3D printing projector

A new spin on 3D printing can produce an object in seconds

Spin me right round —

Ron Amadeo -

-

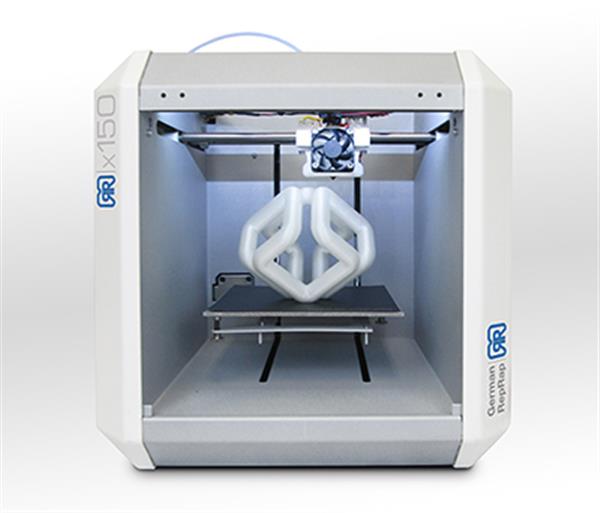

Your 3D printer is not a real 3D printer until you print 3D Benchy, a popular torture test that takes the form of this cute toy boat.

EPFL

-

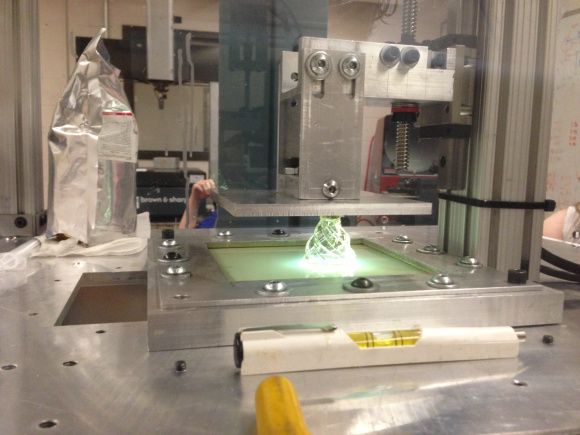

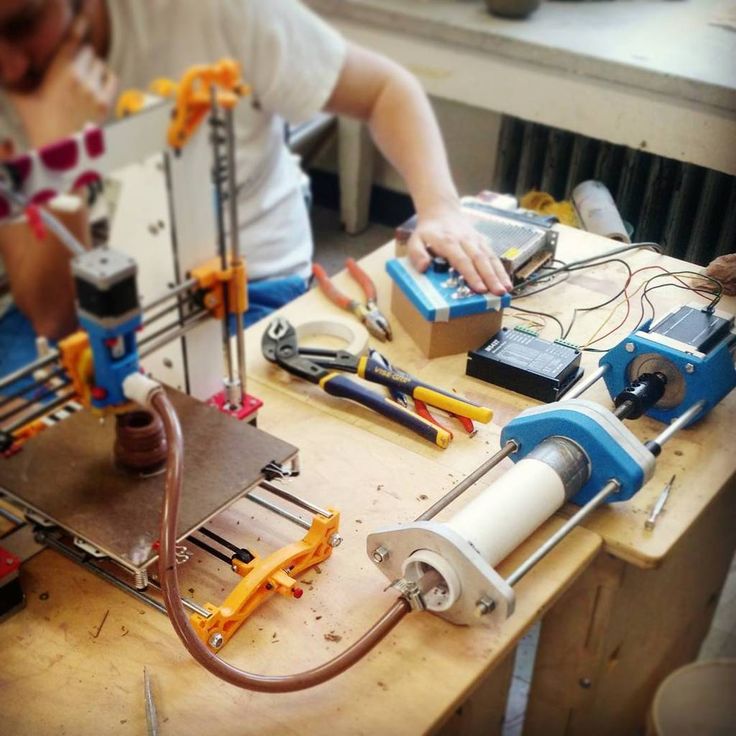

Here's how this works. The blue laser beam hits a DLP chip and produces the resin hardening image for each rotation angle, while the yellow resin container spins around in sync with the image being projected. All the red beams are just a camera system, which is used to monitor the print.

EPFL

-

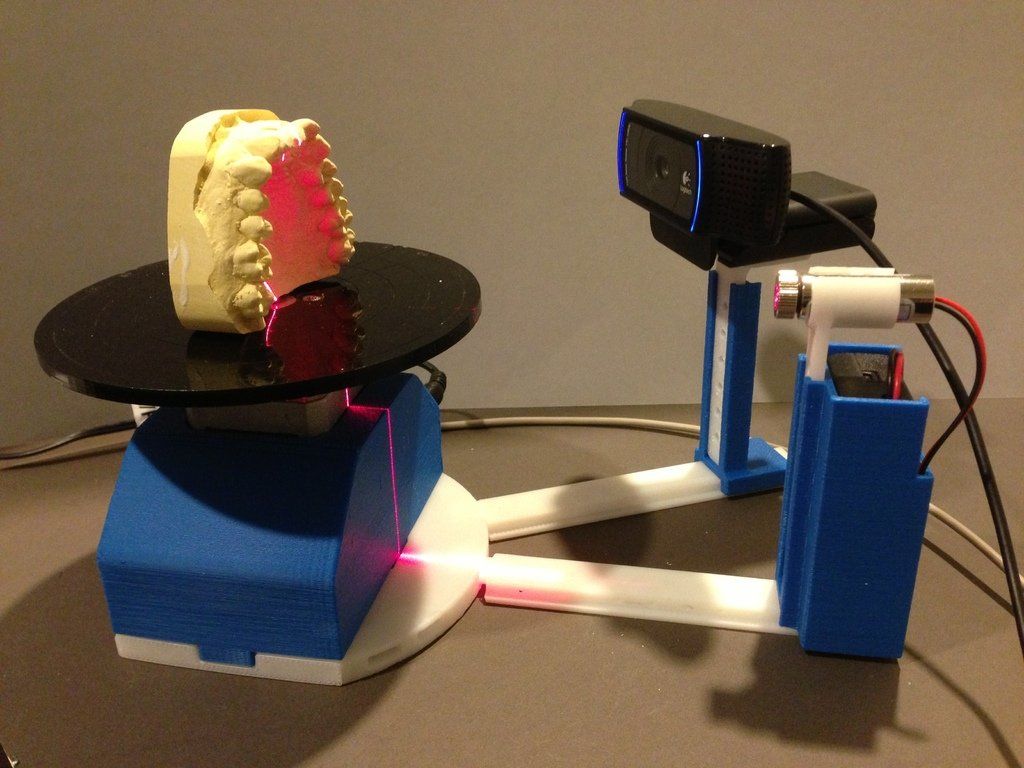

And here's the real thing in action. It's purple and pretty.

EPFL

3D printers are great for rapid prototyping and building low-volume, specialized parts, but they sure can take a while. Today's 3D printers might be called "3D printers" but really, the print heads work in 2D. A 3D model is sliced up into hundreds of 2D horizontal layers and slowly built up, one layer at a time. This layer-by-layer process can take hours or even days, but what if we could print the entire model at once? A new technique demonstrated by researchers from Switzerland's Ecole polytechnique fédérale de Lausanne (EPFL)—and further detailed in this Nature article— does just that and can print an entire model in seconds.

The new technique builds a model by hardening a photosensitive resin with a laser, not unlike existing stereolithography (SLA) printers. The big difference here is the application of tomographic techniques, the same used in x-rays and ultrasounds, that allows for rotational printing. Laser light is modulated with a DLP chip (just like in old rear-projection HDTVs) and is blasted into a container full of resin. The laser covers the entire build volume, and the container of resin actually rotates while it's being exposed to the light. The laser projects the model at different rotational perspectives, which is synced up with the spinning resin, and a whole 3D model can be produced in seconds.

AdvertisementThe EPFL writes, "The system is currently capable of making two-centimeter structures with a precision of 80 micrometers, about the same as the diameter of a strand of hair. But as the team develops new devices, they should be able to build much bigger objects, potentially up to 15 centimeters. " In this first public demonstration, the build volume is 16mm × 16mm × 20mm, making it one of the smallest 3D printers on earth. An 80 um resolution is also nothing to write home about and can be bested by ~$500 consumer SLA printers. It is very fast, though, and the technique is just getting started.

" In this first public demonstration, the build volume is 16mm × 16mm × 20mm, making it one of the smallest 3D printers on earth. An 80 um resolution is also nothing to write home about and can be bested by ~$500 consumer SLA printers. It is very fast, though, and the technique is just getting started.

Today, the most common form of photosensitive resin printers use stereolithography (SLA). These printers have a vat of resin with a window at the bottom, and on the other side of the window is a DLP projector. SLA printers still print one layer at a time: a build platform lowers into the resin from above and nearly touches the window, leaving just enough room for a single layer of resin between the window and the build plate. The DLP blasts the single layer of resin with the specific light pattern for that first layer, then the build platform moves up one layer, more resin pours in, and another layer is projected by the DLP. So a stereolithography printer hardens resin one layer at a time with a 2D display, while this rotational 3D printing method hardens resin all at once with something more akin a 3D laser hologram.

So a stereolithography printer hardens resin one layer at a time with a 2D display, while this rotational 3D printing method hardens resin all at once with something more akin a 3D laser hologram.

Another benefit to this printing technique is that by printing an object suspended in the print solution, there is no need for additional support structures. The EPFL says this makes the technique a good idea for printing delicate or soft objects, including 3D bioprinting.

The researchers have set up a spin-off company called "Readily 3D" to develop and market the technology.

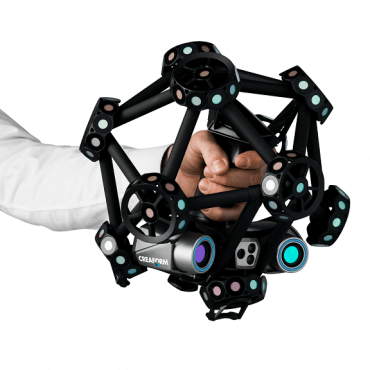

Listing image by EPFL

Projector best 3D printing models・Cults

Lion of Cine Paradiso

€16.25

Gaslands Cannon Two Set

€2.41

Christie LX500 Lens Cap

€0.96

Tombstone projector video

€3

Lithopane projector

€3. 28

28

WS2812B Projector Shroud Ring Mount

Free

Grenade Launcher

Free

Werewolf Silhouette, Wolf Man Outline, STL and SVG, Stencil, Monster, Halloween

€0.96

Fog lamp cover for NISSAN Patrol GR Y61

€3

Haunted Tree on a Hill with Jacko lanterns, Window Stencil, Projector Scene, 2D Wall Art, Silhouette, Halloween

€0.96

Halloween Cauldron Silhouette, Full Cauldron Stencil

€0.96

Witch Silhouette, Witch Head Stencil, Old Witch Halloween 2D Wall Art

€0.96

Witch with Broom Window Silhouette, Stencil, Old Witch, Halloween, 2D Wall Art

€1.44

Witch with Cauldron Silhouette, Witch Stirring Cauldron, 2D Wall Art, Window Art, Projector, Stencil, Art

€1. 44

44

Flying Witch with Moon and Bat Silhouette, Window Art, 2D Wall Art, Witch on Broom, Spooky Shadow, Halloween

€0.96

Basket for thin slides

€3

Chevy Colorado Spyder Mini h2 Adapter Plate

Free

Sliding video projector stand

€5

Acer Projector Light Frame Reducer

Free

Projector Business Card

Free

movie projector 1/12 scale

Free

Film projector Transportation Parts

€1

Mini Projector Mount

Free

BOSCH Power for All 18v Projector WITH BATTERY PROTECTION

€4

ActivEnergy - Ferrex Handheld Projector with battery protection

€5

BOSCH PRO handle projector with battery protection.

€5

Space Communist Prototype Systems Weapons Bundle

€6.11

Space Communist Thermoneutronic Projector

€1.16

Space Communist Dominator Fragmentation Launcher

€1.16

Projector mount for camper van

Free

Adjustable projector holder

€1.95

FERREX ALDI projector WITH BATTERY PROTECTION

€4

Cinema Film Logo,

Free

WORX PROJECTOR

€4

AEG RIDGID 18v projector

€4

8mm Film Reel

Free

Drawing projector, 2mm acrylic

€0. 82

82

Projector holder

Free

Batman Spotlight / Projector

€2

Optoma GT1090HDR Lens Cap

Free

Batman Signal Projector for Echo Dot 3

€3.50

Vintage Projector Bookends

Free

DIY 10$ LASER Microscope - Microscopio LASER casero 8€

Free

MAKITA 18V LXT WORK LIGHT WITH BATTERY PROTECTION

€4

PARKSIDE X20V FLOODLIGHT WITH BATTERY PROTECTION

€4

BOSCH pro 18v PROJECTOR WITH BATTERY PROTECTION

€4

MAKITA LXT 18V work light

€1.25

Light projector- Hexagonal pattern

€2. 73

73

Digital LED Projection (DLP)

- 1 DLP Technology

- 2 Technology

- 3 Application

- 4 Advantages and disadvantages

- 5 Other additive manufacturing technologies

DLP technology

Digital LED projection (DLP) is an additive manufacturing method, a variant of stereolithographic 3D printing.

Technology

One of the most popular methods for additive manufacturing of high-precision prototypes is laser stereolithography (SLA). The method is based on the use of photopolymer resins that harden when irradiated with ultraviolet light. While SLA technology is widely used in a professional environment, its distribution is limited by the rather high cost of devices due to the use of expensive laser emitters.

An alternative method uses digital LED projectors (DLP) to reduce the cost of the devices. Unlike laser systems that scan the surface of a material with one or more laser heads, DLP printers project an image of an entire layer until the polymer resin hardens, after which a new layer of material is applied and an image of a new layer of a digital model is projected.

Unlike laser systems that scan the surface of a material with one or more laser heads, DLP printers project an image of an entire layer until the polymer resin hardens, after which a new layer of material is applied and an image of a new layer of a digital model is projected.

It is difficult to judge the advantages of one method or another. DLP printing is relatively new, but is already showing excellent results, comparable in precision and performance to the original laser stereolithography (SLA) technology patented by Charles Hull in 1986 and gave the first significant impetus to the development of 3D printing. The main advantage of DLP over SLA may be the lower cost of the projectors used compared to laser emitters.

Applications

Since their inception, DLP printers have been in direct competition with SLA devices. DLP printers are used in dentistry, jewelry, freelance design and souvenir production.

Advantages and disadvantages

Like standard stereolithographic devices, DLP printers have high printing accuracy - the minimum layer thickness can be up to 15 microns using existing installations. The minimum layer thickness applied by more affordable FDM printers is usually at least 50 microns. In practice, the resolution is inversely related to the layering speed - the technology allows you to achieve even higher accuracy at the cost of lowering the print speed. Consumables, namely photopolymer resins, have a high range of mechanical characteristics: imitators are possible in the range from hard plastics to rubber. As a rule, printing is carried out with a material of one color, but there are no restrictions on the palette. The main disadvantage of the DLP method, as well as SLA, is the relatively high cost of consumables - about $ 80-160 per liter of liquid polymer. In comparison, a kilogram of FDM printing filament can be purchased for $35. Ultimately, the user must find the right balance between print quality and cost.

The minimum layer thickness applied by more affordable FDM printers is usually at least 50 microns. In practice, the resolution is inversely related to the layering speed - the technology allows you to achieve even higher accuracy at the cost of lowering the print speed. Consumables, namely photopolymer resins, have a high range of mechanical characteristics: imitators are possible in the range from hard plastics to rubber. As a rule, printing is carried out with a material of one color, but there are no restrictions on the palette. The main disadvantage of the DLP method, as well as SLA, is the relatively high cost of consumables - about $ 80-160 per liter of liquid polymer. In comparison, a kilogram of FDM printing filament can be purchased for $35. Ultimately, the user must find the right balance between print quality and cost.

Other AM technologies

- Mask stereolithography (SGC)

- Multi-Jet Simulation (MJM) Technology

- Color Inkjet (CJP)

- 3D Inkjet Printing (3DP)

- Selective Laser Sintering (SLS)

- Selective laser melting (SLM)

- Stereolithography (SLA)

- Selective heat sintering (SHS)

- Lamination of objects (LOM)

- Electron Beam Melting (EBM)

- Direct Metal Laser Sintering (DMLS)

- Electron Beam Fusion Manufacturing (EBFȝ)

- Fused Deposition Modeling (FDM)

Go to the main page of Encyclopedia of 3D printing

EnglishDLP | 3DSLA.

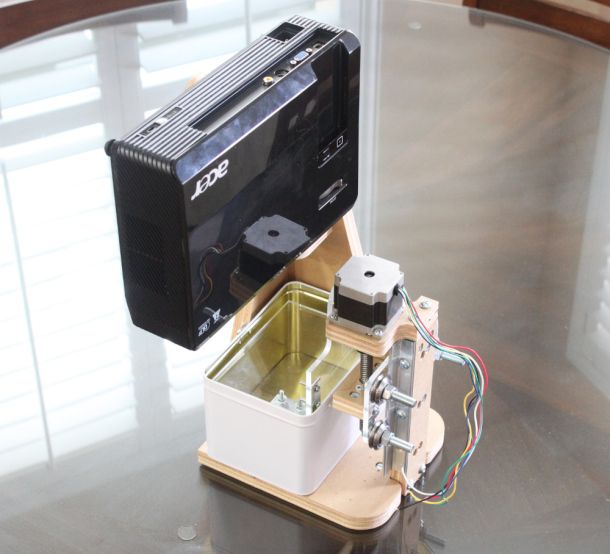

RU - Russian 3D printers® Appearance of 3D SLA DLP printer RussianDLP from 3DSLA.RU

RU - Russian 3D printers® Appearance of 3D SLA DLP printer RussianDLP from 3DSLA.RU

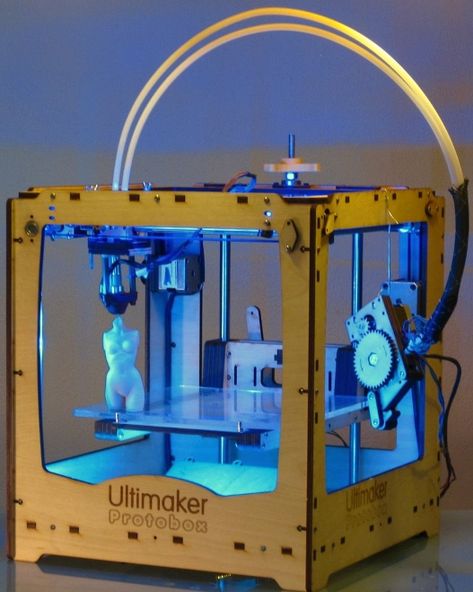

RussianDLP 3D printer — prints the highest quality 3D objects using the stereolithographic process technology (SLA).

Download brochure in PDF format

Combining the simplicity of an open housing design with precision metal printer power components and an advanced FullHD high-resolution imaging system provides a unique opportunity for rapid prototyping, hobby and professional activities.

The design of the printer provides smooth adjustment of the print area from 96x54x180mm (X and Y print resolution of 50 microns) up to 144x81x180mm (X and Y print resolution of 75 microns or more is possible with the optional Large Margin Substrate).

Z-axis positioning of the print carriage ensures layer thickness accuracy of at least 20 microns per layer. This layer thickness is quite sufficient to ensure high quality printing of jewelry prototypes with a visually even surface.

RussianDLP is the ideal printer for education clearly combines 4 areas of science: optics, mechanics, chemistry and physics. Students practicing in the laboratory with a RussianDLP 3D printer get a wonderful practical experience in modeling, and by observing the processes taking place during photopolymer 3D printing, they develop skills immediately in the complex of sciences.

Software

The printer is equipped with two service programs:

- a licensed version of the program for placing products before printing, setting supports in manual and automatic modes and cutting the model into layers for printing;

- host program that provides printing of pre-prepared slices of the model.

The RussianDLP 3D printer comes with a licensed version of a specialized slicer program (a program for preparing a 3D model for printing). The software package is constantly being developed and supplemented with new functionality.