3D printer industrial grade

Industrial 3D Printers: Strong Parts. Right Now

A complete line of machines made to create functional parts. Industrial 3D printers that consistently improve with a connected platform and precision construction.

Talk to an Expert

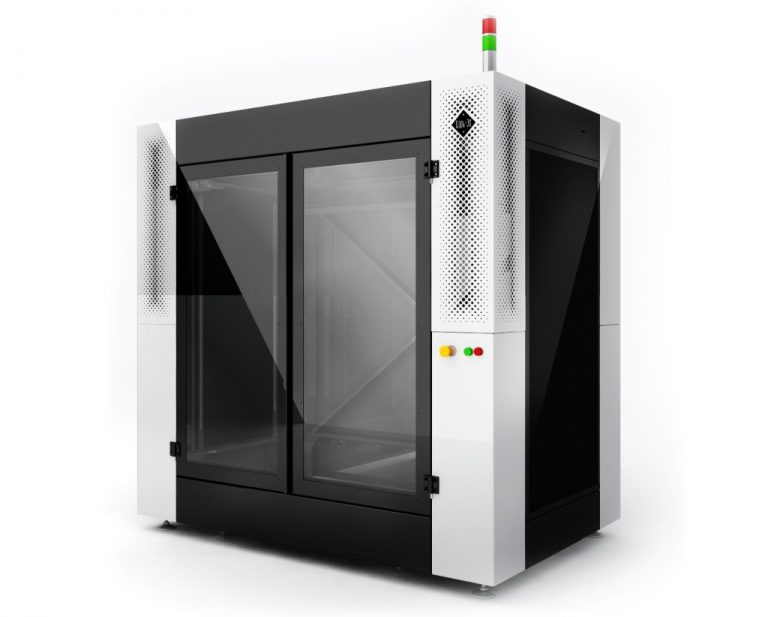

Flagship Industrial Composite 3D Printer

FX20™

An ULTEM™ filament capable production platform for big, strong, high temp parts — usable from factory floor to flight. The ULTEM™ and 9085 trademarks are used under license from SABIC, its affiliates or subsidiaries.

Discover theFX20™

Flagship Metal 3D Printer

Metal X™ System

An accessible way to go from design to metal part — the Metal X System is a leading end-to-end additive manufacturing solution.

Discover theMetal X™ System

Flagship Industrial Composite 3D Printer

X7™

The turnkey industrial 3D printer for many types of functional parts.

Discover theX7™

Flagship Industrial Composite 3D Printer

X7™

The turnkey industrial 3D printer for many types of functional parts.

Discover theX7™

Industrial Composite 3D Printer

X5™

The industrial 3D printer for Continuous Fiberglass reinforced parts.

Discover theX5™

Industrial Composite 3D Printer

X3™

The refined Industrial FFF 3D printer for micro carbon fiber filled nylon parts.

Discover theX3™

Desktop Series

Drive innovation right from your desktop. Powerful professional 3D printers designed to maximize the capabilities of high-quality composite printing.

Explore our Desktop Series

Flagship Desktop Composite 3D Printer

Mark Two™

The powerful professional Carbon Fiber 3D printer for aluminum-strength parts.

Discover theMark Two™

Desktop Composite 3D Printer

Onyx Pro™

The workhorse professional 3D printer for Continuous Fiberglass-reinforced parts.

Discover theOnyx Pro™

Desktop Composite 3D Printer

Onyx One™

The FFF desktop 3D printer for tough, high quality Onyx parts.

Discover theOnyx One™

Strong Parts

Every Markforged industrial 3D printer is built to create strong parts. Period.

Designed for Reliability

Precision design and construction yields predictable, repeatable results.

Platform Connected

Monitored and controlled by a central platform — fabricating functional parts is as easy as pressing print.

1. Design & Slice

Design a part in your chosen CAD platform and export it as an STL. Upload the STL to Eiger and select your material and orientation. The software slices your part, automatically generating a raft, supports where necessary, and a layer of release material between the raft/supports and the part itself.

About Our Software

2. Print

Metal powder bound in plastic is printed a layer at a time into the shape of your part. Parts are scaled up to compensate for shrinkage during the sintering process.

Available Materials

3. Wash

After printing, “green” parts are placed into the Wash-1, which uses a debinding fluid to dissolve most of the plastic binding material.

Learn More About the Metal X System

4. Sinter

Washed “brown” parts are placed in a Markforged furnace, where they are heated with a material-specific profile to remove the remaining binder and solidify metal powder.

Learn More About the Metal X System

5.

Use

Use Parts come out of the sintering furnace as fully metallic objects and can be used in manufacturing, tooling, and prototyping operations.

See 3D Printed Parts At Work

1. Design & Slice

Using the CAD platform of your choice, design a part. Many different parts can be printed, but following Design for Additive Manufacturing (DFAM) guidelines enables you to fully leverage the unique strength and flexibility of Markforged composite printers. Upload the STL to Eiger and select your base materials and part orientation.

About Our Software

2. Reinforce

Unique to Markforged composite printers with Continuous Fiber Reinforcement (CFR), Eiger enables you to print with two types of printing media: a Composite Base filament and a Continuous Fiber. Configure the reinforcement to your application, choosing a Continuous Fiber and layers to reinforce.

Configure the reinforcement to your application, choosing a Continuous Fiber and layers to reinforce.

Available Materials

3. Print

A Markforged composite printer automatically prints your part layer by layer. Composite Base material is printed through one nozzle, and Continuous Fiber is laid in-layer by a second nozzle and extrusion system.

Discover the X7

4. Use

The resulting composite part consists of a Composite Base and a Continuous Fiber, and can be used in a wide variety of industrial applications.

See 3D Printed Parts At Work

Talk to an expert Request a demo Try the softwareLet’s get started.

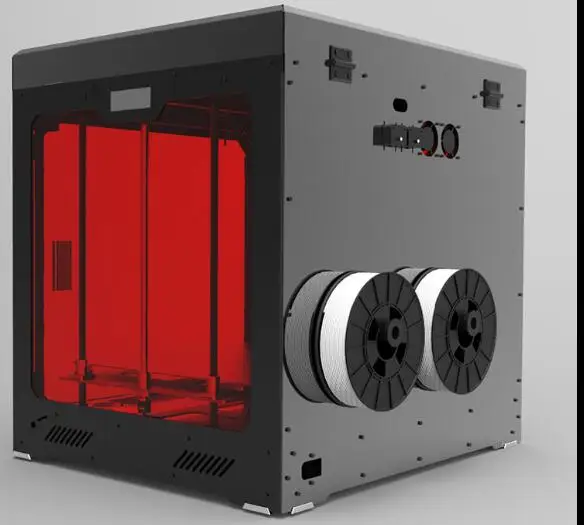

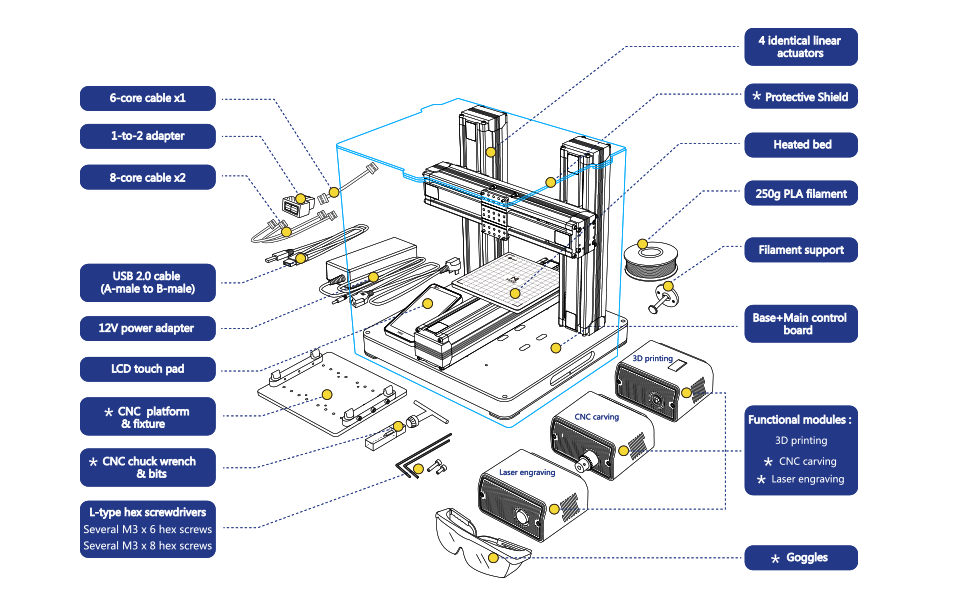

The Metal X 3D Printing System

An accessible end-to-end metal 3D printing solution for functional metal parts, next-day.

Request a Quote

The Metal X System is an accessible way to fabricate complex metal parts in a wide variety of advanced metals.

Simple, Yet Powerful

The Metal X is one of the most intuitive metal 3D printers available today. Print a wide range of materials from stainless steels to copper with minimal training on a closed workflow. Scaling up capacity is easy; just add printers.

Safe and Affordable

The Metal X is designed to be safe to use and accessible for all fabricators. It costs several times less than DMLS metal 3D printing systems and requires no dedicated operator, no powder management system, and minimal PPE.

Quality Parts, Fast

The Metal X is purpose-built for consistent part quality and a seamless user experience. Markforged combines superb software, materials research, and an advanced motion system to deliver industrial-grade parts quickly and reliably.

Specs

From design to fully functional

metal parts in as few as 28 hours.

Physical Dimensions

| Width | 575 mm |

| Depth | 467 mm |

| Height | 1120 mm |

| Weight | 75 kg / 165 lbs |

Build Volume

| Width | 300 mm |

| Depth | 220 mm |

| Height | 180 mm |

Printer primary Specs

- Printing Process

- Metal FFF

- Z Layer Resolution

- 50 μm - 125 μm (Post-Sinter)

- Printing Media

- Bound Powder Filament

- Internal Part Geometry

- Closed Cell Infill (Triangular) or Solid Parts

- Print Bed

- Heated, Auto Leveling, Replaceable Print Sheets

Wash & Sinter

Wash-1

- External Dimensions:

- 609 x 685 x 1,067 mm

- Weight:

- 136 kg (300 lbs)

- Washing Time:

- 12-72 hrs typical

- Solvent:

- Opteon SF-79

- Working Volume:

- 356 x 254 x 203 mm

Sinter-2

- External Dimensions:

- 1,200 x 700 x 1,500 mm

- Weight:

- 350 kg (772 lbs)

- Run Time:

- 17-31 hours

- Sintering Volume:

- 18,356 cu cm

- Peak Internal Temp.

:

: - 1,300° C / 2,372° F

Materials

Compatible Materials

- Release Material

- Ceramic — Becomes Powder During Sintering Process

- Media (Spools)

- Bound Powder Metal Filament

System Details

Metal X PrinterThe Markforged Metal X is a new kind of metal printer. By printing metal powder bound in a plastic matrix, Markforged has eliminated many of the safety risks associated with traditional metal 3D printers. That means no loose powder, no lasers, and none of the traditional safety precautions. It’s safe to use in a shop environment with minimal facility upgrades.

In practice, the Metal X is essentially a very advanced FFF 3D printer. Featuring a precision machined gantry, a heated chamber and print bed, and advanced extrusion hardware, the Metal X is equipped to reliably print you durable parts. It is intentionally designed, with wear components and consumables — including print sheets, nozzles, and brushes — accessible and trivial to swap.

Featuring a precision machined gantry, a heated chamber and print bed, and advanced extrusion hardware, the Metal X is equipped to reliably print you durable parts. It is intentionally designed, with wear components and consumables — including print sheets, nozzles, and brushes — accessible and trivial to swap.

The Wash-1 is a solvent-based debinding system. It primarily uses Opteon SF-79, a high-performance fluid designed to offer superior cleaning power, higher efficiency, and safety in an environmentally sustainable way — Opteon SF-80 or Tergo Metal Cleaning Fluid can be substituted if needed.

The Wash-1 operates with simple ventilation and features an extremely simple user experience. It’s been tested and verified as a shop-safe system.

Sinter-2 and Sinter-1The Markforged Sinter-2 and Sinter-1 are highly optimized tube furnaces used for sintering 3D printed metal parts. They provide leading edge sintering reliability and run times and are equipped with advanced safety features. The Sinter-2 is more advanced than the Sinter-1 — featuring a larger working volume, more precise temperature control, and a mechanical door interlock.

The Sinter-2 is more advanced than the Sinter-1 — featuring a larger working volume, more precise temperature control, and a mechanical door interlock.

The Sinter-1 and Sinter-2 typically have run times between 26 and 31 hours. However, the Sinter-2 can process small parts in express mode, where it can sinter up to 250g of parts in just 17 hours.

Download Datasheet

Materials

From stainless steel to copper,

choose from a wide range of strong,

durable, and capable materials.

Classification of 3D printers / Sudo Null IT News

3D printing is steadily gaining momentum and we are increasingly seeing posts that a 3D printer has been taught to print parts for the ISS, organs, houses and much more. Foreign technology publications are beginning to say that 3D printing is able to resurrect the industry in the states, and the shapeways service, before our eyes, is showing interesting growth rates, albeit far from industrial ones. With such an abundance of laudatory texts about the impending revolution in production, the thought comes to mind that the Russian segment is practically free, but is it so easy to achieve industrial scale with the assurance of the printers themselves and the emergence of open source projects? It's up to you to decide, but food for thought on the topic under the cut.

With such an abundance of laudatory texts about the impending revolution in production, the thought comes to mind that the Russian segment is practically free, but is it so easy to achieve industrial scale with the assurance of the printers themselves and the emergence of open source projects? It's up to you to decide, but food for thought on the topic under the cut.

I’ll make a reservation right away that the standards in the industry are very conditional, so far. But a brief overview with the order of prices can be generated now. And so, let's get started.

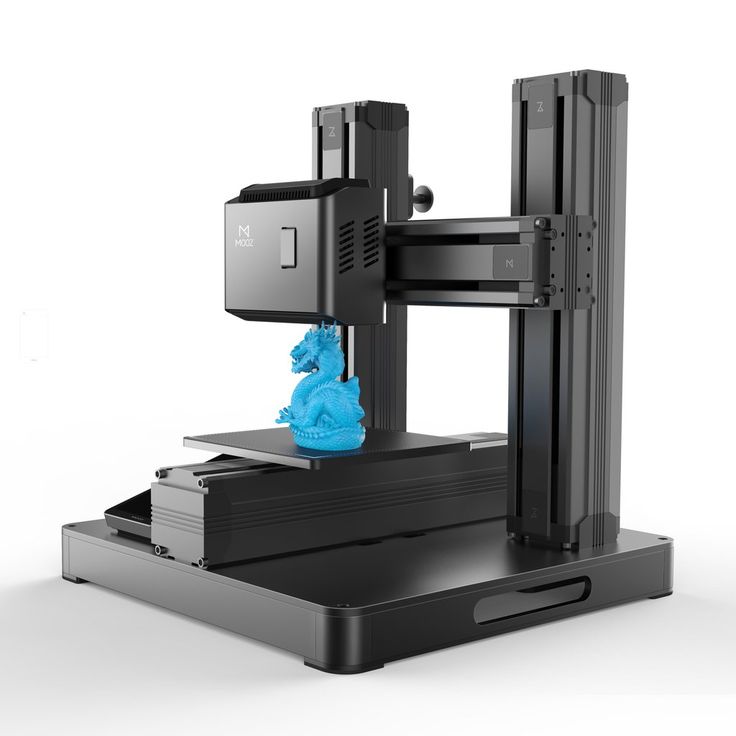

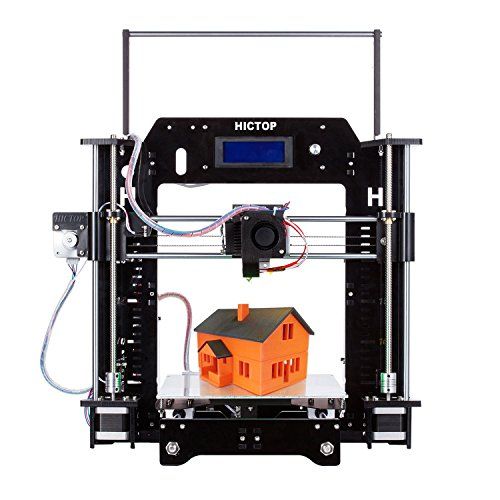

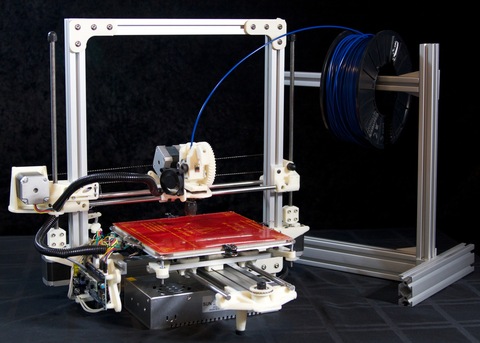

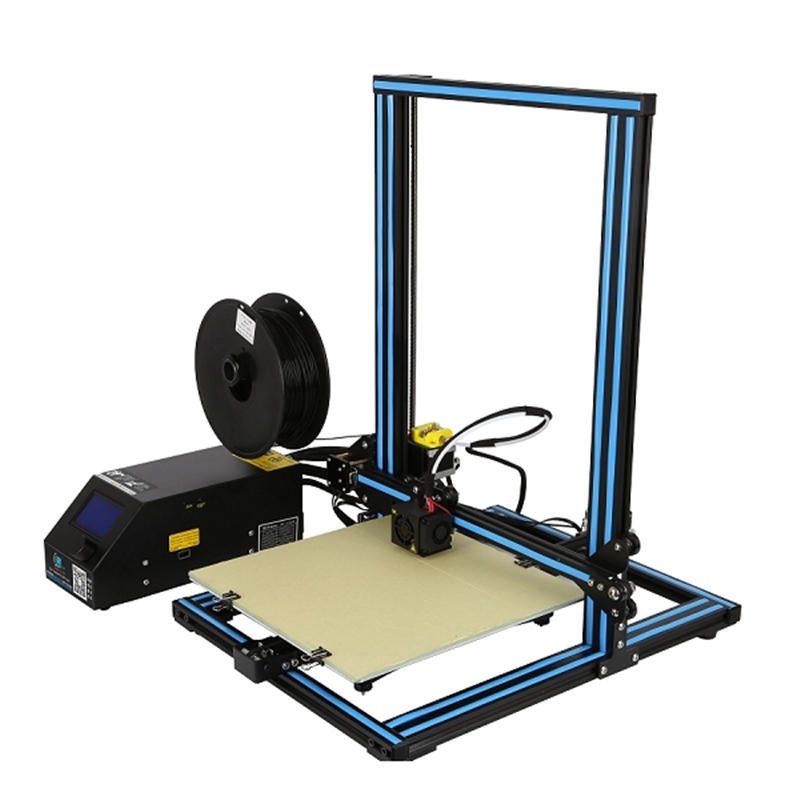

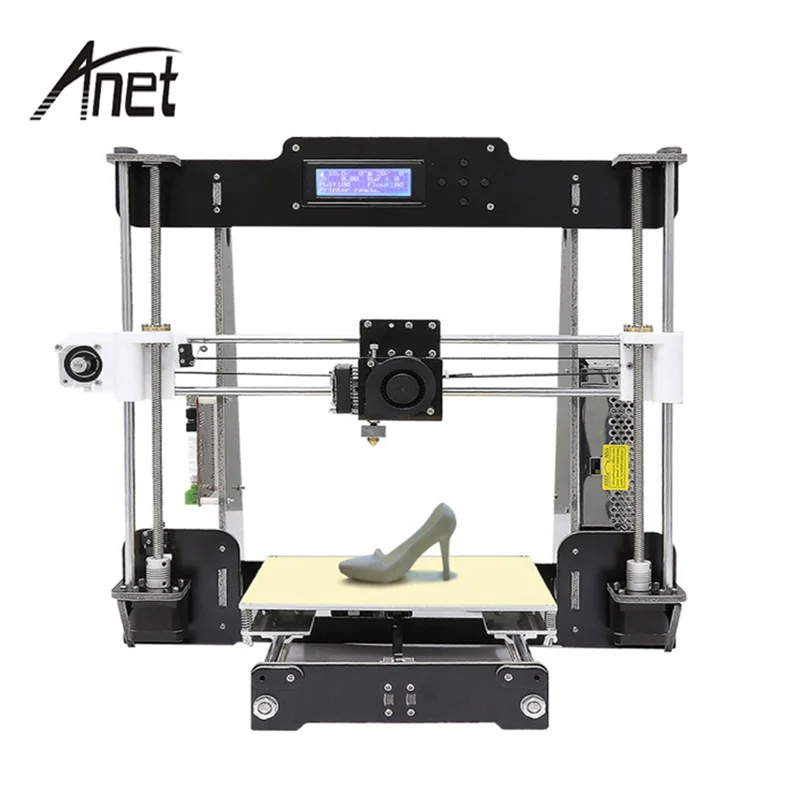

Consumer

A type of printer intended primarily for personal use. Supplied in the form of a designer, or assembled. The vast majority of printer models of this type are derived from the open source RepRap project. Since they have basically the same platform, their characteristics are also very similar.

Designed with an eye on the average user and equipped with a fairly simple and intuitive interface. Printed, as a rule, ABS and PLA plastic. Complex and high-precision objects will be quite problematic to print, but they print ordinary crafts with ease, albeit for a long time.

Printed, as a rule, ABS and PLA plastic. Complex and high-precision objects will be quite problematic to print, but they print ordinary crafts with ease, albeit for a long time.

Price range: $500 - $3500

Target audience:

Designers / artists / inventors who work from home.

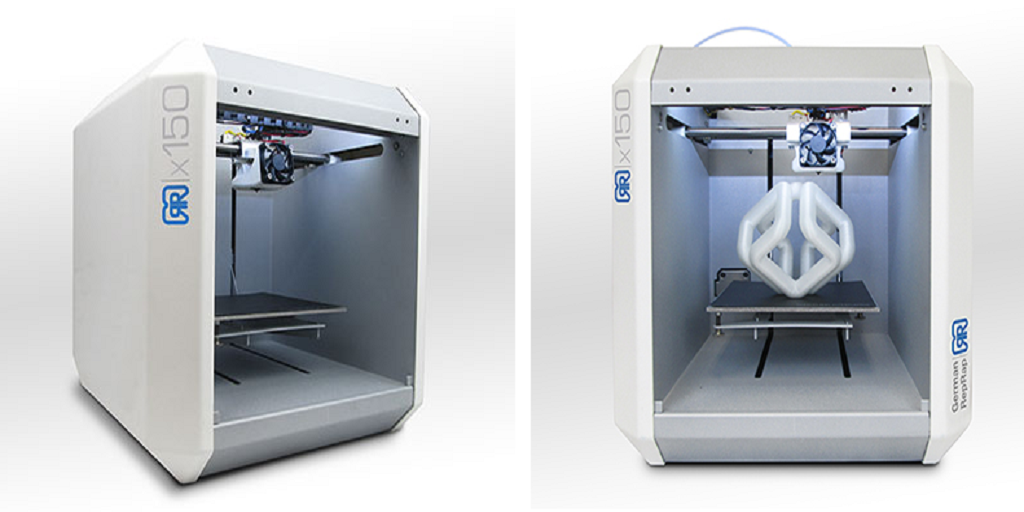

Personal

An edge class of printers that is home but also the lower rung of industrial business printers. These devices have much in common with their consumer-grade brothers, but have the higher quality and precision of printing that is inherent in professional 3D printing systems. The appearance of such printers is rather a reaction of large manufacturers to the growing market for home systems. Given the low accuracy of the consumer class, vendors have offered reduced models of professional systems with performance close to them.

Operating printers of this class is just as simple and boils down to loading an image and pressing the start button. At the same time, this limits the possibilities in terms of various advanced printing options.

Suitable for use in offices, however, the noise and high temperature conditions of some models require their placement at some distance from the working area. The ease of cleaning output objects was not carried over to this class from industrial models, so it would be logical to place them in a separate workspace.

Price range: $7,000 - $40,000

Target audience:

Small business with a small budget but need to use 3D printing occasionally. It can be engineering companies, design studios, marketing agencies.

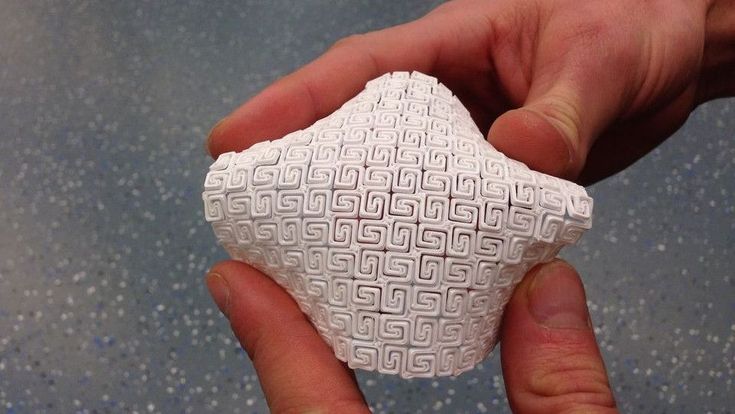

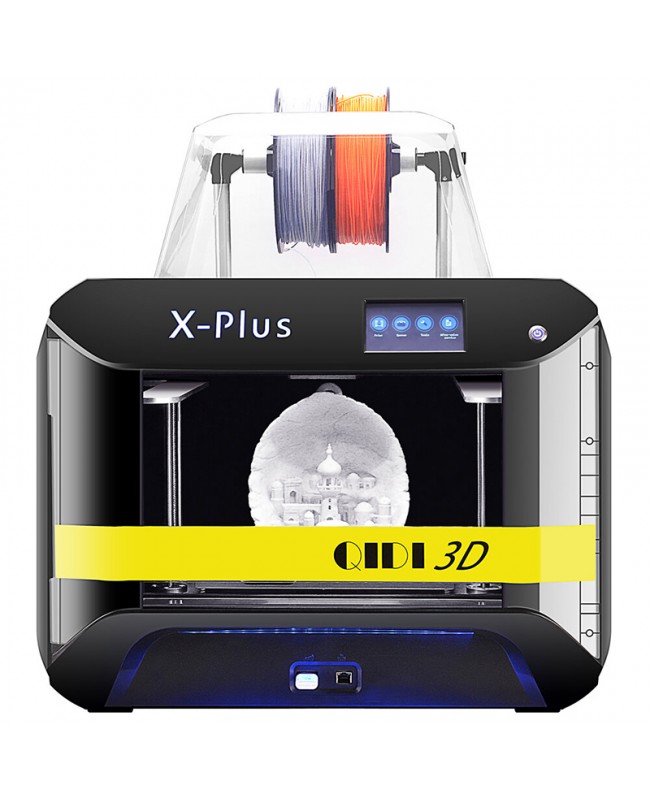

Professional

Systems in this class no longer look compact, but rather look like large refrigerators. This is the basis of 3D printing technology, which includes all the achievements and possibilities available to the industry. The purpose of professional systems can be very different, from prototyping to full-scale production, which in turn makes them an excellent option for both large businesses and high-tech companies with a small staff. ShapeWays, by the way, uses printers of this class.

Unlike their small brothers, these printers, due to the large number of modes and additional options, already require certain skills to work with them, so you cannot do without an operator.

In terms of the workspace, everything is not so simple here either. They are very large and noisy, so they require a separate room with good ventilation. Space requirements vary, but the space should be something like a laboratory and have a high-voltage line connected.

As a result, we get a universal 3D printing machine that provides the highest print quality and increased product sizes compared to the lower grades. ShapeWays, for example, collects several objects per print cycle, placing them at some distance from each other, which ultimately has a positive effect on the speed of order processing.

Price range: $30,000 - $750,000

Target audience:

Companies that have a constant need for prototyping, modeling, manufacturing of various kinds of objects with high quality and accuracy.

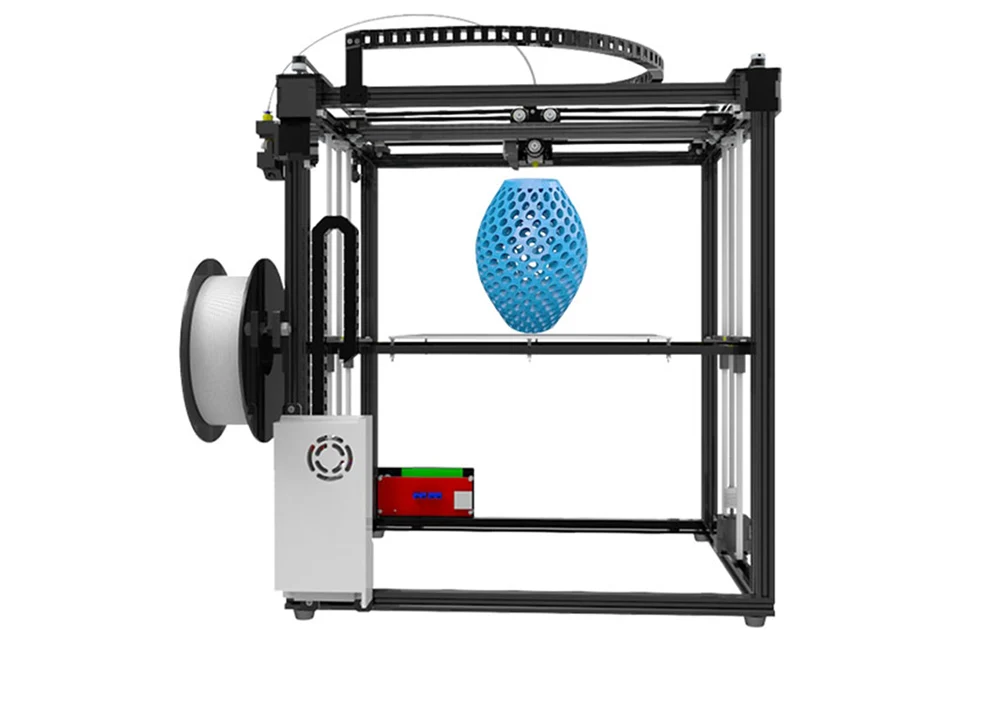

Production

The name of the class speaks for itself. These machines combine the precision and quality of professional printers, large print area, high level of automation and process control. On them, as well as on professional installations, it is possible to print not only prototypes, but also the final consumer product.

Systems of this kind are not intended for ordinary users, and the amounts that will have to be invested in such production will make you logically want to hire an experienced operator who will make the whole mechanism work 24 hours a day without downtime.

Small spaces are no longer enough. Here you need to clearly plan the future line and take care of the supply of the high-voltage line and gas pipe.

The result is a high-tech production that can quickly change the profile and use materials from ABS plastic to titanium.

Price range: $300,000 - $1,000,000

Target audience:

Companies with a need to produce high-precision large-sized products, or companies with a need to produce a large number of smaller volume items with high accuracy and high level quality.

Summing up, I would like to add that despite the fact that the threshold for entering this industry is still very high, the future belongs to such systems. Within the event horizon, we will be able to see a real revolution, at least in high-tech manufacturing. General Electric was one of the first to realize this and has already begun to produce complex titanium parts for aircraft engines using 3D printers.

As Albert Einstein said:

It's very simple. All people think that this is impossible. But there is one daredevil who does not agree with this ...

Total Z industrial 3D printers

FDM and SLS 3D printers, drying and post-processing equipment

About company

FDM 3D printers

Industrial 3D printers Total Z PRO series

450-PRO 950-PRO

Total Z High Performance LPRO Series 3D Printers

1000-PRO-LL

Total Z G3 Series Desktop 3D Printers

250-G3 250-G3 (2X) XL250-G3(2X)

Total Z G5 Series Desktop 3D Printers

G5

SLS 3D printers Total Z

SLS-250

Portal systems for 3D printing with granules

Total Z AnyForm FGF

Total Z machines for drying and post-processing

Total Z D5Vacuum drying chambers

Help prepare plastic for printing. Remove moisture from hygroscopic materials. Reduce the risk of plastic "boiling", extruder breakage, deterioration of the surface quality of the product.

Remove moisture from hygroscopic materials. Reduce the risk of plastic "boiling", extruder breakage, deterioration of the surface quality of the product.

View →

Total Z MPC-310Acetone baths

Equipment for chemical post-processing of finished objects. Helps to achieve a glossy and smooth product surface.

View →

Total Z UB-450; 500; 650; 950; 1200;Ultrasonic baths

Machines for physical and chemical post-processing of models. Remove the supporting plastic from the surface of finished products. They clean the material in places inaccessible for manual processing.

See 5 models →

Our capabilities

The equipment complies with Russian and international standards

Consumables for printers and equipment are always in stock

We participate in R&D, cooperate with research institutes

We work with defense enterprises and government customers

Operational warranty service

Departure and training on the territory of the customer

Implemented projects by industry

Aviation industry and special products

Supply of an industrial 3D printer for the project of the MS-21 passenger aircraft of Irkut Corporation.

Supply of high-temperature 3D equipment for the laboratory of additive technologies of VIAM.

Supply of a 3D printer for printing with experimental materials for the production of the Central Institute of Aviation Motors.

Shipbuilding

Selection of samples of engineering plastic for the project of printing body elements for a shipyard.

Auto industry

Supply of equipment for 3D prototyping to the plant of the AvtoVAZ group.

Rocket and space

Supply of the first production equipment for 3D printing to the Center for Additive Technologies of JSC RCC Progress.

Foundry

Fabrication of a matrix using FDM 3D printing for the production of piece metal parts that have been discontinued or to replace parts with a long delivery time.

Education

Production of a desktop 3D printer for schoolchildren and students in collaboration with a team of developers of teaching materials for classrooms.

Electronics

Implementation of 3D equipment at the Simvol East Kazakhstan region.

Prototyping of lighting equipment for the Pyaterochka grocery store chain.

Agroprom

Complex equipping of the research agro-engineering center with equipment.

Aviation industry and special products

Supply of an industrial 3D printer for the project of the MS-21 passenger aircraft of Irkut Corporation.

Supply of high-temperature 3D equipment for the laboratory of additive technologies of VIAM.

Supply of a 3D printer for printing with experimental materials for the production of the Central Institute of Aviation Motors.

Shipbuilding

Selection of samples of engineering plastic for the project of printing body elements for a shipyard.

Auto industry

Supply of equipment for 3D prototyping to the plant of the AvtoVAZ group.

Rocket and space

Supply of the first production equipment for 3D printing to the Center for Additive Technologies of JSC RCC Progress.

Foundry

Fabrication of a matrix using FDM 3D printing for the production of piece metal parts that have been discontinued or to replace parts with a long delivery time.

Education

Production of desktop 3D printers for schoolchildren and students in collaboration with a team of developers of teaching materials for classrooms.

Electronics

Implementation of 3D equipment at the Simvol East Kazakhstan region.

Prototyping of lighting equipment for the Pyaterochka grocery store chain.

Agroprom

Complex equipping of the research agro-engineering center with equipment.

Services

3D printing

Casting

Reverse engineering

prototyping

Upcoming Events

New models of Total Z industrial 3D printing systems in Moscow at the Interplastica exhibition

Interplastica is a key event for the plastics and rubber market, which annually brings together experts from all over the world at one business platform.