3D print helmets

Helmet best STL files for 3D printing・Cults

Longer snouted Fenrir Death Mask

Free

Drag Racing driver standing in a gas mask

€6

ARC Rail Adapter

€2.80

Recon Helmet

€1.50 -10% €1.35

Spartan helmet

€0.50

Roman legionary helmet, Roman Helmet

€0.99

Neon White Game Cosplay Mask - Neon Red Mask - Halloween Costume Mask

€43

Wraith Mask Demon Wishper Apex Legends cosplay

€11.42

AMERICAN FOOTBALL HELMET - PEN HOLDER

€4. 68

HARLEY DAVIDSON EASY PRINT MOTORCYCLE HELMET WALL BRACKET

€2

Caustic hand protector armor Apex Legends

€10.79

Caustic Mad King shoulder Apex Legends

€16.50

Purge Trooper Helmet - 3D Print Files

€20

Airborne Clone Trooper Helmet - 3D Print Files

€20

Light holder/ Gopro Mount

€0.50

Animated ARC Trooper Helmet - 3D Print Files

€20

Pilot RC

€18.80

Dragon Shiryu Helmet V1

€10 -10% €9

F1 firefighter helmet

€0. 50

50

VALKYRIE HELMET

€18.73

DF001 Space Marine Primaris mk x Helmet

€8

IRON HELM - AGE OF SOULS CONVERSION KIT

Free

k9 tactical helmet

€44.25

Philippine national police A cadet PNPAC 004

€5

Philippine national police A cadet PNPAC 003

€5

Philippine national police A cadet PNPAC 002

€5

Philippine national police A cadet PNPAC 001

€5

Alien magister custom mask

€10.51

Danganronpa Monokuma Inspired Helmet

€8

laptop headset stand - Hp Zbook

€0. 50

50

MATE CASCO YAMAHA NEW MINIMALISTA NOST3D

€2.81

CASCO YAMAHA NEW MINIMALISTA

€2.81

Phase 2 Clone Trooper Helmet - 3D Print Files

€20

HJC C80 GoPro chin mount

€3.50

Republic Commando Clone Trooper Helmet - 3D Print Files

€20

Sith Inquisitor Mask - Tales of the Jedi

€9

Adventures in Babysitting, Maia Brewton, Winged helmet, Helmet, Sara Anderson, Mighty Thor, Cosplay, Costume

€2.49

Mask of the Reluctant Gods

€1.17

Tony Stark Without Helmet IRON MAN

€6.85

Lincoln Viking 3250D Harness Mount Hose Clip

€0. 99

99

NFL Riddell Speed Mini Helmet with Padding

€28.10

Kabuto (Samurai Helmet)

€2.34

Mighty Morphin Lord Drakkon Power Rangers Cosplay Helmet

€35

Dainese key ring

Free

MATE CASCO KAWASAKI MOTOCROSS MINIMALIST SUBLIPLAST

€2.81

MATE CASCO KAWASAKI MOTOCROSS MINIMALIST

€2.81

MATE CASCO KAWASAKI MOTOCROSS MINIMALIST NOST3D

€2.81

Chainsaw Man

€2.50

3d Print Helmet - Etsy.de

Etsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

Find something memorable, join a community doing good.

( 1,000+ relevant results, with Ads Sellers looking to grow their business and reach more interested buyers can use Etsy’s advertising platform to promote their items. You’ll see ad results based on factors like relevancy, and the amount sellers pay per click. Learn more. )

Project of 3D printing of a photopolymer ski helmet

Implementation stories

Rapid prototyping

Art and design

Author: Aleksey Chekhovich

Author: Aleksey Chekhovich

Concept | Project analysis | Challenges | Solutions | Stages of work

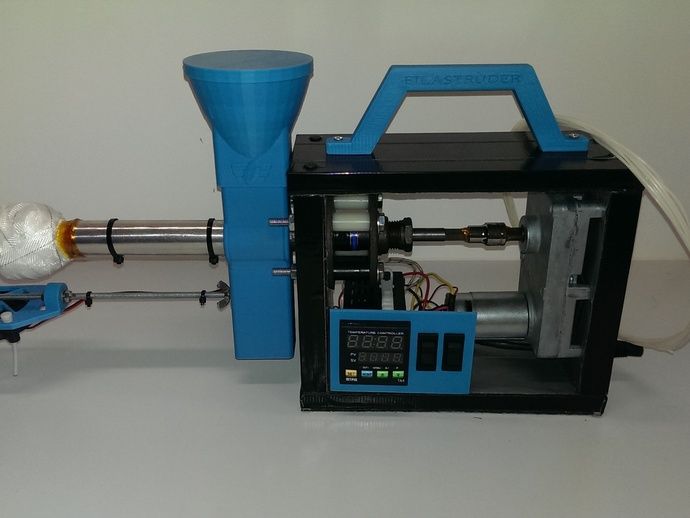

Laser stereolithography is one of the most widespread 3D printing technologies, providing undoubted advantages in prototyping compared to traditional production methods. Let's see how ProtoFab completed a complex project in a short time using a photopolymer 3D printer to create a high-quality model of a ski and snowboard helmet.

Let's see how ProtoFab completed a complex project in a short time using a photopolymer 3D printer to create a high-quality model of a ski and snowboard helmet.

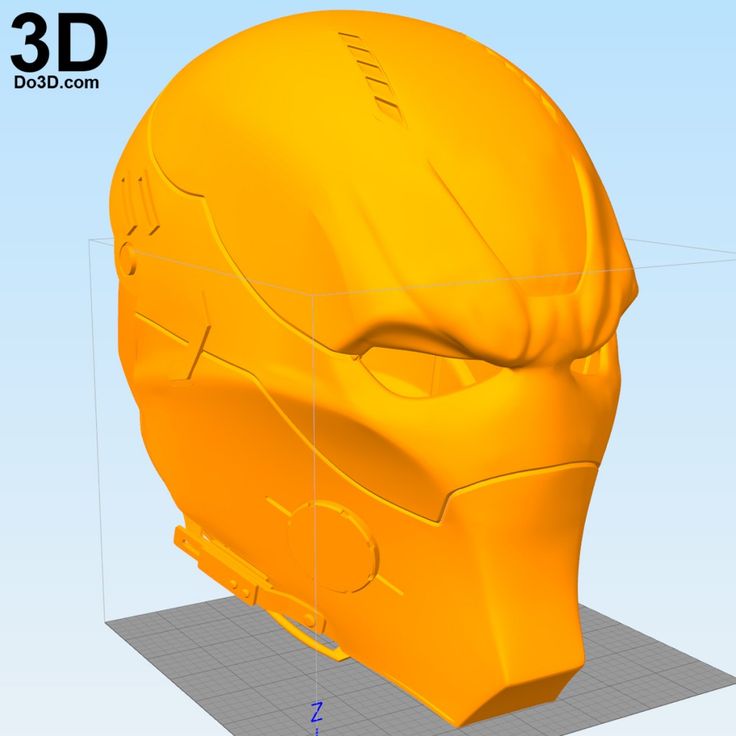

- Model: Blizzard ski helmet with drone

- Material: ProtoFab Formula W photopolymer

- Fabrication Technology: 3D Stereolithographic Printing

- Lead time: 3 days

- Customer requirement: eye-catching lines, uniform coloration, clear color contrast, overall stylish and attractive appearance

ProtoFab was contacted by the organizing committee of the Cross-Strait Industrial Design Awards with a request to produce prototypes for each of the contestants. It will be much easier for the participants to showcase their innovative and original designs if they submit high quality models to the competition. The creators of the ski helmet contacted ProtoFab and sent in their drawings. They wanted bold, streamlined lines to be used in the design, and the quality of the finish to be as high as possible.

Concept

The Blizzard (Snowstorm) helmet is designed primarily for skiers and snowboarders. These extreme sports involve certain risks and can lead to serious injury. Therefore, it is extremely important to use the proper equipment that would provide increased safety. The Blizzard helmet is equipped with a GPS tracking chip, which can significantly speed up the search for an athlete in the event of a fall, disorientation or avalanche. This is especially important in frosty weather, which is typical for alpine skiing.

The Blizzard helmet also features a high-speed camera capable of capturing breathtaking moments with incredible clarity and detail. However, the most unique feature of the helmet is the support for an unmanned aerial vehicle. The video recording drone inside the helmet can fly out of the helmet and return to its place at any time.

Project analysis

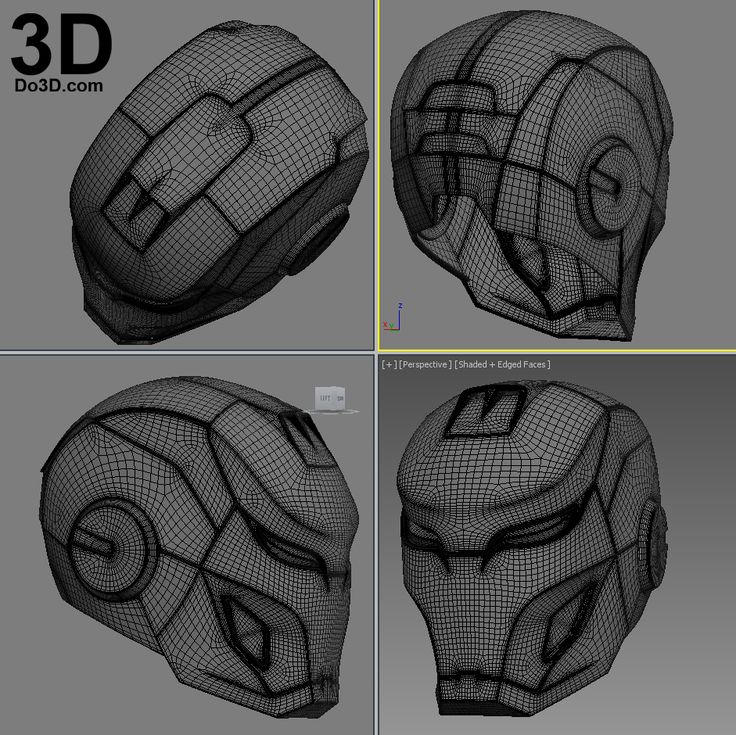

After receiving the drawings from the client, the ProtoFab team had to decide which technology to choose - CNC machining or 3D printing. It immediately became obvious that additive manufacturing would be the best solution. Traditional CNC machining includes careful design analysis, programming, direct machining on the machine, and a number of other complex and time-consuming tasks. All this usually leads to high costs. In turn, 3D printing is a much simpler process, which can significantly reduce the lead time. And for such projects, where the product does not have to withstand a lot of weight, 3D printing is especially suitable.

It immediately became obvious that additive manufacturing would be the best solution. Traditional CNC machining includes careful design analysis, programming, direct machining on the machine, and a number of other complex and time-consuming tasks. All this usually leads to high costs. In turn, 3D printing is a much simpler process, which can significantly reduce the lead time. And for such projects, where the product does not have to withstand a lot of weight, 3D printing is especially suitable.

Calls

Surface quality played a major role in the project. Polishing and painting had to be done exactly according to the client's vision. The design of the helmet features multiple protrusions and four colors - Matte Black, Gloss Black, Gloss Orange and Steel Grey. The experienced ProtoFab team faced some challenges in polishing and ensuring perfect contrast between different colors.

Solutions

Since the model could be printed as a single piece, the technicians only needed to correct the drawings in the software and add the necessary supports. The use of supporting structures ensures the stability of the product during printing and prevents possible deformations. In addition, the entire model can be printed in one session, without the need to break it into parts.

The use of supporting structures ensures the stability of the product during printing and prevents possible deformations. In addition, the entire model can be printed in one session, without the need to break it into parts.

Complex post-processing

Upon completion of printing, the model was carefully removed from the 3D printer and washed with alcohol. This removed any residual liquid material that may have remained in the helmet after printing. The next step - removing supports - requires special care so as not to cause any damage to the model. Below is a view of the product after separation of all supporting structures.

The printed object may be slightly rough and have visible surface defects. ProtoFab sanded the model, starting with coarse sandpaper (400) and gradually moving to fine sandpaper (1500). Polishing was a particular problem due to the complex surface texture on the top of the helmet. The application of paint also required special care. In order to ensure an absolutely uniform coating, three separate polishing and painting cycles were carried out.

In order to ensure an absolutely uniform coating, three separate polishing and painting cycles were carried out.

Top coat application

To get the look the client wanted, it was important to choose the right paint color. The ProtoFab team needed to use all their experience to ensure that the color separation was perfectly sharp and the shades were completely uniform. One of the photos below shows how the paint was matched against the reference shade map provided by the client.

Choosing the right color requires patience and great care. In this case, it was extremely important that the final color exactly matched the client's requirements.

Lacquering and fine polishing

In accordance with the task, the helmet was varnished to give it the necessary shine.

After the varnish had dried, all that remained was to polish the helmet again to ensure the most attractive appearance.

Assembly

Finished model

The project was completed in three days, and the ProtoFab team was very pleased with the result. When the helmet was shown to the client, he also expressed complete satisfaction, especially the colors and the quality of the finishes.

Material provided by ProtoFab

You can learn more about ProtoFab solutions and order a test print here

Article published on May 22, 2019, updated on May 14, 2021

Experience with 3ntr 3D printers in the development of a motorcycle helmet by the Italian company Momodesign

The Italian company Momodesign is an important player in the vehicle accessories market. Since the 1980s, Momodesign has been designing city bikes, including electric bikes, helmets and other accessories. 20 years ago, the design bureau introduced its first motorcycle helmet to the market, which subsequently won serious international recognition. Today, the company is breaking new ground with its latest product, the innovative Aero Helmet, featuring a unique design and high performance.

Today, the company is breaking new ground with its latest product, the innovative Aero Helmet, featuring a unique design and high performance.

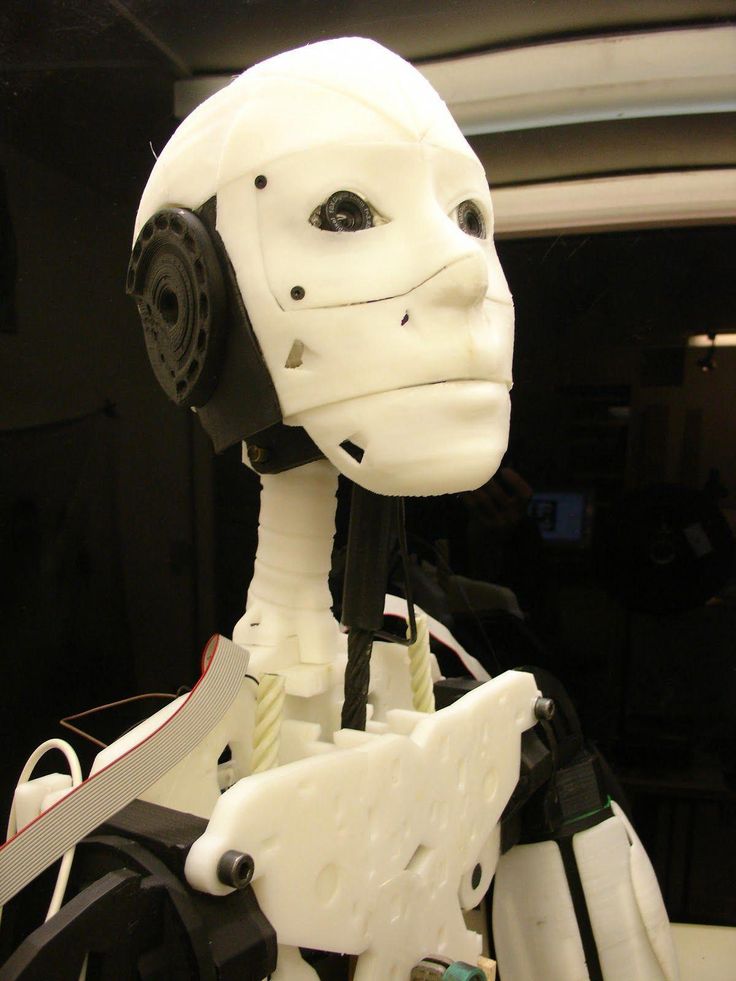

The Aero motorcycle helmet project was realized using 3ntr 3D printers, which once again confirmed the ability of the latter to meet the requirements of professional 3D printing. In this case, we are talking about the use of 3D equipment for rapid prototyping, but not for the production of final products. Nevertheless, the solutions offered by 3ntr provided the project with a number of important competitive advantages.

“The aim of the Aero project was to offer a revolutionary solution to the market, using tools that our competitors have never used,” says commercial director Mirco Rigo. “3D printing has made it possible for us to get functional prototypes in a very short time and it is quite easy to find answers to all questions related to product development. Moreover, this technology was extremely helpful whenever we needed to make the right choice between several possible design and functional solutions. ”

”

It's easy to imagine how important the prototyping stage is for such a project. At the same time, the production of prototypes using classical methods was not economically feasible and took an extremely long time. However, their production using 3ntr 3D printers has become much more profitable both in terms of material costs and in terms of their production time. At the same time, the printed models were reliable and had all the necessary functionality.

“We were extremely short on time,” continues Mirco Rigo. “We set ourselves the goal of completing the project in 1.5 years, although it usually takes two to three years. With clean 3D-printable plastics at our disposal, we were able to make various helmet parts from several materials, compare them and choose the best solution.”

The result of this work was a high-tech helmet, the design of which combined futuristic and military elements. Innovative solutions include a smart ventilation control system (Tornado ventilation system, an optional accessory activated with a special application) and the absence of a classic external visor, which raises rider safety to a new level. The visor of the Aero helmet is integrated into the main body of the helmet and is fixed, this linear design significantly reduces the risk of the helmet getting stuck in the event of a fall from the motorcycle.

The visor of the Aero helmet is integrated into the main body of the helmet and is fixed, this linear design significantly reduces the risk of the helmet getting stuck in the event of a fall from the motorcycle.

As Momodesign CEO Paolo Cattaneo points out, the Aero helmet is designed specifically for motorcyclists and fully meets their needs. “People with their desires, needs and urban lifestyle have always been at the center of our attention, and the ongoing evolution of the metropolis and the emergence of new trends remain a constant source of inspiration for us. All this is the starting point for creating products whose design, style and functionality best meet the needs and expectations of our customers”, - Paolo Cattaneo.

The Aero Helmet is a striking example of the benefits that great design can bring to a product, as well as how useful 3D printing technology can be to bring the most daring and complex projects to life. The new Momodesign product perfectly demonstrates the desire for innovation, including at the level of tools used in production.