3D printer drugs

3D printing of drugs can revolutionise personalised medicine

February 4, 2021

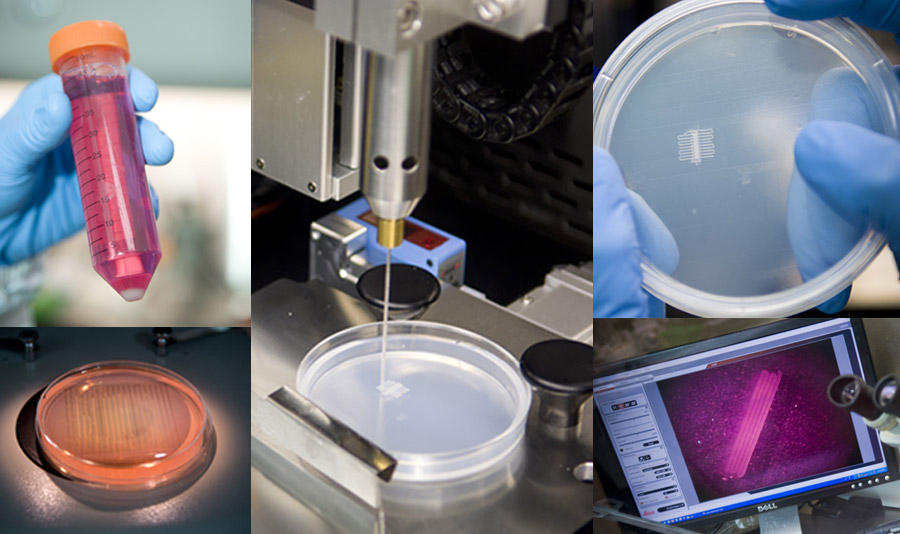

By GlobalData Healthcare

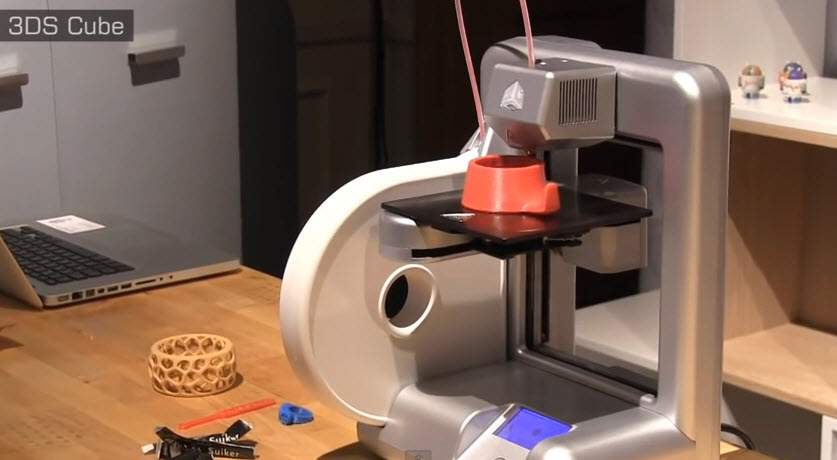

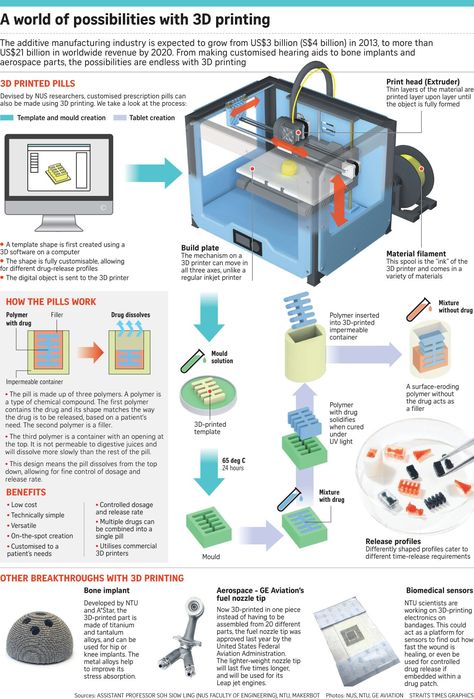

3D printers can be installed in pharmacies, hospitals, clinics, and remote locations, enabling on-demand production of drugs. Credit: Adul10 / Shutterstock.As the pharmaceutical industry moves away from mass production towards a more personalised model, 3D printing of drugs have the potential to revolutionise the market. The main benefit of using 3D printing technology for personalised pharmaceuticals is the ability to produce small batches with carefully tailored dosages, shapes, sizes, and release characteristics. It also allows flavours to be incorporated into a pill without the need of a film coating, entirely masking the taste of chemical compounds. 3D printers can be installed in pharmacies, hospitals, clinics, and remote locations, enabling on-demand production of drugs, particularly those with poor stability or that have cold chain storage requirements. For pharmaceutical companies, 3D printing can significantly reduce costs, waste, and environmental burden as printers only deposit the exact amount of raw materials required.

Aprecia Pharmaceuticals’ Spritam (levetiracetam), an anti-epileptic drug, is the first and only 3D-printed pharmaceutical. It received the Food and Drug Administration (FDA) approval in 2015 and is made using Aprecia’s proprietary ZipDose technology. The orodispersible tablet achieves full disintegration within seconds when in contact with liquid. Additionally, very high doses are achievable (up to 1,000mg), which are not typically possible through conventional methods. ZipDose technology uses a drop-on-solid printing technique where droplets of a liquid binding agent are deposited by a print nozzle onto a free pharmaceutical powder bed, unifying the free-form powder where it lands. The bed is then lowered to allow for another layer of free-form powder to be added. Further droplets are introduced, adding height to the nascent pill, while the surrounding, unbound powder particles act as a support structure to prevent the collapse of the highly porous pill structure.

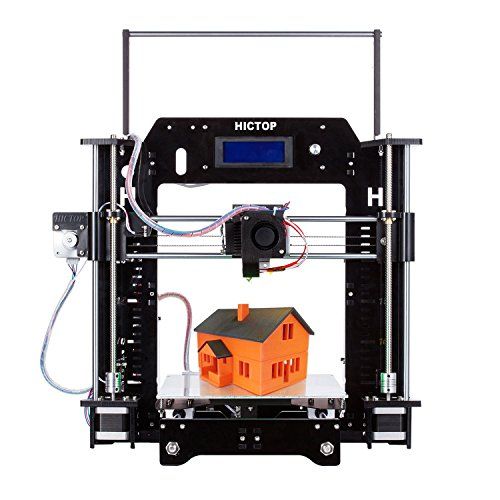

In April 2020, UK-based FabRx launched the first commercially available 3D printer for personalised drug manufacturing. M3DIMAKER is an extrusion-based printer that allows the print nozzle to be changed to accommodate different dosage requirements. Alongside the established extrusion-based fusion deposition modelling printing, whereby the printer melts the pharmaceutical mixture and excipients through a nozzle onto the build plate, the M3DIMAKER also uses a different extrusion-based method developed by FabRx: direct powder extrusion (DPE). Similar to Aprecia’s ZipDose technology, DPE deposits a powdered pharmaceutical agent onto a print bed through a nozzle aided by a single extruder. Both methods enable the manufacture of multiple-drug combination pills and sustained or delayed-release tablets.

To date, large biopharmaceutical companies have shown minimal activity in this area. In February 2020, Merck KGaA announced a collaboration with AMCM for the development and production of 3D printed pharmaceuticals for clinical trials and, later, for clinical manufacturing. The stated goal of the partnership is to develop drugs using powder bed fusion, whereby a laser melts and fuses powder together layer by layer. Merck and AMCM expect this to make the manufacturing of tablets both faster and cheaper due to the avoidance of reformulations. GlaxoSmithKline has also shown interest in 3D printing of drugs, partnering with The University of Nottingham on a study that used nozzle printing and ultraviolet curing to produce 3D printed ropinirole tablets to treat Parkinson’s disease.

The stated goal of the partnership is to develop drugs using powder bed fusion, whereby a laser melts and fuses powder together layer by layer. Merck and AMCM expect this to make the manufacturing of tablets both faster and cheaper due to the avoidance of reformulations. GlaxoSmithKline has also shown interest in 3D printing of drugs, partnering with The University of Nottingham on a study that used nozzle printing and ultraviolet curing to produce 3D printed ropinirole tablets to treat Parkinson’s disease.

The traditional one-size-fits-all model of drug development is inefficient and costly. Pharma companies need to adopt new technologies such as 3D printing to make more personalised treatments, improve R&D efficiencies, reduce costs, and minimise waste. This will not only lead to more streamlined and cost-effective supply chains, it will also improve sustainability, which has been touted as one of the most important trends across industries for 2021 and beyond.

Five companies personalizing treatments with 3D printed drugs

There has been a noticeable shift in recent years towards the personalization of medicine, with the pharmaceutical industry showing interest in pills that are tailored to a patient’s needs. Here are five companies that are leveraging 3D printing to produce customizable drugs.

Here are five companies that are leveraging 3D printing to produce customizable drugs.

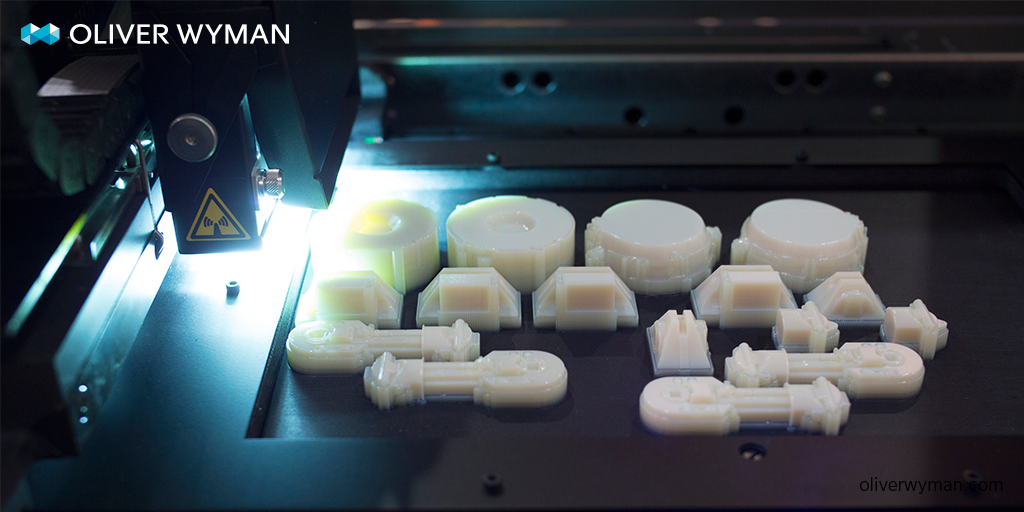

Conventional drug production relies on large-scale batch manufacturing, which is very efficient at churning out large volumes of drugs with uniform characteristics. But this becomes time-consuming and expensive when small batches are needed, such as for clinical trials where the doses need to be adjusted. The process is also associated with an environmental burden resulting from inefficient use of raw materials, expired stock and production of toxic and non-toxic waste.

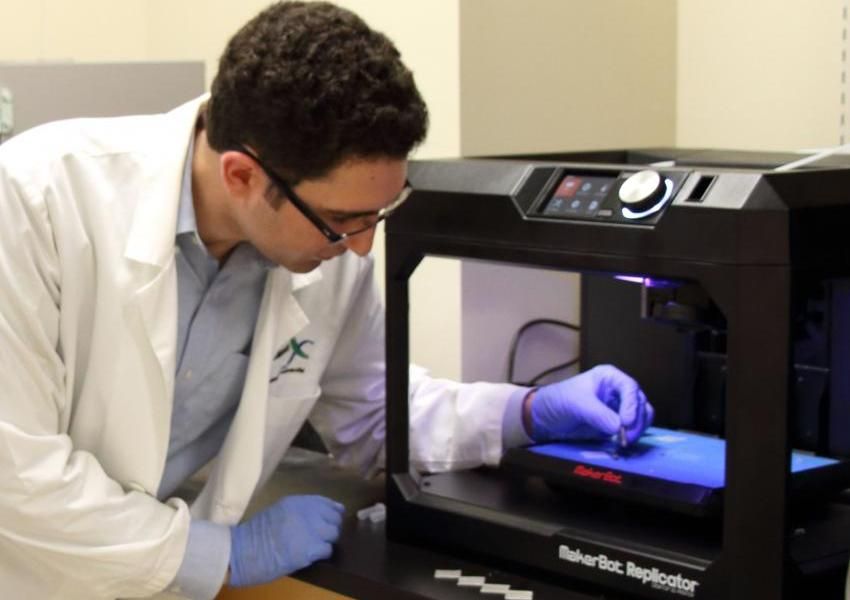

Additive manufacturing, or 3D printing, is a tool that can allow for small-scale production of medicines. This approach uses 3D modeling software to build an object layer-by-layer; for solid drugs, the 3D printer stacks ink with an excipient — inactive substances in drugs added for specific functions like improved stability and bioavailability — and the active pharmaceutical ingredient to print out a finished product. By adjusting the printing parameters, the drug dosages, drug combinations, release profiles and even flavors can be personalized.

By adjusting the printing parameters, the drug dosages, drug combinations, release profiles and even flavors can be personalized.

There are many challenges that have limited widespread implementation of 3D printing technology, such as 3D printers not meeting good manufacturing practice standards and a limited range of excipients suitable for 3D printing. Nevertheless, 3D printing has the potential to revolutionize the pharmaceutical industry, and several companies are making strides in the space.

Aprecia PharmaceuticalsHeadquarters: Pennsylvania, U.S.

Aprecia Pharmaceuticals is behind the first and only U.S. Food and Drug Administration (FDA)-validated 3D printing platform for commercial-scale drug development. Their aim is to make medicines easier to take and reduce the number of pills a patient needs. Using this platform, Aprecia developed ZipDose Technology, which allows tablets to hold a high dosage load of up to 1,000 mg and still rapidly dissolve with just a sip of water.

Content continues below

Related Content

ZipDose is used in the production of Spritam (levetiracetam), a fast dissolving oral medicine for the treatment of specific types of epileptic seizures. It is targeted for patients who struggle to swallow pills or are unable to measure out the precise dosage of liquid levetiracetam. In 2015, Spritam became the first and only 3D printed drug to be approved by the FDA.

FabRxHeadquarters: London, U.K.

Founded in 2014 as a spin-out of University College London, FabRx aims to revolutionize medical treatments by facilitating the production of personalized medicines, where the size, shape, dosage and dosage combinations can be customized. In 2020, the company released M3DIMAKER, the first pharmaceutical 3D printer for personalized medicine, allowing clinicians and other professionals to “print” tailored medicines on demand.

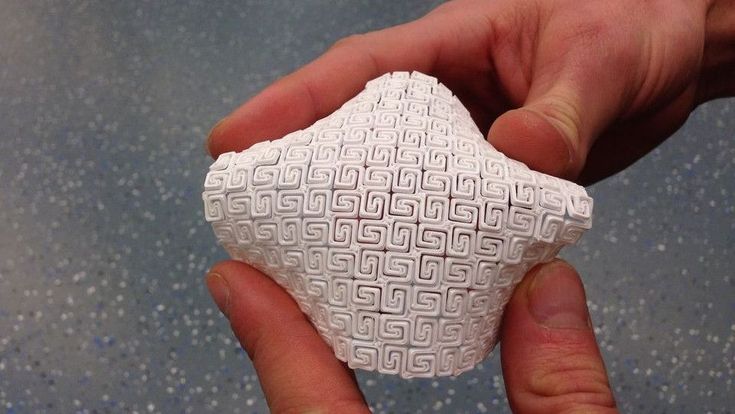

Using their 3D printing technology, FabRx has also created a range of personalized Printlets — medicines with customized shapes, flavors, colors, dosages and release profiles, such as tablets with Braille and moon patterns for patients with visual impairments as well as Polypills, which combine several drugs in one pill.

FabRx technology is also being used to print personalized pills for children with a rare metabolic disorder called maple syrup urine disease, which requires treatments to be strictly tailored based on age, weight and blood concentrations of the amino acid isoleucine. Current manual preparation methods are time consuming and costly, so FabRx’s approach could save time and money for caregivers.

MerckHeadquarters: Darmstadt, Germany

Content continues below

Related Content

The biopharma giant Merck is also taking a stab at next-generation tablet manufacturing through 3D printing. In 2020, Merck announced a cooperation with ACMC — sister company of EOS, a worldwide provider of 3D printing solutions — to produce 3D printed tablets for clinical trials at first, before moving towards commercial-scale manufacturing. This partnership aims to advance the industrial applications of 3D printing technology and digitalization.

Triastek, Inc.

Headquarters: Nanjing, China

Triastek is a global leader in pharmaceutical 3D printing, with 41 patents that account for more than 20% of global 3D printing pharmaceuticals applications. Using their proprietary MED 3D printing technology, Triastek develops their own in-house drugs and partners with others to provide drug development solutions.

The MED 3D printing platform allows for the customizable design of tablets, with the different shapes and geometries controlling drug onset time, duration, and drug interactions with the body. This platform was accepted into the FDA’s Emerging Technology Program in 2020, and two of their 3D printed drugs have been granted investigational new drug clearances from the FDA. The first is a chronotherapeutic drug for rheumatoid arthritis, where the drug is taken at bedtime but its release is delayed until the early morning hours, when pain and joint stiffness are at their peak. The second is a one-dose pill alternative to the twice-daily marketed drug for cardiovascular and clotting disorders.

Triastek recently entered into a research collaboration with Eli Lilly and Company to improve the bioavailability of drugs in the intestine by achieving precise organ targeting and programmed drug release.

GlaxoSmithKlineHeadquarters: Brentford, U.K.

GSK was one of the first big pharma companies to show interest in 3D printing as a manufacturing tool, partnering with the University of Nottingham to study the feasibility of 3D inkjet printing and curing with ultraviolet light to produce solid drug forms; in 2017, researchers demonstrated the successful 3D printing of ropinirole tablets for Parkinson’s disease.

3D inkjet printing deposits liquid materials or solid suspensions layer-by-layer but each deposited layer must first be dried, or “cured,” between the deposition steps. GSK is exploring how to convert active pharmaceutical ingredients into curable ink to enable 3D drug printing.

OBJ File Bugs Drugs・3D Printer Model Download・Cults

Read from the man with the chainsaw

3. 04 €

04 €

Donut Homer

3.04 €

Halloween cat

3.04 €

Terror Magic the gathering

3.04 €

Farting Unicorn

3.04 €

Wednesday Adams

3.04 €

Pot container for car Koopa

1.27 €

Mr. Horse (Ren and Stimpy)

3.04 €

Best Files for 3D Printers in the Art Category

Old Rag Mountain | Shenandoah National Park

Free

SpongeBob (easy printing without support)

0,50 €

Forbidden Watchtower

Free

Spotlight Diorama

4,90 €

Airpod Money Box

Free

Focus and Pocus - mischievous kittens

3. 36 €

36 €

Diorama "The wooden house of my neighbor Totoro"

4,96 €

Cute Flexi Print-in-Place Ant

1.91 €

Art category bestsellers

Cute circus baby elephant with flexi print

2,89 €

Flexi print Imperial dragon

3,87 €

Hannya wall masks

3,80 €

Skeleton hand with flexi print

1,95 €

Leopard gecko ball joint toy, imprinted body, snap head, cute flex

3,33 €

CUTE CROCODILE WITH FLEXIBLE PRINT IN PLACE

2.89 €

Crystal Dragon Articulating Animal Flexi Wiggle Pet Printing In Place Fantasy

3. 92 €

92 €

Articulated bat toy, body with prints, head with latches, cute flexi

3,33 €

Flexi Print-in-Place Dinosaur Brachiosaurus

2.89 €

Cute little fox with flexi print

2,45 €

Cute squirrel with flexi print

2.46 €

Chainsaw Man Pochita

€2.50 -fifty% 1.25 €

Cute Skeleton with Flexi Print

€2.89

Articulated toy "Python Snake", imprint body, snap head, cute flexi

3,87 €

Cute frog with flexi print

1. 91 €

91 €

Adorable articulated axolotl, imprinted body, snap head, cute flexi

3,33 €

Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people, so it is very easy to support us in maintaining activities and creating future developments. Here are 4 solutions available to everyone:

-

ADVERTISING: Disable the AdBlock banner blocker and click on our banner ads.

-

affiliation: Shop online by following our affiliate links here Amazon.

-

DONATIONS: If you want, you can donate via PayPal here.

-

* INVITE FRIENDS: * Invite your friends, discover the platform and great 3D files shared by the community!

15 Incredible 3D Printed Things

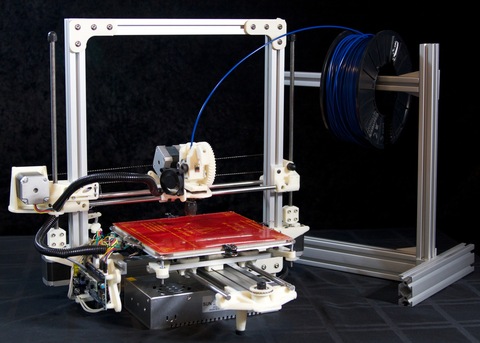

Most likely, you have already heard that a modern 3D printer can print firearms. But what do you say when you find out that the latest 3D printers are capable of recreating a human liver or a prosthetic arm? We invite you to get acquainted with the list of the most incredible things that can be printed on a modern 3D printer!

But what do you say when you find out that the latest 3D printers are capable of recreating a human liver or a prosthetic arm? We invite you to get acquainted with the list of the most incredible things that can be printed on a modern 3D printer!

Parts of the human body

It is unlikely that a 3D printer can print a working human liver yet, but developers are already making attempts to create such a technology. A scientist at Organovo, San Diego, has successfully used biomass as a consumable to print human liver tissue.

The head of the project is sure that in the future they will be able to recreate an exact copy of the human organ. Note that scientists from Cornell University have already been able to create a copy of the human ear, which can be implanted in a living person.

Prostheses for humans and animals

Who said that prostheses are ugly? Bespoke Innovations is a San Francisco-based company that makes beautiful "packages" for dentures.

Thanks to such “clothing”, prostheses look like human limbs. They can even be tattooed! Imagine what will happen if you combine the Robohand project and Bespoke Innovations? Many disabled people will have the opportunity to restore damaged fingers, and even whole hands. This technology also makes it possible to create artificial limbs for animals.

Dinosaur Skeletons

How about a printout of a life size dinosaur skeleton? Scientists from Drexel University, Philadelphia have developed a technology that allows you to print real-size dinosaur bones.

In the future, they plan to create "robosaurs" from these bones and force them to take over the planet. Joke! Note that the total mass of such a "robotosaurus" will be 80 tons.

Dead people

If you can print endangered species of animals, why can't you create an exact copy of a dead person? Scientists from a British university have successfully recreated an exact copy of King Charles III, who died in 1485.

Residents of the island nation are planning to "clone" several more important figures in the history of England.

Meat and leather

If you don't like the world of the dead, we offer printed meat products and leather. Modern 3D printers can actually print a steak for your breakfast!

Modern Meadow, Columbia, is working to improve its meat and leather printing technology.

Fast food and snacks

Don't eat meat? What about printed fast food? NASA and Cornell University researchers are improving the technology to recreate different types of food. Cookies, oysters and gelatin have already been successfully opened and eaten. All participants in the experiment are alive and well.

It remains to remember the famous student from New York, Mark Manricos, who developed a 3D printer for making delicious burritos.

Legal drugs

After smoking legal drugs, you always want to eat and here you may need the above described burritos.

By the way, the Thingiverse society produces hookahs, grinders and boats printed using a 3D printer.

Intimate Group Products

If the production of hookahs using 3D printers did not impress you, then Maker Love offers you to purchase sex toys.

You can come up with the design of the "device" yourself or download samples from the site.

Cars

Cars can also be 3D printed, and there is nothing surprising here. Today, many car manufacturers use 3D printing technologies to create car body or engine parts.

Also, 3D printers are already being used to create a full-size electric car that has a "futuristic design".

Drones

Modern 3D printing has already taken to the skies. The University of Southampton in the UK has developed the first radio-controlled aircraft SULCA, which was printed in 10 minutes on a 3D printer.

The SULCA Mini Plane operates on autopilot and is capable of flying for half an hour non-stop at 90 mph.

Houses on the Moon

It is unlikely that we can derive any practical benefit from a drone, but a new house would not hurt us. A professor at the University of Southern California, who currently works for NASA, is developing a project to create houses so that people can live on the moon.

All objects will be 3D printed. The researchers note that such buildings will be cheap and durable.

Clothing

3D printing has long been used in the world of fashion and jewelry. However, there is one more element of the wardrobe that the modern woman may like - a 3D printed bikini!

The creator of this bikini also offers to wear glasses that were created in a similar way.

Human masks

You already know that with the help of modern 3D printing technologies it is possible to recreate an approximate copy of a human face. However, New York City professor Heather Dewey-Hagborg used his knowledge of human DNA research and was able to develop a printer that prints accurate sculptures of people's faces.

Crazy professor collects cigarette butts and chewing gum from students, extracts DNA samples and creates an image on the computer!

An exact copy of the soon-to-be-born baby

Don't want to look at the printed face of a person? What about an exact copy of the baby in the womb? Brazilian company Technologia Humana3D uses 3D printers to print replicas of small, unborn babies.

This service may be of interest to parents who are expecting a child.

Surfboard

Unique surfboards have never been so cheap! One of the most important advantages of modern 3D printing is that it allows you to independently design any thing for everyday use. The MADE organization from Chicago has developed a special chip that is inserted into the surfboard.

While riding the waves, it reads information about your way of "riding on the sea surface" and helps to create a board shape that is ideal for the client.