Ciclop 3d scanner accuracy

BQ Ciclop 3D Scanner In-Depth Review

8.4Expert Score

BQ Ciclop

BQ Ciclop has a simplistic design and extremely affordable pricing. Available under $250, it manages to surprise users by offering extraordinary features.

Affordability

10

Quality

8

Speed

7

Capability

8

Practicality

7

User Expectations

10

PROS

- The scanner has a simple design that is easy to understand even for beginners.

- It features a dual laser setup allowing for maximum accuracy while capturing objects.

- Extremely reliable Logitech C270 HD camera captures fine details of any object and translates it into computer images that can even be manipulated for betterment.

- Being an open-source 3D scanner, its information is completely accessible to the masses online.

CONS

- The scanner is available in a DIY kit and hence would consume more time while setup.

Also, it would require you to go through the stepwise documentation available online.

Table of Contents

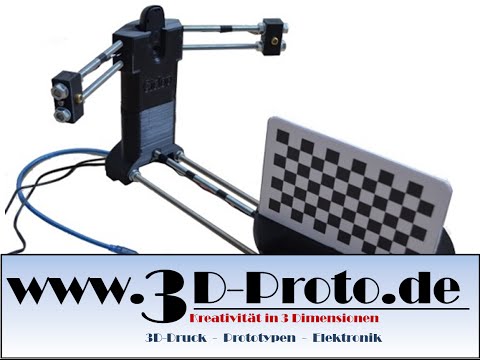

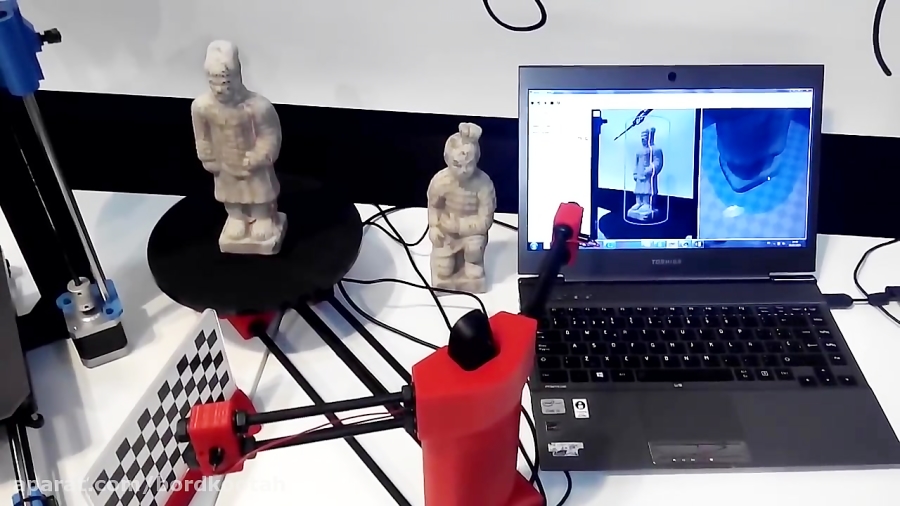

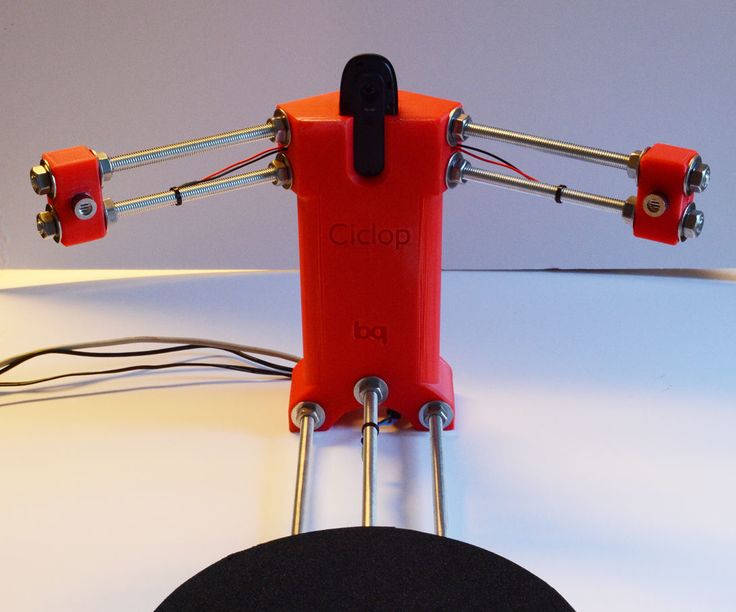

Ciclop is a desktop 3D scanner designed in kit form by the manufacturer BQ – based in Spain. The machine’s flexibility is displayed from two of the most striking features i.e. open-source and affordable.

Its hardware and operating software are called Horus; both of them are available under a creative commons attribution and share-alike license, and general public license respectively.

The scanner allows scanning any physical object that fits on its circular rotating platform of 9.8 inches * 8 inches.

The manufacturer also allows users to manipulate objects even after they are scanned, which is a huge plus when compared to scanners falling in the same price range. But, to know whether the scanner offers value for money, let’s dive through it in-depth.

Features

Ciclop is specially designed keeping in mind easy installation. The set that’s delivered to you contains all the assembly parts with instructions necessary for building the machine. Below mentioned and explained are some of such striking features that the scanner possesses.

The set that’s delivered to you contains all the assembly parts with instructions necessary for building the machine. Below mentioned and explained are some of such striking features that the scanner possesses.

Dual Laser Setup

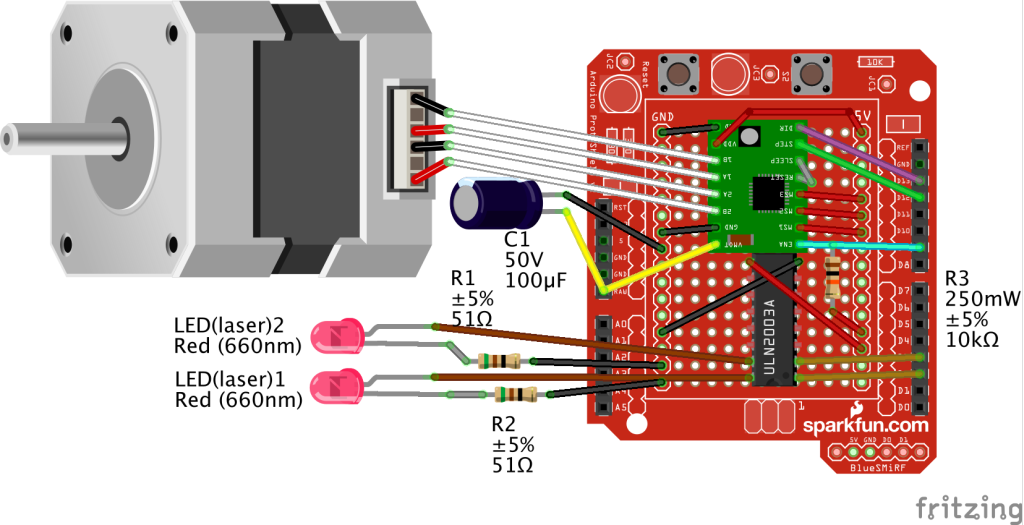

Ciclop hosts not just one but two laser sources present on each side of the rotating platform. These are class one lasers that can deliver extremely high precision while scanning parts and functional prototypes. The manufacturer claims how lasers, in combination with the camera, are able to capture details up to 500 microns.

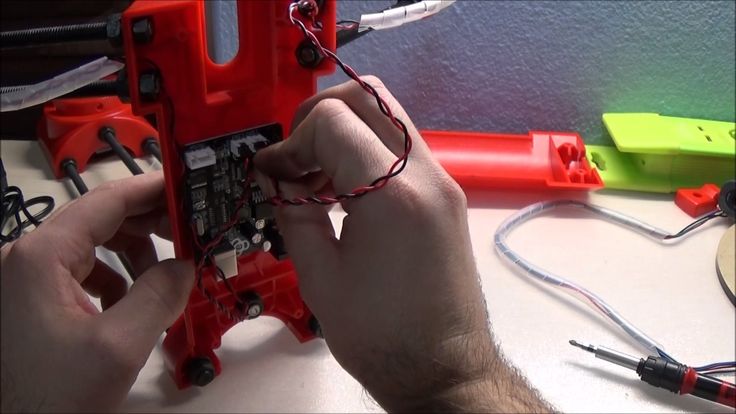

DIY kit

To ensure all its users know the exact mechanism and function of each and every component the scanner is designed from; BQ offers it in the form of a DIY kit.

Also, the entire information about the scanner is available on open sources making it extremely accessible for the operators to follow. Moreover, by keeping it as a DIY kit, BQ allows you to do things differently. Like, simply designing your own parts that can be used on the scanner for increasing its functionality! Amazing, isn’t it?

Open-source

As mentioned above, Ciclop’s specialty is that it’s open-sourced. And this is what makes it an ideal scanner for the masses.

And this is what makes it an ideal scanner for the masses.

Open-source technology makes it accessible to anyone who wishes to get their hands on the files needed to operate the scanner easily. All the documentation related to Ciclop can be found online including important aspects such as mechanical design, algorithms, mathematics, and experiments.

So, with the files already present online, all you need is the hardware to create the structure. Meaning that after buying the scanner, you are good to go independently. How cool is that!

Proprietary Horus software

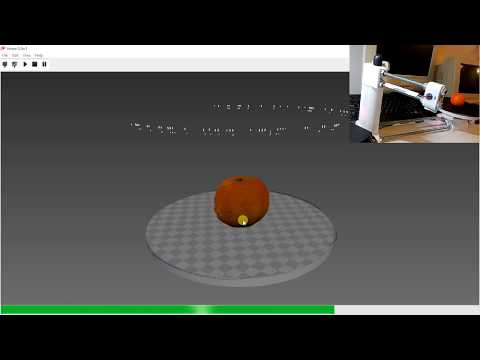

Capable of controlling, not just one, but many 3D scanners is the company-made Horus software. It manages the complete communication that takes place between the computer and the scanner. Not only that, its multi-purpose use extends to capturing and syncing of data, image processing, and also calibrating the scanner.

The application is completely reliable as one of the best 3D software for dealing with an open-source scanner. It can be run on Windows as well as Mac operating systems. Users can juggle up with numerous useful tools and advanced calibration capabilities. The software can also be fine-tuned for improvement via GitHub.

It can be run on Windows as well as Mac operating systems. Users can juggle up with numerous useful tools and advanced calibration capabilities. The software can also be fine-tuned for improvement via GitHub.

High definition camera

To ensure its users can capture high-quality videos with 1280 * 720 pixels and images up to 3 megapixels, BQ has put in place a Logitech C270 HD camera.

This component does an excellent job of not only capturing finer details of any object but also translating them into computer images for you so that you can manipulate them in the future.

The camera hosts a VGA image sensor that runs on Right Light Technology which enables it to capture clean and sharp images even in low natural light areas.

Simple design

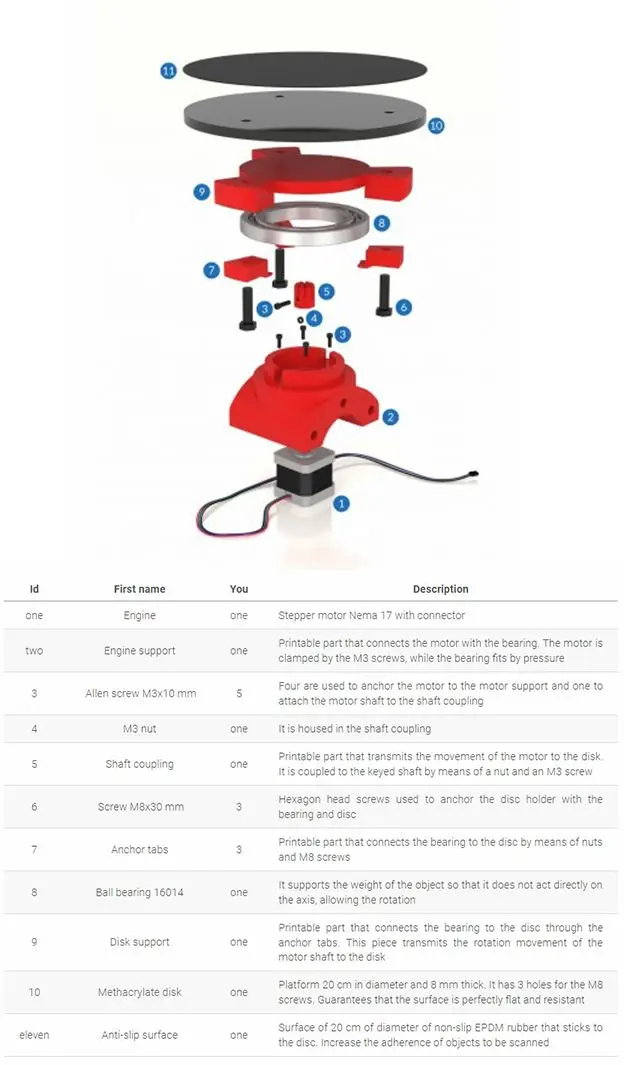

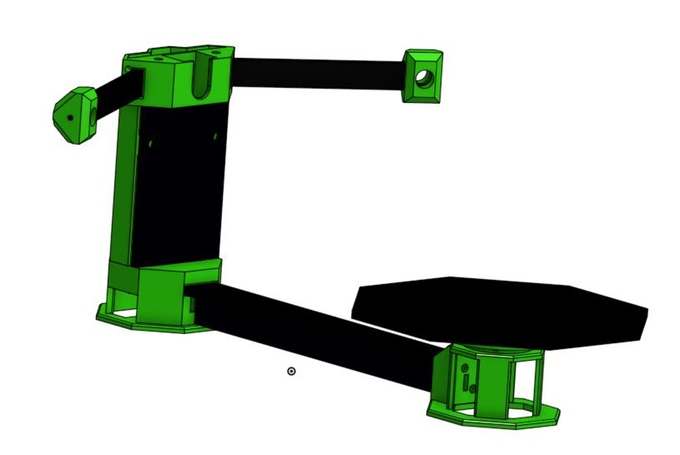

Ciclop works on an easy mechanism that can be duplicated also. Its main structure consists of 3D printed parts. The rest of the hardware comprises a few M8 threaded rods and screws, with some M3 screws, nuts, and washers. And the object sits on a 9.8 inches non-slippery methacrylate platform.

And the object sits on a 9.8 inches non-slippery methacrylate platform.

Specifications

BQ Ciclop allows users to scan objects with a maximum area of 250 mm * 205 mm weighing 3 kilograms. It offers a scan precision ranging from 100 to 300 microns.

Operators can scan their objects using dual lasers that are fixed at two sides of the scanner. A Logitech C270 HD camera promises highly accurate images and videos that can be converted into models for creating detailed parts and functional prototypes.

The scanner undergoes a maximum of 1600 steps per revolution. It needs a power supply unit of 12 Volts and 1.5 Amperes. The scan speed of Ciclop ranges anywhere from 2 to 8 minutes!

Price

BQ Ciclop is available for $219.

Setup

Credit: pinimg

As BQ Ciclop is delivered in a DIY kit, you’d have to take some time out in constructing the scanner. But given the fact that the stepwise instruction manual guides you all the way through the setup, it’s entertaining.

In fact, it’s enriching in terms of learning the exact mechanism the scanner works on. So, if you have any fault during its operation, it can be corrected easily.

Scan Type

Based on Laser triangulation technology, Ciclop accurately scans an object by capturing it in millions of points. In fact, the dual laser setup takes it to the next level by projecting multiple laser lines onto the part or functional prototype you are willing to scan.

Once the capturing in points is done, its reflection is apprehended with multiple sensors that are located at a fixed distance from the source. This allows for accurate point measurements by even calculating the reflection angle of the laser light.

Scan Quality

The dual laser set up on each side of the platform and Logitech C270 HD camera ensures that each and every scanned object is of fine quality.

While the former is capable of capturing details up to 500 microns, the latter enables apprehension of clean and sharp images even in low light areas.

Customer Support

Answers to all your queries related to the scanner and its functioning are available online. But, if you wish to contact the technical team over the phone and by email, it’s possible.

Software

Credit: instructables

The scanner comes integrated with Horus software that is a multi-platform application capable of controlling more than one scanner at a time. It handles complete communication between the computer and the scanner.

Windows, as well as Mac operating systems, are compatible with the software and it comes with advanced calibration capabilities. Because of this, first-time users can have a run-through in the pre-scanning phase!

Parameters Influencing Buying Decision

Below mentioned is a summary of all the main points that are worth checking out before making your buying decision.

3D Scanner Cost: Considering the scan area it is capable of processing and other striking features $219 is a very affordable cost for BQ Ciclop.

3D Scan Speed: Compared to other scanners in the same price range, Ciclop’s scanning speed is commendable. It’s above the industrial average of small to mid-range scanners.

3D Scan Quality: The scanner offers a scan precision of 0.5 mm which means, each and every part that you process on Ciclop will have fine detailing.

3D Scanner Capability: Users can utilize the dual laser setup for objects with a scan area of 250 mm * 205 mm. The scanner is capable of capturing particularities up to 500 microns.

3D Scanner Printability: The scanner is designed keeping in mind the beginner-level scanner users in mind and that’s why it’s kept completely open-source. Its information can be accessed online for free.

3D Scanner User Expectations: Novice-level individuals that make use of scanners and are willing to learn how to set up a scanner from scratch will enjoy using it the most.

The Verdict

In a nutshell, Ciclop turns out to be great value for money. Its simplistic design and extremely affordable pricing make the scanner beginner-friendly.

Its simplistic design and extremely affordable pricing make the scanner beginner-friendly.

Available under $250, it manages to surprise users by offering extraordinary features such as dual laser setup, extremely easy functioning software, high-definition camera, and a lot more.

Above all, its open-sourced nature lets you comfortably tweak and juggle around with this newer technology. Yes, there are a few complaints about the parts that the manufacturer supplies for its construction, but they are not a huge turn-off especially after taking into consideration the striking features that the scanner is a host to.

CowTech Ciclop 3D Scanner

CowTech Ciclop 3D Laser Scanner

Over $180,000 raised on Kickstarter! 1700+ scanners sold and counting.

The 3D printing revolution has come, and it’s time for 3D scanning to follow. The CowTech Ciclop is a RepRap 3D scanner with a large scan volume, simple, yet elegant design, and a disruptive price point that blows any other laser scanner out of the water. The user prints the plastic parts on their own printer in any color and resolution they choose, and can assemble the scanner in less than 30 minutes. Then, simply take any object you want to replicate, set it on the 200mm laser cut acrylic turntable, and start scanning. We wanted to make sure our product was usable for anyone who owns a 3D printer, so we meticulously designed our parts for a print bed volume of only 115mm x 110mm x 65mm (4.5 x 4. 3 x 2.6in) so they can be produced on even the smallest of printers.

3 x 2.6in) so they can be produced on even the smallest of printers.

Print your own parts and save money!

How It Works

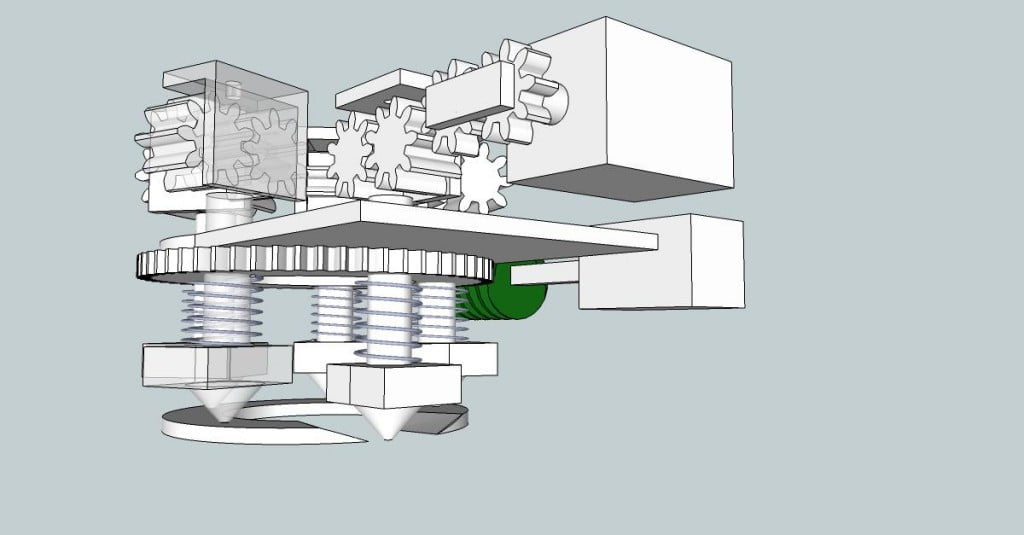

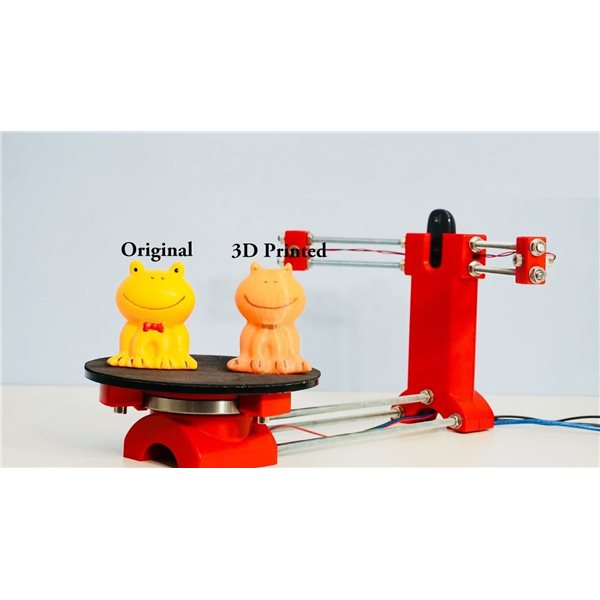

Laser scanners are a very common type of 3D scanner that use a pair of line lasers that flash in succession in combination with a camera and a rotating turntable. As the lines flash on the object, they trace the outline of the object in red light. The camera then picks up the location of the laser lines in 3D space, converting those lines into hundreds of thousands of points, and as the turntable rotates, every side of the object is scanned into a cloud of points, which can then be stitched together to form a mesh that replicates the surface of the object with up to 0.5mm precision.

3D printed model lion, 0.2mm resolution, PLA, Prusa i3

The term 3D scanner is a bit of a misnomer. Technically, most 3D scanners are actually point cloud generators. The scanner itself is a tool to make a .PLY file, or a point cloud, made up of hundreds of thousands of points that represent the geometry of the object. The typical user will want to convert this point cloud to an .STL file, which can easily be printed on a 3D printer.

The typical user will want to convert this point cloud to an .STL file, which can easily be printed on a 3D printer.

Scanned and post processed model loaded into Cura for slicing alongside the model mesh in CloudCompare

User submitted 3D prints

Once you have a digital 3D file of the part, the possibilities are endless. The CowTech Ciclop uses Horus, software developed by BQ for their version of the scanner. Unfortunately, Horus doesn't support direct .STL exports at this time, but this feature may be developed in later versions of the program. Fortunately, there are many options for post processing programs that can stitch the point clouds together into a printable file. These include Meshlab, Cloudcompare, Netfabb, Blender, and more. We recommend Meshlab and Cloudcompare, and provide detailed documentation with the scanner on how to use these programs.

The CT Ciclop scanner is a fully open source Rep Rap project, and part files and details on how to build your own can be found in the downloads section of our website.

All laser scanners can struggle with objects that are very black, very shiny, or furry, as the laser doesn't register properly with the camera. The CowTech Ciclop, is designed for experienced users who can familiarize themselves with different software programs in order to use the scanner and get high quality outputs from it.

We like to think of a 3D scanner like a video camera. A nice camera gives you the tools to take great pictures and videos, but without post production work in a video editing or photo editing program, you will likely be disappointed in the end result.

Shop Now

CT Ciclop

Ready to Scan Kit

Now Just $179

Ships Free!

Shop Now

CT Ciclop

Standard Kit

Now Just $139

Ships Free!

Shop All CowTech Ciclop Scanners and Accessories

Techno Print 3D Company

This is our first review of the most popular and inexpensive 3D printers for 2020. The list will include the best-selling devices in two price ranges (up to 30 tr and up to 60 tr). Printers working with both plastic filament (FDM) and photopolymers (LCD/DLP) will be presented. This list will always be up to date, as it is periodically updated and supplemented. Read more→

Printers working with both plastic filament (FDM) and photopolymers (LCD/DLP) will be presented. This list will always be up to date, as it is periodically updated and supplemented. Read more→

The Chinese company Dazz3D announces the launch of the project on KickStarter and accepts pre-orders for Dazz3D Basic and Dazz3D Pro 3D printers. These revolutionary new devices are aimed at both the professional and amateur markets. Read more→

We all know that precise calibration of the 3D printer desktop is the foundation and the key to successful printing on any FDM printer. In this article we will talk about the main and most popular ways to level the "bed". So, as mentioned above, 3D printing without desktop calibration is impossible. We face this process Read more→

It's hard to go through a day today without hearing about 3D printing technology, which is bursting into our lives at an incredible speed. More and more people around the world are becoming addicted to 3D printing technology as it becomes more accessible and cheaper every day. Now almost anyone can afford to buy a 3D printer, and with the help of Read more→

Now almost anyone can afford to buy a 3D printer, and with the help of Read more→

The FormLabs Form 2 and Ultimaker 3 are perhaps the most popular 3D printers today, capable of high quality printing with incredible surface detail. Moreover, these two devices use completely different technologies, and therefore, there are a lot of differences between them. Many will say that it is wrong to compare them or Read more→

XYZprinting, best known for its daVinci line of desktop 3D printers, is bringing five new devices to the professional and industrial environment. One will use laser sintering technology, the second full color inkjet printing and three DLP machines. First of all, the novelties will be of interest to dentists and jewelers. Read more→

Cleaning the nozzle of a 3D printer is a fairly common process that any user of such a device has to deal with. This is not at all a complicated procedure that anyone can handle. You can complete this task in 15 minutes, using only handy tools and accessories. Read more→

Read more→

Acetone steam polishing of ABS plastic is a process for smoothing the surface of 3D printed models. The result of this treatment makes your printed products look as if they were made by a professional mold casting method. If you want to understand how this is done correctly, then read this article. Aceto Read more→

Cloning is legal again: Ciclop 3D scanner

Business

Follow author

Subscribe

Don't want

20

Good morning!

As you may have noticed, the collection of pre-orders for the first DIY 3D scanner has started on the official website of Witbox Russia. On this occasion, we are organizing a festival of unprecedented generosity - each 3DToday user who pre-orders will receive a 10% discount.

Using your discount is extremely simple - just write in the comment field when ordering that you came from 3Dtoday. ru. You will also need to specify your nickname on this site. I'm not kidding. This is not a second action that will turn into a pumpkin at 00:00. This is a special love for an active community.

ru. You will also need to specify your nickname on this site. I'm not kidding. This is not a second action that will turn into a pumpkin at 00:00. This is a special love for an active community.

Cyclops is the first 3D scanner available. The DIY format and the general bq paradigm made it possible to lower the price to the minimum threshold. But a logical question arises:

WHY DOES A 3D PRINTER USER NEED A SCANNER?

Obviously to scan. But as with 3D printing, this concept is abstract and represents a huge field for imagination. We are sure that many people have come across the question: “What can be done on a 3D printer?”. And what questions will there be about a bunch of printer + scanner ...

The first thing to ask yourself is what can a Cyclops scan? The basic model (more on that later) allows you to scan an area 205 mm high and 250 mm in diameter. Man is a proud bird, you cannot stuff him into such a framework. If the task of a 3D printer is to turn virtual objects into quite real and tangible, then the task of a 3D scanner, on the contrary, allows you to translate real things into a digital file with maximum accuracy. What opportunities does it give?

If the task of a 3D printer is to turn virtual objects into quite real and tangible, then the task of a 3D scanner, on the contrary, allows you to translate real things into a digital file with maximum accuracy. What opportunities does it give?

First, you can "clone" any part or toy that you have in a single copy on hand. To the extent that you can create a digital library of things dear to your heart and, in case of a sad loss, you can always find this same object again with the help of 3D printing.

Secondly, it allows you to make changes to existing objects. You can open the scan result in a 3D editor and change whatever you want in it. To make a longer part of complex geometry for some kind of aggregate? Add a third hand to an anime character figurine? Engrave your name on the Champions Cup? Anything. This scanner from bq is a great addition to your 3D printer like Hephaestos - DIY or DIE .

Like any decent Cyclops, the Spaniard is armed with one single eye. But what!

But what!

The Logitech C270 HD is a great webcam, owners will confirm. Such a “peephole”, coupled with a scanning accuracy of 0.5 mm, will allow anyone who wants to get a “cast” of even a complex technical object. In his article series daymon showed how important this can be, especially for those who do not know how to model.

So, back to the original question - does the user need a 3D scanner? The fact that such devices have areas of application is a proven fact, which is only confirmed by new scanners entering the market. But do you personally need such a scanner? What tasks can he solve, where can he help a person who has just stepped into the world of 3D printing? We know the answer to these questions, but what could be more valuable than the opinions of users? Well, if they manage to bake pancakes on Gefesh ...

A little higher it was said - “base model”. Does this mean that Cyclops has a lineup with more “pumped” versions? No. But he doesn't need it! All improvements are incorporated in the design and personally in you. Do it yourself.

But he doesn't need it! All improvements are incorporated in the design and personally in you. Do it yourself.

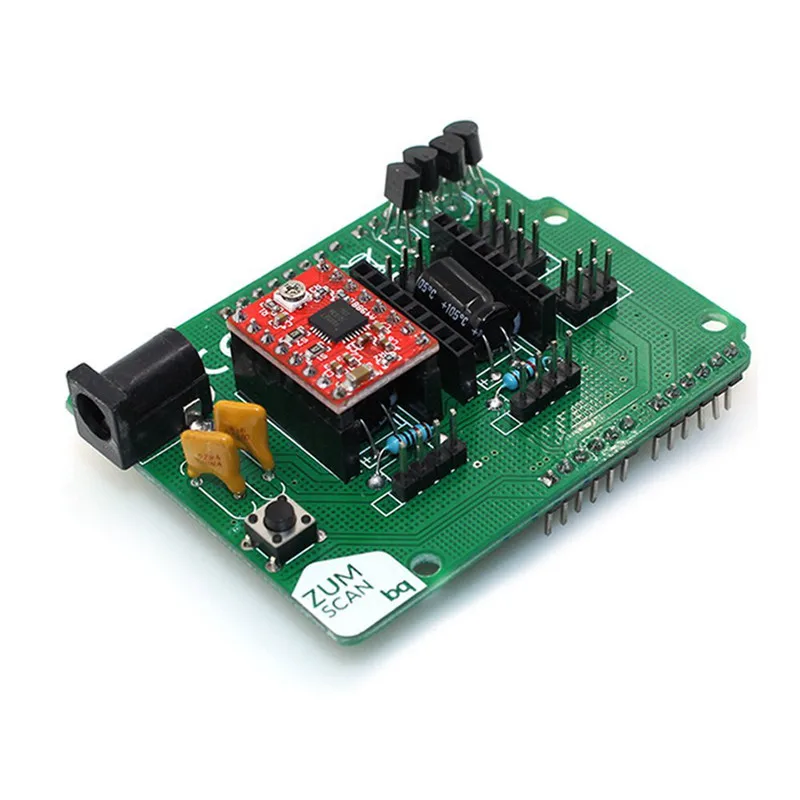

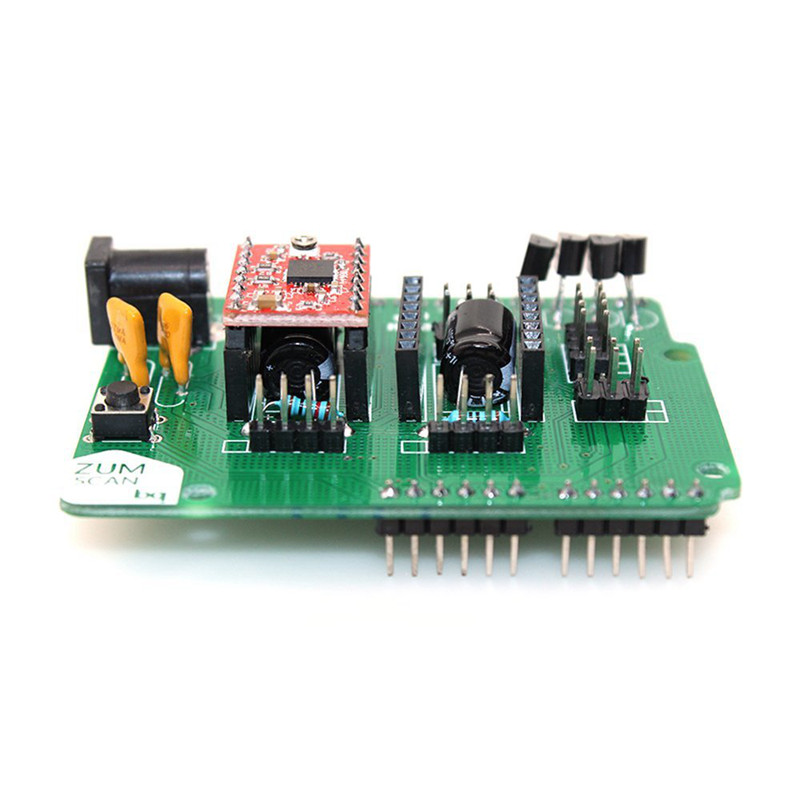

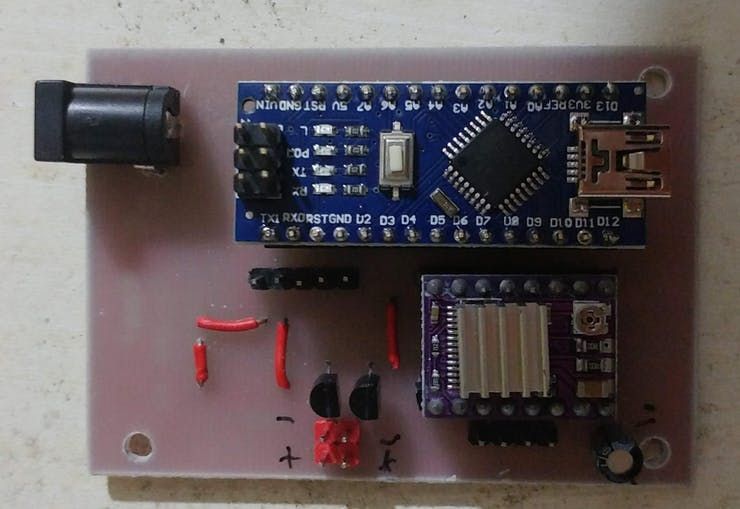

ZUM BT-328 is installed on board the Cyclops instead of the usual Arduino Uno. Instead of releasing a supposedly new device that differs from the previous one only in the size of the working area, bq gives “human right to technology” - the number of pins allows you to install new or additional “eyes” or lasers. There will also be no problems with the software stuffing - the software for Cyclops, Horus (Horus) is absolutely open source and you can do whatever you want with your scanner and what is enough technical capabilities.

Since Horus has been mentioned, there is one feature that DIY printers lack. It often happens that the user assembles the device not quite as planned by the developer. Every backlash, under-twisted bolt, under-finished detail - all this upsets the delicate balance. However, not in the case of Cyclops - Horus's auto-calibration allows you to adjust the internal scanning parameters in such a way that any user design (within reason) will work.