How big is the biggest 3d printer

Largest 3D printers in 2022 for XXL prints

Large-scale 3D printers are able to print massive objects thanks to their gigantic build volumes. This guide covers some of the largest 3D printers in the world that are commercially available.

Last update June 23, 2022

We removed discontinued products and updated the BLB Industries The BOX lineup, which has been replaced by The Industry MAGNUM. We also added MASSIVit's latest solution, the Massivit 10000.

Table of contents

Handpicked related content

Large scale 3D printers (XXL): 2022 selection

BIG-Meter V4

F1000

BigRep ONE v4

400 Series WORKBENCH XTREME

T3500

MAGNUM

Massivit 10000

MAMA

3D printing furniture

3D printing large prototypes

3D printing production series

Customized large scale 3D printers

What are the best large scale 3D printers?

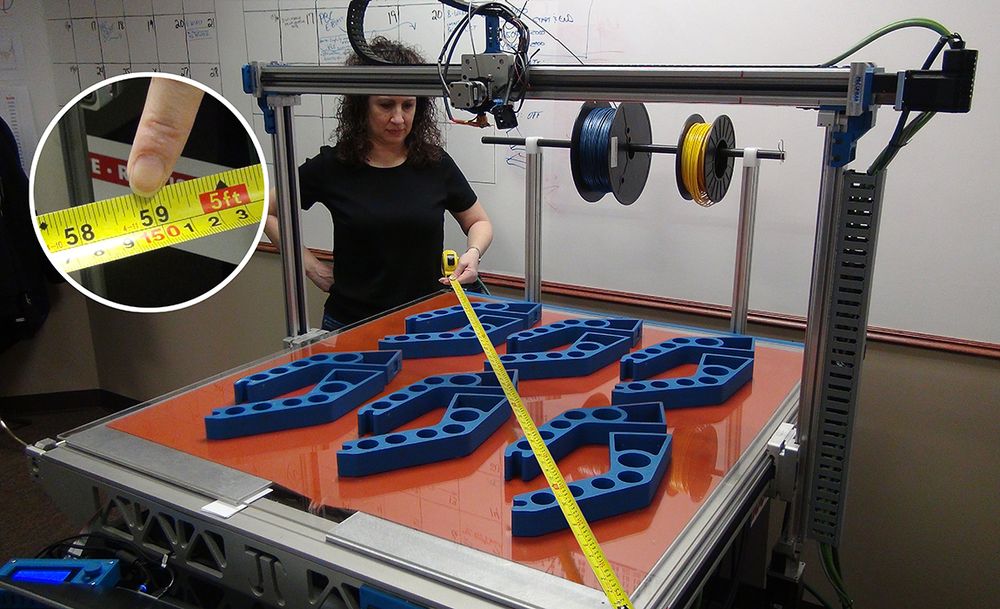

Large-scale 3D printers have been in the spotlight for quite some time. When we say large scale, we mean it– these machines can 3D print objects of over 1 square meter. They can be used to 3D print pieces of furniture, large prototypes, or several series of smaller objects in one go.

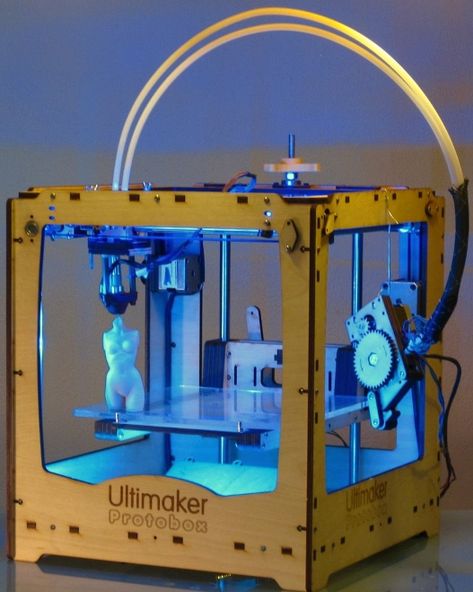

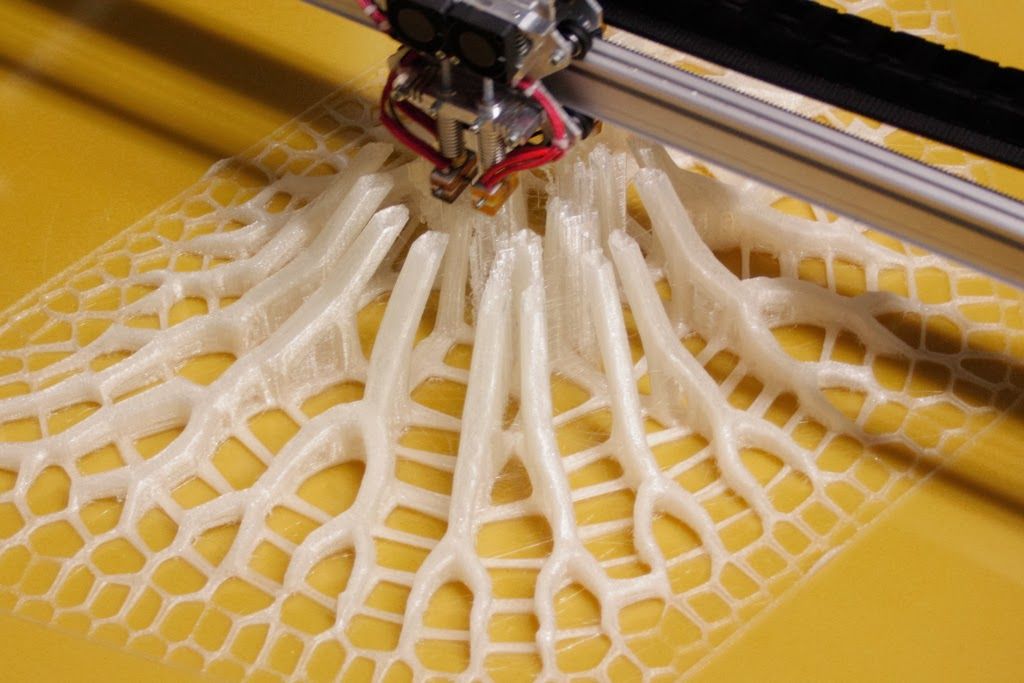

The professional 3D printers featured in our article are basically super-sized versions of ordinary desktop 3D printers. They almost all use extrusion 3D printing technology (FFF) and work the same way as regular desktop printers.

Our “largest 3D printers” selection does not include construction 3D printers, which fit into a different category.

Handpicked related content

If these large scale 3D printers (XXL) are too big, check out our other selections:

- Large format 3D printers (XL)

- Large volume 3D printers (L) for desktops/benchtops

- Large resin 3D printers (L)

Large scale 3D printers (XXL): 2022 selection

| Brand | Product | Build size | Country | Price Approximate starting prices based on supplier-provided information and public data. | |

|---|---|---|---|---|---|

| Modix This brand is a certified partner from our network. | BIG-Meter V4 | 1010 × 1010 × 1010 mm39.76 × 39.76 × 39.76 in | Israel | $ 13,50013 723 €11,975 £2,012,256 ¥ | Buy |

| CreatBot | F1000 | 1000 × 1000 × 1000 mm39.37 × 39.37 × 39.37 in | China | $ 29,99930 494 €26,610 £4,471,531 ¥ | Buy |

| BigRep | BigRep ONE v4 | 1005 × 1005 × 1005 mm39.57 × 39.57 × 39.57 in | Germany | $ 30,00030 000 €26,611 £4,471,680 ¥ | Quote |

| 3D Platform | 400 Series WORKBENCH XTREME | 1000 × 1500 × 700 mm39.37 × 59.06 × 27.56 in | United States | $ 49,99950 823 €44,351 £7,452,651 ¥ | Quote |

| Tractus3D | T3500 | ⌀ 1000 x 2100 mm | Netherlands | $ 59,00049 900 €52,335 £8,794,304 ¥ | Quote |

| The Industry | MAGNUM | 1500 × 1200 × 1200 mm59. 06 × 47.24 × 47.24 in 06 × 47.24 × 47.24 in | Sweden | $ 135,000129 990 €119,750 £20,122,560 ¥ | Quote |

| MASSIVit 3D | Massivit 10000 | 1420 × 1110 × 1500 mm55.91 × 43.7 × 59.06 in | Israel | upon request | Quote |

| Modix This brand is a certified partner from our network. | MAMA | 2000 × 5000 × 1000 mm78.74 × 196.85 × 39.37 in | Israel | upon request | Quote |

Expand to see more specs

The products in the table are ranked by price (low to high).

| Brand | Product | Build size | Build volume | Country | Price Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …). | |

|---|---|---|---|---|---|---|

| Modix This brand is a certified partner from our network. | BIG-Meter V4 | 1010 × 1010 × 1010 mm39.76 × 39.76 × 39.76 in | 1030.3 L | Israel | $ 13,50013 723 €11,975 £2,012,256 ¥ | Buy on Modix |

| CreatBot | F1000 | 1000 × 1000 × 1000 mm39.37 × 39.37 × 39.37 in | 1000 L | China | $ 29,99930 494 €26,610 £4,471,531 ¥ | Buy on CreatBot |

| BigRep | BigRep ONE v4 | 1005 × 1005 × 1005 mm39.57 × 39.57 × 39.57 in | 1015.08 L | Germany | $ 30,00030 000 €26,611 £4,471,680 ¥ | Get a quote |

| 3D Platform | 400 Series WORKBENCH XTREME | 1000 × 1500 × 700 mm39.37 × 59.06 × 27.56 in | 1050 L | United States | $ 49,99950 823 €44,351 £7,452,651 ¥ | Get a quote |

| Tractus3D | T3500 | ⌀ 1000 x 2100 mm | 1649.34 L | Netherlands | $ 59,00049 900 €52,335 £8,794,304 ¥ | Get a quote |

| The Industry | MAGNUM | 1500 × 1200 × 1200 mm59. 06 × 47.24 × 47.24 in 06 × 47.24 × 47.24 in | 2160 L | Sweden | $ 135,000129 990 €119,750 £20,122,560 ¥ | Get a quote |

| MASSIVit 3D | Massivit 10000 | 1420 × 1110 × 1500 mm55.91 × 43.7 × 59.06 in | 2364.3 L | Israel | upon request | Get a quote |

| Modix This brand is a certified partner from our network. | MAMA | 2000 × 5000 × 1000 mm78.74 × 196.85 × 39.37 in | – | Israel | upon request | Get a quote |

Overview of the best large scale professional 3D printers

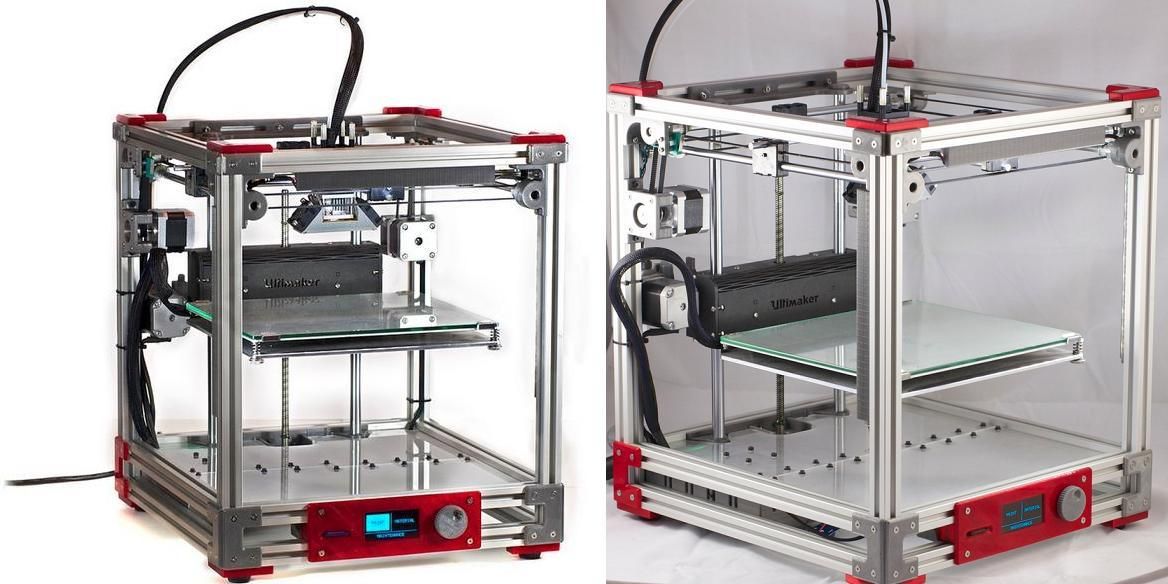

The Modix BIG-Meter offers over one cubic meter of build volume. As all Modix printers do, the BIG-Meter is delivered as a self-assembly kit, which contributes to the printer’s relatively low price point.

This large scale 3D printer comes with a dual extruder (E3D Aero and E3D Volcano print heads), full automatic bed leveling (bed tile and bed mapping), a Wi-Fi controller, and a range of industrial-grade components. The print bed heats up to 120°C.

The print bed heats up to 120°C.

Buy on Modix Get a quote Add to comparison

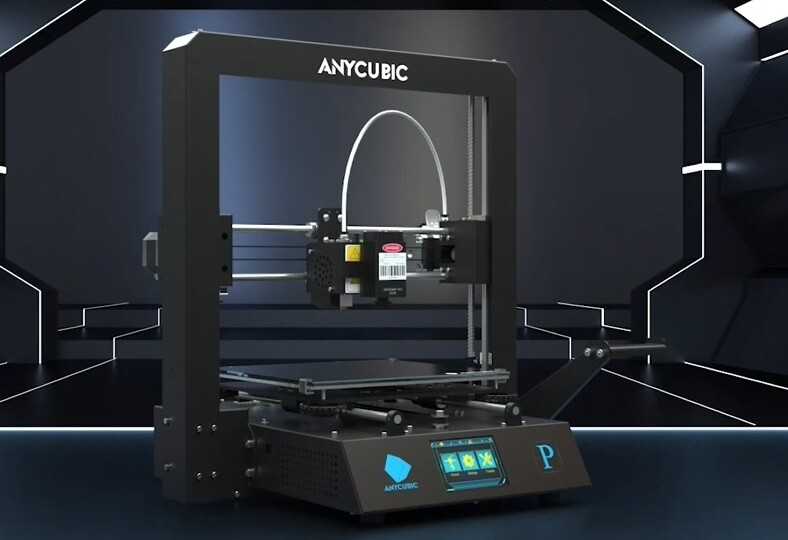

The F1000 from CreatBot offers a full cubic meter of fully enclosed and heated (60°C) build volume. There’s also a filament chamber that can hold two spools of up to 5kg each and heat up to 45°C or 65°C.

Its dual nozzles are able to heat up to 420°C, while the print bed heats up to 100°C. Compatible materials range from standard PLA and ABS to PETG and carbon fiber-filled and flexible materials.

Buy on CreatBot Get a quote Add to comparison

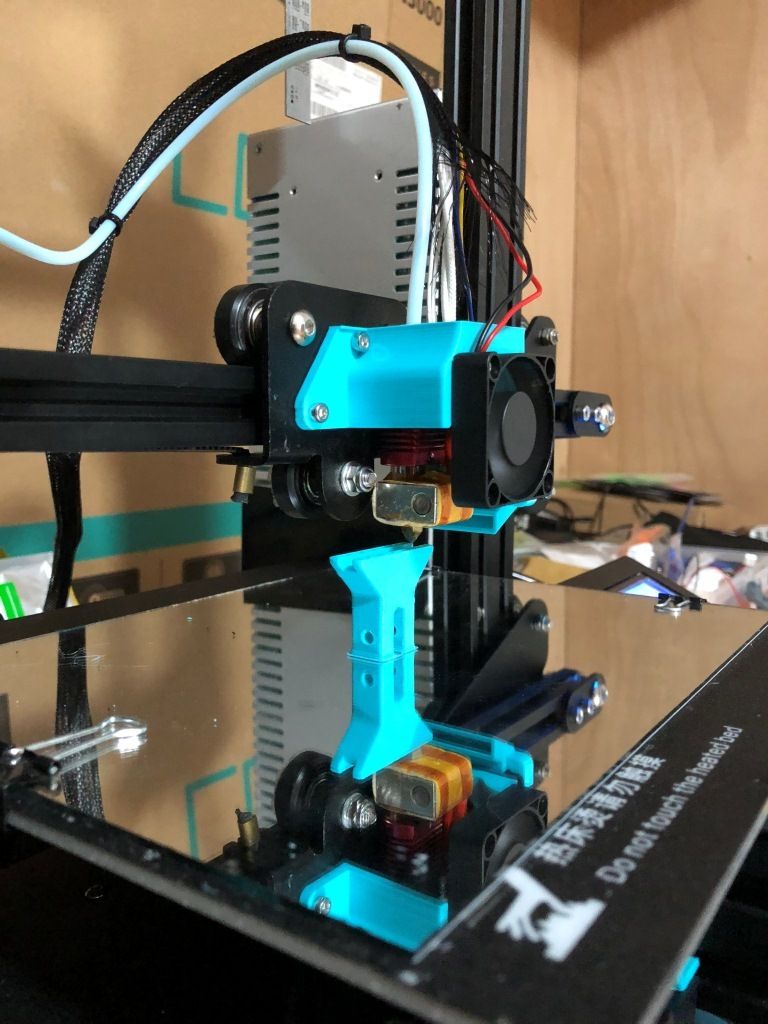

The BigRep ONE, currently in its third generation of upgrades and updates, is one of the only large-sized 3D printers to provide independent dual extrusion (IDEX). IDEX can cut production times in half thanks to duplication or mirror modes.

The printer’s large touchscreen grants access to the webcam and allows users to resume prints even after a power outage. The filament holder is able to hold multiple spools of up to 8kg.

Contact manufacturer Get a quote Add to comparison

This large format 3D printer with dual extrusion is customizable. Various extruders are available, and it’s possible to add an enclosure. The enclosure can be heated and/or include an air filter as well.

Various extruders are available, and it’s possible to add an enclosure. The enclosure can be heated and/or include an air filter as well.

It’s possible to choose from two different control systems; with Wi-Fi or with Ethernet connectivity. The automatic leveling probe touches over 400 points on the print bed to ensure optimal calibration.

Contact manufacturer Get a quote Add to comparison

The T3500, a huge delta 3D printer, offers a massive build size that can 3D print to an exact scale of 1:1 up to 2.1 meters high.

The large-scale Tractus3D T3500 can 3D print exotic materials with its hot-end extruder capable of reaching up to 300°C. This 3D printer features a heated bed and can be equipped with an optional dual extruder.

Contact manufacturer Get a quote Add to comparison

The Industry MAGNUM is a very large format 3D printer by The Industry (previously called BLB Industries), a manufacturer based in Sweden. This XXL 3D printer offers a build volume of 2. 16m³ and comes with a set of nozzles ranging from 2 to 8mm in diameter. The MAGNUM is based on the company’s previous model, the BLB Industries THE BOX.

16m³ and comes with a set of nozzles ranging from 2 to 8mm in diameter. The MAGNUM is based on the company’s previous model, the BLB Industries THE BOX.

Contact manufacturer Get a quote Add to comparison

The Massivit 10000 is an industrial large format 3D printer produced by MASSIVit 3D. MASSIVit 3D is a 3D printer manufacturer based in Israel. This 3D printer offers a build volume of 1420 x 1110 x 1500 mm.

Contact manufacturer Get a quote Add to comparison

Modix has nicknamed their printer “Personal Car Factory”, a quick way to indicate how big the MAMA (Modular Additive Manufacturing Assembler) system really is. It’s equipped with a high-speed pellet extruder, and is also capable of 3D printing with spools of filament.

This huge FFF 3D printer isn’t available yet.

Contact manufacturer Get a quote Add to comparison

Applications for large scale 3D printing

3D printing furniture

The largest 3D printers can be used to 3D print furniture in one go. This includes tables, chairs, and even bathtubs. 3D printing furniture can also generate unique, complex pieces that would be difficult to create otherwise.

This includes tables, chairs, and even bathtubs. 3D printing furniture can also generate unique, complex pieces that would be difficult to create otherwise.

Hence, customized furniture is becoming more and more accessible thanks to extra-large 3D printers.

The BigRep One is in action. Source: QMES3D printing large prototypes

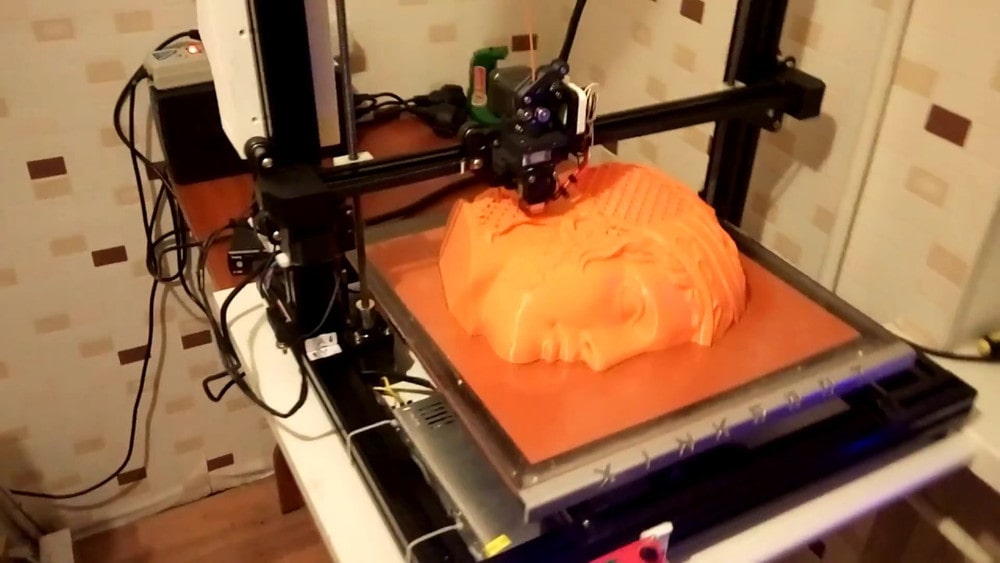

The professional large-scale 3D printers featured in our article can also be used to 3D print large prototypes. This enables businesses to test out their products before actually launching production. Industrial designers and engineers are able to perform more revisions in significantly less time.

They can test their future products extensively while at the same time reducing the production-to-market time.

3D printing production series

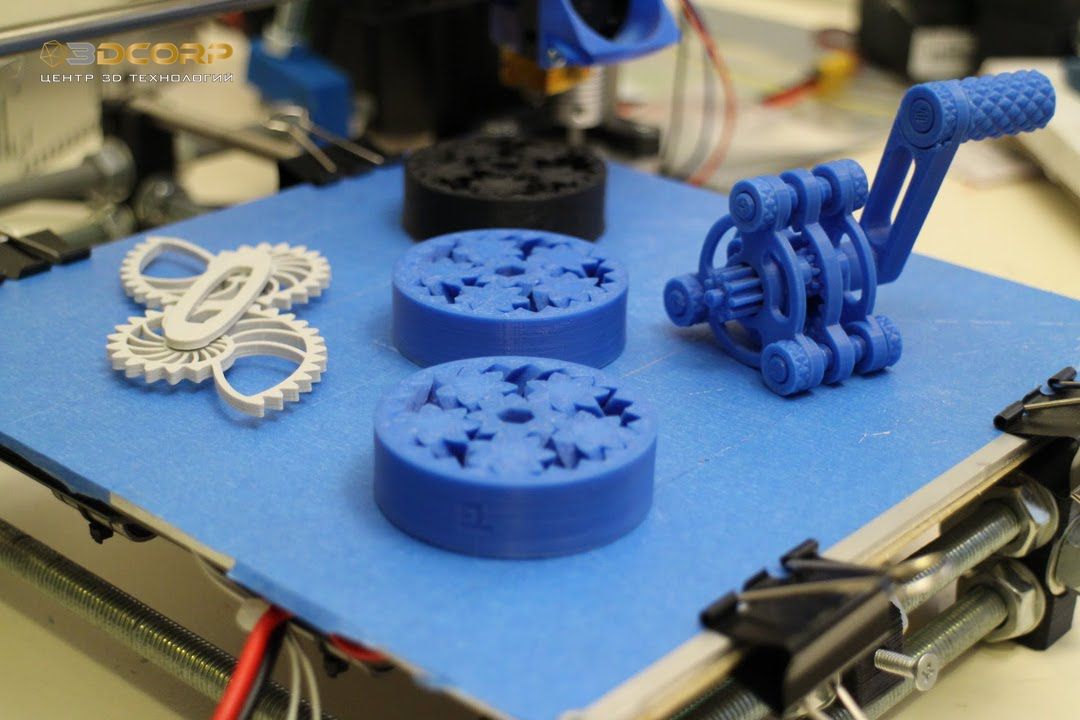

Large-scale 3D printers don’t have to exclusively 3D print large objects and prototypes. Their huge build platform also enables 3D printing big series of smaller objects.

Customized large scale 3D printers

There are several manufacturers that mainly offer tailored solutions rather than standardized 3D printer models. Tobeca, for instance, is a French team that builds 3D printers from scratch and is based entirely on their customers’ needs and requirements.

US-based Erectorbot also provides on-demand builds, although they do have a lineup of standard models. Then there’s Colossus, a company in Belgium that constructs 3D printers within shipping container-like structures. CNC Barcenas, a Spanish manufacturer, also offers tailored, large-scale 3D printers with a range of options to choose from.

9 Largest 3D Printers in the World

by Jennifer Jones

The future is now in terms of 3D printing technology! 3D printers can be manufactured to work with a variety of different materials, making their potential applications nearly endless. Today’s 3D printers are able to produce everything from plastic figurines and scale models to entire vehicle shells and buildings! As you might imagine, some of these printers have to be pretty huge in order to accommodate such impressive prints.

Today’s 3D printers are able to produce everything from plastic figurines and scale models to entire vehicle shells and buildings! As you might imagine, some of these printers have to be pretty huge in order to accommodate such impressive prints.

So, just how massive can the largest 3D printers get? Today we’ll look at 9 of the biggest 3D printers available for use today and rank them according to the volume of printing space each one provides. We’ll also learn some cool facts about each amazing machine!

-

Norsk Titanium Direct Metal Deposition

Size: 2.6 – 3.1 cubic meters / 94 – 112 cubic feet

Type of Process: Additive manufacturing

Material Types: Metals

Use and Accessibility: Industrial

Source: 3dprintingmedia.network

This 3D printer features Norsk’s carefully-developed Direct Metal Deposition technology in its 3D printing process. This process utilizes a plasma arc to weld metal directly on top of itself, building up layer after layer until the 3D print is complete. The Norsk company has a worldwide presence and boasts such influential partners as Boeing and Mecachrome.

This process utilizes a plasma arc to weld metal directly on top of itself, building up layer after layer until the 3D print is complete. The Norsk company has a worldwide presence and boasts such influential partners as Boeing and Mecachrome.

This 3D printer is capable of printing titanium parts that measure up to 120 x 120 x 180 cm.

-

ExOne Exerial

Size: 3.696 cubic meters / 130.52 cubic feet

Type of Process: Additive manufacturing / Powder binder jetting

Material Types: Metals and ceramics

Use and Accessibility: Commercial and industrial

Source: digitalengineering247.com

This 3D printer was designed specifically with a focus on serial sand core and mold production. It features ExOne’s Binder Jetting technology, meaning that it precisely places a liquid binding agent that particulate matter can adhere to. Alternating layers of liquid binder spray and particulate building material, such as metal or ceramic, are built up until the 3D print is complete.

Alternating layers of liquid binder spray and particulate building material, such as metal or ceramic, are built up until the 3D print is complete.

This 3D printer is available for purchase, but it costs a pretty penny at $500,000 or more!

-

Voxeljet VX4000

Size: 8 cubic meters / 282 cubic feet

Type of Process: Sand Casting (Powder binder jetting)

Material Types: Sands

Use and Accessibility: Commercial and industrial

Source: wikimedia.org

The Voxeljet VX4000 is used to create similar prints to those of the ExOne Exerial, maintaining a strong focus on sand casting molds. The molds produced with the VX4000 are usually then used to serially cast architectural parts, artistic components, and jewelry. The 3D printer is versatile and adaptable in that it can print either one large mold, or numerous batches of smaller ones.

The Voxeljet AG company has been listed on the New York Stock Exchange since 2013.

-

D-shape

Size: 9 cubic meters / 317 cubic feet

Type of Process: Powder binder jetting

Material Types: Sands and ceramics

Use and Accessibility: Industrial

Source: esa.int

This one-of-a-kind 3D printer was patented in 2006 after being developed by Enrico and Riccardo Dini, who also founded the Monolite UK Ltd company that built the printer. The 3D printing project actually started in 2004 with the idea to take the best parts of a standard, office-sized 3D printer and scale them up. The D-shape project operates in several different sectors, each of which focuses on different applications of 3D printing.

Did you know?The D-shape uses particulates and a magnesium-based binder to build up a finished printed material that’s extremely similar to sandstone or cement.

-

KamerMaker

Size: 14 cubic meters / 494 cubic feet

Type of Process: Additive manufacturing

Material Types: Metals, sands, and ceramics

Use and Accessibility: Industrial and construction

Source: flickr.com

DUS Architects advertises the KamerMaker as “The World’s first portable large-scale 3D printer” and has won numerous awards for its innovative achievements. This printer was also the first one to build an entire house on the canal in Amsterdam while making use of RepRap FFF-type technology. And, just in case one incredible 3D printer wasn’t enough, a second KamerMaker was created soon afterwards in order to speed up production!

Did you know?The name “KamerMaker” means “Room Builder” in Dutch.

-

Cincinnati Incorporated BAAM (BAAM CI)

Size: 25 cubic meters / 930 cubic feet

Type of Process: Additive manufacturing

Material Types: Plastics

Use and Accessibility: Industrial

Source: thefabricator. com

com

This printer is known for being able to 3D print plastic industrial parts that are strong enough to bend metal, as well as for printing an entire life-size car! The BAAM CI has also been used to produce a wide variety of other scale models, such as models of the Orion spacecraft and the F-22 Raptor. This 3D printer’s method of using thermoplastics for its prints makes the process unusually low-cost, considering the size of the final products.

Did you know?BAAM pulled off its 3D print of the Strati car with help and technology from Oak Ridge National Laboratory.

-

Sciaky EBAM 300

Size: 112 cubic meters / 368 cubic feet

Type of Process: Electron Beam Additive Manufacturing

Material Types: Metals

Use and Accessibility: Commercial and industrial

Source: sciaky.com

The titanium thread that’s melted for the printing process for the massive Sciaky EBAM 300 is 3 mm thick! This 3D printer is primarily used to repair and manufacture high-performance industrial parts. The Sciaky company launched its EBAM project in 2009 with the goal of streamlining and simplifying the manufacturing process in order to save industrial companies time and money.

The Sciaky company launched its EBAM project in 2009 with the goal of streamlining and simplifying the manufacturing process in order to save industrial companies time and money.

Among the benefits of time-cost effectiveness, the EBAM 3D printing systems also produce less waste throughout their printing processes!

-

BetAbram P1

Size: 288 cubic meters / 10,170 cubic feet

Type of Process: Electron Beam Additive Manufacturing

Material Types: Sands and ceramics

Use and Accessibility: Industrial and construction

Source: YouTube.com

Slovenian company BetAbram is said to be one of the key pioneers in terms of 3D printing houses, and the P1 is specifically engineered for the purpose of printing houses. This printer uses the reliable binder jetting process to produce a material that’s extremely comparable to concrete, making it perfectly suited to printing out architectural elements that are structurally sound. The printer also utilizes two different nozzles for different types of prints.

The printer also utilizes two different nozzles for different types of prints.

There are two different methods of operating the machine that require one to three people and strike different balances between speed and monetary expenses.

-

Winsun

Size: 2,466 cubic meters / 87,120 cubic feet

Type of Process: Powder binder jetting

Material Types: Sands and ceramics

Use and Accessibility: Industrial and construction

Source: siliconangle.com

The Winsun 3D printer is the largest 3D printer in the world. The company, known as Winsun in China and Yingchuang Building Technique throughout much of the world, states that its 3D printer can print out an entire standard-sized house for the cost of approximately $4,800 in a single day! However, there has been a fair amount of debate and controversy over whether the technology was ethically developed and some people claim that stolen patents were used to formulate Winsun’s 3D printer.

Winsun states that its printer can obtain up to 50% of the ink material used in its printing process from mine tailings and construction waste.

Top 10 biggest 3D printers in the world

Share on Facebook Share on Twitter Share on Vkontakte

Have you ever wondered how big 3D printers can be? If this has happened to you, then it's time to satisfy your curiosity, we will tell you about 10 largest 3D printers in the world. The selection criterion was the size of the object that can be created in the camera (or workspace) 3D printer .

At the end of the article you will find a slider with examples of the work of 3D printers included in this top ten.

So, let's start with the smallest large printer in our top ten.

10. Norsk Titanium

This 3D printer was created by the American company "Fabrisonic" . The technology by which it works is direct metal deposition. The size of 3D printed parts is 120 x 120 x 180 cm. Although the maximum length of the product can be up to 215 cm according to the company.

The technology by which it works is direct metal deposition. The size of 3D printed parts is 120 x 120 x 180 cm. Although the maximum length of the product can be up to 215 cm according to the company.

9. ExOne Exerial

This is Dual Chamber 3D Printer, each chamber measures 220 x 120 x 70 cm, can use metal, ceramic and sand as material, the latter is used to create sand cores and molds .

8. Voxeljet VX4000

The chamber measures 4 x 2 x 1 m and is currently the largest industrial machine, mainly used for making sand molds.

7. D-shape

The working surface of this 3D printer is a 6 x 6 meter aluminum frame. To create three-dimensional objects, a special sand material is applied layer by layer, the layers are fixed with a special binder.

The printer was patented in 2006 by Enrico Dini, founder of the British company "Monolite UK Ltd" . The first model of the printer used epoxy resin as a binder, but Dini later switched to using a magnesium-containing substance. After making this change, he again patented 3D printer in 2008. In the future, Dini wants to use the 3D printer to create full scale buildings.

After making this change, he again patented 3D printer in 2008. In the future, Dini wants to use the 3D printer to create full scale buildings.

6. Sciaky EBAM 300

The working chamber size of this 3D printer is 7.620 x 2.743 x 3.353 m. The electron beam melts the metal, which is fed in the form of a wire, and a three-dimensional object is created layer by layer according to the CAD model. Sciaky EBAM 300 works with metals such as titanium, titanium alloys, inconel 718 and 625, tantalum, niobium, stainless steel, aluminum alloy 2319 and 4043, steel 4340, zircalla and others.

5. KamerMaker

This printer was one of the earliest large scale 3D printers, and it uses fusing technology. With his help, the first 3D printed house was built on one of the canals of Amsterdam. The sizes of printed objects reach dimensions of 2 x 2 x 3.5 m, bioplastics and bioplastics are used as materials. This is an open public project that anyone can join.

This is an open public project that anyone can join.

4. WASP GigaDelta

This 3D printer can grow objects up to 8-10 meters high. The creator of this machine, Massimo Moretti, dreamed of building houses using clay as a material and with minimal energy consumption. Now the company is developing a printer with a special extruder. After the work is completed, it will be possible to create objects up to 12 meters high.

3. Cincinnati Incorporated's BAAMCI

Workspace is 25 cubic meters.

This huge thermoplastic machine was created to print the "Strati" car for "Local Motors" , which was shown at an international technology event in Chicago in 2014. Now the creators of BAAM are working on the next, even larger version of the machine, its name will be "Bertha" .

2. BetAbram P1

Working space 288 cubic meters.

Slovenian company BetAbram manufactures (on request) 3D printers in three sizes for house printing. The largest of them has a span of 9 x 16 m (the average is 12 x 6 m, and the smallest is 4 x 3 m). The printer works according to the extrusion method, the layer thickness is 25 centimeters, but it can be more. The material used is concrete.

The largest of them has a span of 9 x 16 m (the average is 12 x 6 m, and the smallest is 4 x 3 m). The printer works according to the extrusion method, the layer thickness is 25 centimeters, but it can be more. The material used is concrete.

1. WinSun

And here is the winner of the Biggest 3D printer , this is "Winsun" from China. He can create furniture and houses that can be up to 5 stories high. The material used is recycled concrete construction waste. The process of building buildings in this way is more environmentally friendly, unlike the traditional one.

And there is a scandal associated with this Chinese 3D printer : Dr. Koshnevis said that the manufacturers of "WinSun" completely copied his patented technology.

In the slider below you can see what these big additive monsters are capable of.

-

Voxeljet VX4000

Learn more about the possibilities of 3D printing:

3D printing and vacuum casting in silicone: Creation of a small series of handles of the soldering station

We create a laser diode mount for 3D printing

3D printing3d printernews

The most expensive 3D printers in the world

- home

- News AT

- World

- The most expensive 3D printers in the world

Various technologies do not stand still, they are constantly developing. This article proposes to consider the evolution of industrial 3D printers today, which are the most expensive in the world and why.

This article proposes to consider the evolution of industrial 3D printers today, which are the most expensive in the world and why.

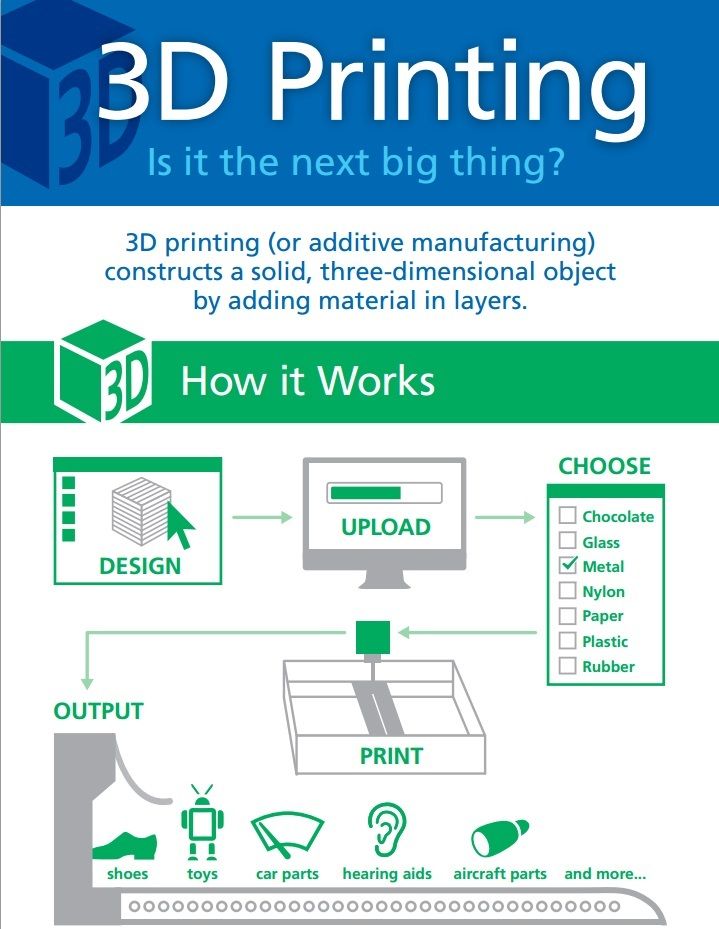

3D printers are unique in terms of the variety of different 3D printing methods, materials used and their applications. You can spend as little as $100 to get a reliable 3D printer to make a huge variety of parts from affordable plastic material. On the other hand, you can spend over a million dollars to buy a 3D printer to 3D print parts with large and complex construction geometries. They can be used in the aerospace industry, the production of space satellites or miniature biocompatible devices for medical purposes. The most expensive 3D printers on the market today use 1 to 12 powerful lasers to fuse metal powder, sinter polymer materials, or polymerize resin, and 3D printing from a given 3D model occurs by applying the powder layer by layer, which is a process additive manufacturing.

It can be noted that the size of the 3D printer does not determine how expensive the 3D printer will be. Today, the price often depends on advanced patented technologies and features that allow a 3D printer to produce fast and high-quality 3D-printed parts without requiring special technical knowledge from the operator.

Today, the price often depends on advanced patented technologies and features that allow a 3D printer to produce fast and high-quality 3D-printed parts without requiring special technical knowledge from the operator.

Some of the most expensive printers are not even for sale. Carbon 3D's 3D printers are available for rent only, which allows them to be used by many users. Others use their 3D printers on a project-by-project basis, such as the Vulcan construction printer from homebuilder Icon 3.

Stargate, the world's largest metal 3D printer built by Relativity Space to 3D print rockets, it's not for sale, but if it was, it would definitely be on our list. Many of the most exciting technologies in 3D printing can only be used for custom 3D printing, not for purchase. (Source: Relativity Space)

Let's look at the criteria that affect the cost of a modern industrial 3D printer.

Features 3 D -Printers affecting their price:

- The uniqueness of the technology when creating

- How automated the processes in 3D accuser

- Obligo

- Obligate software

- Numerous controls and adjustments

- Controlled environment inside the working chamber (use of inert gas, possibility of heating/cooling the working platform)

Let's break down these features:

Features that drive up the price of 3D printers include printer technology-specific software, real-time 3D printing control systems, and anything that automates processes that sometimes are performed manually in cheaper systems (layer leveling, subsequent post-processing or powder sieving) or processes that require knowledge of metallurgy or polymers.

Production technology requiring a vacuum chamber in a 3D printer, filling the working chamber with an inert gas, or printers that are certified for use in clean rooms and having these characteristics are significantly reflected in the final price of this equipment.

The materials used in the 3D printing process also have a significant impact on the final cost of a 3D printer. Many 3D printers only work with proprietary materials that have been developed by the manufacturer for that 3D printer. They can be metal powder, special resins filled with carbon fiber particles, and unique polymer powders. At this point in time, it is possible to 3D print anything from pure gold to advanced engineering plastics on 3D printers, even in the harsh environment of space.

There are 3D printers that can 3D print multiple materials in one job, and there are multicolor 3D printers that are also in the higher price segment.

MOST EXPENSIVE 3 D -PRINTERS

The 3D printer manufacturers discussed below are reluctant to publish exact prices for their products. This is due not only to competition, but also to the fact that 3D printers have a basic package, as well as a package with additional options according to customer requirements. That said, with that in mind, below is a look at some of the most expensive 3D printers available today - all costing over half a million US dollars - and what they provide.

This is due not only to competition, but also to the fact that 3D printers have a basic package, as well as a package with additional options according to customer requirements. That said, with that in mind, below is a look at some of the most expensive 3D printers available today - all costing over half a million US dollars - and what they provide.

E-Plus3D EP-M450H

3D printer EP-M450H LPBF (Source: E-Plus 3D)

Chinese company E-Plus3D produces industrial metal 3D printers with a large construction camera for additive manufacturing for various industries in the country. These 3D printers are used in the aerospace, automotive, electronics, and engineering industries to produce not only large-sized parts such as heavy-duty molds, but also mass-produced parts.

The EP-M450H Metal 3D Printer is the company's largest 3D printer with a build chamber of 456 x 456 x 1080 mm, producing 99.9% density metal parts from a wide range of materials at a speed of 55 cm³ per hour.

XJet Carmel 1400C

Israeli company XJet has developed a unique ceramic 3D printing technology. NanoParticle Jetting (NPJ) technology allows the production of metal and ceramic parts with a high level of detail, smooth surface roughness and geometric accuracy. The high cost of this 3D printer is not only due to the technology itself, patented materials that make this printer a serious investment, but also to the advanced automation of the 3D printer itself, which makes it easy to use.

Carmel 1400C, equipped with one of the largest 1,400 cm² work platform in the industry, which allows the production of several ceramic parts at the same time.

SLM Solutions NXG Xll 600

NXG XII 600 Large Metal 3D Printer (Source: SLM Solutions) range of printers, but its NXG Xll 600 is what the company says is a revolution in industrial additive manufacturing. The NXG XII 600 was designed for high-volume additive manufacturing and features the industry's first 12 1,000W lasers with a 600x600x600 build chamber. Lasers provide high build speed up to 1000 cm 3 /h and capacity not available for other machines.

Lasers provide high build speed up to 1000 cm 3 /h and capacity not available for other machines.

In addition to lasers, the NXG Xll 600 has all the benefits that SLM Solutions customers have been asking for over the years, including automatic start-up, laser focusing, closed powder feed and material sieving, and other latest developments.

UpNano NanoOne Bio

The Austrian company UpNano has developed a two-photon 3D printer using hydrogel-based bio-ink, which allows direct printing of 3D structures containing living cells, both at the meso- and microscale. The NanoOne Bio printer is based on the NanoOne line of laser printers capable of creating structures of 12 orders. The new hydrogel is the only commercially available resin that allows live cells to be embedded directly from culture plates into 3D printed structures for biological applications.

UpNano claims that the combination of X Hydrobio INX U200 and NanoOne Bio opens up new possibilities in biomedical research and development, both in industry and academia, allowing pharmaceutical companies and research institutes to create cell models that mimic natural growth conditions in the body person.

Black Buffalo 3D

Black Buffalo's new 1G construction printer (Source: Black Buffalo)

Black Buffalo 3D, an American company based in South Korea, officially unveiled its Nexcon 1G earlier this year, which is a 3D printer for building houses and other large concrete objects. The printer can create a 92.9 square meter structure in less than 20 hours. It uses Black Buffalo's patented cementitious material, the company calls it ink, that can be dyed to a chosen color and is also customizable to 3D print locally according to the temperature, humidity and altitude conditions of the area.

The Nexcon 1G is a modular 3D construction printer that can be extended along the X, Y and Z axes to scale up (or down) a project up to three stories high. The 1G printer is unique in that users can reposition the base rails and move the printer to a new printable area without having to remove the X or Z axis.

Optomec LENS 860

Energy Deposition (DED), which allows the recovery of large titanium components, such as those used in aircraft engines. Optomec offers several models of 3D printers that have large build chambers like 860x600x610 and laser power of 3 kW.

Optomec offers several models of 3D printers that have large build chambers like 860x600x610 and laser power of 3 kW.

The LENS 860 machining systems are ideal for the fabrication, repair or coating of medium to large metal parts.

ExOne S-Max Pro

Although many ExOne printers (now owned by Desktop Metal), they are still very affordable given that high volume 3D printers can cost quite a few zeros.

3D printers are used to 3D print complex and detailed sand molds and cores for foundries producing large metal parts for industrial use. The S-Max Pro features a 1,260 liter build chamber for fast 3D printing of sand molds and cores. A new automated print head enables fast 3D printing, while improved sand compaction ensures the density and strength of complex sand mold designs. As the most advanced system in the ExOne family of sand 3D printers, the S-Max Pro is focused on continuous 24/7 production and offers Industry 4.0 integration with cloud connectivity and real-time machine monitoring.

Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …).

Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …).