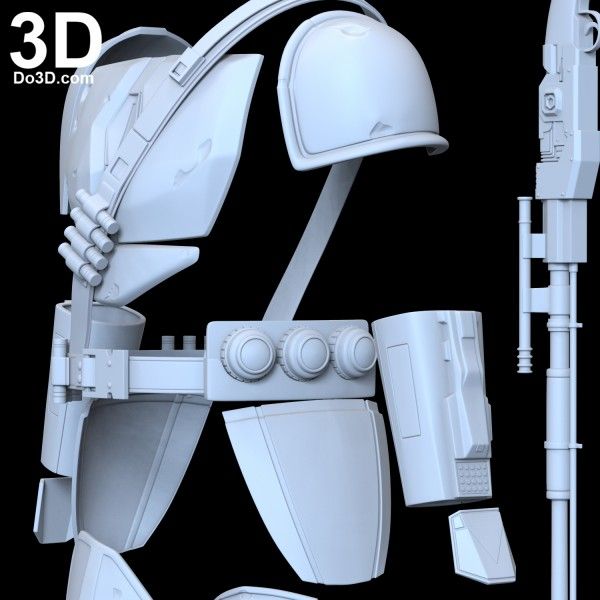

Nylon 3d print material

Ultimate Materials Guide - 3D Printing with Nylon

Overview

Nylon (a.k.a. Polyamide) is a popular material in the plastics industry, known for its toughness and flexibility. Nylon filaments typically require extruder temperatures near 250 ºC, however, some brands allow printing at temperatures as low as 220 ºC due to their chemical composition. Many printers do not include a hotend that can safely reach 250 ºC, so these lower-temperature versions can be useful and potentially save you from needing to upgrade your hotend. One big challenge with Nylon filaments is that they are hygroscopic, which means they readily absorb moisture from their surroundings. Printing Nylon after it has absorbed moisture will lead to several print quality issues, thus filament storage becomes very important and requires special attention.

- Tough and partially flexible

- High impact resistance

- No unpleasant odor while printing

- Good abrasion resistance

- Prone to Warping

- Air-tight storage required to prevent water absorption

- Improperly dried filaments can cause printing defects

- Not suitable for moist and humid environments

Hardware Requirements

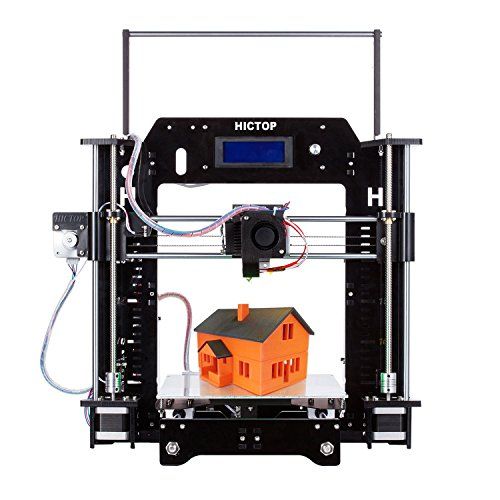

Before 3D printing with Nylon make sure your 3D printer meets the hardware requirements listed below to ensure the best print quality.

Bed

Temperature: 70-90 °C

Heated Bed Required

Enclosure Recommended

Build Surface

Glue Stick

PEI

Extruder

Temperature: 225-265 °C

May require All-Metal hotend

Cooling

Part Cooling Fan Not Required

Best Practices

These tips will help you reduce the chances of common 3D printing issues associated with Nylon such as warping and moisture absorption.

Filament Storage

One of the challenging aspects of using Nylon is the need for a special storage system. Unlike other filaments, you cannot keep the filament spool exposed to the air for extended periods of time. Nylon easily absorbs moisture from the environment. Printing the moist filament will result in print quality issues like a foggy rough surfaces or even tiny holes or bubbles on the exterior. These printing issues can also significantly decrease the strength and performance of the printed parts. The typical solution for this issue is to remove the Nylon spools from the printer once you are done, and store the spools in an air-tight container along with some desiccants to remove the moisture from within. If you do not want to constantly mount and remove your filament spool, there are also commercially available storage containers that will keep the filament dry, while allowing it to feed out of a hole in the container.

If you do not want to constantly mount and remove your filament spool, there are also commercially available storage containers that will keep the filament dry, while allowing it to feed out of a hole in the container.

Use an Enclosure to Prevent Warping

Some high-temperature Nylons are prone to warping due to the large temperature change between the extruded plastic and the ambient environment. Heated beds can reduce the warping to a some extent, but using a printer that has a heated chamber or enclosure would be the ideal solution. Keeping the air around your part at a temperature of about 45 ºC will help eliminate warping by reducing this temperature variation. If your printer doesn’t include a heated chamber and you aren’t able to add an enclosure, there are other tips that you can use to help prevent warping. Our Print Quality Guide has an entire section devoted to this issue which summarizes other common techniques: How to Prevent Warping.

Using Brims and Rafts

In situations where adding an aftermarket enclosure may not be an ideal option, consider using a brim or a raft to help with first layer adhesion. Adding a brim will add several loops around the bottom layer of your model, creating a larger surface area to hold down the edges of your print. Version 4.0 of Simplify3D introduced a completely new raft design that can also be very useful if you continue to have printing difficulties. For more information on the differences between rafts, skirts, and brims, please consult our in-depth article on this topic.

Adding a brim will add several loops around the bottom layer of your model, creating a larger surface area to hold down the edges of your print. Version 4.0 of Simplify3D introduced a completely new raft design that can also be very useful if you continue to have printing difficulties. For more information on the differences between rafts, skirts, and brims, please consult our in-depth article on this topic.

Pro-Tips

- If you do not have air-tight containers for storing your filament, you can dry the spools just before use by running them through a Food Dehydrator. A few hours in this device will dry the filament significantly.

- Nylon makes a good filament for cleaning your nozzle. You can use a technique called “cold pulling” where you allow the Nylon to bond to debris within the nozzle, and then after it partially cools, you pull the filament (and debris) out of the hotend.

Get Started with Nylon

Nylon can be a great material once you have mastered the basics. Once you’re ready to give it a try, here are some tips to help you get started.

Once you’re ready to give it a try, here are some tips to help you get started.

Common Applications

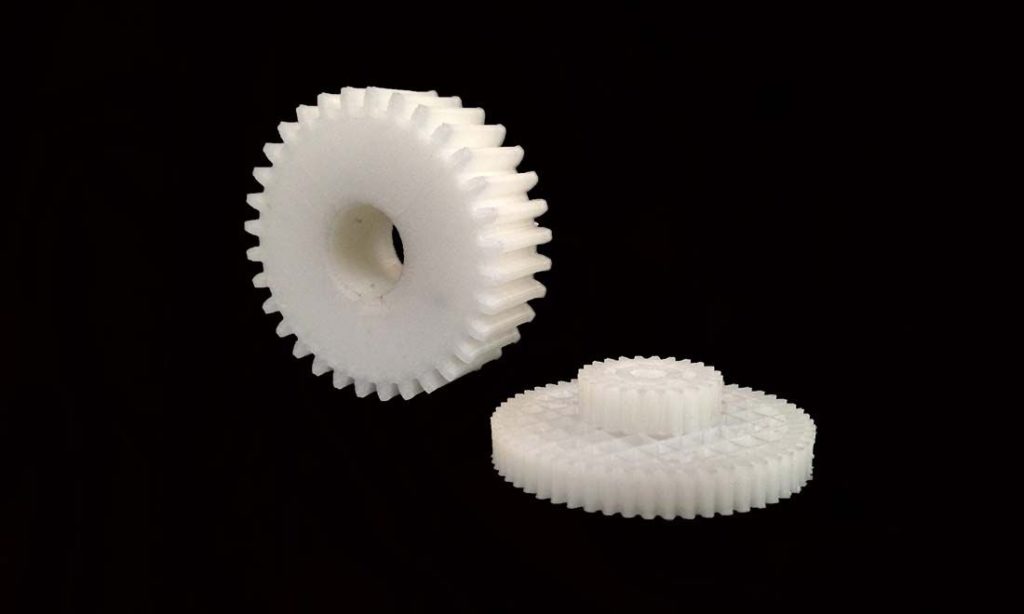

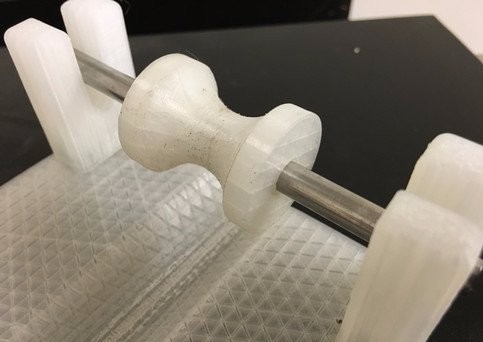

- Plastic Gears

- Screws, nuts, bolts

- Cable ties

Sample Projects

- Cable ties

- Nut, Bolt, Washer

- Servo Gears

Popular Brands

- Taulman Nylon

- Matterhackers PRO Nylon

- HobbyKing Nylon

- GizmoDorks Nylon

Everything you need to know about Nylon 3D printing

Before you get started with Nylon 3D Printing, we’ve compiled some of the basic information you’ll need to know. Read on to learn the advantages, disadvantages, history and applications of Nylon 3D printing

Nylon Filament and 3D Printed Gear

When it comes to 3D printing materials, Nylon has to be mentioned as one of the most popular materials for professional users. This can be attributed in large part to its popularity outside of 3D printing. Nylon has a wide range of applications thanks to its unique properties and the benefits of 3D printing mean that parts can be made on the fly easily and inexpensively.

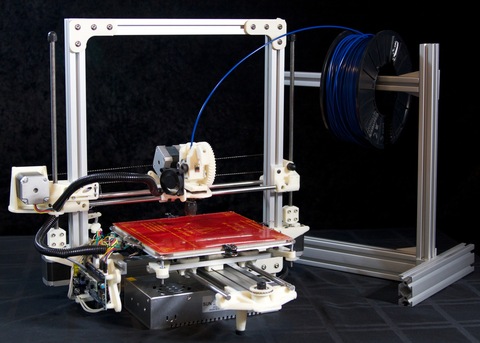

That said, desktop Fused Deposition Modeling (FDM) 3D printing technology, which is one of the most widely-used types of 3D printing, can sometimes involve a lot of trial and error. Some materials are easy to print with while others have a comparatively bigger learning curve.

Through this article, we will share everything you should know about Nylon 3D printing. Nylon can be 3D printed using three different technologies, namely FDM, Selective Laser Sintering (SLS), and MultiJet Fusion (MJF). However, the scope of this article is focused around FDM 3D printing.

UNDERSTANDING NYLON AS A MATERIAL

Chemical Composition

Nylon was first synthesized by DuPont, the American chemical company, in 1935. It developed the material for commercial usage and since then Nylon has become a common feature in numerous industries.

Nylon refers to a group of plastics known as polyamides. They are mostly semi-crystalline and generally very tough materials. It is found in many variants but the most common ones are Nylon 6, Nylon 6-6, and Nylon 12. It is a thermoplastic material, i.e., it becomes soft on heating or liquid when heated beyond its melting point and hardens on cooling. This process of heating and cooling can be carried out multiple times without significantly affecting its inherent chemical or mechanical properties.

It is found in many variants but the most common ones are Nylon 6, Nylon 6-6, and Nylon 12. It is a thermoplastic material, i.e., it becomes soft on heating or liquid when heated beyond its melting point and hardens on cooling. This process of heating and cooling can be carried out multiple times without significantly affecting its inherent chemical or mechanical properties.

Nylons can be easily blended with numerous other plastics to form composites, enhancing their performance parameters. This is widely done in automotive industries and some common composites in 3D printing are glass-filled nylon and carbon-fiber-filled nylon. Nylon is a versatile material and is suitable for almost all types of manufacturing operations like injection molding, extrusion, and additive manufacturing (in FDM, SLS & MJF).

Some of the most popular applications of nylon material are:

➜ In the textiles industry, nylon is used in the manufacturing of fishing lines, and food packaging.

➜ In the fashion industry, nylon is used as a fabric to manufacture products like hosiery, lingerie, raincoats, windbreakers, and athletic wear used in sports.

➜ In the electronics industry, nylon is used as insulators and switch housings.

➜ In the automotive industry, nylon is used in the production of parts such as intake manifolds, door handles, and radiator grills.

In consumer products, nylon is used in sporting goods such as ski bindings and skateboard wheels.

➜ In manufacturing machinery for moving parts such as gears and rollers.

NYLON in 3D PRINTING

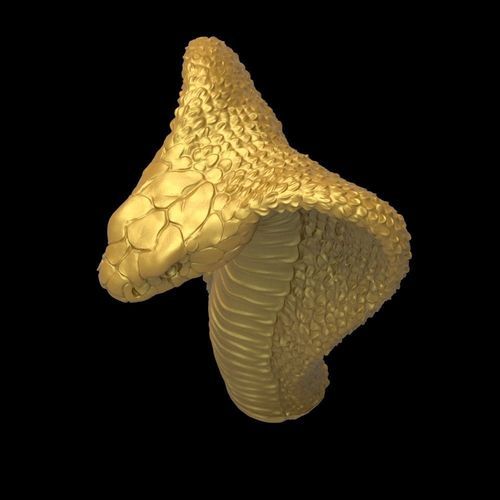

In the same way that nylon has become a go-to material in traditional manufacturing, nylon has become a popular material to use with 3D printers. 3D printing provides the added benefits of unlimited geometries, iteration and customization, and low-volume affordability.

Nylon’s flexibility and durability help in 3D printing parts with thin walls. Its low coefficient of friction with a high melting point makes it especially resistant to abrasion and enables it to be used in printing for parts such as functional interlocking gears.

Nylon exhibits mechanical properties comparable to ABS (another widely used material in traditional & additive manufacturing). ABS is defined by its strength but Nylon’s resistance to wear and fatigue makes it superior for applications requiring such properties.

Apart from the advantages, nylon has one major drawback that can often hamper its printing performance – hygroscopicity, i.e., its moisture absorption property. This property is detrimental in delivering predictable performance. But this same property helps nylon in easy post-processing with fabric dyes and spray paints thereby making it suitable for use in the printing of aesthetic (display) models.

There have been successful cases of a patient receiving a titanium pelvis implant, another getting a new titanium lower jaw. A motorcyclist patient whose face had been seriously injured in a road accident had it rebuilt with 3D printed parts.

Bioprinting allows for the 3D printing of artificial organs, helping solve organ failure issues in patients faster, important to both the patient and his/her family and to healthcare systems.

3D printed tissues have been developed for pharmaceutical testing as a cost-effective and ethical means of helping identify the side effects of drugs and validating safe dosages.

Pills can be produced, using the 3D printing process of Binder Jetting. The process allows the pills produced to be very porous, therefore enabling high dosages in a single pill that can be dissolved quickly and easily digested, useful for treating conditions such as epilepsy.

FUSED DEPOSITION MODELING (FDM) NYLON 3D PRINTING

As mentioned earlier, nylon 3D printing in FDM is a bit difficult but with the right tools it can be used to produce consistent results. We will start with some of the common challenges with nylon 3D Printing.

Common Challenges with Nylon 3D Printing

One challenge in nylon 3D printing is that nylon is highly hygroscopic. Even short-term exposure to high humidity can result in “wet” filament which, when printed, can lead to inconsistency in dimensional accuracy and part strength. Due to this property, it is critical to store the nylon filament in a dry place. Professional FDM 3D printers are enclosed so moisture can be safely avoided but for new users working with DIY or cheaper desktop printers, the material is exposed to air while printing. This makes it prone to moisture. The moisture absorbed by nylon gets heated up when it passes through the heater and the moisture forms bubbles only to burst during the heating process. This bursting leaves visible gaps in the 3D printed parts, leading to poor output.

Additionally, nylon is prone to warping issues. Warping occurs when there is uneven cooling of the print and the print curls from the build plate, distorting the printed part. This can be avoided by efficient gluing of the print bed and using a heated bed to keep the bottom layer of the print mildly heated so that it sticks to the bed for the duration of the print. As an extra precaution, the cooling fans can be switched off (all slicers have options to switch off fans during printing) while printing with nylon.

It is also recommended that printing nylon is conducted in a well-ventilated area due to its chemical composition.

Solutions to Nylon 3D Printing

Luckily, there are professional 3D printers such as the MakerBot METHOD that are both affordable for businesses, and have features that enable easy and consistent 3D printing with nylon. One example of these advanced professional features is an enclosed heated build chamber, which minimizes warping and inconsistent cooling during the print, and can also be used before printing to dry the filament on the spool. Another such feature is sealed material bays, which prevents the material from contact with the surrounding environment. These two additions almost entirely solves the problems associated with nylon 3D printing and might be worth considering during purchase if nylon is a preferred 3D printing material.

FDM NYLON MATERIAL PROPERTIES

| PARAMETER | Imperial | Metric |

|---|---|---|

| Heat Deflection (ASTM 648, 66 psi) | 196°F | 91°C |

| Flexural Modulus (ASTM D790, 15 mm/min) | 250,000 psi | 1,700 MPa |

| Flexural Strength (ASTM D790, 15 mm/min) | 14,000 psi | 97 MPa |

| Tensile Strength at yield (ASTM D638, 50 mm/min) | 9500 psi | 66 MPa |

| Tensile Modulus (ASTM D638, 50 mm/min) | >320,000 psi | >2,200 MPa |

| Strain at Yield - Elongation (%) | >10% | >10% |

| Notched Impact Strength (ASTM D256) | >3. 5 ft-lb/in 5 ft-lb/in | >187 J/m |

(Specifications for MakerBot Nylon)

ADVANTAGES

➜ Mechanical Properties

➀ High impact resistance - Durable in situations where parts are constantly banging together or being dropped.

➁ Abrasion resistant - Nylon’s low coefficient of friction allows nylon to be used in applications with moving parts that would otherwise wear on each other

➂ Flexible - In thinner geometries nylon can be flexed repeatedly without fracturing

➜ Post-Processing: Nylon is hygroscopic and this property helps it to be easily post-processed by absorbing fabric dyes and spray paints.

DISADVANTAGES

➜ Hygroscopic: Nylon is hygroscopic, i.e., it absorbs moisture from the air which can affect its print quality and ultimately the part performance.

➜ Pre-Drying: Nylon should be pre-dried to remove any moisture it has absorbed. This requires extra effort, extra equipment, and extra time. And if the drying is insufficient, then the print shows

This requires extra effort, extra equipment, and extra time. And if the drying is insufficient, then the print shows

➜ Warping: Nylon is prone to warping and thus can distort the part.

WHERE TO BUY?

Nylon material can either be bought from filament manufacturers or 3D printer manufacturers.For the MakerBot 3D METHOD, we recommend use of MakerBot Nylon as it is optimized to deliver great results.

Looking for a professional 3D printing platform that works with a variety of manufacturing-grade materials? Learn more at makerbot.com/method.

Related Posts

3D Printable Nylon

- 1 Description

- 2 Specifications

- 3 Advantages and disadvantages of nylon

- 3.1 Features

- 3.2 Disadvantages

- 4 3D printing use

- 5 Use of available materials

Description

Nylon is attractive as a material for 3D printing due to its high wear resistance, affordability and excellent slip coefficient, which allows the use of nylon in bearings and other similar mechanisms, often without the use of lubricants.

An example of a model created using Stratasys Nylon 12

Despite the widespread use of nylon in the industry, the use of this material in 3D printing is quite limited due to certain technological difficulties. However, in recent years, specialized nylon consumables have appeared, focused on use with SLS and FDM printers.

Taulman and Stratasys nylon threads are the most popular examples.

Specifications

| Taulman 618 | Taulman 645 | Stratasys Nylon 12 | |

| Density | 1.134 g/cm³ | – | – |

| Hygroscopicity | 3.09% | 3.09% | – |

| Tensile strength | 65. 99 MPa 99 MPa | 85.68 MPa | 48.26-53 MPa |

| Elongation at Break | Over 300% | Over 300% | 9.5-30% |

| Melting point | 218°C | 214°C | 178°C |

| Glass transition temperature | 49.4°C | 68.2°C | – |

| Extrusion temperature | 235-260°C | 235-260°C | – |

| Pyrolysis temperature | 350-360°C | 350-360°C | – |

Stratasys Nylon 12 is designed for use with Fortus brand 360mc, 400mc and 9 professional rigs00mc, while Taulman's nylon filaments are designed to work with any home and office 3D printer optimized for the popular ABS plastic. In addition, Taulman is testing a range of laser sintered nylon materials, including a powder version of Taulman 618.

In addition, Taulman is testing a range of laser sintered nylon materials, including a powder version of Taulman 618.

Advantages and disadvantages of nylon

Advantages of

- High wear resistance

- High elasticity

- Resistant to most organic solvents

- High temperature resistance

- Easy to machine

Disadvantages

- High hygroscopicity

- Release of toxic fumes during pyrolysis

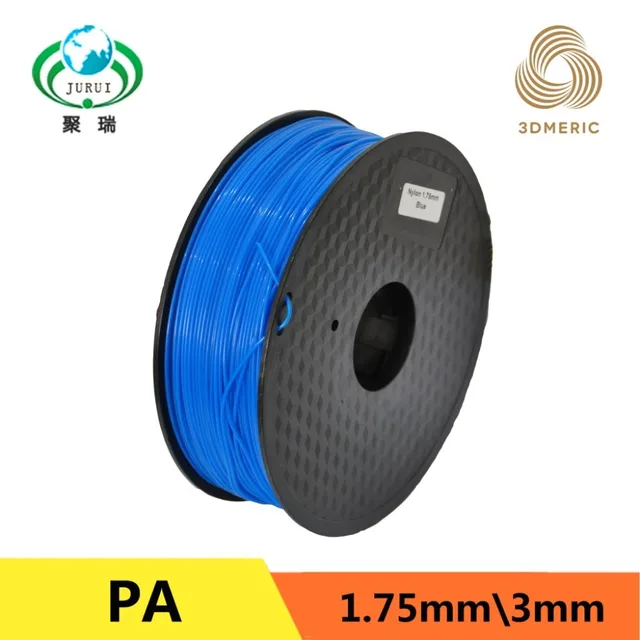

- Taulman brand nylon threads available in 1.75mm and 3mm diameters

3D printing use

Taulman brand nylon filaments are available in 1.75mm and 3mm diameters

Nylon printing technology is similar to ABS printing, but with some differences. Like ABS, nylon is prone to twisting and warping when cooled unevenly, requiring the use of a heated bed.

The nylon layers have excellent adhesion, which minimizes the chance of delamination of models. Users of Taulman plastics note the durability of models at the level of analogues made by traditional injection molding.

Users of Taulman plastics note the durability of models at the level of analogues made by traditional injection molding.

Nylon is almost impossible to bond, which makes it difficult to manufacture large-sized parts from components. Alternatively, it is possible to connect nylon parts by melting the surfaces to be joined.

Nylon can be dyed with acid-based dyes.

Nylon does not adhere to glass or other smooth surfaces, so it is recommended to apply painter's tape to the desktop or use a wood backing when printing.

Due to the high hygroscopicity of nylon (the ability to absorb moisture), it is recommended to dry the nylon filament immediately before printing. Otherwise, water vapor may be released from the nozzle, which is not catastrophic for the extruder, but may affect print quality.

Use of scrap materials

Some hobbyists prefer to use inexpensive nylon line for printing, which is fraught with some unpleasant consequences. As a general rule, trimmer line is preferred, available in 3mm diameter, which is the same diameter as commercially available ABS filaments for FDM printing. However, these "nylon threads" are not pure nylon, which is evident due to their excessive stiffness, which is not characteristic of nylon. The reason for this is additives - usually in the form of fiberglass. Additives are designed to both increase stiffness and reduce the cost of the material. It should be borne in mind that the melting point of fiberglass is much higher than the melting point of nylon and, in fact, exceeds the pyrolysis temperature of nylon. Thus, it is impossible to achieve complete melting of such composite materials. As a result, tough glass fiber particles will contribute to increased wear and clogging of the extruder nozzle.

As a general rule, trimmer line is preferred, available in 3mm diameter, which is the same diameter as commercially available ABS filaments for FDM printing. However, these "nylon threads" are not pure nylon, which is evident due to their excessive stiffness, which is not characteristic of nylon. The reason for this is additives - usually in the form of fiberglass. Additives are designed to both increase stiffness and reduce the cost of the material. It should be borne in mind that the melting point of fiberglass is much higher than the melting point of nylon and, in fact, exceeds the pyrolysis temperature of nylon. Thus, it is impossible to achieve complete melting of such composite materials. As a result, tough glass fiber particles will contribute to increased wear and clogging of the extruder nozzle.

Go to the main page of the Encyclopedia of 3D Printing

3D printing of nylon (Nylon) technology features

Nylon is known as a durable, versatile material. It is a synthetic composition formed from polyamides, which are polymers linked by amide bonds. When it comes to 3D printing, Nylon is often considered an "advanced" resource as it requires certain skills and equipment to work with. For printing on a 3D printer, the material is taken in the form of a powder or thread.

It is a synthetic composition formed from polyamides, which are polymers linked by amide bonds. When it comes to 3D printing, Nylon is often considered an "advanced" resource as it requires certain skills and equipment to work with. For printing on a 3D printer, the material is taken in the form of a powder or thread.

Physical Properties of Nylon

Nylon is a popular choice in industrial 3D printing because of its durability and abrasion resistance. If the surface printed with Nylon is thin enough, it can show good flexibility while maintaining strength.

The compound's low coefficient of friction means it is well suited for making moving parts. Nylon is often used to create functional prototypes, hinges, gears and similar parts.

Chemical Properties of Nylon

In order to fully understand nylon 3D printing, it is important to consider other characteristics as well. The filament has a high melting point and is hygroscopic, that is, it absorbs moisture well. The latter property can be both an advantage and a disadvantage. The advantage is that the surface of the printed part lends itself well to coloring. Minus - the thread absorbs moisture from the air, which affects the printing process and the characteristics of the finished part.

The latter property can be both an advantage and a disadvantage. The advantage is that the surface of the printed part lends itself well to coloring. Minus - the thread absorbs moisture from the air, which affects the printing process and the characteristics of the finished part.

The choice of technology

3D printing with nylon on a 3D printer has its own peculiarities - it can be implemented by the method of layer by layer deposition (FDM) using a nylon filament, by means of selective laser sintering (SLS) or by the method of multi-jet fusion (MJF) using a powder.

FDM

Using Nylon for 3D printing was an expensive procedure because MJF and SLS printers are expensive and FDM printers have become a cheap alternative. Today, you can use an FDM printer and a special nylon filament that is melted down and then extruded through a nozzle onto a build platform in layers until the part is complete. Although nylon 3D printing on FDM equipment is much more affordable than SLS or MJF, the quality of the printed object is not as impressive.

Also, not all FDM machines can work with nylon filament. It is important to have a quality (all-metal) hot end that can withstand temperatures above 250°C. Nylon is also prone to warping, so traction becomes a separate issue.

Nylon thread is available in various grades, the most common of which are PA 6 and PA 66. Both options have standard strength, abrasion resistance and low coefficient of friction, but have one significant drawback - high moisture absorption.

Anide (nylon-66) and nylon (nylon-6) fiber formula.

Photo: en.wikipedia.org

Storage and Nylon Printing

The hygroscopicity of the material may adversely affect the filament. The thread begins to lose its properties, decompose within a few hours. To prevent such a scenario, proper storage is of fundamental importance.

A simple plastic sealed container is a good solution when not using filament, but what about when printing? The ideal output is a moisture controlled storage unit that also feeds the filament to the extruder. If the material on the coil has absorbed a lot of moisture, then it can be dried in a special chamber or oven.

If the material on the coil has absorbed a lot of moisture, then it can be dried in a special chamber or oven.

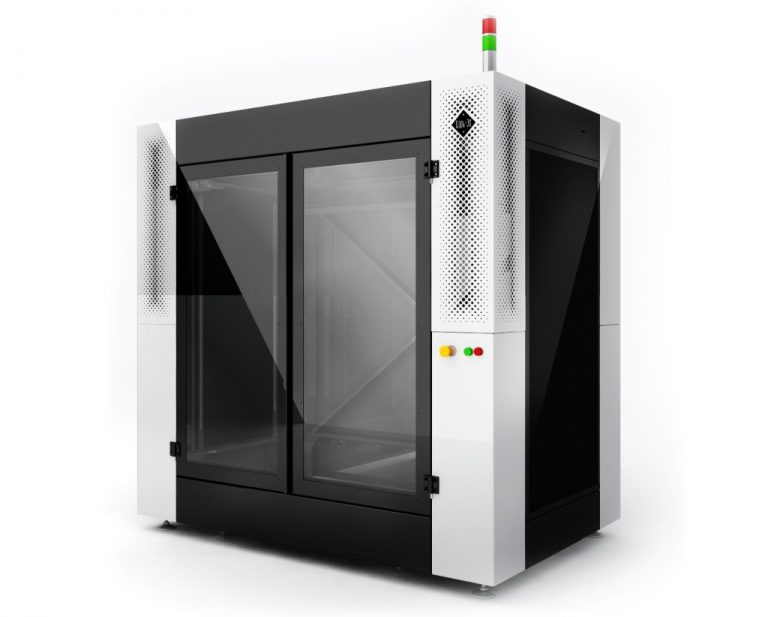

SLS

The selective laser sintering method uses a laser to sinter the powder layer by layer. Most of these 3D printers are focused on polymers.

One of the main materials used in this equipment is Nylon, specifically PA 11 and PA 12 nylon powders. There are also powdered versions of reinforced polyamide, known as nylon composites, which, in addition to Nylon, usually contain particles of glass, aluminum or carbon fiber.

Sinterit

Photo: Sinterit

characteristics:

| Category | Powder for SLS printing |

| Material type | Nylon 11 |

| Packaging | Plastic bottle |

| Color | Gray |

| Elongation at Break | 27% |

| Tensile strength | 46 MPa / 50 MPa (primary powder) |

| Shore hardness D | 76 |

| Material refresh rate | 60 [%] - to reuse the remaining PA11 powder, add 60% FRESH powder |

| Designed for | Lisa Pro |

Photo: Sinterit

Characteristics:

| Category | Powder for SLS printing | |

| Material type | Polyamide 12 powder | |

| Packaging | Plastic bottle | |

| Granulation | 18 - 90 [µm] | |

| Color | Dark gray / anthracite | |

| Elongation at Break | 10% | |

| Tensile strength | 32 [MPa] | |

| Softening point (Wick method, type A50 / B50) | 172/155 [°C] | 342/311 [°F] | |

Thermal deflection temperature B 0. 45 [MPa] 45 [MPa] | 143[°C] | 289[°F] | |

| Hardness on Shore scale D | 74 | |

| Modulus of elasticity / Young E | 1029 [MPa] | 148 [thousand pounds / sq. Inch] | |

| Material refresh rate | 26 [%] - to reuse the remaining PA12 powder, add 26% FRESH powder. | |

| Designed for | Lisa Pro | 43 J / M * |

| Elongation at break | 8% * | |

| Heat deflection temperature | 177°C | |

| Flexible Force | 47 MPa * | |

| Maintained wall thickness | min. 0.5 mm | |

| Designed for | Sintratec S2 Sintratec KIT |

3D printer Sintratec S2 nylon

photo: Sintratec

Characteristics:

| Country | Switzerland |

| Power supply | 230 V | 11 A max. | 50-60 Hz | 50-60 Hz |

| Print material | nylon |

| Print Technology | SLS |

3D Printer Sintratec Kit

photo: Sintratec

Characteristics:

| Country | Switzerland |

| Maximum Printvolume | 110 x 110 x 110 mm |

| Recommended print volume | 90 x 90 x 90 mm |

| Laser speed | 5-20 mm/s * |

| Layer height | 100 - 150 micrometer * |

| Temperature | 80 - 150 ° C * |

When completed, objects are completely surrounded by unspent powder, which serves as a support for printed models. SLS machines can reuse up to 50-70% of the remaining material for future print runs. In terms of rationality, this is an advantage over FDM, since any resource used as supports is usually not converted back into a thread for reuse. Nylon is excellent for making functional parts, and selective laser sintering technology helps create complex configurations.

Nylon is excellent for making functional parts, and selective laser sintering technology helps create complex configurations.

The downside of this method is the cost. Industrial SLS printers sell for over $200,000. However, more affordable solutions have recently appeared on the market, such as the Fuse 1 desktop SLS machine from Formlabs, priced at about $10,000. You will have to pay at least $60 per kg for the powder.

MJF

Multi Jet Fusion is a unique powder sintering technique developed by Hewlett Packard. The technology is similar to the previous one, but also has something in common with the method of jet application of the binder.

MJF and SLS start the Nylon printing process in the same way. Before sintering begins, a layer of powder is spread onto the assembly platform. However, while with SLS the laser would start sintering, MJF introduces an additional step into the printing process in the form of adding chemical agents.

A chemical is sprayed on top of each fresh powder layer where future layers will sinter to help the substance absorb energy from the printer's heat source.