How to 3d print a prosthetic hand

BUILD A HAND – Enabling The Future

Find the files and assembly instructions you need to build a hand!

The e-NABLE community has developed a collection of different 3D-printable assistive devices that are free for download and fabrication by anybody who would like to learn more about the designs or fabricate a device for somebody in need.

If you are interested in building your own 3D printed upper limb device and have access to a 3D printer, here is the information you will need to get started:

- Decide which kind of device is recommended for the limb different person in need.

Visit our Which Design page to see what your options are and choose from the designs that are currently available and recommended for those types of limb differences. Please note, that the e-NABLE Community does not currently have designs for above elbow limb differences, so the recipient or user must have a functional wrist or elbow to make these devices function properly. - Make sure to take photographs correctly to ensure a proper fit. Watch the tutorial video to learn how to take images that will help you get the measurements you need to create a device that will fit properly.

- Refer to the e-NABLE Device Sizing page to learn how to properly size an e-NABLE device.

- Check out our e-NABLE Devices page for tutorials, assembly kits and other helpful information!

If you have any questions along the way, feel free to ask our volunteers by posting a message in the forum.

If you would like to make your own device but do not have access to a 3D printer, check our our e-NABLE Chapters page, which includes a searchable map of e-NABLE Chapters. This map includes many libraries and makerspaces that may have 3D printers available for public use. You can also check this Google Map for libraries with 3D printers available.

Please note: It is very important that you work with your physician, occupational therapist, physical therapist or prosthetist when using a 3D printed open-source e-NABLE device.

ACCEPTANCE

By accepting any design, plan, component or assembly related to the so called “e-NABLE Hand” , I understand and agree that any such information or material furnished by any individual associated with the design team is furnished as is without representation or warranties of any kind, express or implied, and is intended to be a gift for the sole purpose of evaluating various design iterations, ideas and modifications. I understand that such improvements are intended to benefit individuals having specific disabilities and are not intended, and shall not be used, for commercial use. I further understand and agree that any individual associated with e-NABLE organization shall not be liable for any injuries or damages resulting from the use of any of the materials related to the e-NABLE hand.

Like this:

Like Loading...

The Basics Of 3D Printing Prosthetic Hands – Print Your Mind 3D

0 comments / Post by Colin Pischke

We know many people have now heard of 3D printing prosthesis, but there is a lot of misinformation out there about what the advantages and limitations of 3D printing prosthetics. We are writing this with a goal to help people better understand the current world of 3D printed prosthesis, and provide you with all the resources for others to get involved.

We are writing this with a goal to help people better understand the current world of 3D printed prosthesis, and provide you with all the resources for others to get involved.

Why 3D print prosthetics?

This is a fair and common question. Why not just use traditional methods of producing a prosthetic hand? In our opinion, it comes down to two main things; cost and means of production.

Cost

The cost of producing a prosthetic hand on a 3D printer can be as little as $100. This is a fraction of the cost of traditional hands which can cost from $5000-$25,000. However, there are limitations in terms of fitting the prosthesis unless using 3D scanning and/or moulding to get a perfect fit to the effected limb. Because of this, some people who are financially secure would not go the route of 3D printing to fit their needs. If you have the money to purchase a prosthetic produced through traditional means, you will generally get an attachment that fits better to the effected limb, as the standard process involves casting the effected limb for a perfect fit. That is not to say this same process cannot be done when producing via 3D printing, simply that this is a step not always taken. For those less fortunate, 3D printing can be an extremely cost effective way of giving a child a new chance at feeling normal with similar but limited capabilities of a regular hand. Sizing can be done simply with photos and measuring devices for 3D printing. This is often done for organizations like e-NABLE, who produce prosthetic hands for children in developing countries they can't actually sit down with to take a mould.

That is not to say this same process cannot be done when producing via 3D printing, simply that this is a step not always taken. For those less fortunate, 3D printing can be an extremely cost effective way of giving a child a new chance at feeling normal with similar but limited capabilities of a regular hand. Sizing can be done simply with photos and measuring devices for 3D printing. This is often done for organizations like e-NABLE, who produce prosthetic hands for children in developing countries they can't actually sit down with to take a mould.

Means of production

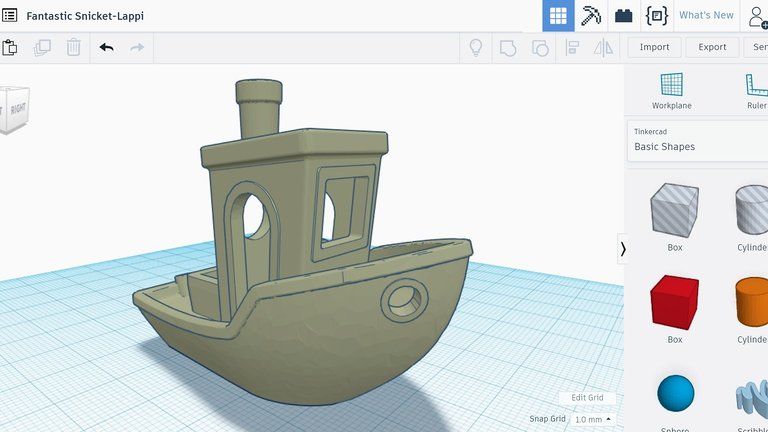

3D printing prosthetics is in many ways still in it's infancy. Organizations like e-NABLE and Open Bionics are now making it easier than ever for anyone with a 3D printer to create a prosthetic. These organizations have only been around for a few years now. They have spent many hours developing and refining designs which can be 3D printed. They have also made the designs compatible with easily sourced components to go along with the 3D printed items. In this way, anyone with a 3D printer now has the means to produce prosthetics. Years ago this would have been far more difficult for the average person.

In this way, anyone with a 3D printer now has the means to produce prosthetics. Years ago this would have been far more difficult for the average person.

So you own a 3D printer and want to learn more about making prosthetics?

If you own a printer and haven't tried making a hand yet, you may wonder how the heck you can get started. There are a ton of organizations out there who are involved in 3D printing around prosthetics, but we will highlight the two we believe are the best for someone just starting out.

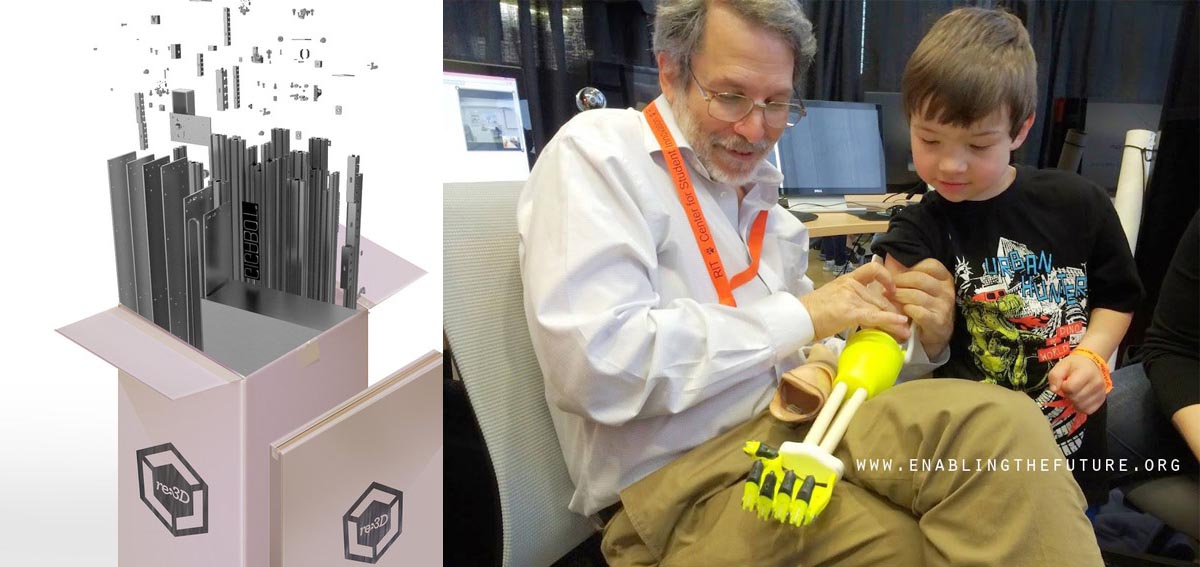

e-NABLE

e-NABLE is an organization made up of thousands of volunteers around the world with the goal of using their 3D printer to create free 3D printed hands and arms for those in need of an upper limb assistive device. The founder of the e-NABLE community and the Enable Community Foundation is Jon Schull. Back in 2013 he started the movement as a collective effort to crowd-source the design and delivery of 3D printed prosthetic hands to those who need them. The organization has gathered a ton of steam in the last few years, including snagging a $600,000 grant from Google. There are now groups working through their network around the globe to donate hands, improve designs, and make it as easy as possible for every day people to 3D print prosthetic hands for children in need.

The organization has gathered a ton of steam in the last few years, including snagging a $600,000 grant from Google. There are now groups working through their network around the globe to donate hands, improve designs, and make it as easy as possible for every day people to 3D print prosthetic hands for children in need.

Where are there e-NABLE volunteers?

Want to see where there are e-NABLE volunteers? You can view this interactive map to see who else is working with e-NABLE in your country.

Research & Development

There is constant innovation happening in the e-NABLE community. They put on regular Google Hangouts just to talk about R & D. This kind of open communication with designers, teachers, and specialists around the world help develop the many new designs that are constantly being released and improved upon. Below are a few examples of the research happening within the community:

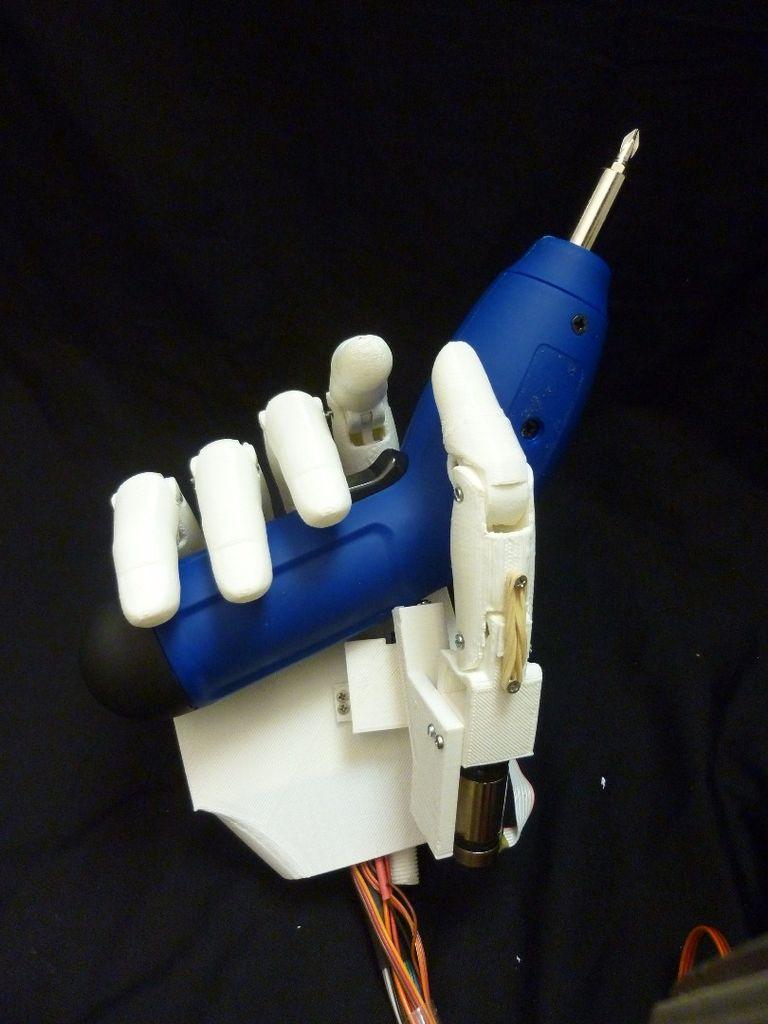

Photo credit www.enablingthefuture.org

Thermo Forming

Photo credit www. enablingthefuture.org

enablingthefuture.org

Experimenting With Elastics

EMG muscle sensing

Demonstration videos

It is one thing to see photos of the hand. To really get an understanding of how these hands work to change a child's life, we think you have to see them in action.

Luke's 3D Printed Hand by Ultimaker

Swimming with a Cyborg Beast 3D Printed hand by e-NABLE Community Foundation

Biking, tennis and eating with e-NABLE hands by e-NABLE

Different Designs

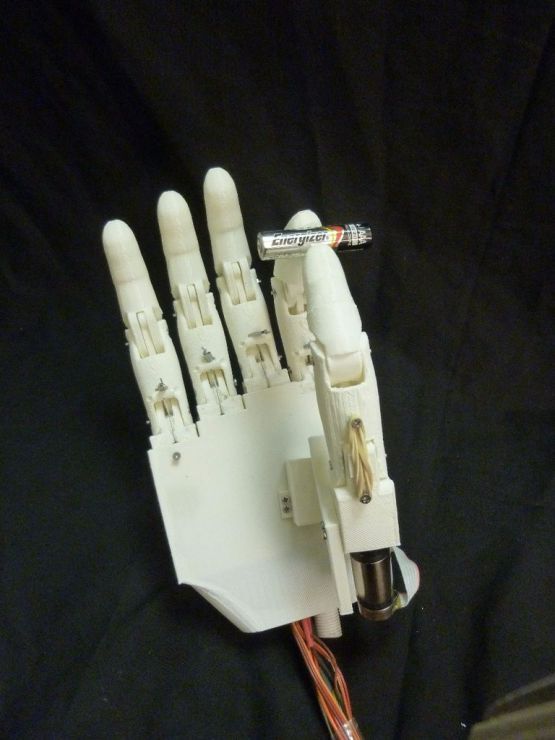

e-NABLE community members have developed many different designs for hands. We will cover a few of the most commonly used designs. These hands work on a purely mechanical basis meaning the recipient will need to be able to bend his wrist or elbow in order to make the hand function properly.

Cyborg Beast

This design was developed by community member Jorge Zuniga and his research group at Creighton University. This was one of the most common design prior to the release of the Raptor Reloaded and the Phoenix hand which is currently being developed.

Photo credit Enable Community Foundation

Download the files

Raptor Reloaded

This hand was developed collaboratively by some of the e-NABLE community's top designers. They have taken sizing a step further and developed the Hand-o-matic to make fitting a recipient more automated. This has become another of the top e-NABLE designs.

Photo credit Enable Community Foundation

Download the files

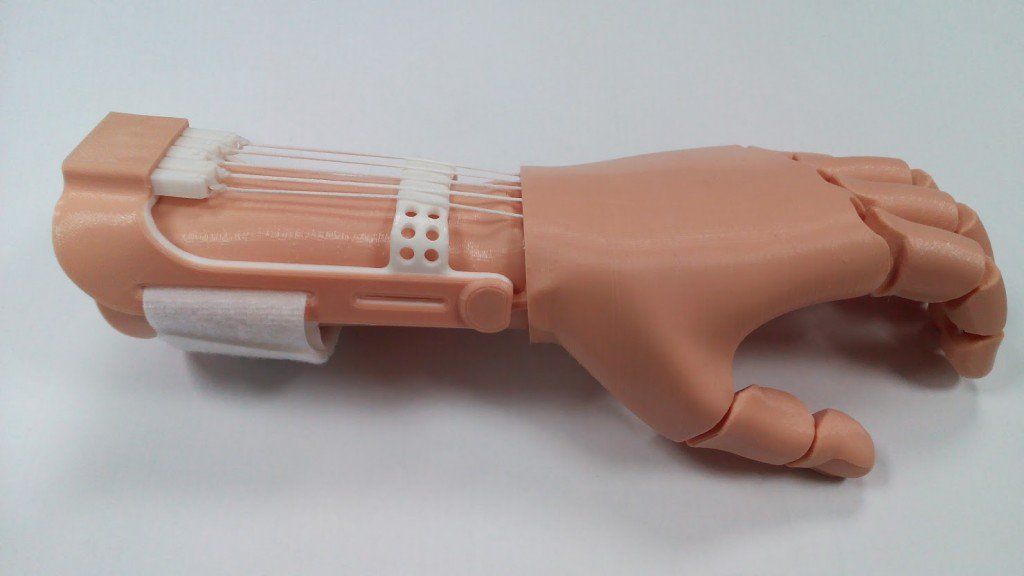

Phoenix Hand

This was designed by Jason Bryant who is a researcher and teacher at Shandong University in China. This had has a number of added benefits over the previous two including using elastics rather than nylon strings, as well as having the thumb and fingers oriented for better grip.

Photo credit Enable Community Foundation

Download the files

UnLimbited Arm

This arm was developed for those that have a functional elbow and a considerable amount of forearm but no wrist, or at least not enough to power a wrist driven device like the ones above. It was developed by Stephan Davies and Drew Murray of Team UnLimbited.

Photo credit Enable Community Foundation

Download the files

Materials

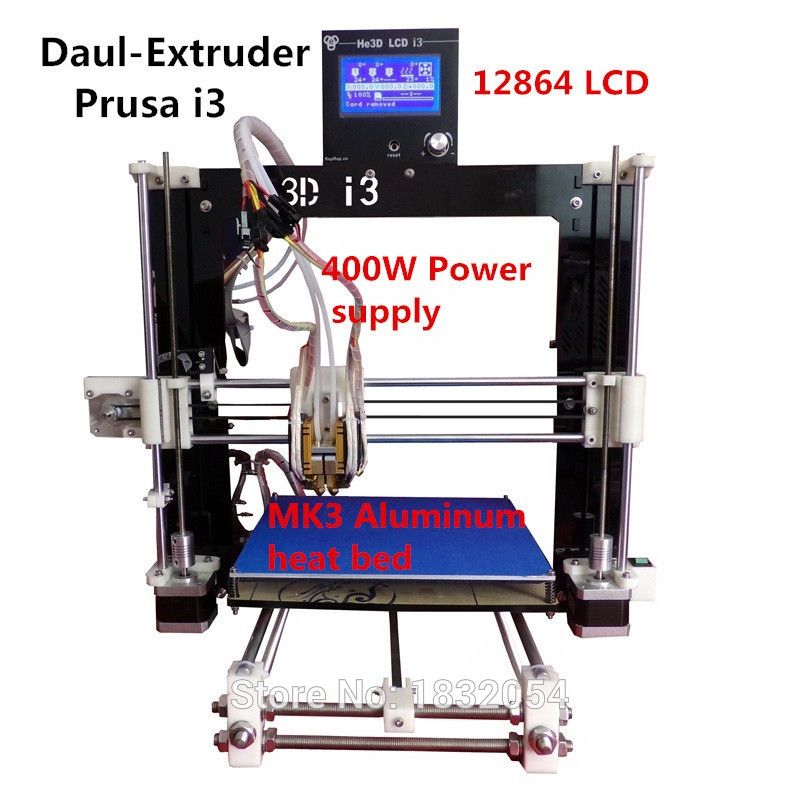

Although these hands can be made from nearly any 3D printing thermoplastic, e-NABLE generally recommends you use one of these 3: ABS, PLA or Nylon. ABS and PLA are the most common filaments used in 3D printing. If you are looking to make your hand extra durable, try using Nylon.

Along with the 3D printed components, each hand requires a few additional hardware items like medical foam, screws, velcro and elastic connecting materials. These materials will vary depending on the hand you want to make. Be sure to check what the required hardware is for each design in it's description.

Be sure to check what the required hardware is for each design in it's description.

For more information about e-NABLE, or to get signed up to print a hand for a child in need, visit www.enablecommunityfoundation.org.

Open Bionics

Photo credit Open Bionics

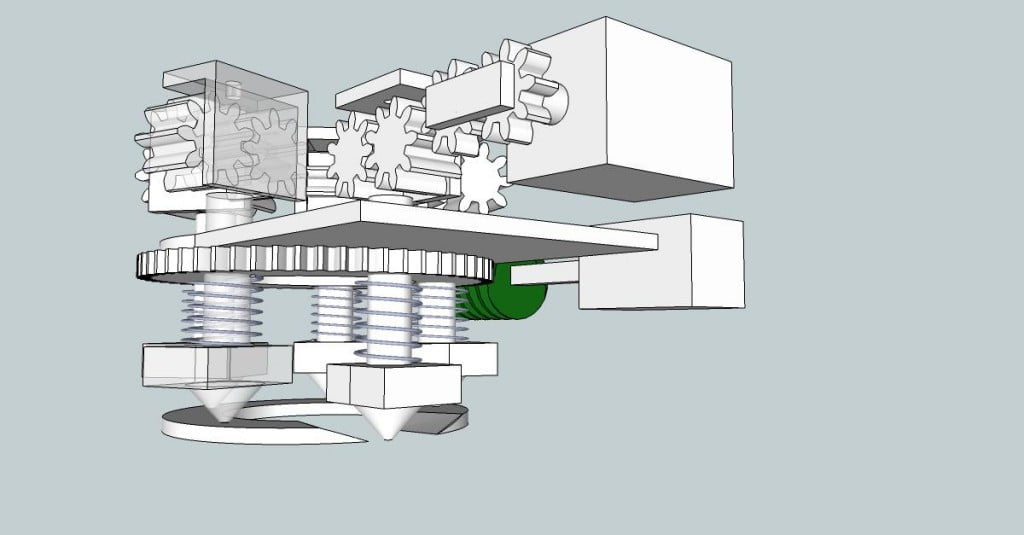

Open Bionics has developed an open source initiative which uses a combination of 3D printed and robotic components to take these hands to the next level. The company was started by Joel Gibbard only a few years ago and has gone on to win many prestigious awards for the contribution to lowering the cost of advanced prosthetics.

Video from Open Bionics Youtube

As you can see, these hands work by utilizing linear actuators hidden within the fingers. A micro-controller is used to deliver information taken from muscle sensors on the user. This technology comes at a cost of about $3000 but allows the user far more capabilities than you will find in a wrist or elbow driven device.

This technology comes at a cost of about $3000 but allows the user far more capabilities than you will find in a wrist or elbow driven device.

Demonstration Videos

Open Bionics Ada Robotic hand Controllable Via EMG from Open Bionics Youtube

This 3D Printed Prosthetic Costs Way less Than Alternatives from Vocativ Youtube

Devices

Ada Hand

Photo credit Open Bionics

This is the first release from the Open Bionics team. They recently released a kit you can purchase to create your own Ada hand on their website.

Materials

Open Bionics has specific requirements when it comes to their hands as certain functionality is needed. They suggest using Ninjaflex for the palm, and ABS for the fingers and other components.

Conclusion

We are thrilled to see organizations like e-NABLE working diligently to produce extremely low cost prosthetics for those in need around the world. It is also exciting to see how organizations like Open Bionics are developing more advanced 3D printed prosthetics, which are still a fraction of the cost of traditional products. This new era where passionate makers have the equipment and resources to produce life changing devices like prosthetics so easily and affordably, is truly game changing. If this is where we are today, you can only imagine what things will be like 5 to 10 years from now. We don't know about you, but that is something we sure want to be a part of.

Older Post

Newer Post

3D printing of prostheses using crowdsourcing / Sudo Null IT News ivansychev

Time to read 2 min

View count 7. 2K

2K

Biotechnology Crowdsourcing 3D printers Medgadgets

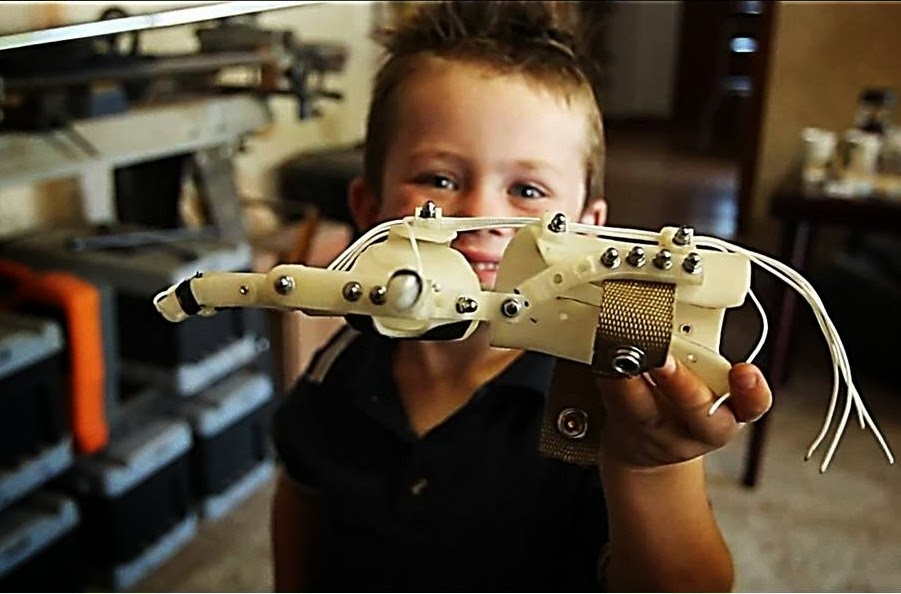

Using ready-made projects to print prostheses is much more effective than creating a prosthetic arm from scratch. The Enablingthefuture.org project works on the principle of crowdsourcing: it allows you to find people who can help design a prosthesis, and people who can print it on their 3D printer.

The video shows Isabella, an 8-year-old girl who received her hand thanks to Enablingthefuture.org. The prosthesis was designed by Stephen Davies, who previously received his own hand thanks to this project.

The parents of an eight-year-old girl found out about the e-NABLE project on Facebook. They watched the videos on the page and read the stories until they asked Isabella if she would like to try such a device. The girl agreed. The project paired her with volunteer developer Stephen Davis. Stephen traveled to Bristol, UK to personally present the girl with her new arm.

Isabella has become one of the beta testers who will help develop stronger and more comfortable prosthetic hands for other recipients. One of the difficulties was control: Isabella has to use muscles that she had not used before. Now she is experimenting, trying to grab different objects, exploring what she can and cannot do with them.

The girl's father was worried that Isabella would be embarrassed by the prosthesis. But the girl was glad to go to the store with a multi-colored hand and walked with her, she wanted to show the prosthesis to the whole world, she constantly told how this hand works.

She is magical and I love the colors! I will use it the best way I can! Isabella

Stephen Davis is forty years old. He knows what it is like to live without a hand, and how to live with an uncomfortable prosthesis. He was born without a left arm. The National Health Service gave him a prosthesis that "could be described as a hook from the Middle Ages. " The e-NABLE project helped Stephen find developer Drew Murray. After receiving his first hand, Stephen raised money for a 3D printer in a few months and became a volunteer.

" The e-NABLE project helped Stephen find developer Drew Murray. After receiving his first hand, Stephen raised money for a 3D printer in a few months and became a volunteer.

Ivan Sychev @ivansychev

Communication Specialist.

Comments Comments 3

Affordable 3D-printed prosthetic hands could become even more technologically advanced

To date, the project has been based on several key models that can be printed and assembled for only about $50, although some volunteers make changes depending on specific goals or needs of the person for which the prosthesis is intended. Now a group of experts from the Massachusetts Institute of Technology (MIT) Technological Innovation Laboratory intends to contribute to the further development of the product, granting the right to use their developments e-NABLE and other non-profit organizations.

It's easy to 3D print a prosthetic arm, which is why e-NABLE and others like it are able to attract so many volunteers. On the other hand, creating a functional 3D printed prosthesis is much more difficult. A group of scientists from the Massachusetts Institute of Technology is working on improving the popular models of prostheses available on the Internet.

On the other hand, creating a functional 3D printed prosthesis is much more difficult. A group of scientists from the Massachusetts Institute of Technology is working on improving the popular models of prostheses available on the Internet.

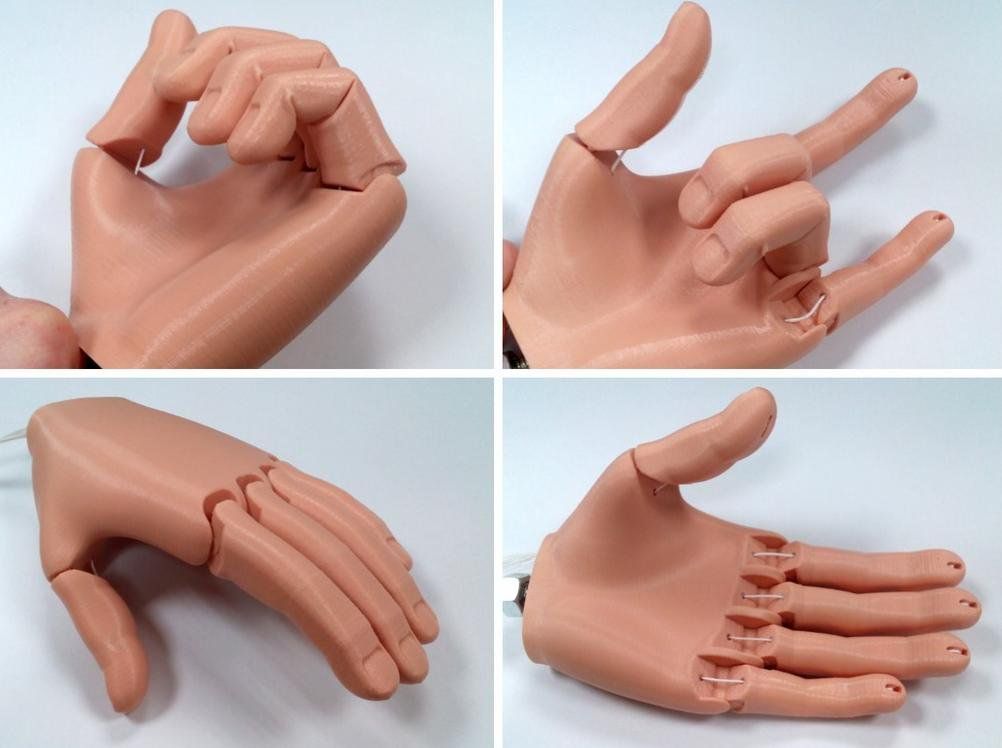

To begin with, the team downloaded and made several models - most of them in PLA plastic. The researchers found that these prostheses have several limitations, particularly in terms of holding objects. The developers proposed new models in which all fingers act separately, connecting to a central point of load distribution - this design improves the flexibility of the prosthesis and grip strength, and also allows you to hold objects of almost any shape.

MIT scientists have found other ways to improve prosthetic hand models. In particular, they managed to add a substance to the plastic that changes color depending on the temperature - so users can "feel" the heat. This innovation can help avoid injury or damage to the prosthesis, such as melting.