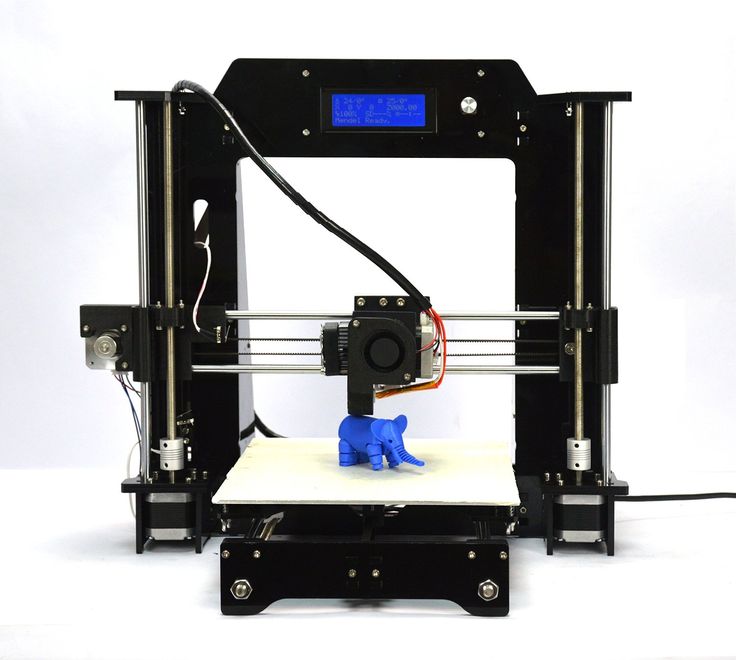

Zotrax 3d printer

Zortrax 3D Printers - Online Store

zortrax.com

Albania Argentina Australia Austria Belarus Belgium Bosnia and Herzegovina Brazil Bulgaria Canada Chile China Colombia Costa Rica Croatia Cuba Cyprus Czech Republic Denmark Dominica Dominican Republic Ecuador Estonia Finland France, Metropolitan FYROM (Macedonia) Germany Greece Guatemala Hong Kong Hungary Iceland India Indonesia Ireland Israel Italy Japan Jordan Korea, Republic of Kuwait Lao People's Democratic Republic Latvia Liechtenstein Lithuania Luxembourg Malaysia Maldives Malta Mexico Moldova, Republic of Montenegro Morocco Netherlands New Zealand Nigeria Norway Panama Paraguay Peru Philippines Poland Portugal Puerto Rico Qatar Romania Russian Federation Saudi Arabia Serbia Singapore Slovakia Slovenia South Africa Spain Sweden Switzerland Taiwan Thailand Turkey Ukraine United Arab Emirates United Kingdom United States Venezuela Viet Nam

Copyrights © 2023 Zortrax. All rights reserved

Zortrax 3D Printers | MatterHackers

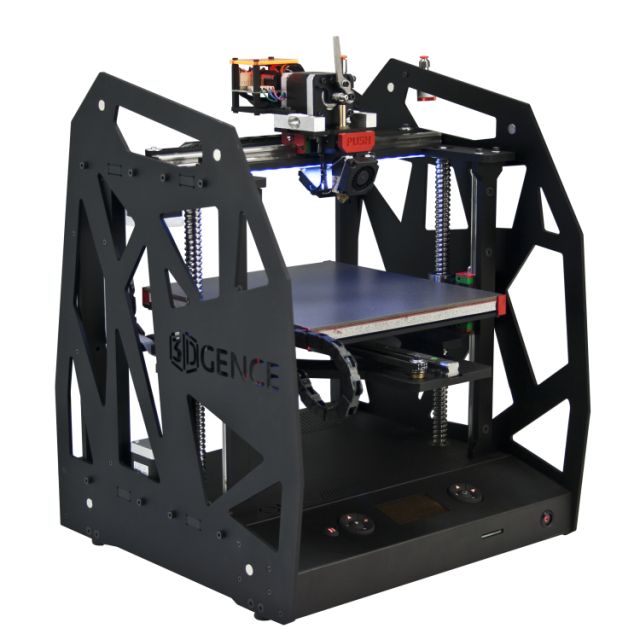

Zortrax 3D printers are developed with precision in mind! With dual extrusion and single extrusion options available, Zortrax 3D printers are perfect for any environment. Zortrax is a polish manufacturer of 3D printers for a range of industries including architecture, medicine, automotive, engineering, industrial prototyping, and fashion. The company uses innovative solutions and high quality materials to build a strong position on the global market of desktop 3D printers.

Guides & Articles

What is 3D Printing?

3D printing is a process where physical, three-dimensional objects, parts, or models are made layer-by-layer from Computer-Aided Design, or CAD, and digital files.

Anatomy of a 3D Printer

Get an understanding of how 3D printing works, from the inside and out. This guide will walk you through each of the critical components of a 3D Printer, answering the question: "How does a 3D printer work?"

The Top Ten Tips For Getting Started With 3D Printing

We were all noobs at one point! Here the ten best tips for getting started with 3D printing - whether it's your first time 3D printing or you need to brush up on the basics, this guide will help you out!

3D Printer Troubleshooting Guide

Use this guide to help you identify and solve the most common issues that may occur while 3D printing.

How To Calibrate Your 3D Printer's Extruder

This quick and informative guide will help you calibrate your extruder perfectly, resulting in accurate, quality prints.

3D Printing 101: How to Succeed with a Perfect First Layer for Every 3D Print

The first layer of your 3D print is the foundation of everything that comes after, which makes it such an important part of the 3D printing process.

How To Get The Best 3D Printed Parts By Understanding Extrusion Settings

Melting is a critical concept to 3D printing, and yet it hasn’t received a lot of in-depth attention. This article will teach you how to extrude your filament properly so it flows smoothly. Make filament jamming, delamination, and weak parts things of the past.

3D Printing Essentials: How to Succeed with Every Bed Surface Solution

Matching 3D printing filaments with the proper bed surface material is an important part of the 3D printing process. Read more to find out the best path to success.

Read more to find out the best path to success.

3D Printing Essentials: Filament Loading

Proper filament loading and unloading is a necessary part of 3D printing without trouble. Read on to learn the essential method you should be following.

3D Printing Essentials: Bed Leveling

For some, levelling a 3D printer's bed can be challenging, but it doesn't need to be. Read this essential guide to see what it takes to do it right.

Quick Tips: How To Get Started With Batch 3D Printing

Utilizing 3D printer time most efficiently is much easier once you start batch printing parts to maintain 3D printer uptime and minimize downtime.

Zortrax 3D printers are developed in Poland with precision in mind! With automatic bed leveling, calibrating Zortrax 3d printers is as easy as the click of a button. With dual extrusion and single extrusion options available, Zortrax 3D printers are perfect for any environment - from the garage workbench of a hobbyist, to the desk of an engineer, Zortrax is the machine you are looking for.

Every Zortrax 3D printer is made in Poland by the experienced team at Zortrax and shipped to 3D printer users around the world with the help of companies like MatterHackers.

What is Z-SUITE?Z-SUITE is Zortrax's in-house designed 3D print preparation and slicing program made to be the easy for brand-new 3D printer users to jump into 3D printing and get their 3D models sliced. Many settings are at the user's disposal to get the best print possible no matter the material you're using. Zortrax filaments have built-in profiles pre-calibrated for each Zortrax 3D printer, but at any time you can try using 3rd party materials.

Overview Zortrax M200 or 3D printing

Good afternoon friends.

In today's post I'll tell you about the Polish 'wonder machine' Zortrax M200, which I was kindly allowed to drive at IGO3D.

I currently own a CubeX Trio and have used Witbox, Ultimaker 2 and a little bit of Up Plus. In general, there is something to compare with, but do not judge strictly - I am not a professional, let alone a guru in 3D printing!) Therefore, I ask you to read the review as from an ordinary user. One more caveat: I got the printer used ... therefore, I can’t tell you what is included in the kit - I only received a printer, a holder for the coil and a scraper.

In general, there is something to compare with, but do not judge strictly - I am not a professional, let alone a guru in 3D printing!) Therefore, I ask you to read the review as from an ordinary user. One more caveat: I got the printer used ... therefore, I can’t tell you what is included in the kit - I only received a printer, a holder for the coil and a scraper.

Let's get started!

Appearance

The printer body is made of metal and has a decent weight. According to the manufacturer, it weighs 13 kg, but it feels like all 20. Also, in appearance, the printer is similar to the Chinese HORI, which was recently reviewed on the portal. I would even say that these are twin brothers... it is not clear who licked the design from whom)

Heated perforated platform:

Plus perforation - the model being made is fixed very well, the first layers of plastic are 'pressed' into holes. Those. all standard options for increasing adhesion are eliminated. Cons - if the model is not carefully removed from the table - then plastic remains in these holes and then the platform needs to be cleaned ... plus there is a problem of 'peeling off' large models.

Those. all standard options for increasing adhesion are eliminated. Cons - if the model is not carefully removed from the table - then plastic remains in these holes and then the platform needs to be cleaned ... plus there is a problem of 'peeling off' large models.

The platform is calibrated with three screws (one in front, two in the back):

Placement of the coil on the back side:

The display is standard, the control knob is very comfortable and responsive, the SD card slot is conveniently located:

What does he eat?

The manufacturer recommends its line of consumables: these are Z-ABS, Z-Hips, Z-ultrat, Z-Glass with a diameter of 1.75. Plastics can be used by any manufacturer - no problem. But relatives are simply fabulous in terms of print quality, which cannot be said about the price - 40 euros per reel. It is very strange that the manufacturer does not offer us to print with PLA and Flex - it's a shame and incomprehensible!). I tried using Filamentarno Aquamarine plastic and failed with a clogged extruder. The reason is that Zortrax has only 4 presets for printing with different plastics (listed above), which are wired into the native Z-Suite slicer and, accordingly, the print files have the z-code extension..

I tried using Filamentarno Aquamarine plastic and failed with a clogged extruder. The reason is that Zortrax has only 4 presets for printing with different plastics (listed above), which are wired into the native Z-Suite slicer and, accordingly, the print files have the z-code extension..

Yes, this is a big and fat minus - you can't play with fine settings. In the near future, the manufacturer promises to add both PLA and Flex to the list of materials ... we are waiting!)

Let's talk about software - Z-Suite

All software is downloaded officially from the manufacturer's website https://zortrax.com/, and you need to download be sure to enter the serial number of the device (You can find it at the bottom of the device. Maybe it is still in some official book that comes with the kit, but I don’t have it). Further, the code will again be required to install the software on the computer.

Limited functionality:

Left menu - perform actions with the model: load/delete/rotate/reduce, etc.

Pressing the 'print' button brings up a menu with print settings. It has 2 modes - standard (normal settings) and advanced mode (advanced). The temperature regime cannot be adjusted - everything is sewn into a type of plastic.

As for the raft - it is put down by default by the software - there is no way to remove it.

Print settings:

NORMAL SETTINGS mode:

- set the type of plastic

- layer thickness: (0.09-0.14-0.19-0.29-0.39)

- print speed: 2 options - Normal, High

- filling - 4 options from maximum to minimum

- support - we play from 0 to 90 degrees and you can also check the box - light - minimum support setting for more convenient removal apparently ...

- blowing speed

advanced settings mode :

- plastic type

- layer thickness

- SURFACE LAYERS: number of layers in the base and cover (3-6)

- SEAM: starting point for printing a new layer (normal - from one point, random - the point can be anywhere)

- added 2 filling modes

- OFFSETS: setting the thickness of the inner and outer contours

- SMART BRIDGES - remove/remove - setting supports in cavities and small circles. ..

..

Calibration of the platform and threading the filament and comes to mind without tubes and additional fixtures.There was a slight hitch with the refilling - I did not immediately find a channel in my head for loading the filament. Everything turned out to be simple:

A very unfortunate constructive solution - the filament is in contact with the oblique wires and can fray them at any time. As a solution to the problem - model a channel for a bar and attach it to the head.

Calibration: three-point automatic calibration. The printer at each point rests the hotend against the platform and offers to tighten the wheel (raise it higher, lower) .... there is actually no micro-adjustment.

Test printBoot launched for test print - first approach: material Z-ABS (native yellow), layer 0.09 mm, maximum filling (FULL), no supports, raft - automatic:

Layers are almost invisible.

- Second approach - material Z-ABS yellow, layer 0.39 mm, SOLID filling, no supports, raft - by default. (the thickest layer)

Next we print the pyramid and the test model of Ilya (saamec). We pre-change the plastic for mini ABS from PrintProduct

First approach - layer 0.14, speed Normal, fill Medium:

Quite tolerable, but the bridge screwed up...

Try another speed - set HIGH:

Layers are more visible here.

Third approach - bridges Settings - layer 0.09, Normal speed, FULL filling, no support, default raft. I tried it on plastic from Zortrax and PrintProduct:

We will print moreI decided to print a silkworm from the Picasso competition. Print options. Layer 0.14, the rest is default... printing lasted about 8 hours, then another clumsy removal of supports. + a piece of blue plastic was not left on the nozzle (I just didn’t notice) - it ruined all the raspberries) Here’s what happened:

Now for the big models.

We print an adjustable wrench and immediately get into problems with adhesion:

The reason for this is the open case and there is no way to build a 'shirt' around the model in the slicer.

What technical support advised - make a mixture of ABS and acetone and smear the table, as well as cover the printer with something ... in general, keep the temperature.

ConclusionsPros:

- 3D printer ready to print out of the box. Does not require long dances with a tambourine

- Native plastic is just fabulous - excellent print quality

- Very quiet

- Quite good printing for inexperienced users

- I also forgot to mention the WI-FI function - I haven’t tried it myself, but I think it’s more a plus, than a minus)

Cons:

- Software with presets - you won't overclock far

- Problems with printing large models

- Raft constantly prints - you can't get rid of it filament conductor

- Does not print PLA, flex, etc.

In my opinion, this printer is not suitable for professionals who fight for every millimeter and print quality. The reason for this is native software. I think if the manufacturer supplied Kuru in addition to its software, then the printer's capabilities would increase significantly. It is not yet clear what potential is hidden in it. In general, I am satisfied with the print quality, even at hardwired settings.

I rate the printer 4 (out of 5). Quite a workhorse for a wide audience.

Personally - I would not hesitate to put this printer on my desk - I really liked the machine!

short FAQ for future owners- in order to stop or pause printing - you need to press the button and hold it for about 10 seconds

- do not remove the model from the table until it has cooled down

- the serial is at the bottom printer

- I told about filament refilling at the beginning of the post

The price of the printer (in the tab where to buy) and the description in the 3Dtoday catalog: http://3dtoday.

ru/3d-printers/zortrax/m200/Thank you all for your attention. If you have any questions - welcome!) Printer while chasing)))

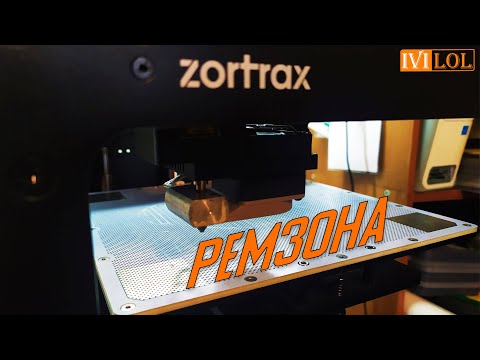

Zortrax 3D printer review: Reliable and high-quality 3D printing

12+

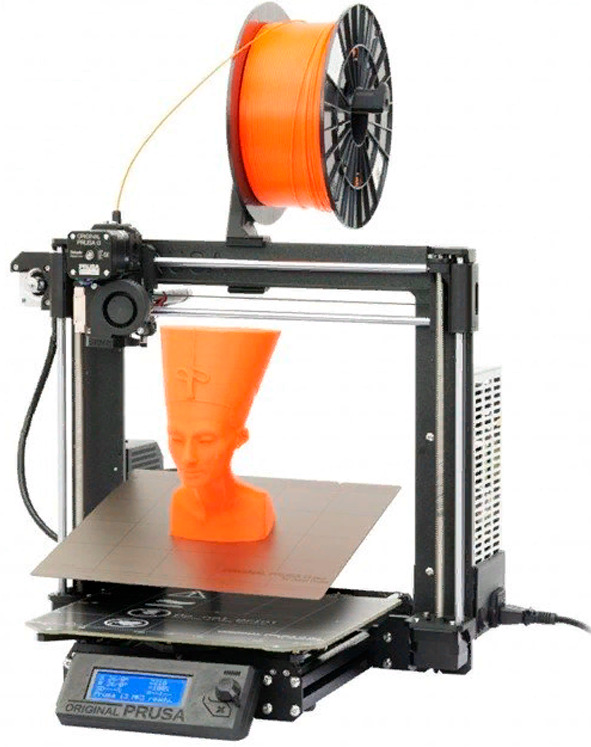

11 months ago Polish Zortrax Buy Zortrax 3D printers in Top 3D Shop — https://top3dshop.ru/search/?search=zortrax Hi all! With you Top 3D Shop [top three de shop] and in the next review we talk about 3D printers from the Polish company Zortrax [zOrtraks]. Zortrax's current line of 3D equipment includes several FDM devices and a desktop LCD printer. The two basic models of Zortrax 3D printers are M200 Plus and M300 Plus [em-200-plus, em-300-plus]. They are based on the Layer Plastic Deposition technology, abbreviated as LPD [leir plastic deposition, el-pi-dI] - this is how the layer-by-layer deposition method is called within the walls of the company. Both printers have a fully enclosed chamber and a heated bed. The maximum operating temperature of the extruder is 290 degrees Celsius.

3D printers are ready to work with both proprietary filaments and third-party plastics. The only difference between one model and another is the volume of the working chamber. Its dimensions in millimeters are indicated by a numerical index in the title. M300 Dual [em-trista dYual] is a dual-extruder modification of the M300 Plus model for printing parts with soluble supports or creating two-color objects. A useful option for the M300 Dual is a translucent cap-cap with a built-in HEPA filter [hepa]. For printing complex engineering parts and biological forms, Zortrax recommends using the Inventure FDM printer [invencha] and specially designed Z-Support Premium plastic. Supports made of such material quickly dissolve in water. Using the washing station, you can get a finished model with complex geometry that does not require additional post-processing. The Endureal 3D printer is a professional-grade device that is ready to work with refractory materials such as polyetheretherketone. The maximum temperature of the extruder reaches 420 degrees, the working chamber - 130, the table - 140 degrees.

Endureal can be equipped with two extruders. Zortrax's first photopolymer 3D printer, the Inkspire, is based on LCD technology. The minimum pixel size for printing is 50 microns, the layer thickness is from 25 microns. The printer is ready to work with third-party resins cured by UV light at 405 nanometers. You have watched the Top 3D Shop review of Zortrax 3D printers. Subscribe, comment, like. See you later! ZORTRAX M200PLUS PRINT AREA 200x200x180 MM LAYER THICKNESS 90-390 MKM MATERIALS ABS, ASA, PETG, HIPS, PLA, FLEX, NYLON ZORTRAX M300PLUS PRINT AREA 300x300x300 MM LAYER THICKNESS 90-290 MKM MATERIALS ASA, PETG, HIPS, PLA, FLEX, NYLON ZORTRAX INVENTURE PRINT AREA 135x135x130 MM LAYER THICKNESS 150-200 MKM MATERIALS ABS, PLA, PETG, NYLON, Z-SUPPORT ZORTRAX ENDUREAL PRINT AREA 400x300x300 MM LAYER THICKNESS 100-300 µm MATERIALS PEEK, NYLON, ABS, PLA, Z-SUPPORT ZORTRAX INKSPIRE PRINT AREA 132x74x175 MM LAYER THICKNESS 25, 50, 100 µm RESIN MATERIALS (ZORTRAX AND OTHERS) Vasily Kiselev in social networks, subscribe: Facebook: https://www.

Learn more