How strong is 3d printer plastic

How Strong Are 3D Printed Parts? Central Scanning

How strong 3D printed parts are depends on several key aspects, including:

- The material you use for printing, and

- How you design and print your 3D parts.

Why 3D Printing Materials Matter

Your 3D print will only ever be as good as the material you use.

This means selecting a quality material from a reliable supplier. But, also ensuring that the material you select will be right for the intended purpose of your finished part.

There is a broad range of 3D printing materials available. In addition, the options will depend on the properties you want the material to have.

For example, you might want your part to be:

- Impact resistant

- Chemically resistant

- Flexible

- Rigid

- Heat resistant

- Water resistant.

PLA OR POLYLACTIC ACID

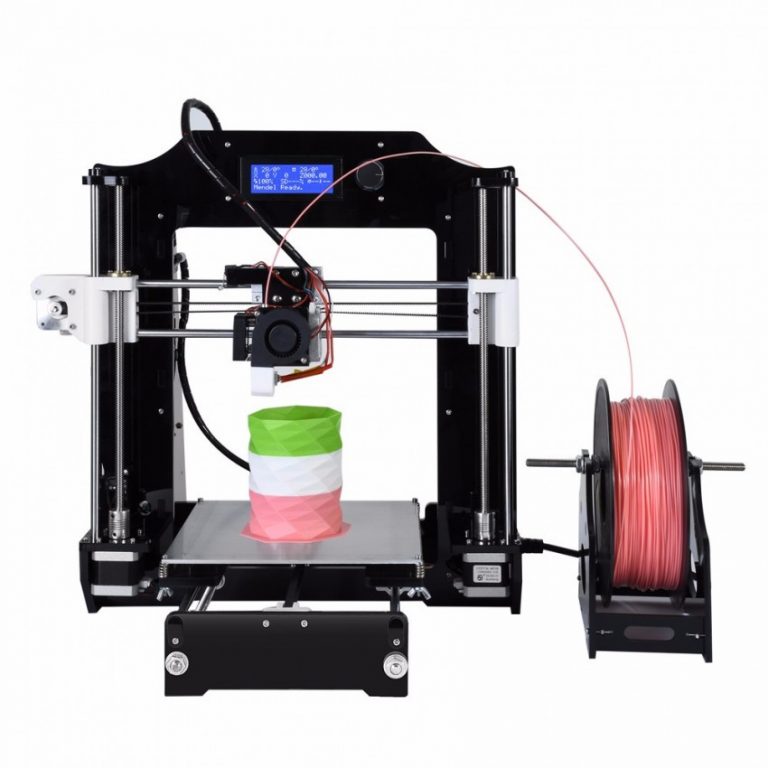

One of the most popular materials users select for desktop 3D printing is PLA, or Polylactic Acid.

Why do so many people choose PLA as their 3D printing filament?

It provides ease of use at a low cost and, importantly, it is reasonably strong. Additionally, you can print with PLA at a low temperature, without a heated bed, but it has a tensile strength of 7,250 psi. However, PLA is also biodegradable, so while it is environmentally friendly, it is unlikely to be suitable for bearing heavy loads, as it can become brittle.

ABS – ACRYLONITRILE, BUTADIENE AND STYRENE

A more advanced engineering material for 3D printing is ABS. ABS is the combine polymers Acrylonitrile, Butadiene and Styrene. It is widely used in everyday household items and in cars. It is an engineering-grade material and more stable than PLA. There is a catch here though. When it comes to actual tensile strength, ABS is weaker than PLA.

There are other alternative 3D printing materials out there. For example, there is a type of nylon suitable for 3D printing that is stronger and more durable than either PLA or ABS.

NYLON

Nylon filament is flexible when thin but with excellent adhesion between layers. It has a high melting temperature and a low friction coefficient. Nylon is suitable for various functional applications and parts such as hinges.

POLYCARBONATE

Another strong 3D printing material is polycarbonate. It offers a high level of toughness and a very good thermal and dimensional stability. In addition, it is ideal for high-strength, functional components. For instance, it is commonly used in manufacturing bullet-proof glass.

Matching Material with Design and Production

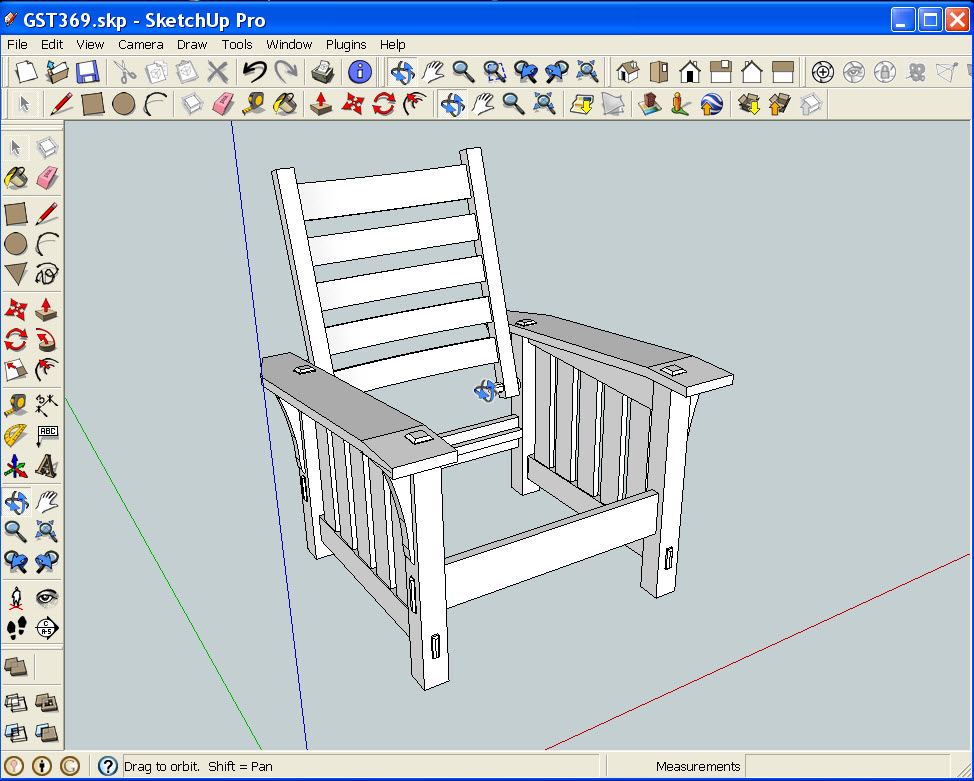

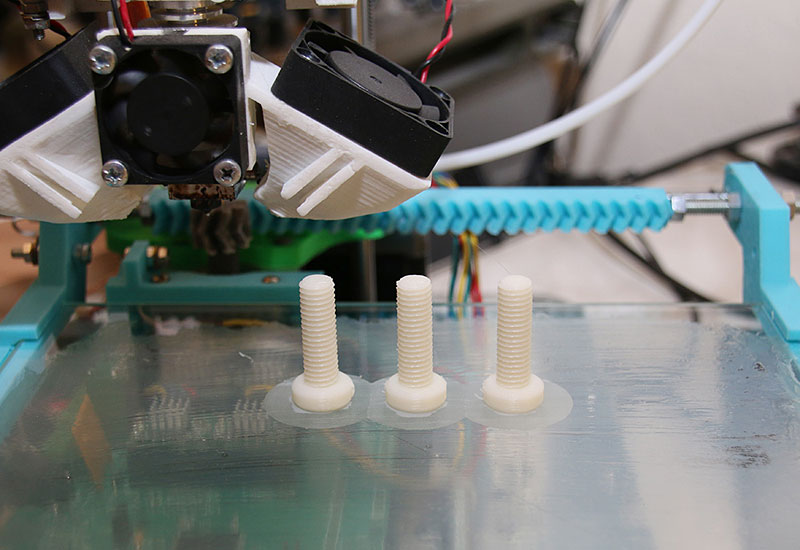

To ensure you have sufficiently strong 3D printed parts you need to make sure they are well designed and that you use appropriate print settings.

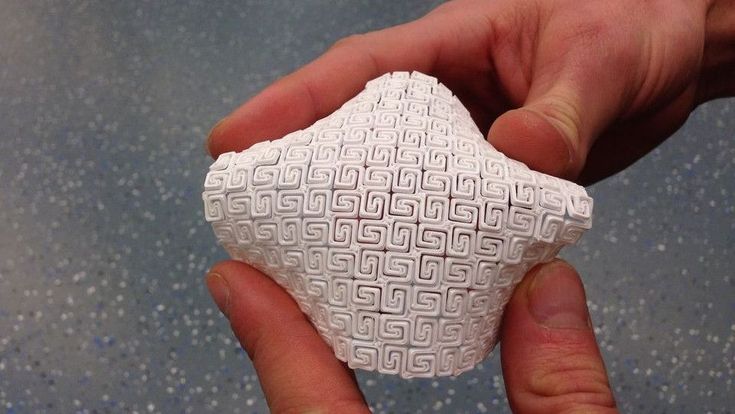

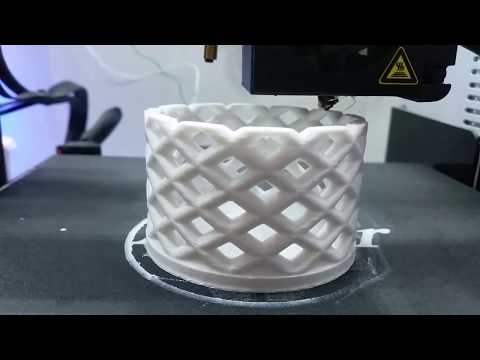

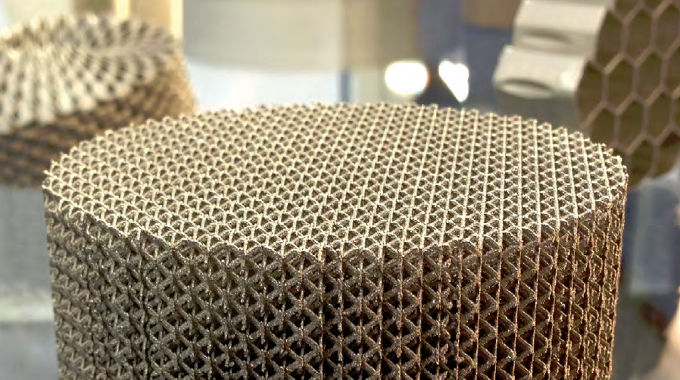

- First, select a suitable infill pattern. This is the printed material inside the walls of your print. Selecting a naturally strong infill design pattern, such as honeycomb or rectilinear, will add strength to the finished 3D part, regardless of the material you choose.

- Next, you should ensure your print settings are of a sufficient quality, as this can influence the final result.

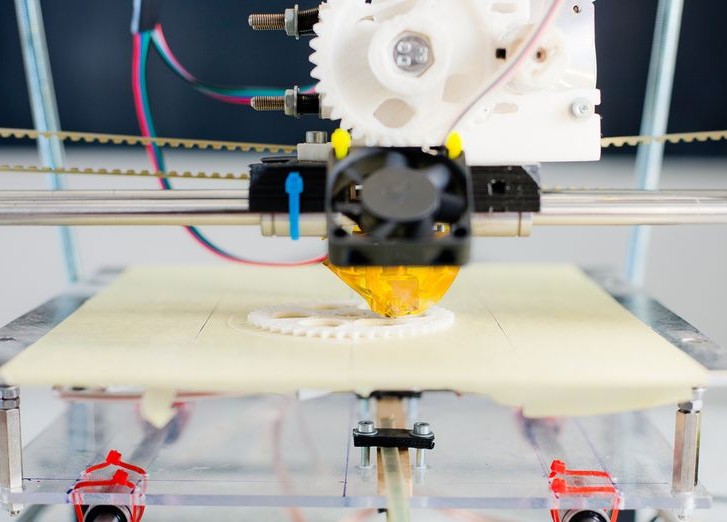

- Finally, choose the right orientation for your 3D print. You will find that 3D parts tend to be weakest along the z axis. Therefore, you must make sure that the areas of the part receiving the most stress will not be along this axis.

The strength of 3D printed parts is relative to their function and the material you choose should reflect this.

For more information about our 3D printing solutions, please use our online contact form, or call us direct on 01527 558 282.

Are 3D Printed Parts Strong & Durable? PLA, ABS & PETG – 3D Printerly

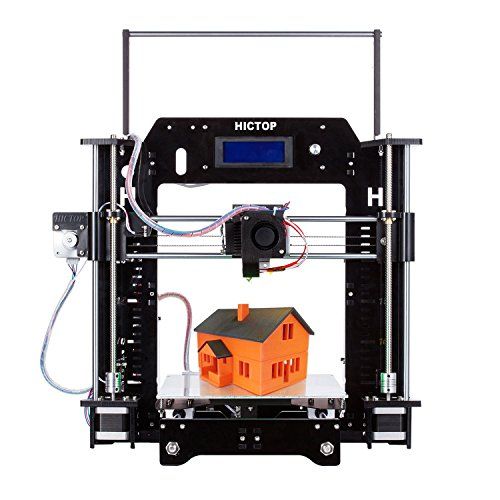

Companies worldwide have recently turned to 3D printing to create technical parts quickly while saving some money in the process. But, developing 3D versions of pieces involves using new materials that might not be as durable. So, are 3D printed parts strong?

3D printed parts are very strong, especially when using specialized filament like PEEK or Polycarbonate, which is used for bullet-proof glass and riot shields. Infill density, wall thickness and print orientation can be adjusted to increase strength.

Infill density, wall thickness and print orientation can be adjusted to increase strength.

There’s a lot that goes into the strength of a 3D part. So, we’re going to be reviewing the materials used during 3D printing, how strong they really are, and what you can do to increase the strength of your 3D printed parts.

Are 3D Printed Parts Weaker & Fragile?

No, 3D printed parts aren’t weaker and fragile unless you 3D print them with settings that don’t give strength. Creating a 3D print with a low level of infill, with a weaker material, with a thin wall thickness and low printing temperature is likely to lead to a 3D print that’s weak and fragile.

How Do You Make 3D Printed Parts Stronger?

Most 3D printing materials are rather durable on their own, but there are some things that can be done to increase their overall strength. This mostly comes down to the minor details in the design process.

Most important would have to be manipulating the infill, wall thickness, and the number of walls. So, let’s take a look at how each of these factors can impact the strength of a 3D printed structure.

So, let’s take a look at how each of these factors can impact the strength of a 3D printed structure.

Increase Infill Density

Infill is what’s used to fill in the walls of a 3D printed part. This is essentially the pattern within the wall that adds to the density of the piece overall. Without any infill, the walls of a 3D part would be completely hollow and rather weak to outside forces.

Infill is a great way to increase the weight of a 3D part, also improving the strength of the part at the same time.

There are plenty of different infill patterns that can be used to improve the strength of a 3D printed piece, including a grid infill or a honeycomb infill. But, just how much infill there is will determine the strength.

For regular 3D parts, up to 25% is likely more than enough. For pieces designed to support weight and impact, closer to 100% is always better.

Increase Number of Walls

Think of the walls of a 3D printed part as the support beams in a house. If a house only has four exterior walls and no support beams or interior walls, just about anything can cause the house to collapse or give under any amount of weight.

If a house only has four exterior walls and no support beams or interior walls, just about anything can cause the house to collapse or give under any amount of weight.

In the same way, the strength of a 3D printed piece will only exist where there are walls to support weight and impact. That’s exactly why increasing the number of walls inside a 3D printed piece can increase the strength of the structure.

This is an especially useful strategy when it comes to larger 3D printed parts with a greater surface area.

Increase Wall Thickness

The actual thickness of the walls used in a 3D printed piece will determine how much impact and weight a part can withstand. For the most part, thicker walls will mean a more durable and sturdy piece overall.

But, there does seem to be a point at which it’s difficult to print 3D printed parts when the walls are too thick.

The best part about adjusting the wall thickness is that the thickness can vary based on the area of the part. That means the outside world probably won’t know that you’ve thickened the walls unless they cut your piece in half to dissect it.

That means the outside world probably won’t know that you’ve thickened the walls unless they cut your piece in half to dissect it.

Generally speaking, extremely thin walls will be quite flimsy and won’t be able to support any exterior weight without collapsing.

Generally, walls that are at least 1.2mm thick are durable and strong for most materials, but I’d recommend going up to 2mm+ for a higher level of strength.

The Strength of Materials Used to Create 3D Parts

3D printed parts can only be as strong as the material that they’re made of. With that said, some materials are a lot stronger and more durable than others. That’s exactly why the strength of 3D printed parts varies so greatly.

Three of the more common materials used to create 3D parts include PLA, ABS, and PETG. So, let’s discuss what each of these materials is, how they can be used, and how strong they really are.

PLA (Polylactic Acid)

PLA, also known as Polylactic Acid, is perhaps the most popular material used in 3D printing. Not only is it quite cost-effective, but it’s also very easy to use to print parts.

Not only is it quite cost-effective, but it’s also very easy to use to print parts.

That’s why it’s often used to print plastic containers, medical implants, and packaging materials. In most circumstances, PLA is the strongest material used in 3D printing.

Even though PLA has an impressive tensile strength of about 7,250 psi, the material does tend to be a little brittle in special circumstances. That means it’s a little more likely to break or shatter when placed under a powerful impact.

It’s also important to note that PLA has a relatively low melting point. When exposed to high temperatures, the durability and strength of PLA will severely weaken.

ABS (Acrylonitrile Butadiene Styrene)

ABS, also known as Acrylonitrile Butadiene Styrene, isn’t quite as strong as PLA, but that doesn’t at all mean that it’s a weak 3D printing material. In fact, this material is much more capable of withstanding heavy impact, often flexing and bending rather than shattering completely.

That’s all thanks to the tensile strength of about 4,700 PSI. Given the lightweight construction yet impressive durability, ABS is one of the best 3D printing materials out there.

That’s why ABS is used to make just about any type of product in the world. It’s quite a popular material when it comes to printing children’s toys like Legos, computer parts, and even piping segments.

The incredibly high melting point of ABS also makes it able to withstand just about any amount of heat.

PETG (Polyethylene Terephthalate Glycol-Modified)

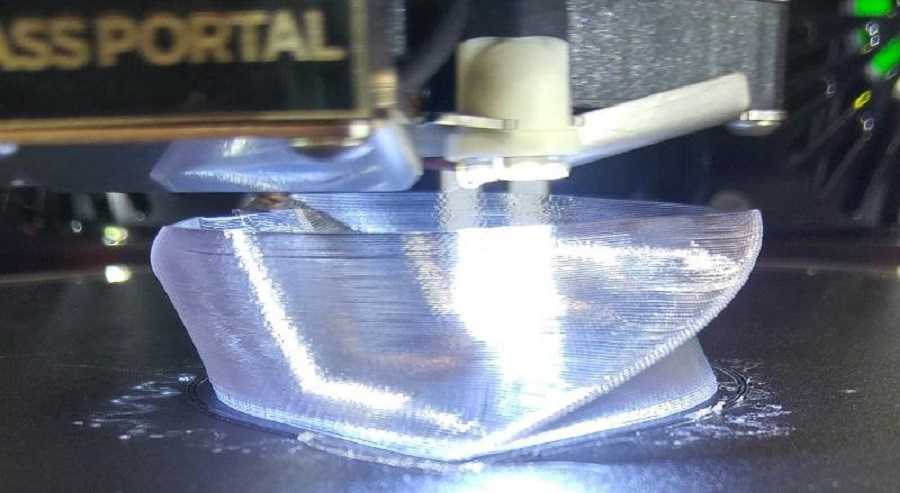

PETG, also known as Polyethylene Terephthalate, is usually used to develop more complex designs and objects when it comes to 3D printing. That’s because PETG tends to be much denser, more durable, and more rigid than some of the other 3D printing materials.

For that exact reason, PETG is used to make plenty of products like food containers and signage.

Why Use 3D Printing at All?

If 3D printed parts weren’t at all strong, then they wouldn’t be used as an alternative production method for many supplies and materials.

But, are they as strong as metals like steel and aluminum? Definitely not!

However, they are quite useful when it comes to designing new pieces, printing them at a lower cost, and getting a good amount of durable use out of them. They’re also great for small parts and have a generally decent tensile strength given their size and thickness.

What’s even better is that these 3D printed parts can be manipulated to increase their strength and overall durability.

Conclusion

3D printed parts are definitely strong enough to be used to make common plastic items that can withstand great amounts of impact and even heat. For the most part, ABS tends to be much more durable, though it does have a much lower tensile strength than PLA.

But, you also need to take into consideration what’s being done to make these printed parts even stronger. When you bump up the infill density, increase the number of walls, and improve the wall thickness, you’re adding to the strength and durability of a 3D printed piece.

What is the most durable material for 3D printing?

3DPrintStory 3D printing process What is the most durable material for 3D printing?

While the 3D printing process seems like a great alternative to traditional manufacturing methods, the parts produced can be fragile and unusable. As a rule, this is the result of using standard materials that are not designed for strength and durability. But there is a solution: use durable materials! Durable 3D printing materials can greatly enhance your options, as you can print parts and assemblies for small projects without fear of breakage.

In this article, we'll take a look at the three most durable types of 3D printing materials. However, before that, we will take a closer look at what strength means in terms of filament materials.

However, before that, we will take a closer look at what strength means in terms of filament materials.

What is strength and how do we evaluate it?

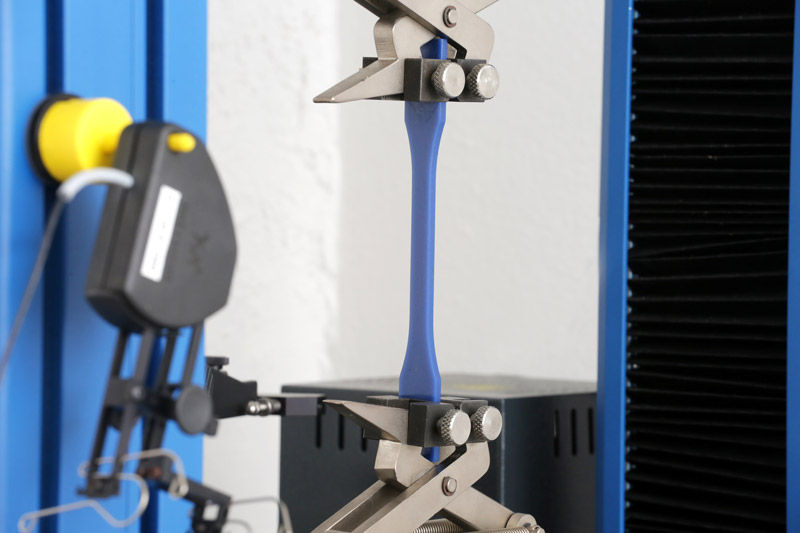

The strength of a material can be measured and evaluated in different ways. In this article, we will mainly use tensile strength (stress before something breaks). We will list the tensile strength of each 3D printing material in pounds or pounds per square inch (PSI).

Despite the obvious number of pounds the material can support, there is still a margin of error depending on how the part was printed. We've compiled research from a variety of sources to make sure these three materials are the strongest.

You must also understand that the material itself is not the only factor that affects the strength of the finished product. The design itself, post-processing and the 3D printing process also affect the strength of the part.

Polycarbonate

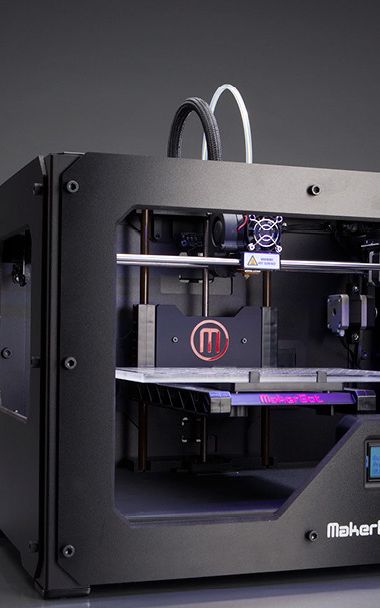

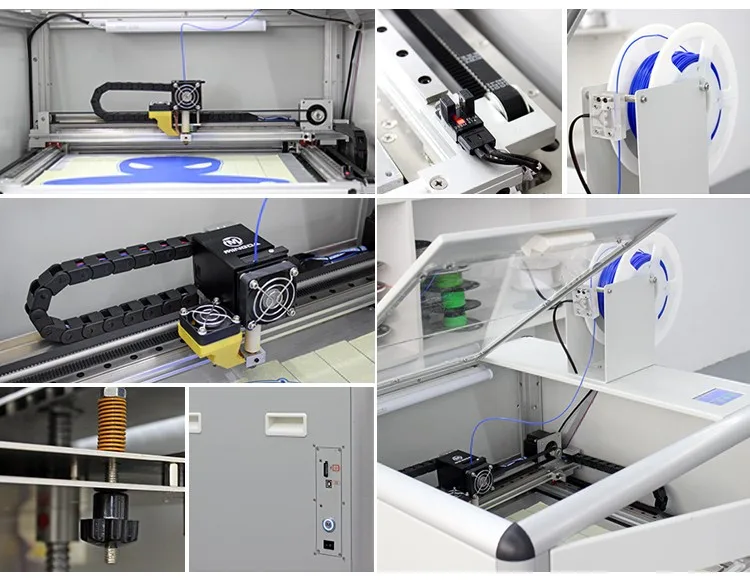

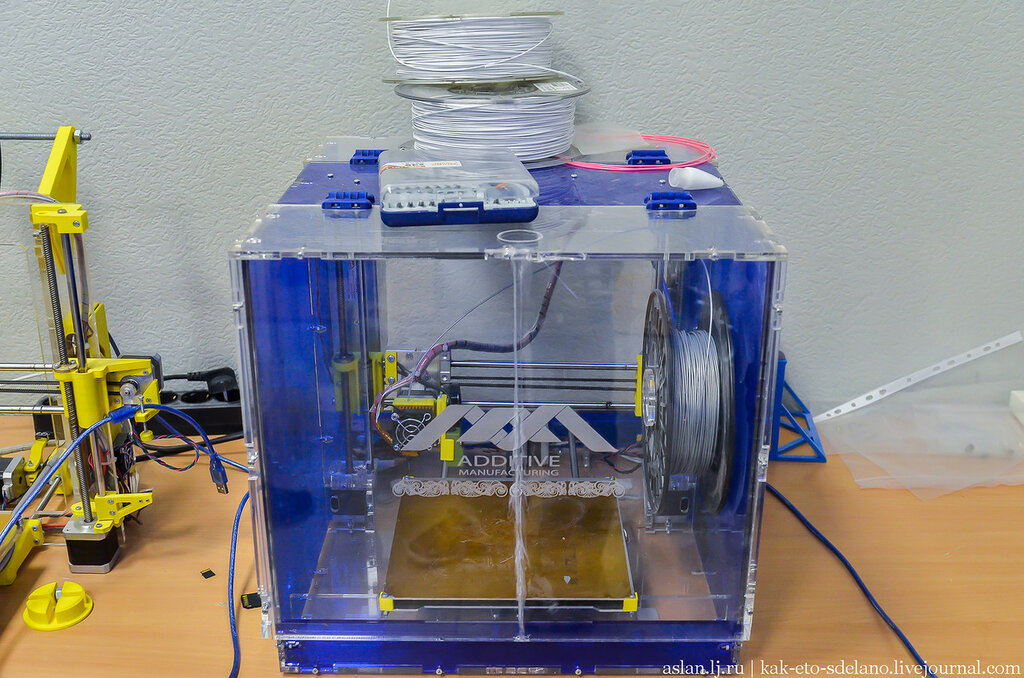

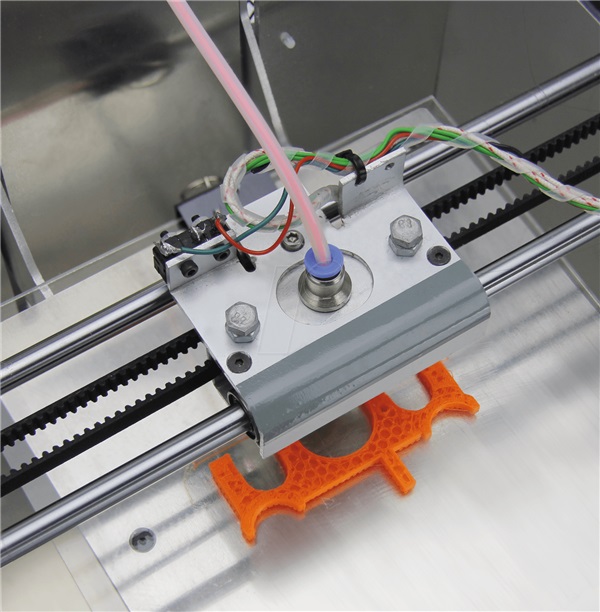

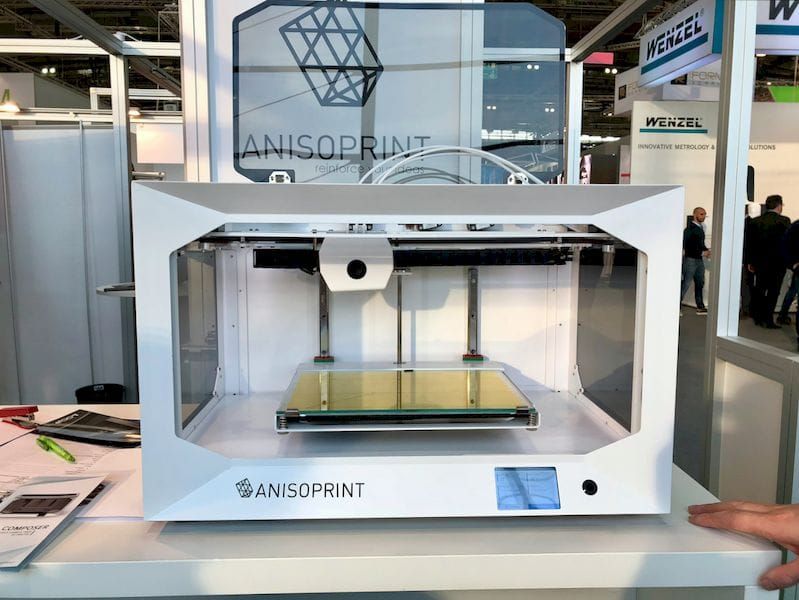

Polycarbonate (PC) is considered by many manufacturers and reviewers to be the strongest 3D printing filament available. In particular, it is possible to achieve high strength of polycarbonate products by 3D printing with an all-metal hot end and a 3D printer in a case that is isolated from the influence of the external environment.

In particular, it is possible to achieve high strength of polycarbonate products by 3D printing with an all-metal hot end and a 3D printer in a case that is isolated from the influence of the external environment.

Some Numbers

Airwolf 3D has come to the conclusion after many filament tests that polycarbonate is the best choice of durable filaments for desktop 3D printers. They were able to hang up to 685 pounds on a polycarbonate printed hook and found that this material had a tensile strength of 9800 psi. In contrast, the same part printed in PLA could only support 285 pounds.

Using a similar test, MatterHackers studied the tear strength of this type of thread, as well as a number of other materials. They were able to hang an average of 409 pounds on the polycarbonate hook, while the PLA parts had a significantly lighter average weight of just 154 pounds.

Finally, renowned 3D printing YouTuber Thomas Sunladerer reviewed several polycarbonate materials and gave very positive feedback on the strength of the material.

3D printing with polycarbonate

It is worth noting that the quality of 3D printing with polycarbonate is not very good. Compared to other materials, protrusions and small details may not turn out as well as using the same PLA.

According to Rigid.Ink, polycarbonate is mostly sold in clear. This 3D printing material has excellent heat resistance as well as impact resistance. But note that you will have to print at high temperatures. As mentioned above, it is better to use an enclosed 3D printer and a solid metal hotend.

Pros of polycarbonate : extra strong, excellent thermal and impact resistance.

Cons of polycarbonate : does not cope well with protrusions and small details of a 3D model, requires a body and an all-metal hot end, a limited number of colors.

Nylon

Next on our list of durable 3D printing materials is nylon. This material is considered by many to be the most reliable for desktop 3D printers. Nylon is inferior in strength to polycarbonate, but still clearly stronger than other competitors such as PLA and ABS.

Nylon is inferior in strength to polycarbonate, but still clearly stronger than other competitors such as PLA and ABS.

Some numbers

A hook printed with nylon (910) thread had a breaking strength of 7,000 psi, while the same ABS hook only had a strength of 4,700 psi, according to Airwolf 3D. Airwolf 3D also noted that the nylon filament-printed clip holds 485 pounds.

MatterHackers posted similar results and noticed that a hook printed with their NylonX material can hold an average of 364 pounds before it breaks. Rigid.Ink also reviewed some nylon threads and gave them a four out of five rating for strength and a five for durability. For comparison: the strength and durability of PLA is three conventional units.

Nylon 3D printing

Nylon is slightly easier to print than polycarbonate, but it's still not PLA. Nylon filament is quite hygroscopic, so it must be kept dry and requires a high printing temperature of 220-270°C. This material is prone to slight warpage, but is also resistant to impact, fatigue, and high temperature.

Nylon pros: impact resistance, fatigue resistance, heat resistance, easier to print than polycarbonate.

Nylon 9 cons0042 : hygroscopic, warping, very high hot end temperature required.

Composites

Finally, composite threads, although not essentially a single material, can be extremely strong. Composites are threads with certain additives that affect the properties of the material, including to increase strength. The names of these threads usually have the words "pro", "reinforced" (reinforced) or "infused" (infused), since they are usually a mixture of different materials.

For this reason, it is impossible to assess where the composite fibers are compared to the two previous materials. Some composites, such as Carbonyte, can compete with nylon threads for strength, while some composites are less durable.

It all depends on what the composite thread consists of. Durable is usually a high strength material such as nylon impregnated with another high strength material such as carbon fiber or glass.

Speaking of carbon fiber, this is also a very strong filament that is sometimes used for 3D printed bicycles. However, some composite fibers are stronger than many pure carbon fibers, so they are not in the top three, but deserve special mention as composite fibers.

Some numbers

We will use carbon fiber nylon and glass fiber nylon threads as examples. MatterHackers has determined that hooks printed on these materials can hold an average of 349and 268 pounds respectively.

Rigid.Ink gave the fiberglass nylon filament four out of five ratings for strength and five for durability. They also gave the carbon fiber nylon a five out of five rating for both strength and durability. In comparison, PLA and ABS were in the top three for strength.

3D printing with composites

Composites vary in the way they are 3D printed, but they are generally relatively similar to their base material. Durable composite fibers are usually made from nylon, so you'll have to print at fairly high temperatures. These threads are also quite expensive.

These threads are also quite expensive.

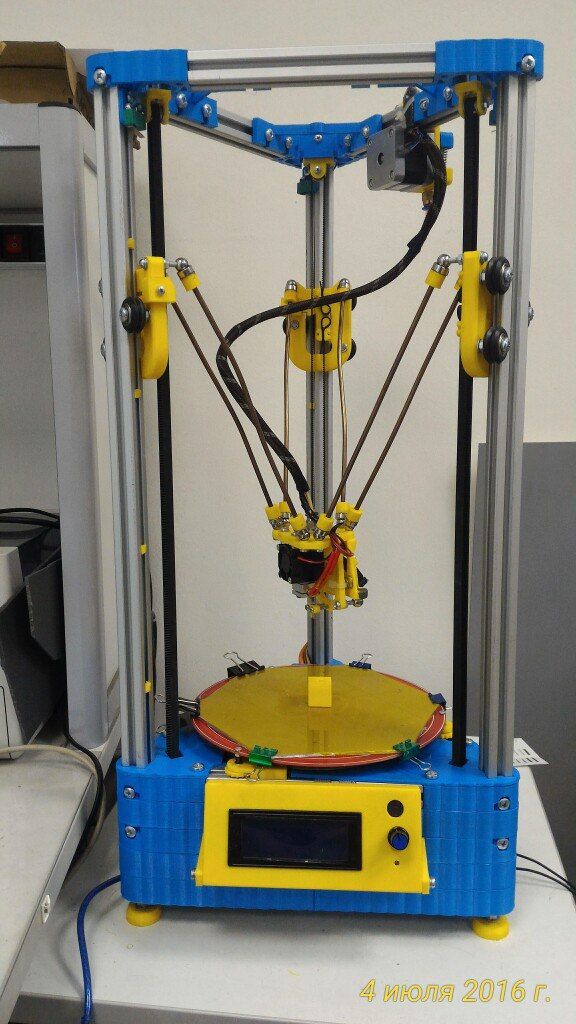

Every year 3D printing becomes more popular and accessible. Previously, a 3D printer was more like a complex CNC machine, but now manufacturers are meeting users. Simplified and automated settings that many beginners drove into a stupor. Despite this, it can be difficult for a novice user to understand the variety of constantly appearing plastics for a 3D printer.

The choice of plastic for a 3D printer is very important, especially when the goal is to print a functional model with certain properties. It will be a shame if the printed gear breaks almost immediately, or the decorative model quickly loses its beauty.

It is important to understand whether the printer will be able to work with the selected plastic. Some materials (most often engineering) require certain conditions for successful printing.

First, decide which model you want to print. What properties should it have? Does the model need to be durable? Or is it a master model for further replication, in which the quality of the surface is important?

What properties should it have? Does the model need to be durable? Or is it a master model for further replication, in which the quality of the surface is important?

90% of 3D printers use 1.75 diameter filament. 3mm diameter is rare, but it is better to check in advance which size is used in your printer.

PLA

PLA (Polylactide) is the most popular and affordable 3D printer plastic. PLA is made from sugar cane, corn, or other natural raw materials. Therefore, it is considered a non-toxic, biodegradable material.

Extruder temperature - 190-220 degrees. Table heating is not needed, but if the printer's table has a "heater" for better adhesion, you can heat it up to 50-60 degrees. PLA is very easy to work with. The only requirement is to blow the model. There is practically no shrinkage in this material. When printed, it is practically odorless, and if it smells, it smells like burnt caramel.

Pros:

-

Does not shrink.

This makes it easy to build prefabricated or huge models without changing dimensions.

This makes it easy to build prefabricated or huge models without changing dimensions. -

There are no specific requirements for a 3D printer. Any working 3D printer will do. PLA doesn't need a heated table or a closed case.

-

Non-toxic. Due to this, during printing it does not smell or has a barely perceptible aroma of burnt caramel.

-

Diverse color palette.

Cons:

-

PLA is poorly sanded and machined.

-

It begins to deform already with a slight heating (about 50 degrees).

-

Fragility. Compared to other materials, PLA is very brittle and breaks easily.

-

Decomposes under the influence of ultraviolet radiation. Of course, it will not fall apart into dust, but it can become more brittle and fade.

PLA is perfect for making dimensional or composite models. For example, decorative interior items, prototyping, electronics cases, etc.

Recently, PLA+ has appeared on the market. It may differ from conventional PLA in improved performance. For example, more durable, with improved layer adhesion.

Dummy turbine

Decorative coasters

ABS

ABS (acrylonitrile butadiene styrene) is the second most popular plastic for 3D printing due to its properties, availability and low price.

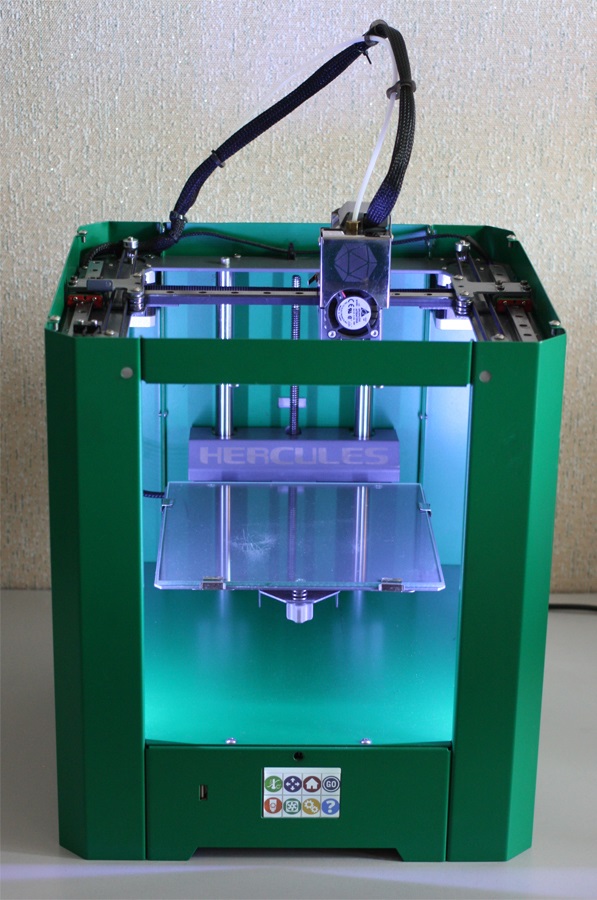

Extruder temperature - 220-240 degrees. The temperature of the table is 80-100 degrees. For printing, a heated table is required at the printer. It is desirable to have a closed chamber, because ABS "does not like" drafts. Due to a sharp temperature drop, it can “unstick” from the table or crack in layers. ABS can smell bad when printing, so it is recommended to use the printer with a closed chamber and filters, or print in a well-ventilated area.

Pros:

-

Good strength characteristics allow the production of functional prototypes from ABS.

-

Simple mechanical and chemical processing. ABS is easy to sand and drill, and with an acetone bath you can achieve a perfectly smooth surface.

-

It is currently the most inexpensive type of plastic for 3D printing.

-

Large selection of colors and shades.

Cons:

-

High shrinkage. Because of this, it can be problematic to manufacture overall products.

-

Printing requires a heated bed and a closed chamber. Without this, the ABS may peel off the table or crack in layers.

-

During the printing process, ABS can smell bad. Therefore, it is recommended that you print in a ventilated area or use the printer with a sealed chamber and filter.

ABS is an engineering plastic. It is suitable for the manufacture of simple functional products.

ABS after chemical treatment in an acetone bath

RU model made of ABS

ABS+ differs from conventional ABS in improved strength characteristics (elasticity, rigidity, hardness), less shrinkage and sometimes resistance to certain oils and solvents (eg gasoline).

HIPS

HIPS (high impact polystyrene) - originally conceived as a soluble support plastic for materials with high printing temperatures. For example for ABS or Nylon.

The extruder temperature is 230-260 degrees. The temperature of the table is 80-100 degrees. It is desirable to have a closed camera for a 3D printer.

Pros:

-

Less shrinkage than ABS.

-

Ease of machining.

-

The matte surface looks very advantageous on decorative products.

-

Food contact allowed (but be sure to check with a specific manufacturer for certificates)

Cons:

-

For printing, you need a printer with a heated table and a closed chamber.

-

More flexible and less durable than ABS. Because of this, it will not be possible to produce functional products.

-

Small palette of colors.

Most often, HIPS is used for its intended purpose for printing on 2x extruder printers as a support for ABS. It dissolves perfectly (though not very quickly) in limonel.

Sometimes HIPS is used as an independent material. Products from it are not very durable, but this plastic is loved for easy post-processing. HIPS can be used for models that will subsequently come into contact with food (not hot).

Using HIPS as a Soluble Support

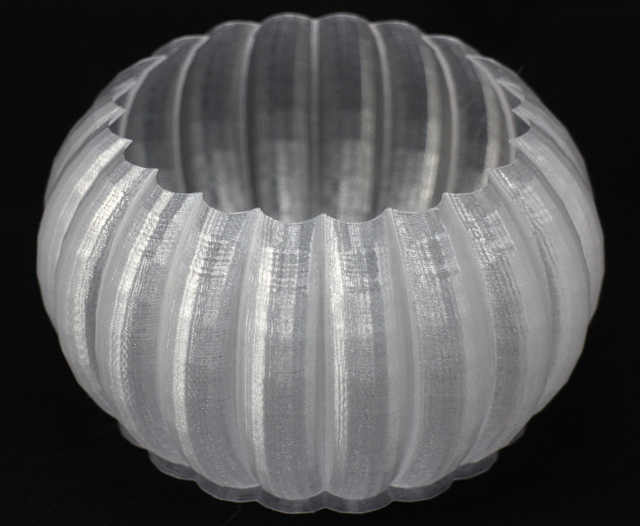

Decorative vase made of HIPS

PVA

PVA (polyvinyl alcohol) is a material that was developed as a water-soluble support for PLA.

Extruder temperature - 190-210. Table heating is not required. PVA is a slightly "capricious" material, it is not recommended to overheat it and print at high speeds.

PVA is very hygroscopic and dissolves in ordinary water. Therefore, it is only used as a support for PLA or other plastics with print temperatures close to PVA.

Soluble PVA Support

Add to compare

Item added to compare Go

| Manufacturer | Tiger3D |

Add to compare

Product added to compare Go

| Manufacturer | Tiger3D |

Add to compare

Product added to compare Go

| Manufacturer | Esun

Add to compare

Product added to compare Go

| Manufacturer | Esun

PETG

PETG (polyethylene terephthalate) combines the best properties of PLA and ABS. It is easy to work with, it has a low percentage of shrinkage and excellent sintering of the layers.

Extruder temperature - 220-240 degrees. Table temperature - 80-100 degrees. During the printing process, the model must be well blown.

Pros:

-

Excellent sinterability of layers.

-

PETG is very strong and wear resistant. Good impact resistance.

-

Virtually no smell when printing.

-

Non-toxic.

-

Little shrinkage.

Cons:

PETG is perfect for printing functional models. Due to its low shrinkage, it is often used to make large or composite models. Due to its low toxicity, PETG is often used for products that will come into contact with food.

Cookie cutters and patterned rolling pin

SBS

It is a highly transparent material. At the same time, it is durable and resilient. SBS is a low toxicity plastic. It can be used to print food contact models.

Extruder temperature - 230 -260 degrees. Table temperature - 60-100 degrees. You can print without the closed case on the printer.

Pros:

-

slight shrinkage

-

Transparency.

After treatment with solvent, limonel or dichloromethane, beautiful transparent products with an almost smooth surface can be obtained.

After treatment with solvent, limonel or dichloromethane, beautiful transparent products with an almost smooth surface can be obtained. -

Easily processed mechanically or chemically.

-

Allowed contact with food.

Cons:

SBS is excellent for translucent vases, children's toys and food containers. Or functional things that require transparency, such as custom turn signals for a motorcycle or car, lamps or bottle prototypes.

Vases are perfectly printed with a thick nozzle (0.7-0.8) in one pass (printing in 1 wall or spiral printing in a slicer).

Models of bottles after chemical treatment

Nylon

Nylon (polyamide) is considered the most durable material available for home 3D printing. In addition to good abrasion resistance and strength, it has a high slip coefficient.

Extruder temperature - 240-260 degrees. The temperature of the table is 80-100 degrees. Nylon is a very capricious and hygroscopic material - it is recommended to dry the coil with plastic before use. For printing, you need a printer with a heated table and a closed chamber, without this it will be difficult to print something larger than a small gear.

The temperature of the table is 80-100 degrees. Nylon is a very capricious and hygroscopic material - it is recommended to dry the coil with plastic before use. For printing, you need a printer with a heated table and a closed chamber, without this it will be difficult to print something larger than a small gear.

Pros:

-

High strength and wear resistance.

-

High slip factor.

-

Heat resistance compared to other 3D printing plastics.

-

High resistance to many solvents.

-

Good for mechanical processing. Perfectly polished and drilled.

Cons:

Nylon is perfect for making wear-resistant parts - gears, functional models, etc. Sometimes nylon is used to print bushings.

Nylon gear

Add to compare

Product added to compare Go

| Manufacturer | Tiger3D |

Add to compare

Product added to compare Go

| Manufacturer | Tiger3D |

Add to compare

Product added to compare Go

| Manufacturer | Esun

Add to compare

Product added to compare Go

| Manufacturer | Bestfilament |

Soft plastics

FLEX (TPU, TPE, TPC) is a material similar to silicone or rubber. It is flexible and elastic, but at the same time tear-resistant. For example, TPE is a rubbery plastic, while TPU is more rigid.

It is flexible and elastic, but at the same time tear-resistant. For example, TPE is a rubbery plastic, while TPU is more rigid.

FLEX are printed at a temperature of 200-240 (depending on the material). A heated table is not required. On printers with direct material feed (feed mechanism on the print head), there are usually no problems with printing. On a bowden feeder (the feed mechanism is located on the body), printing with very soft plastics can be difficult. Usually it is necessary to additionally adjust the clamping of the bar. The main nuance is the very low print speeds - 20-40mm.

Pros:

Cons:

Depending on the type of FLEXa, the models can be flexible or rubber-like. This material, depending on its softness, can be used to print gaskets, insoles, belts, tracks or other models that require flexibility or softness.

FLEX belt

Trainers with flexible soles

Wheel for switchgear model

Decorative plastics

Decorative plastics are PLA plastics with various fillers (wood or metal shavings). Or with dyes selected to imitate different materials. Since the base of the plastic is PLA, it is very easy to print.

Or with dyes selected to imitate different materials. Since the base of the plastic is PLA, it is very easy to print.

Extruder temperature - 200-220 degrees (depending on the manufacturer). A heated table is not required.

Pros:

Cons:

-

Some fillers (eg clay) are abrasive. For such plastics, the standard brass nozzle cannot be used. Will have to buy a harder steel nozzle.

-

Some decorative plastics can clog the small nozzle (0.4 or less). For them, you need to use a “thicker” nozzle.

Depending on the filler, different material properties are obtained. Plastics that use only dye do not require additional processing. Materials with "fillers" may sometimes require additional post-processing.

Plastics with metal fillers after printing must be processed with a metal brush. Then the Metal content will show through and the model will resemble a metal casting.

Plastics with metallic powder

These plastics are often used for printing key chains, decorative models and interior details.

If the plastic has a high content of wood dust, then it is recommended to use a larger nozzle diameter (0.5 or more), a smaller nozzle can quickly become clogged during printing.

Wood-filled plastic ground

Plastic key rings with copper dust

Engineering plastics

These are nylon-based plastics with fillers that improve strength, heat-resistant and other characteristics, help to achieve less shrinkage of the material. For example - carbon fiber, carbon fiber or fiberglass.

Extruder temperature - 240-300 degrees (depending on the manufacturer). Table temperature - 90-110 degrees. Since plastics are based on nylon, the requirements for printing are similar. This is a heated table and a closed printer case.

Pros:

-

Hardness and strength.

-

Low flammability or non-combustibility.

-

High precision due to low shrinkage.

Cons:

3D printers use brass nozzles, some plastics can quickly “waste” it during printing. For such materials it is recommended to use steel nozzles.

These are highly specialized plastics used for a specific task, depending on the filler. For example, functional parts that do not lose their shape when heated, are resistant to many solvents, etc.

Functional Carbon Fiber Composite Prototype

Composite frame

Polycarbonate ashtray

Totals

This is of course not the whole list of materials for 3D printing. There are many highly specialized engineering and decorative plastics for specific tasks.

Manufacturers are constantly trying to replenish the range of materials for 3D printing. Already familiar materials are improved for more comfortable printing. There are many interesting decorative plastics imitating different materials - ceramics, clay, wood, metals.

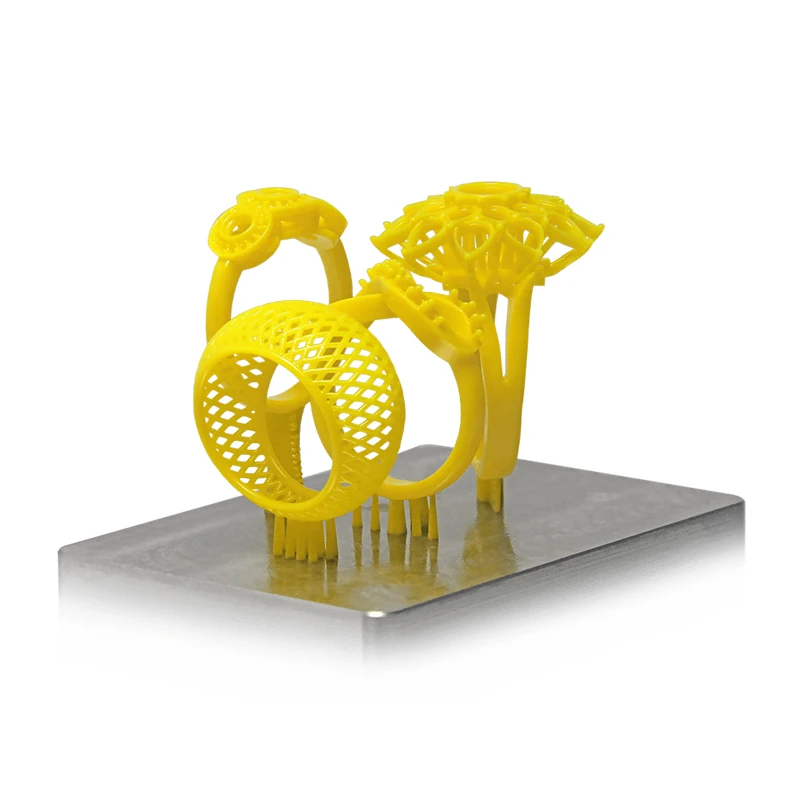

And of course, the assortment of engineering plastics is constantly updated. Now there are many interesting materials for highly specialized tasks - for example, burnable plastic with a low ash content for subsequent casting in metal.

Burnout plastic

Before buying a coil, read the information on the website of the manufacturer or seller. There you can find some nuances of printing for a particular plastic. The manufacturer indicates the recommended temperature range on the box. Sometimes, for quality printing, it is recommended to print several tests to adjust the temperature settings, retract, etc.

Try to store the started coil in silica gel bags.