Philippines 3d printer

The 3D Services Pioneer in the Philippines

The Pioneer of 3D Services in the Philippines

How Can We Help You?

3D2GO is the only one-stop shop for everything 3D printing in the Philippines. We offer end-to-end full-service scanning, prototyping and printing with a streamlined process that guarantees a top quality end product.

3D Scanning

Digital capture an object's physical dimensions so it can be converted into a precise 3D representation.

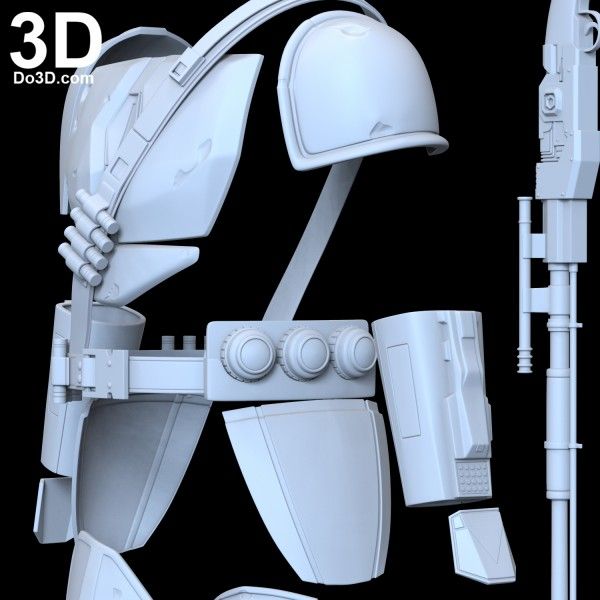

3D Designing

We conceptualize your ideas into 3D Digitize any object in the form of industrial designs, concept models, and 3D models with texture and color.

3D Modeling

We create a reverse-engineered file using specialized 3d softwares to produce engineering files.

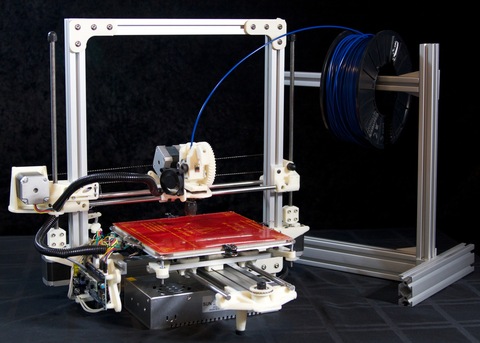

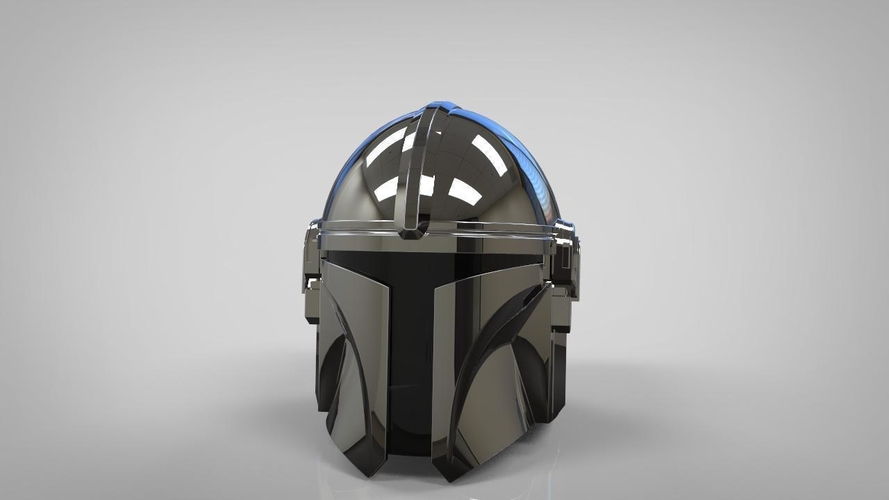

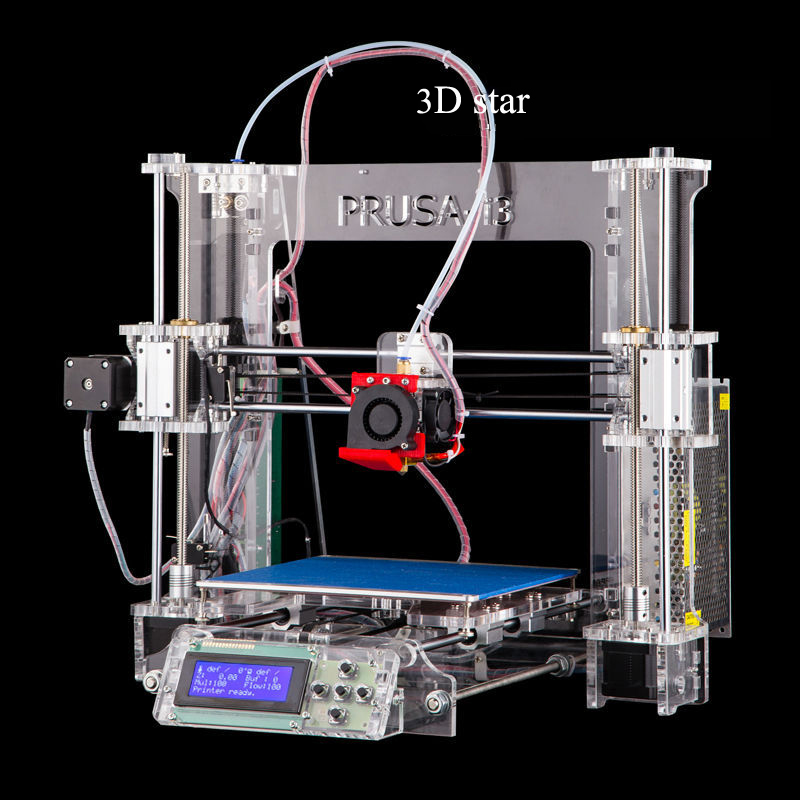

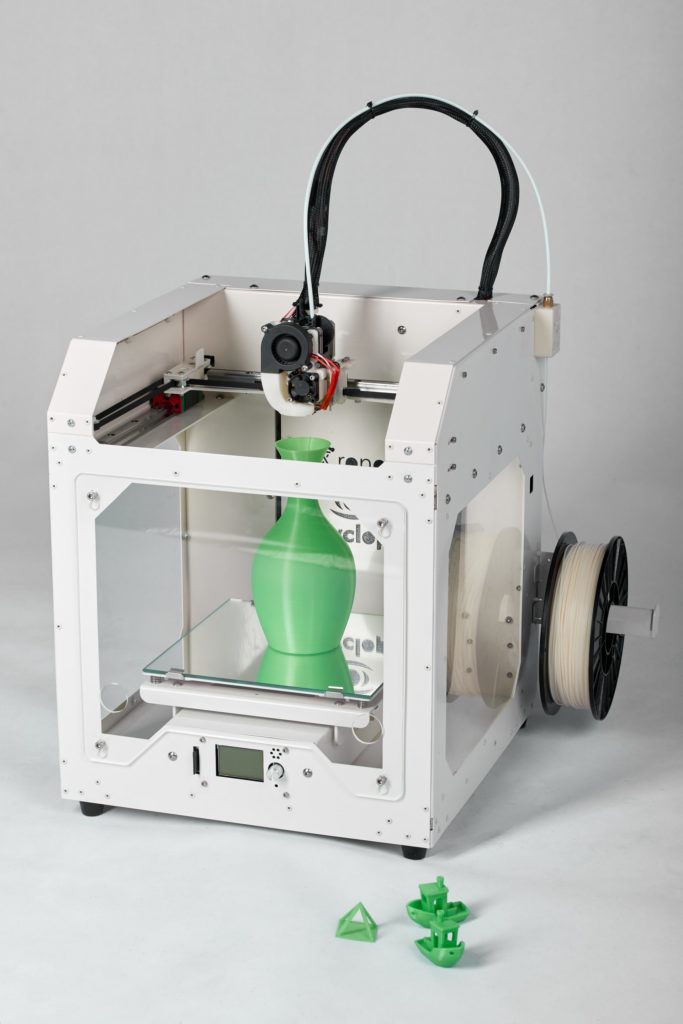

3D Printing

Now let's breathe life into that 3D design. In 3D printing or additive manufacturing.

Benefits of 3D Printing

At 3D2Go, we believe in the power of 3D printing. With our 3D scanning, modelling and printing services, we can help you create products that are both unique and functional. From replacement parts to customized toys, our team is dedicated to bringing your ideas to life. So whether you’re in the market for a new toy or an innovative product, come to us and trust in our expertise.

Play Video about 3d video cover

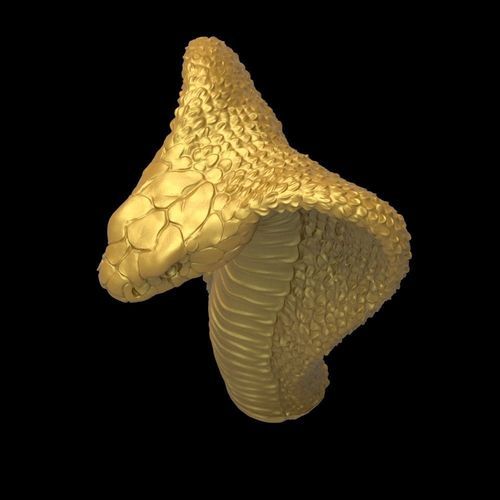

OUR WORKS

GALLERY

CONTACT US

LET'S WORK

Click here

Testimonials

3D Use Cases

3D Printing, Scanning and Modelling can be useful in the following use cases.

Architecture

Create detailed three-dimensional models of buildings and other structures.

Automotive

3D can be used in the automotive industry to create prototypes of cars, car parts, and accessories.

Bobblehead

Add a unique and personal touch to your home or office. It is perfect for any room and makes a great gift for any occasion.

Engineering

Create models and designs of products or structures. Visualize and test out scenarios before moving forward with a project.

DIY Projects

If you love crafting and DIY projects, you need 3D in your life! Create unique and one-of-a-kind pieces. Let your imagination run wild.

Houseware

3d print your own houseware. Check out the latest 3d printing technology and get started!

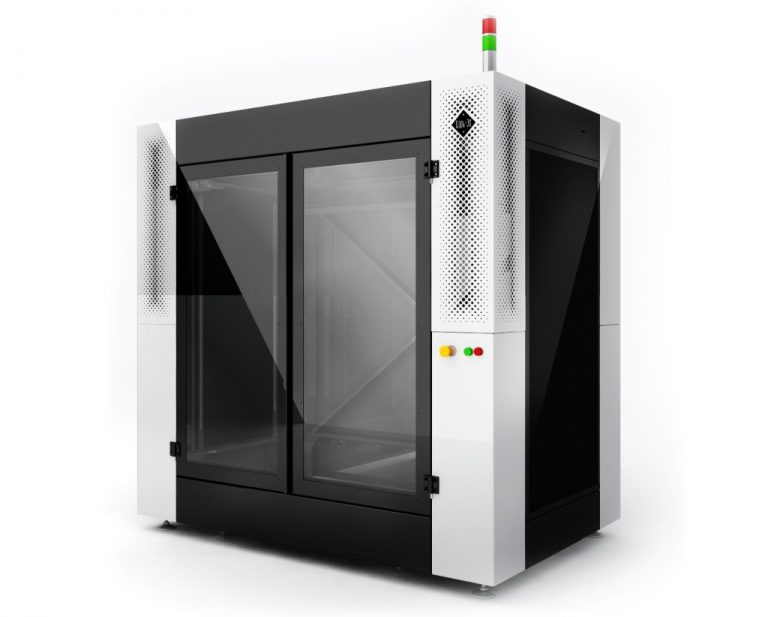

Manufacturing

Create products with precision and accuracy never before possible. Get ahead of the competition with 3d!

Medical

From X-rays to MRIs, 3d technology is changing the way we see the world. Learn more about how it's helping medical professionals here.

Learn more about how it's helping medical professionals here.

Restoration

With 3D printing technology, you can restore statues, broken wares, and equipment.

Toys

With 3d printing, you can make toys that are just as fun and exciting as the ones you buy. Go and create something new!

3D Scanning Services in the Philippines

Frequently Asked Questions

What is 3D Scanning?

Scanning in 3D is the process of determining the shape, dimensions, and important features of an object using a 3D scanner. The result of this is a 3D file of the object, which you can save, edit, or 3D print.

The Use of 3D Scanning

3D scanning makes it more convenient to capture and determine an object’s actual shapes, dimensions, and its finest details. It is an easier way to get a digital version of the item to create a 3D representation.

For businesses

- It helps businesses do engineering, designing, and manufacturing processes.

It helps create products faster in high quality and low-cost processes.

It helps create products faster in high quality and low-cost processes.

For end-users/consumers

- Some people want to scan and print their favorite stuff. Through this innovative way, consumers can save time in design work.

What are the Things that I Can 3D Scan?

Ever wonder what items you can 3D scan? In 3D2Go, we can scan almost any object, environment (such as a room), and even a person. Exceptions may be a building or a mountain.

3D Scanning Applications

Architecture - It helps scan and analyze high details when conducting architectural surveys. It has the ability to capture precise information that converts to vast savings in productivity and time.

Engineering - It helps in getting detailed measurements of an object. Analyzing mechanical properties is also simplified.

Automotive - It allows producing products related to automotive all around the globe through digital production.

Construction - We can use 3D scanning for construction to develop its interior and exterior 3D models. It can help in planning and designing renovations.

It can help in planning and designing renovations.

And many more.

3D Scanning and Modeling

Enjoy a quicker way to get a 3D file and transform it into a design that is ready for 3D printing with 3D scanning and modeling services.

What is the advantage of scanning an object first before modeling?

Scanning an object first is a shortcut to obtain a 3D file. Although the file still needs to undergo modeling, it is easier for designers as they don’t have to start modeling from scratch. Their task will focus more on improving the design for a quality output.

Full-service 3D Scanning to 3D Modeling

3D2Go offers full service 3D scanning to 3D modeling services. We use advanced scanners that can handle the most complex shapes and measurements to generate accurate results.

We are more than willing to serve and help you with your 3D needs. With the help of our seasoned 3D modelers, 3D2Go guarantees a top-quality end product.

3D Scanning and Printing Services in the Philippines

In 3D2Go, we provide quality 3D scanning and printing services. We can scan and print objects as small as a coin and as massive as a vehicle with our state-of-the-art 3D scanners and 3D printers.

We can scan and print objects as small as a coin and as massive as a vehicle with our state-of-the-art 3D scanners and 3D printers.

View the world in three-dimensional imagery with a digitally captured physical dimension of an object. Connect with us today to experience a top-of-the-line 3D scanner company.

A top hotel in the Philippines will have a suite built with a concrete 3D printer.

News

Subscribe author

Subscribe

Don't want

3

Lewis Yakich, an experienced US developer, teamed up with renowned concrete 3D printing expert Andrey Rudenko to come up with the design of the hotel. The duo also worked tirelessly to figure out the right type of printer for the big project. Thanks in large part to Rudenko, the process of building the printed module took only two months. Rudenko even admits that their builds can be reproduced within a few weeks now.

After testing materials and blends for one month, the duo embarked on a revolutionary print.

The room designed for 3D printing will also have a printed Jacuzzi.

If you could stay in a hotel room built entirely with 3D printers, would you? Well, if you're planning a trip to the Philippines soon, you might just get the chance. In this country, the Lewis Grand Hotel has recently completed the construction of a new addition. A suite that was made almost entirely with a construction concrete printer.

In Angeles City (Pampanga), a 3D printed villa has appeared in the Lewis Grand Hotel. It has two bedrooms, a room with a jacuzzi (the jacuzzi was also 3D printed). The total area of the villa is approximately 120 square meters. The whole villa is approximately 10 by 12 meters in size, with high ceilings in the entire room - as much as 3 meters. This is a revolutionary number. The most impressive feature is the fact that he has a total number of hours to complete the printing of the entire issue - about 100. Add to this the time it took to install the plumbing, fittings and wiring.

Add to this the time it took to install the plumbing, fittings and wiring.

“The Philippines is actually a great place to print with concrete because of the weather,” Yakich tells 3DPrint.com, “Nowadays everything is made of concrete. A 3D printer can do a lot of good in disaster areas, etc.'

Although construction has already finished at the Grand Lewis Hotel and the villa is ready, it is not known exactly when the hall will open to the public, and how much it will cost a night at the villa.

But it is known that this building made a splash and captured the attention of other enterprises in the Philippines. A construction pro like Yakich is in a position to secure a contract to build affordable housing in the country, something he plans to start in November. Considering how much money and time was spent on an addition to his chic Philippine hotel, such construction can be considered very effective. It seems likely that his next 3D printer construction contract won't be his last.

It seems likely that his next 3D printer construction contract won't be his last.

Follow author

Follow

Don't want

3

More interesting articles

12

Subscribe to the author

Subscribe

Don't want

In the village of Aisha, Zelenodolsk district of Tatarstan, work is underway to build thirty-four houses with the use of...

Read more

5

Follow the author

Subscribe

Don't want

Scientists from the Perm National Research Polytechnic University have designed an exp...

Read more

sarkazm

Loading

04/01/2016

39816

68

Subscribe to the author

Subscribe

Don't want

News from the world of printing in a short line

FDplast announced the release of a free.-kupit-v-soin-store.ru-1.png) ..

..

Read more

Philippine Hotel's First Printed Suite Coming Soon / Sudo Null IT News With its task, according to Lewis Yakic, the owner of the hotel, the giant 3D printer coped brilliantly in 100 hours, while implementing a rather complex design concept. The room printed in concrete at the Lewis Grand Hotel is the first comfortable hotel apartment in the history of mankind built in this way.

The owner of the hotel is Lewis Yakic from California, a structural engineer by profession, has accumulated solid experience in building houses in the United States to date. But the room built at the Lewis Grand Hotel most likely would not have been destined to go down in history if not for the idea of Lewis to involve Andrey Rudenko from Minnesota, widely known as the creator of a unique concrete 3D printer and the world's first 3D printed castle. from concrete.

A little about the author of the concrete 3D printer and his invention

A few words for those who are not familiar with the invention of Andrey Rudenko - a concrete 3D printer for the construction of large-scale building structures and solid houses. The first mentions of Rudenko's concrete 3D printer and the author of the invention are associated with Minnesota, where a concrete mini-castle was built as part of the experiment, which became Andrey's first experience.

The first mentions of Rudenko's concrete 3D printer and the author of the invention are associated with Minnesota, where a concrete mini-castle was built as part of the experiment, which became Andrey's first experience.

Building a castle using 3D printing

Having successfully completed the castle project, Rudenko returned to the idea of 3D printing a residential building. Initially, he planned to build his first home in Minnesota, but due to harsh climatic conditions and harsh winters, the Philippines and the Lewis Grand Hotel were chosen as the site for a subsequent, larger experiment.

Some difficulties were associated with the transportation of a large 3D printer from Minnesota. Fortunately, one of the most important issues is that the ingredients for the production of building mixtures were found in abundance in the region. The main components of the composition used as a filler were sand and volcanic ash. All structural elements of the hotel building are built from them. Another factor in the successful implementation of the planned plan was the climate of the Philippines, which favors the rapid drying of the building mixture.

Another factor in the successful implementation of the planned plan was the climate of the Philippines, which favors the rapid drying of the building mixture.

The dimensions of the Rudenko printer make it possible to carry out not element-by-element, but monolithic printing of structural elements, which eliminates the need for their subsequent assembly with the formation of joints.

Apartments in size of 10.5 m X 12.5 m and a height of 3 m are located in a separate extension to the main building of the hotel and have all the necessary for a comfortable rest - engineering communications, including water and power supply systems, modern plumbing kits, a jacuzzi, elements of heat and waterproofing systems and "Smart Home". The strength of the erected structure is increased due to reinforcement with steel reinforcement.

Perhaps using 3D printing at the current level of technology is not the fastest way to erect building structures with a predominance of rectilinear geometry, but where the concept of the architect and designer goes beyond the usual geometric shapes and involves the use of complex patterns, alternatives to 3D technology no. Using the Rudenko 3D printer, it is possible to apply layers of cement up to 10 mm high and up to 30 mm thick. The main advantages of the model are the speed, accuracy and accuracy of the operations performed.

Using the Rudenko 3D printer, it is possible to apply layers of cement up to 10 mm high and up to 30 mm thick. The main advantages of the model are the speed, accuracy and accuracy of the operations performed.

Serious help in optimizing the operation of the printer was provided to the inventor by the participants of the RepRap “self-copying 3D printer” project.

Larger 3D construction projects supported by professional construction companies are getting closer today in China, where the issue of cheap housing is most acute. The main research in the field of building 3D printing is carried out in Europe and the USA.

WinSun projects

In April last year, the Chinese company WinSun announced the successful completion of the construction of 10 houses with an area of 200 square meters. meters by 3D printing during the day! At the same time, the cost of each house made from industrial and construction waste was estimated at only 30,000 yuan = $ 4,800. For element-by-element printing, a printer 32 meters long, 10 meters wide and 6.6 meters high was used. The walls and the frame, printed separately, were assembled into a single structure at the final stage. Naturally, it is inappropriate to talk about any architectural value of the houses printed in one of the districts of Shanghai Qingpu, as is the case with the Rudenko hotel room, but the Chinese definitely managed to lay the foundation for solving the problem of cheap housing.

For element-by-element printing, a printer 32 meters long, 10 meters wide and 6.6 meters high was used. The walls and the frame, printed separately, were assembled into a single structure at the final stage. Naturally, it is inappropriate to talk about any architectural value of the houses printed in one of the districts of Shanghai Qingpu, as is the case with the Rudenko hotel room, but the Chinese definitely managed to lay the foundation for solving the problem of cheap housing.

To ensure the pace of printing, the company has planned to set up at least 100 factories to recycle construction debris into ultra-efficient inks for construction 3D printers.

Less than half a year

WinSun set another record in the construction of large-scale 3D-printed structures six months after the completion of a project of 10 houses. This time, during the implementation of the pilot project, specialists erected a 5-storey residential complex and a quite respectable two-storey mansion in the Suzhou Industrial Park area.

Building area 1100 sq. m.

After getting acquainted with the projects implemented by WinSun, Rudenko's achievement no longer looks like something incredible. At the same time, one of the main obstacles to the large-scale introduction of 3D construction technologies is the complete absence of unified national legislative and regulatory regulations. So far, the implementation of solid or prefabricated low-rise building structures looks much easier today, which Andrey Rudenko managed to brilliantly confirm by printing a chic room at the Lewis Grand Hotel in just 100 hours.

The successful completion of a suite at the Lewis Grand Hotel on a tight schedule is the best advertisement for Lewis Yakic, who has already signed a contract to build 20 more suites by November 2015. According to Rudenko himself, the use of an improved model of his 3D printer will allow printing up to 6 low-rise buildings per week using a similar technology, and, importantly, with a reduction of up to 60 percent in material and physical costs.