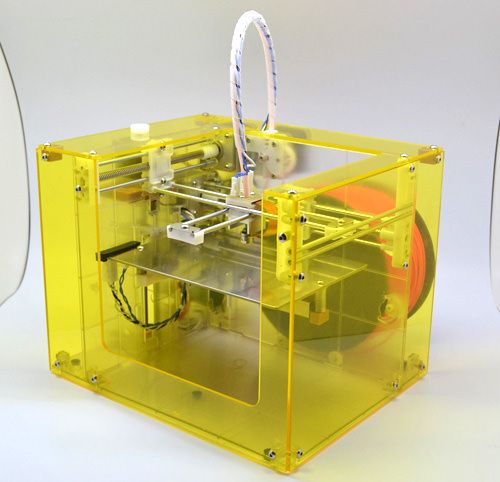

10. 3D printer

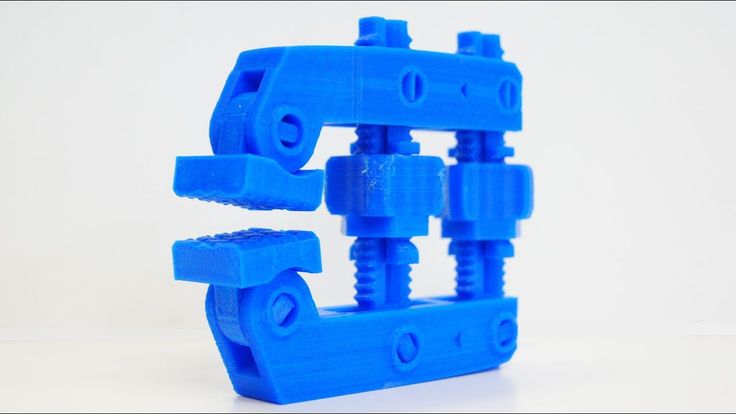

That’s right: a 3D printer has printed a 3D printer. [13] This is the most “meta” item on this list. You can’t print a 3D printer in its entirety, but people have printed all of its individual parts, and then they’ve manually assembled them.

Honorable mention: light-created objects

Researchers at the University of California, Berkeley discovered how to 3D print solid objects out of liquid and light. The researchers used a gooey liquid that turns solid when exposed to a certain amount of light. They used light beams to sculpt solid figures within the liquid. The benefit of this technique is that it’s easier to print bendable items. Objects printed in this way are also much smoother than those that are 3D-printed by traditional methods. [14]

None of the objects that they printed were uniquely “strange.” But the printing process itself is strange enough to be worthy of a mention on this list.

Your turn to contribute

What are you waiting for? You could be the next great inventor of a strange (or useful) 3D-printed object. Learn about HP 3D printing technology.

Here are some 3D printing ideas for you. You can print them on a large 3D printer or a home 3D printer. Some of these objects have been designed and 3D-printed by ordinary people!

- Musical instruments

- Busts

- Makeup

- Toys

- Cable catchers

- Pen holders

- Phone docks

- Tablet stands

- SD card holders

- Garden decor

- Recycling/sustainability equipment

There are so many cool items you can make with a 3D printer, no professional assistance needed. Get out there and start creating, and be sure to share your innovative or wild ideas with the rest of us. You can change the world with 3D printing, or you can print something that’ll make all of us laugh.

[1] TheGuardian.com; 3D-printed ovaries allow infertile mice to give birth

[2] Gizmodo. com; The First 3D Printed Cheese Was as Bizarre as You’d Expect

com; The First 3D Printed Cheese Was as Bizarre as You’d Expect

[3] Fabbaloo.com; 3D Printing Is Revolutionizing The Chocolate Industry

[4] CNet.com; This Handheld 3D printer can print skin onto people

[5] Science.Org.Au; Printing the future: 3D bioprinters and their uses

[6] BusinessInsider.com; The World’s First Bikini Made Using A 3D Printer

[7] Geek.com; World’s smallest working drill created with a 3D printer

[8] UniverseToday.com; Watch This 3D Printer Make a Microscopic Car

[9] 3DPrintingIndustry.com; 3D Printed Wall-Climbing Robot Emulates Gecko By Walking Upside Down And Underwater

[10] CNNMoney.com; New 3D-printed robot can walk on sand and rocks

[11] TechTimes.com; Expectant Parents Can Have 3D Models Of Unborn Babies

[12] CityLab.com; Is the Revolution of 3D-Printed Building Getting Closer?

[13] Sculpteo.com; Can you 3D print a 3D printer?

[14] BerkeleyNews.com; New 3D printer uses rays of light to shape objects, transform product design

About the Author

Zach Cabading is a contributing writer for HP® Tech Takes. Zach is a content creation specialist based in Southern California, and creates a variety of content for the tech industry.

Zach is a content creation specialist based in Southern California, and creates a variety of content for the tech industry.

10 Crazy Things 3D Printers Can Make Today

It’s been over 30 years since Chuck Hull invented the first 3D printer in 1983. Ever since then, the idea of machine-printing objects from scratch has gone from fiction to reality, opening up new opportunities for every field from science to art.

See also: Why You’ll Want A 3D Printer In Your Home

3D printing may not be quite there yet, but in three decades the technology has progressed leaps and bounds in terms of the scope and utility of 3D-printed objects. Surprise, surprise: It’s not just gimmicks and toys.

It’s easy to be skeptical of 3D printing, which is still slower, more expensive, and less effective than traditional manufacturing. But by focusing only on the technology’s few remaining shortcomings, we fail to observe how far 3D printing has already come.

Here are 10 of the most incredible objects that can already be 3D printed with today’s technology.

Body PartsEars, kidneys, blood vessels, skin and bones have all been successfully 3D printed by scientists around the U.S. Instead of the typical plastic normally associated with 3D printing, these 3D medical “bioprinters” use a gel-like substance made from cells. (The outlier is bones, which use a ceramic powder instead.)

Advances in 3D bioprinting mean that some day soon, doctors will be able to provide every patient with a perfectly matching bone fragment, skin graft, or kidney (3D printed kidneys exist, but they are not yet functional).

And until 3D bioprinting gets around to printing whole human limbs, 3D plastic printers are already capable of printing artificial limbs for less than $100 in just a few hours.

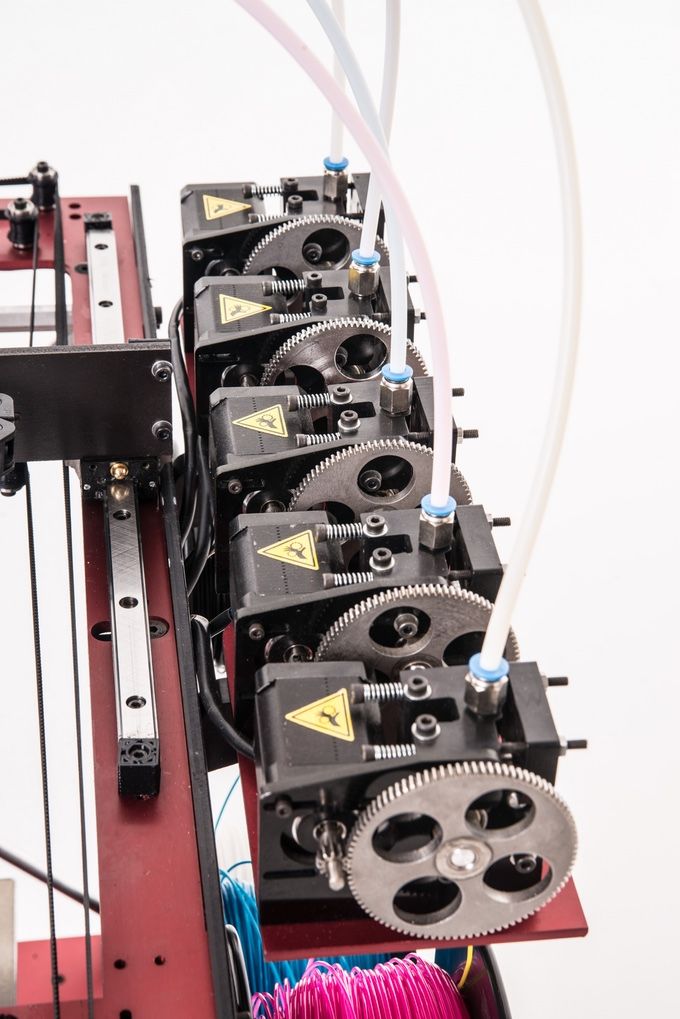

PizzaThis NASA-funded 3D printing project is good enough to eat. The organization began funding 3D-printed food in order to feed astronauts in space.

Usually, a 3D printer works from just one material cartridge. But the pizza printer works by printing from multiple cartridges at once, containing material like dough, cheese, or sauce.

You can watch the entire process on YouTube:

ChocolateReplace the typical plastic in a 3D printer’s cartridge with melted chocolate and the possibilities for futuristic desserts are endless. You can print any writing or drawing that can be processed by a computer, and it’ll be edible.

Chocedge is one of the first chocolate-exclusive 3D printers, at several thousand dollars a pop. But there’s a surprisingly large amount of competition in the field of 3D-printed candy. In January, the Hershey Company and 3D Systems announced a partnership to create all kinds of 3D printed confections. If the company replaces factory workers with 3D printers, it might be able to streamline its process while giving us slightly more futuristic Hershey’s Kisses.

Clothing3D printed clothing may not be in stores yet, but it’s already debuted on the runway. Model Dita Von Teese wore the first fully articulated 3D printed gown—made especially to fit her. With nearly 3,000 joints, the dress flows according to her curves.

Model Dita Von Teese wore the first fully articulated 3D printed gown—made especially to fit her. With nearly 3,000 joints, the dress flows according to her curves.

For regular people, 3D-printed clothing could mean a level of customization beyond the abilities of any tailor—clothing literally printed to any body’s specifications. Though unless you’ve got a figure like Dita’s, you might not be just ready for that yet.

Musical InstrumentsIt’s now possible to create functional musical instruments wholly or partly out of 3D-printed objects. Commercially, there’s the Odd 3D printed guitar, which promises a unique look as well as premier acoustics. MIT Media Lab researcher Amit Zoran was able to print a working flute. German firm EOS printed a polymer-based violin.

The only problem? 3D printed instruments don’t sound very good yet, at least not compared to traditional instruments. Violin soloist Joanna Wronko demoed a standard violin and the 3D printed one side by side at TED Amsterdam, and it’s clear which one audiences preferred.

Urbee 2 looks more like a jelly bean than a car. But it’s actually the first vehicle in existence that has been manufactured chiefly from 3D-printed parts.

This three-wheeled car is cheaper and more fuel efficient than just about any vehicle on the market today, but its 23 horsepower engine (with batteries combined) means it could struggle to reach top highway speeds.

Urbee 2’s inventors aspire to drive the 3D-printed vehicle across the U.S. within the next two years, but they’ll need to do some work first. Right now, the car is nowhere near compliant with the U.S. highway code.

GunsPossibly the most controversial creation you can build with a 3D printer is a firearm. The first model was called the Liberator, developed by 26-year-old Cody Wilson.

Now, anybody who has a 3D printer and an Internet connection can download and print their own gun out of plastic parts. But just because they’re made of plastic doesn’t mean they’re not deadly—according to the FBI, the Liberator fires bullets capable of piercing internal organs.

Although the gun exploded when the FBI tried to print its own copy of The Liberator to test it, Wilson uploaded a video of himself firing it successfully. Just how long 3D printed guns will be legal, however, is hard to tell, as local legislatures work to ban them.

Drones

One disruptive technology begets another when 3D-printed drones roam the skies.

Researchers at Southhampton University have developed the SULSA (Southampton University Laser Sintered Aircraft), an unmanned aerial vehicle that can be mass produced through 3D printing. It has a top speed of 90 miles per hour, and can remain in the air for a total of 30 minutes.

The drone can be assembled from plastic parts in 10 minutes, without the use of screws or other conventional fasteners. As a result, it is virtually silent in cruise mode. You’ll never see this 3D printed drone coming.

Adult ProductsOf course, one of the first things people figured out with 3D printers was how to make something sexy. The adult industry has already harnessed the technology to print dildos, vibrator sleeves, and other accessories. Some are heavily customized(link NSFW): 3DEA, a popup shop in Chelsea, is providing toys for customers tailored to personal scans. .

The adult industry has already harnessed the technology to print dildos, vibrator sleeves, and other accessories. Some are heavily customized(link NSFW): 3DEA, a popup shop in Chelsea, is providing toys for customers tailored to personal scans. .

At this point it’s predictable that the next step in human progress would involve sex. Perhaps this is a sign that 3D printing really has potential—after all, we can’t forget what people first began using the Internet for.

3D Printers

Yes, you can even print 3D printers with a 3D printer.

With the advent of a 3D printer capable of printing itself, we’ve gone full circle. The RepRap is an open source printer that does just that. The RepRap is released under a free software license, so you can freely print and put together all the parts that make it up. Just buy the machine (for $500-$600 online), and program it to self replicate until you’ve made 3D printers for all of your friends.

What have I missed? List your favorite 3D prints in the comments.

Photos by Subhashish Panigrahi, Albert Sanchez, 3dilla, Southampton University, and RepRap.

10 Incredible Things 3D Printers Can Do Today

It's been more than thirty years since Chuck Hull invented the first 3D printer in 1983. Since then, the idea of printing objects on a machine has gone from fantasy to reality, opening up new possibilities for every field, from science to art.

3D printing may still be evolving, but the technology has grown exponentially over the last thirty years, both in terms of volume and utility of printable objects. And you know, it's not just stuff-dryuki and toys.

It's easy to be skeptical about 3D printing, which is still slower, more expensive and less efficient than traditional manufacturing. But if we focus on a few of the technology's remaining drawbacks, we won't be able to see how far 3D printing has already come.

Here are ten of the most incredible objects that you can already print.

Contents

- 1 Parts of the body

- 2 Pizza

- 3 Chocolate

- 4 Clothing

- 5 Musical instruments

- 6 Cars

- 7 Weapons

- 8 Drones

- 9 Toys for adults

- 10 3D printers

Ears, Kids, blood vessels, leather and bones-leather and bones-leather and bones-leather and bones-leather and bones-leather and bones-leather and bones-leather and bones-skin and bones-leather and bones-leather and bones-bones and bones-bones and bones-bones and bones-bones and bones-bones and bones-bones and bones-bones and bones-bones and bones-bones and bones-bones and bones-bones and bones-bones and bones-bones and bones-bones and bones. all of this was successfully printed. Instead of the usual plastics associated with 3D printing, medical bioprinters use a gel-like substance made from cells. Except for the bones, which are based on ceramic powder.

Advances in 3D bioprinting mean that doctors will one day be able to provide every patient with a perfectly matched bone fragment, skin flap or kidney. The kidneys, by the way, are already there, but not yet working.

The kidneys, by the way, are already there, but not yet working.

And while bioprinters can't print whole human limbs, plastic printers can already print artificial limbs for less than $100 in just a couple of hours.

Pizza

This NASA project is quite edible. The organization has begun funding 3D printed food to feed astronauts in space. Usually 3D printers work with one material cartridge. A food printer prints from several cartridges at once, containing materials like dough, cheese or sauce.

Chocolate

If you replace ordinary plastic in a 3D printer cartridge with melted chocolate and give it the ability to write futuristic monograms on cupcakes and chocolates, a real paradise for the sweet tooth will begin. You can print or paint whatever you draw on the computer and then eat it.

Chocedge is one of the first multi-thousand dollar exclusive chocolate printers. However, 3D printing of sweets is fiercely competitive. In January, Hershey and 3D Systems announced a partnership to create all kinds of printed candies. If a company replaces its workers with 3D printers, it will greatly streamline the workflow.

In January, Hershey and 3D Systems announced a partnership to create all kinds of printed candies. If a company replaces its workers with 3D printers, it will greatly streamline the workflow.

Clothing

3D printed clothing may not be available in stores yet, but it already exists. Model Dita Von Teese wears the first fully 3D printed dress made especially for her.

For ordinary people, 3D printing can mean an incredible level of personalization of clothes, up to having your own tailor, literally. A 3D printer will be able to print clothes for any body. On the other hand, if you don't have a figure like Dita, you may just not be ready yet.

Musical instruments

It is now possible to create functional musical instruments completely 3D printed. The commercial realm already has the Odd 3D guitar, which promises a unique look and top class acoustics. MIT lab researcher Amit Zoran has printed a fully working flute. The German company EOS has printed a polymer violin.

The only problem is that 3D printed musical instruments don't sound as good as traditional ones. Violinist Joanna Vronko played a regular violin and a printed one at a concert in Amsterdam, and it became clear that the audience liked it better.

Cars

The Urbee 2 looks more like a bean than a car. But in fact, this is the first car made from 3D printed parts.

The three-wheeled car is cheaper and uses less fuel than any other car on the market, but the 23-horsepower engine (with batteries) allows it to reach incredible speed. The creators of Urbee 2 want to get the car on American roads within two years, but they still have a little work to do. The car, for example, does not comply with US traffic regulations at the moment.

Weapons

Perhaps the most controversial thing to print is firearms. The first model was called the Liberator and was designed by 26-year-old Cody Wilson. Now, just about anyone with a 3D printer and an internet connection can download and print their own plastic handgun. But just because it's made of plastic doesn't mean it's safe.

But just because it's made of plastic doesn't mean it's safe.

Even though the Liberator exploded when the FBI decided to unseal it, Wilson uploaded a video of him successfully shooting himself. In general, it will soon be banned at the legislative level.

Drones

What about 3D printed drones flying through the skies?

Researchers at the University of Southampton have developed SULSA, an unmanned aerial vehicle that can be mass-produced in 3D printing. Its top speed is 150 km/h and it can stay in the air for a total of 30 minutes.

The drone can be assembled from plastic in 10 minutes without the use of screws or other fasteners. The result is an absolutely quiet aircraft.

Toys for adults

And of course, one of the first things people started doing with the advent of 3D printers was sex toys. The industry is already giving out dildos, vibrating sleeves and other accessories. Some of them are highly personalized.

It was possible to predict what all this would lead to. After all, we all know what people started using the Internet for.

3D printers

In fact, a 3D printer can also print on a 3D printer. With the advent of such an opportunity, we closed the circle. RepRap is an open source printer that does just that. Open source means you can print and assemble all the parts with ease. You just need to buy the device itself (500-600 dollars) and a program for printing, and then you can give all your friends a printer.

10 amazing things created with 3D printing

3D printing technology is improving every day. There is no doubt that in the future, 3D printers will be considered as important an invention of mankind as, for example, the creation of the Internet. Researchers, investors and even scientists from NASA see the huge potential of these devices and are eager to find practical applications for them. Below, we'll highlight some of the amazing things that have already been 3D printed.

Below, we'll highlight some of the amazing things that have already been 3D printed.

Foodstuff

3D Systems has made incredible strides in printing a variety of food products. The Chefjet is capable of printing chocolates and candies in dozens of flavors. It works on the same principle as other 3D printers, layering on top of each other the building blocks of confectionery until they are ready.

You might think that printing products has no practical use. However, it is not. Representatives of 3D Systems claim that they can create complex structures, including moving parts. Their printer will be in demand in restaurants, as it will allow to print any desserts requested by customers. Thus, the need to purchase and store products until they are used will disappear.

NASA is also conducting research into printing food for astronauts aboard spacecraft. The fact is that products delivered to orbit take up a lot of space and have a limited shelf life. Food cartridges of 3D printers are smaller and can perform their functions for up to 30 years. In the future, food printing technology will solve the problem of providing food for people who go on long-term interstellar travel.

In the future, food printing technology will solve the problem of providing food for people who go on long-term interstellar travel.

Medical implants

World medicine has also benefited from 3D printing technology. So, in 2012, an 83-year-old patient was implanted with a new titanium jaw. The device printed it by fusing layers of titanium powder under the influence of lasers. The operation was successful, and the doctors began to vied with each other to praise the benefits of printed implants. There were no complications during the procedure, the next day the patient ate and talked on her own.

Other artificial body parts have also been 3D printed. Scientists at Princeton University have created a functioning human ear with integrated electronics. Previously, it seemed that the fusion of mechanical parts with body tissues was something from the category of science fiction. But modern technology has helped bring this idea to life. And scientists have the opportunity to create and implant patients with devices that theoretically exceed the characteristics of real parts of the human body. Agree, this is another step towards the creation of cyborgs.

Agree, this is another step towards the creation of cyborgs.

This is interesting: Doctors have no doubt that in the near future, printers will even be able to print internal organs for patients, eliminating the need to look for a suitable donor.

Racing car

A group of students from the Institute of Science and Technology in Changsha, China built a car using 3D printed parts. The car accelerates to 100 kilometers per hour, while its net weight reaches only 220 kilograms. True, the assembly of such cars today is much more expensive than the industrial production of their counterparts. But scientists expect that in the coming years, the cost will decrease, because consumables used for 3D printing will become cheaper.

The experimental car is made of durable plastic and carbon fiber. The 3D printer allowed students to create complex parts in one go, rather than assembling them from dozens of small parts. An additional advantage of this approach is that the replacement of worn parts in the future will be carried out many times faster than now.

Exoskeleton

The Alfred Dupont Children's Hospital has developed a functional exoskeleton to help disabled children with musculoskeletal disorders. It supports the little ones and allows them to move freely.

One day, two-year-old Emma was unable to use the exoskeleton because it was too heavy for her. After that, a team of scientists developed a lighter analogue and printed it using a 3D printer.

The exoskeleton provided Emma with the support she needed to move without pain and use her limbs effectively. I am also glad that this device was created to order in the hospital. This means that its design can be modified as the patient grows.

The benefits of 3D printing for medical purposes don't end with the creation of exoskeletons. Scientists from the University of Victoria are developing special casts for broken limbs that are very light and strong. Created using 3D printing technology, plasters reliably protect the bones from any external influences while they grow together after fractures.

Personalized Star Wars characters

In 2012, Walt Disney Pictures acquired the rights to the Star Wars franchise. A few months later, fans of the exciting epic got the opportunity to purchase personalized figures of their favorite characters. Disneyland visitors can now become Imperial Stormtroopers, Jedi Knights, and more.

The client's face is scanned from different angles using a special machine. After that, it is printed in 3D on the chosen 7-inch model. The cost of the service is $100.

3D scanning technology has been used in video games for over 3 years. Thanks to her, players get the opportunity to "impose" their face on the in-game character. Other companies make money by creating specific personalized superheroes for each client. To work, they need only 5 photographs of a person's face, taken from different angles.

Nylon Bicycle

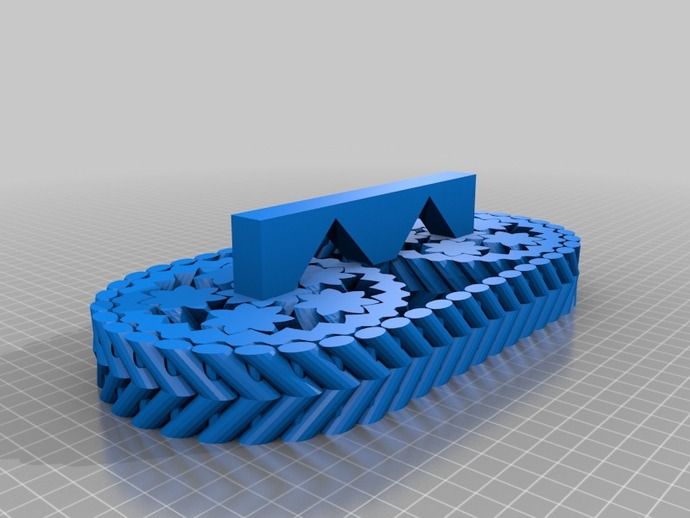

Developers from the European Aerospace and Defense Concern have developed a unique aerobike, demonstrating their achievements in the field of 3D printing. Powerful lasers are used to create the layers of the structure. They heat the nylon and give it the desired shape. Gradually, the layers overlap each other. The bike presented by scientists is fully functional, despite the fact that even the pedals and chains in it were printed on a 3D printer.

Powerful lasers are used to create the layers of the structure. They heat the nylon and give it the desired shape. Gradually, the layers overlap each other. The bike presented by scientists is fully functional, despite the fact that even the pedals and chains in it were printed on a 3D printer.

Representatives of the concern claim that their nylon bike has a number of advantages over traditional models. It weighs 2 times less, not inferior in strength to steel. It also plays a big role in the fact that the process of 3D-printing a bicycle is more “cleaner” in environmental terms than standard production. Any spare mechanism for this type of transport in the future will be able to be printed on the spot. That is, users do not have to overpay for shipping and waste time waiting for the right part.

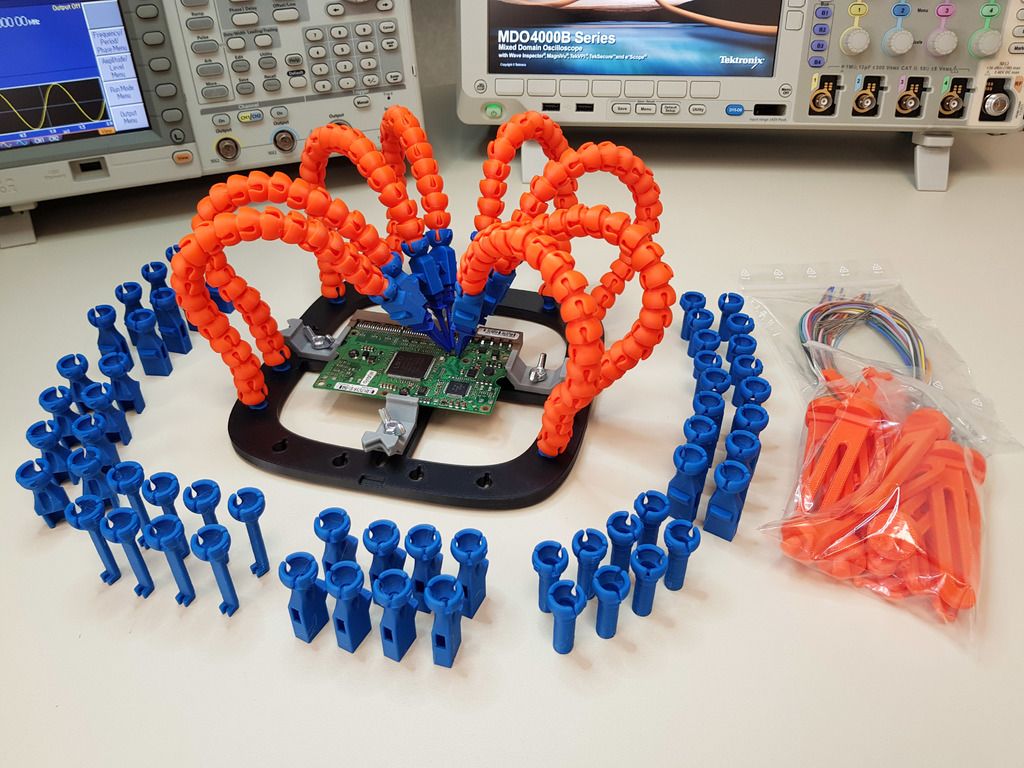

Tools

3D printing technology is already being used by leading manufacturers to produce highly specialized tools. Among them are both ordinary wrenches, screwdrivers and hammers, as well as surgical scalpels. Experts assure that in 5-10 years, customers will be able to print self-designed tools at home or order them from manufacturers.

Experts assure that in 5-10 years, customers will be able to print self-designed tools at home or order them from manufacturers.

Interesting: Stratasys announced a year ago that it had successfully built a cordless drill using a 3D printer. It is made up of dozens of different polymers. The handle of the drill for the convenience of users is made soft, the body is made of impact-resistant plastic. Drills are not inferior in strength to industrial counterparts.

Batteries and generators

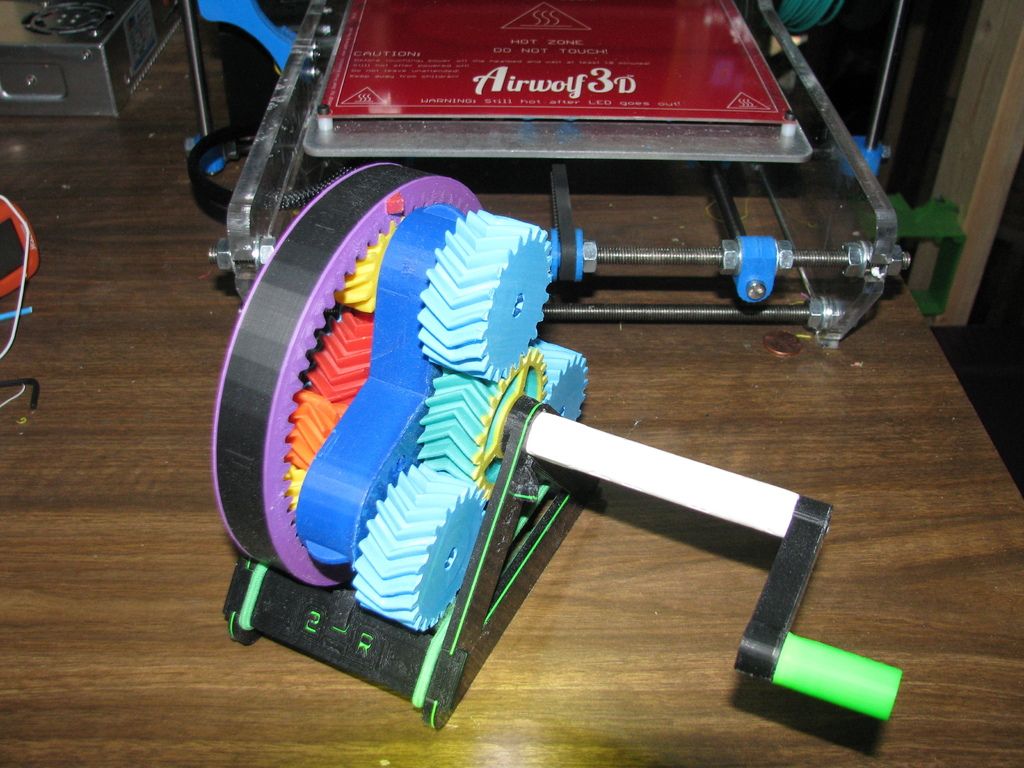

Everyone knows the situation when the phone's battery runs out at the most inopportune moment - for example, when you go on a date or ride the bus to a neighboring city. Unfortunately, there is no possibility to charge the device on the spot. But Erichsen representatives believe that they have found a solution to this problem. They designed a range of hand-operated power generators and 3D printed them. The rotor of these devices rotates at a frequency of 70 revolutions per second. This allows you to generate enough electricity to charge a small device - a smartphone, an e-reader, etc.

This allows you to generate enough electricity to charge a small device - a smartphone, an e-reader, etc.

Interesting: At the same time, other firms are exploring the possibility of 3D printing lithium-ion batteries for gadgets. Note that the created prototypes are superior in performance to standard batteries. They weigh 2-3 times less and have smaller dimensions, which allows developers to significantly increase the usable capacity.

Automatons

Basically, scientists are exploring the possibilities of printing various useful things on 3D printers - tools, prostheses, food, etc. But you must admit: solving actual problems is good, but sometimes you want to get distracted and create some kind of fun little thing for the soul. As 3D printing technology is already well adapted to everyday use, some experts have started designing automatons – in other words, winding mechanisms that perform simple actions.

Lets Make Robots user Cevinius has created a walking automaton powered by gravity. A slight push will allow the mechanism to smoothly descend from a gentle slope. The cost of such an automaton is only 6 dollars. On the Internet, you can also order more complex mechanisms created using 3D printers. For example, a dragon flapping its wings and moving across the surface when a lever is turned.

A slight push will allow the mechanism to smoothly descend from a gentle slope. The cost of such an automaton is only 6 dollars. On the Internet, you can also order more complex mechanisms created using 3D printers. For example, a dragon flapping its wings and moving across the surface when a lever is turned.

And viewers of the British television project QI recently saw the so-called Sand Beast. It is a 3D printed mechanism powered by the wind. It consists of over 70 moving parts. The Sand Beast begins to crawl along the surface when its turbine is started by the air currents.

3D Printers

RepRap is working on a 3D printer that can print... itself! This project is open, that is, anyone can contribute by contributing to the achievement of the goals set by the researchers.

This is interesting: At the moment, 4 different versions of the printing device “cloning” itself have already been released. A 3D printer easily prints almost all the parts used to create a copy of it.

If the goal of the researchers is achieved, users from all over the world will be able to access a machine capable of printing a wide range of useful items much earlier. Such devices will become especially important in poor countries, whose inhabitants will be able to create the vital things that they currently lack.

It is likely that very soon 3D printing technology will be significantly improved and will become available to anyone. Just imagine: you do not have to go to the grocery store and cook breakfast, because it can be simply printed. And the closet shelves will be bursting with outfits that you designed and created yourself, without touching the sewing machine. Now it seems like a fantasy, but do not forget that at the end of the 19th century, the director of the US National Patent Office proposed to American President William McKinley that this organization be closed down. He supported his proposal with the words: "Everything that could be invented has already been invented by mankind.