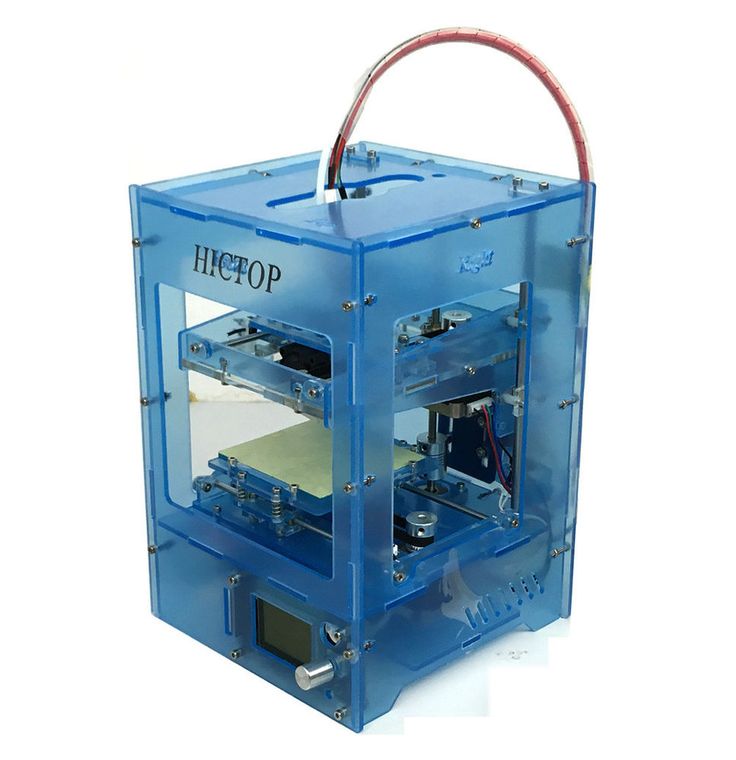

Hictop desktop 3d printer review

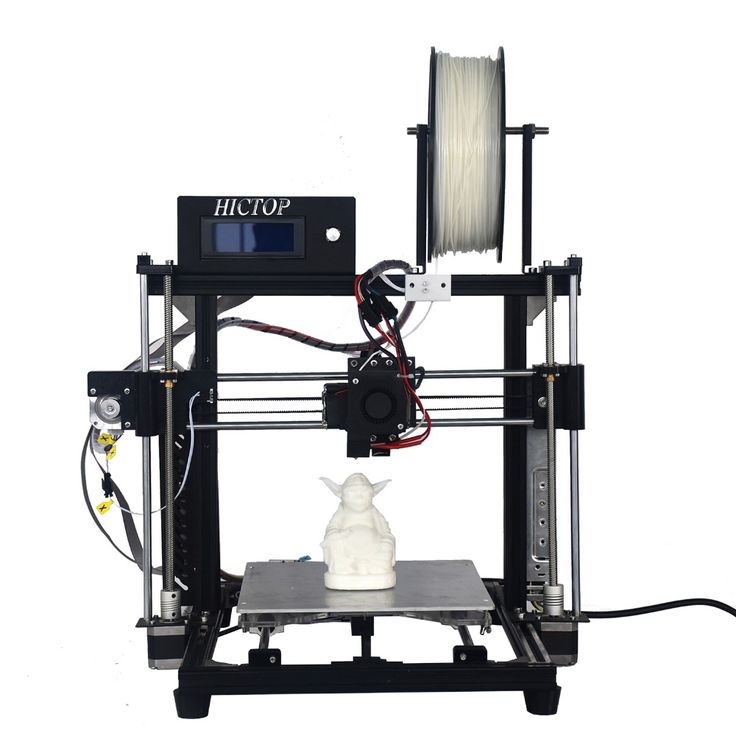

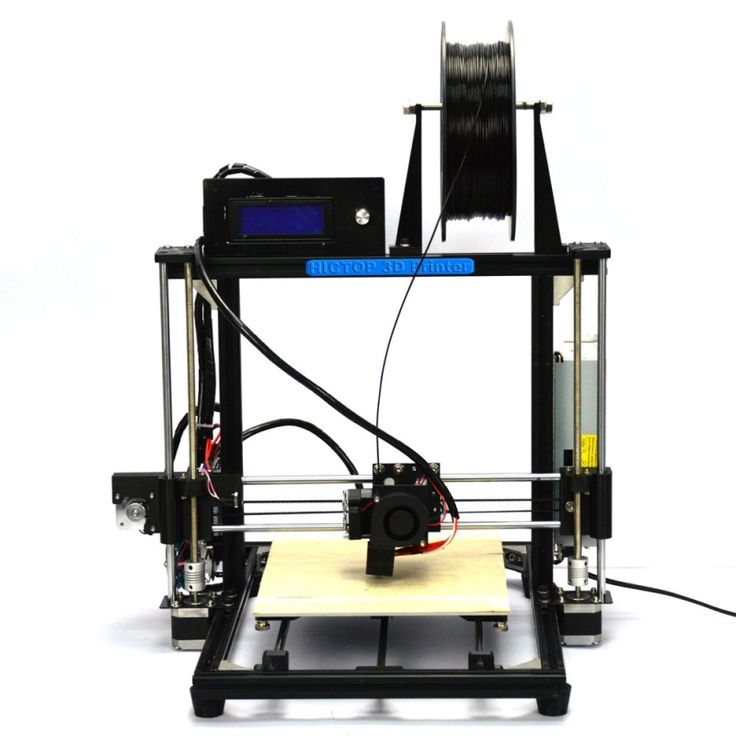

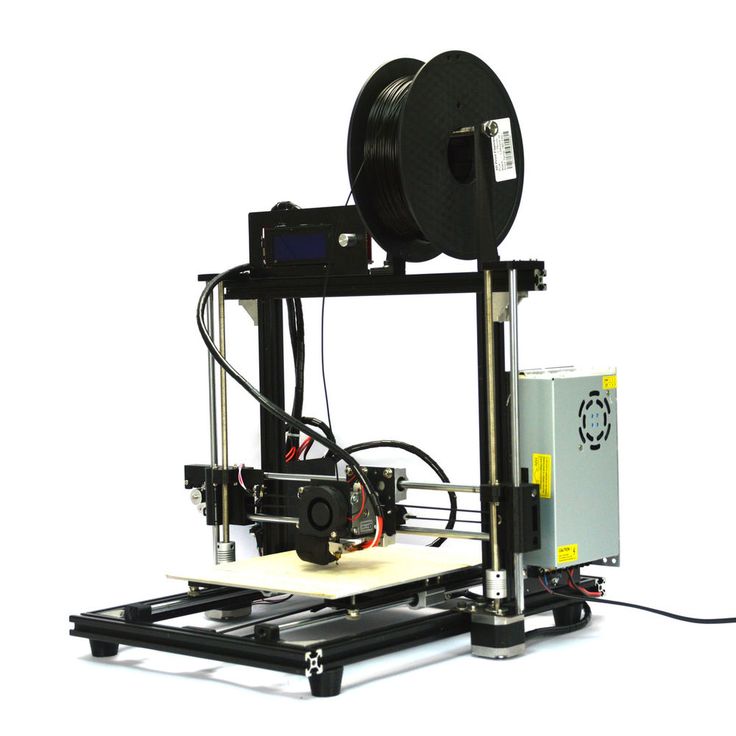

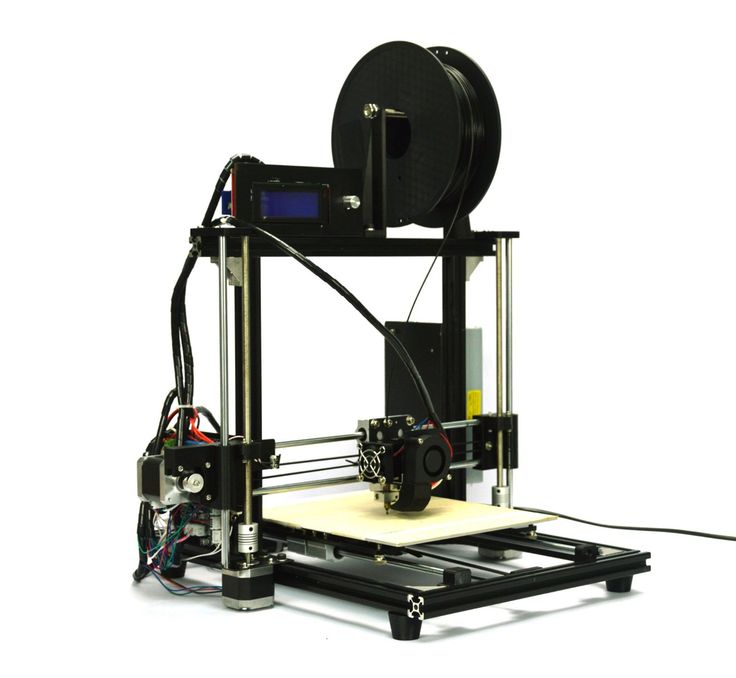

HICTOP Prusa I3 3D Desktop Printer Review (Updated 2022)

If you’re currently trying to decide what’s the best 3D printer to buy on the market at a lower budget, look no further than the HICTOP Prusa I3 3D Desktop Printer.

Before making this purchase, I literally spent hours on-end looking through every option. Reviews form other customers were an integral part to my decision-making process.

When reading reviews, make sure to take your time, because they are all accurate in a way.

This printer is for people who are comfortable with learning something new and challenging themselves, and tends to be a predominant theme with other customers purchasing the same printer.

If you do it right, you can get the print quality to be superb, and I highly recommend this printer to any teacher, student, or someone looking to gain a new hobby in the field.

Print Quality

You may notice that when you first open the printer, the quality of the prints may not be that great. That’s because you have to automatically adjust the printer settings to get it where you want to be.

The HICTOP Prusa I3 3D Desktop Printer came with the Cura software, which isn’t bad, but I prefer to use Reeptier.

After messing around with the exrusion speed, printing speed, and fill densities, I noticed that it made a big difference in the quality of my prints.

After adjusting Repeater settings, I managed to print moving parts that are key to structural integrity of certain products. This is definitely a 5-star printer for anyone who is a do-it-yourselfer.

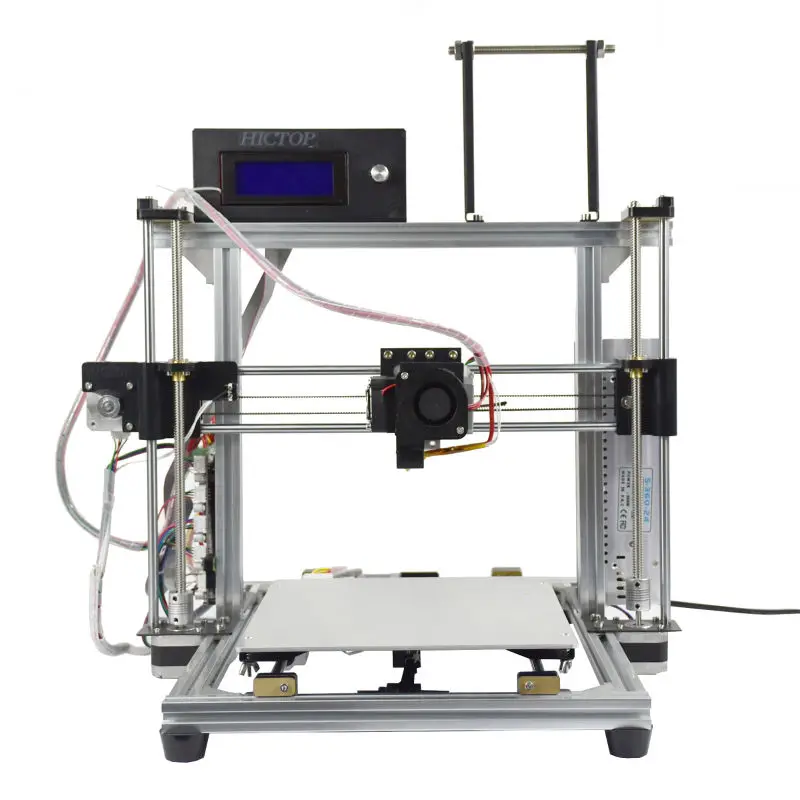

Assembly

This was a bit of a concern for me, especially given the fact that it’s my first time ordering a 3D printer.

I noticed many comments that stated that the instructions were poor. The video that shows instructions are incredibly fast and come with no words, only making the assembly that much more stressful and difficult.

However, in the midst of all of this, the building and tinkering process was definitely the most enjoyable part of buying this product. For visual learners, it’s not difficult to rewind and pause at certain points of the instructional video.

For visual learners, it’s not difficult to rewind and pause at certain points of the instructional video.

Doing so, it was easy to learn that the support structures of the z-axis movement work best when one side is left without the vertical support rod.

If both supports are in, it’s possible that the motor becomes jammed up.

It’s possible to build this machine by yourself, but if you have a friend nearby, it’s not a bad idea to have him help you out during the installation of some larger parts.

If you’re wondering how long it actually took me to completely assemble, I spent three days on it with 5 hours each day, for a total of 15 hours.

The main reason for taking such a long time is because I made a lot of mistakes having it been my first printer, and thus I had to go back and correct them.

However, this was a LOT of fun and totally worth it. Spending so much time on something that can be used for both instruction and fun is definitely worth it.

Software And Motherboard

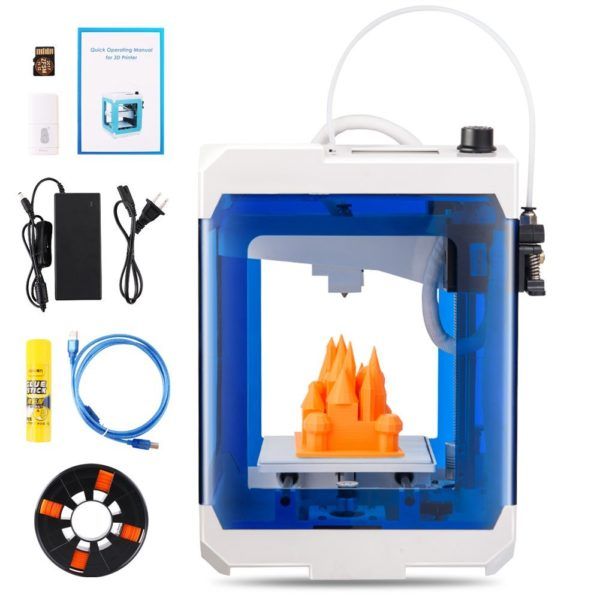

The HIC company is kind enough in the fact that they consider everything that you need to get your printer going, and therefore place it in one box.

As mentioned above, the software that’s included is called Cura and comes with a nice slicer to make your 3D prints exactly how you like them, but I definitely prefer to use the Repeater software so that I can obtain manual control of the different axes.

The motherboard that’s included is not a common one (MKS Base v1.2). While some of you might consider this a small speed bump, if you know how to code using Arduino software, it’s completely compatible (Firmware for motherboard can be found here).

My one negative comment is that the HIC Technology Company doesn’t come with a configuration.h file, the file that tells the board exactly what to do.

Ihad to mess around with a config file, but afterwards rendered the board as inoperable due to my frustration.

I emailed the company and told the my dilemma, only to be met with excellent customer service who will be able to help you troubleshoot problems if you’re patient.

Fortunately, a kind person who bought this printer was able to give me a working configuration. h file that I was able to edit for my own preferences.

h file that I was able to edit for my own preferences.

Overall, I give the motherboard 4 stars. I don’t rate it at 5 stars due to the fact that it’s not mainstream and they didn’t include a configuration file. Other than that, no complaints.

DO NOT let this deter you from purchasing this product if you’re looking for the best 3D printer out there for your budget.

Future Use

They did a good job in making the Prusa I3 3D Desktop Printer completely customizable and upgradable.

There were some things that I would’ve liked to change, and I found out that I can simply purchase different parts. For example, the Y-axis endstop.

I noticed that it doesn’t make contact with the printing bed, meaning you have to manually stop the bed while homing the printer.

For me personally, I plan on developing my own printing part that will allow the bed to auto-home, and I’m going to use this printer to make it. Definitely 5 stars for the printer’s adaptability.

Furthermore, it’s possible to install an additional extruder if you’re willing to buy the parts – the motherboard has plenty of room for that.

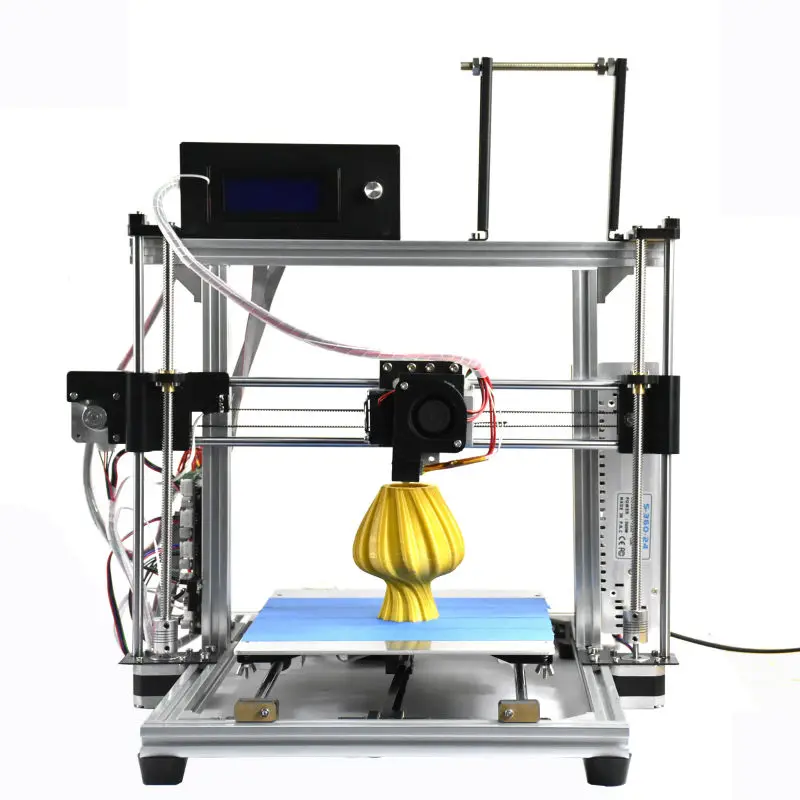

What Can You Make?

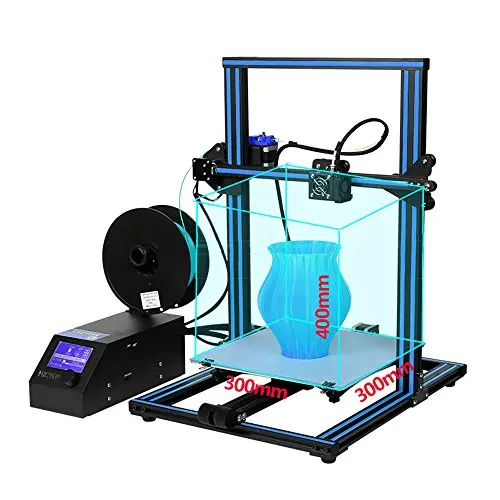

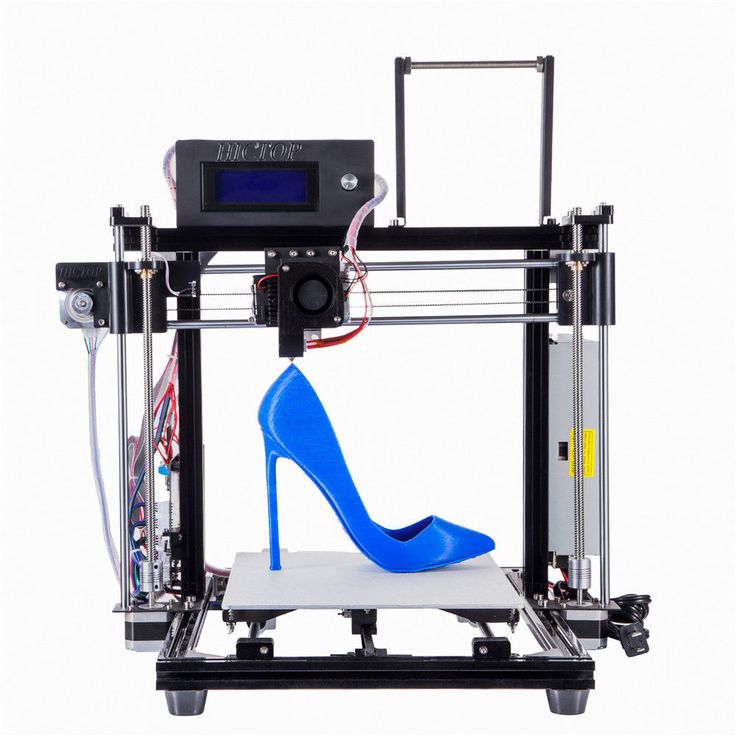

The bed is a nice, large size, especially for an introductory printer. My Repeater software thinks the bed has a size of 200x200x170, but the printer can definitely make things that are much larger.

All you have to do is adjust the configuration, endstops, and software and you’ve got yourself a top-shelf machine. The other printer that my company uses costs about $15,000 (Tech Printer).

With that being said, I’ve had friends show me their phone case projects along with other printed objects, and this printer makes projects that are highly comparable.

While this one doesn’t come with all the fancy bells & whistles, you’re still getting something that can make products that are just as good for only a fraction of the price.

I’ve made gyroscopes, toys, printer parts, office supplies, phone cases, and I don’t plan on stopping there. I plan on designing some printing disks this weekend. Another 5 stars for its potential and performance.

I plan on designing some printing disks this weekend. Another 5 stars for its potential and performance.

Final Thoughts

Based on what I’ve stated in this review, I have to give the HICTOP Prusa I3 3D Desktop Printer a 4.5 star review.

I highly recommend reading all other reviews before you purchase, as understanding that this is a learning tool is key to avoid frustration with this product.

While learning can be a bit stressful, it definitely makes the reward that much more satisfying. The software & motherboard can use some improvement, yet you can find all of the resources that you need at no cost.

Print quality is incredible, but you have to remember that this depends completely on the user. Get this printer to hone your skills in the new 3D realm.

Customer service is great, so don’t worry if you see any negative reviews on this end. If you’re looking for something that’s both a learning-tool and a powerful workhorse, you’ve definitely chosen the right printer.

For those of you who are intelligent and optimistic learners with a passion for improving and driving the scientific progress of life, it would be a huge favor to yourself to treat yourself to this experience, which I cannot fully express in words.

After my purchase, I can’t possibly be happier, as it’s EASILY the best $400 I’ve ever spent. I hope this review helps you in your 3D Printer purchasing process.

Highly recommended.

Tags:HICTOP, Prusa

[mc4wp_form]

HICTOP HICTOP Prusa I3 3D Printer

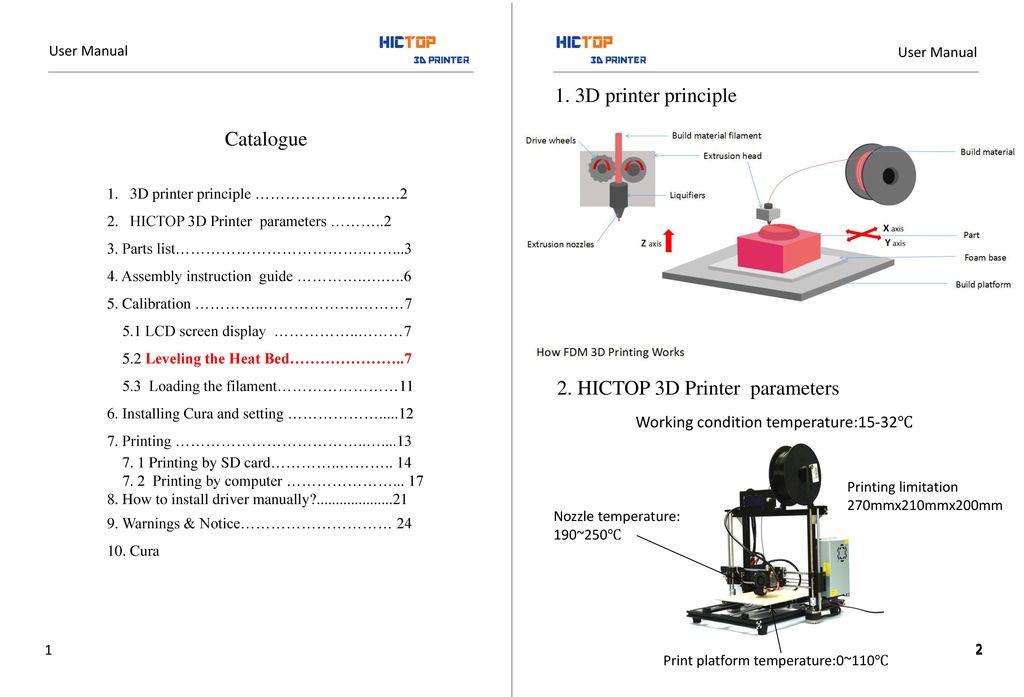

| Brand | HICTOP |

| Machine type | 3D Printer |

| Technology | FDM (Fused Deposition Modeling) |

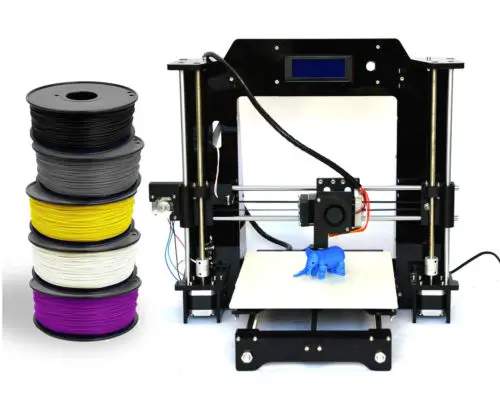

| Materials | PLA, ABS, Nylon, Bronze PLA, Copper, HIPS, FLEX (Elastic TPE), Wood PLA, Copper PLA, Rubber-like (TPU) |

| Website | http://www. hic3dprinter.com/productshow.asp?ArticleID=0&id=15&cid=001 hic3dprinter.com/productshow.asp?ArticleID=0&id=15&cid=001 |

| Average Price | Contact manufacturer |

Specifications:

Extruder quantity: 1

Printing size: 270*200*170mm

Layer sickness: 0.1-0.4mm

SD-card: Support

LCD screen: Yes (Support off-line printing)

Printing speed: 120mm/s

Standard extruder dimeter: 0.4mm

Extruder temperature: 250

Hot bed temperature: 110

Hot bed parts material: Acrylic,aluminum,PCB

XY axis positioning accuracy: 0.011mm

Z axis positioning accuracy: 0.004mm

Printing material support: ABS, PLA

Printing material diameter: 1. 75mm

75mm

Software language: English

Date import format: STL, G-Code

Device dimension: 430*505*380mm

Device weight: 8kg

Packing dimension: 470*470*330mm

Packing weight: 11KG

Power supply: 12V

Operating system: XP, WIN7, MacOS

Printing software: ReplicotorG

Working condition Temp: 10-30 degree, Humidity:20-50%

Reviews 5.0

1 reviewsPrint Quality

Reliability

Ease Of Use

Failure Rate

Running Expenses

Software

Build Quality

Customer Service

Community

Show reviews Hide reviews

Aug 4, 2022

Prusa Mini+ is a solid entry level printer that was ready right out the box. I have printed several structural items to replace broken parts around the house. Customer support from Prusa is also great to use. No issue with PLA or PETG even for a beginner. Would recommend for anyone wanting an out of the box ready 3D Printer.

I have printed several structural items to replace broken parts around the house. Customer support from Prusa is also great to use. No issue with PLA or PETG even for a beginner. Would recommend for anyone wanting an out of the box ready 3D Printer.

XYZ Nobel Superfine

Photopolymer 3D Printer ReviewHello everyone, 3DTool is with you!

Recently, we have focused on reviews of photopolymer 3D printers from Photocentric and undeservedly bypassed solutions from the Dutch company - manufacturer XYZ , known to a wide range of buyers for its line of FDM 3d printers DaVinci . But not a single filament, as the paraphrased catchphrase says. In the company's model range, there are quite a few photopolymer solutions that work both on technology SLA and DLP technology. And today we will consider one of these machines - XYZ NOBEL SUPERFINE , working on technology DLP .

Specifications

Let's start with the characteristics. Nobel XYZ SuperFine DLP 3D printer with classic design. The photopolymer is illuminated not by an LCD screen, but by an ultraviolet LED, the optical system of which is clearly visible in this photo:

Equipment

As usual, we will continue with the assembly. Complete with the printer, in addition to the original packaging, you can also find:

- Quick Start Guide.

- Quick Start Guide.

- Power supply unit and cable.

- USB cable.

- Spatula.

- USB flash drive.

- Tube for photopolymer jar.

- Resin bottle.

- Latex gloves.

- Test photopolymer itself and a cap for it.

Not the richest package, especially for a 3D printer for quite a lot of money. However, let's leave it on the conscience of the manufacturer, perhaps the printer will be able to surprise us with something else.

Appearance

As we can see, outwardly, Nobel does not really stand out from its classmates in photopolymer 3D printing technology. Powerful and heavy base with control interface, center of gravity shifted down and a large protective cap made of red translucent glass. By the way, as on the Photocentric reviewed by us in the last article, the glass is simply removed upwards. However, such a manipulation can no longer lead to illumination of the polymer, since Nobel Superfine - operates on a more understandable 405 wavelength for a wide range of users.

Working area

Obviously, the not very large size of the working platform is compensated by the print quality of the printer. However, the Nobel Superfine is designed mainly for working with jewelry, waxes and matrices, and therefore this size should be enough for most typical jewelry. 64 by 40 and 120 millimeters in height will allow you to combine products on the platform and, if necessary, place them diagonally. Fortunately, the height of the region is sufficient.

Fortunately, the height of the region is sufficient.

Of course, such dimensions will not be enough for more serious tasks, but each technique has its own purpose. So here. Print quality comes at a cost.

Mechanics and electronics

A rather well-made table console bracket provides good rigidity (it is impossible to bend by hand) and contains a driving drive, classic for such printers, in the form of a trapezoidal screw on a stepper motor. The carriage itself runs on 2m Taiwanese TBI Motion rail guides. Below is a removable cuvette with the material. By the way, the film on it also changes. On the left side of the console bracket is a cunningly shaped end switch. It is difficult to say why it is of such a shape, but apparently it allows you to determine the force of pressing.

On the left in the corner is a niche for a jar of photopolymer. Nobel is also equipped with a pumping system and an RFID tag on the bottle of material, allowing the printer to determine what he has to work with and how much resin is left.

Nobel is also equipped with a pumping system and an RFID tag on the bottle of material, allowing the printer to determine what he has to work with and how much resin is left.

Below is the cuvette presence sensor. In this case, optical.

Control systems and connectors

The connectors on the XYZ Nobel Superfine case are nothing at all. On the front there is a USB slot for connecting a UBS flash card, or a cable for diagnostics. On the back wall there is a printer on / off button and a power connector. The printer has a built-in Wi-Fi module and does not have an ethernet connection.

Let's take a closer look at the display interface.

Main menu

In addition to the control joystick with "smart" LED backlight, the front panel has an "OK" key in the middle of the joystick and a "home" key at the top right.

When the power is turned on, the printer will say hello and exit to the main menu.

- Utilities menu

The utilities menu includes the functions of refilling the polymer in the cuvette, the movement of the platform (up and down), and the function of cleaning the cuvette from the photopolymer.

- Settings menu

In this section, we can turn on or turn off the built-in Wi-Fi, sound (we are talking about the sound of keystrokes) And also turn on the power saving mode (in it, the display goes out and does not consume excess electricity)

Moving the cursor a little lower reveals more options. The first is language switching - unfortunately, Russian is not yet available. Next is Name Change. If desired, we can change the name of the device displayed on the network.

- Menu INFO

The next one will be the INFO menu. It contains diagnostic functions - Resin Status and Sensor Status, as well as the System Version section, which displays information about the assembly of the device's firmware.

It contains diagnostic functions - Resin Status and Sensor Status, as well as the System Version section, which displays information about the assembly of the device's firmware.

If desired, we can read the RFID tag of a bottle of material and see how much material it is designed for and how much is left.

Sensor Status allows you to read the printer status as follows:

C: 1 - cover (top cover) closed; C: 0 - cover not closed

Z-T: 1 - platform on top; Z-T: 0 - platform lowered

Z-B: 1 - platform in a ditch; Z-B: 0 - platform up

T: 1 - pump on T: 0 - pump off

- PRINT FROM USB menu

By default, the printer stores jobs in internal memory and must be run from there. Through this menu, we can run tasks directly from the flash card.

P.O. and features

XYZ Nobel Superfine is compatible with XYZware's standard 3D printer software, the XYZware slicer. Quite ascetic at first glance, the interface has all the necessary features. We can import a new or export an old 3D model, save the job and send it to print.

Quite ascetic at first glance, the interface has all the necessary features. We can import a new or export an old 3D model, save the job and send it to print.

After loading the 3D model, other menus and options will be available to us. Such as "formation of supports", "movement", "scaling", "rotation" and "deletion". As you can see, when loading P.O. automatically built the necessary structures under the body of the model. We can also change them manually.

After clicking on "PRINT", a window will appear with a choice of material and additional options. For example - the quality of the layer. By the way, the maximum quality and minimum layer thickness of Nobel Superfine is 25 microns. What is a kind of standard for photopolymer 3D printers at the moment.

Features and printing examples

XYZ would not be themselves if they did not provide additional equipment to their line of photopolymer 3D printers. And it is here. The company offers to buy a special ultraviolet curing chamber, which we partially considered in our review of the Photocentric Liquid Crystal Pro 3D printer, as a kit for the device itself.

Brief specifications of the camera:

Unlike some other UV curing chambers that use mercury lamps, the XYZprinting UV curing chamber uses UV LEDs. The service life of such diodes can be up to 10,000 hours. And the process itself is more even.

The chamber is also equipped with a door opening sensor. When the door is opened, the lighting process will be stopped. At the top, through the ventilation grill, you can see a rather massive radiator for the LED cooling system.

Using the user-friendly interface on the front panel, you can set the intensity of the glow, the off timer and follow the process with the indication LEDs. Also, on this panel there are buttons for turning the camera on / off and starting / interrupting the illumination process.

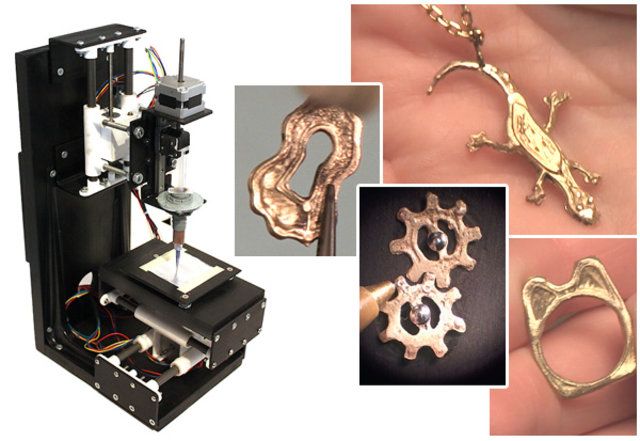

Print examples

All print examples are made from proprietary material XYZ Castable Resin with a layer thickness of 25 - 50 microns and aged in an ultraviolet chamber for 30 - 40 minutes. This material is mainly used to create matrices and waxes in jewelry and dentistry. The degree of burning out of this material is minimal.

And that's it. 3DTool was with you, see you in the next articles!

You can buy XYZ Nobel Superfine, consumables for it, or any other 3D printer right now on our website:

https://3dtool.ru/category/3d-printery/filter/manufacturer_us-is-xyzprinting /

If you need help, purchase advice, or other questions, you can contact our managers:

By mail: [email protected]

Or by phone: 8(800) 775-86-69

Don't forget to subscribe to our YouTube channel:

And to our groups in social networks:

Our website

INSTAGRAM

VKontakte

Facebook

8 nuances to pay attention to

Sooner or later, everyone will learn about 3D printing. And only a few lucky people, imbued with the opportunities that 3D printing opens up, catch themselves thinking that they want to purchase a 3D printer. The desire gradually develops into a serious decision and the search for the right option begins. And here the potential buyer is faced with the fact that he does not fully understand what to choose among the whole variety of 3D printers. We will try to answer this question in as much detail as possible. What to look for, and how to make a choice? We want to offer a small checklist of the nuances that you need to pay attention to when choosing a 3D printer. You need to decide for yourself for what tasks you will use this technique? What features should a 3D printer have to solve your problems?

And only a few lucky people, imbued with the opportunities that 3D printing opens up, catch themselves thinking that they want to purchase a 3D printer. The desire gradually develops into a serious decision and the search for the right option begins. And here the potential buyer is faced with the fact that he does not fully understand what to choose among the whole variety of 3D printers. We will try to answer this question in as much detail as possible. What to look for, and how to make a choice? We want to offer a small checklist of the nuances that you need to pay attention to when choosing a 3D printer. You need to decide for yourself for what tasks you will use this technique? What features should a 3D printer have to solve your problems?

Tip 1 : Decide on 3D printing technology

The first step is to decide on the technology of 3D printing. There are two main paths here. If you are faced with the task of manufacturing high-precision and miniature products, such as jewelry, then 3D printers using SLA or DLP technology are suitable for you. Such printers are specially designed for the manufacture of high-precision models. 3D printing in these printers occurs using a laser beam that illuminates the photopolymer resin. Hence the accuracy of the models. Prominent representatives of this segment: Form 2 3D printer or B9 3D printercreator If you are faced with a wider range of tasks, and functionality, part size, and low manufacturing cost are more important, then an FDM printer will suit you. 3D printing on this equipment involves layer-by-layer melting of plastic. If according to SLA printers everything is clear. The scope of their application is jewelry, dentistry, high-precision prototypes of small parts. Then we will dwell on FDM printers in more detail. There is a lot more variety of different options for implementing printers.

Such printers are specially designed for the manufacture of high-precision models. 3D printing in these printers occurs using a laser beam that illuminates the photopolymer resin. Hence the accuracy of the models. Prominent representatives of this segment: Form 2 3D printer or B9 3D printercreator If you are faced with a wider range of tasks, and functionality, part size, and low manufacturing cost are more important, then an FDM printer will suit you. 3D printing on this equipment involves layer-by-layer melting of plastic. If according to SLA printers everything is clear. The scope of their application is jewelry, dentistry, high-precision prototypes of small parts. Then we will dwell on FDM printers in more detail. There is a lot more variety of different options for implementing printers.

Nuance 2: Assess your needs soberly

Of course, you always want to get all the best and with maximum opportunities. Do you need all this to solve your current problems? What can be cited as an example? For example, the size of the working area of the FDM 3D printer. There are printers on the market with a large print area (1m x 1m x 1m), and with a very small one (100mm x 100mm x100mm). But for most tasks, a certain standard has already developed. This is the printable area within 200 x 200 x 200 mm. With slight fluctuations in size in one direction or another. Most 3D printers have exactly this size of the working area. This volume is enough to solve 95% of any tasks. But options are possible ... If you plan to manufacture small parts, then a smaller size will probably be enough for you. But if your work will be related to manufacturing, for example, a master model for casting, or large prototypes, then only then it makes sense to pay attention to a printer with a large print area. In other cases, the size of the print area larger than the standard is nothing more than a nice bonus. But as they say, you have to pay for everything. Therefore, most often it makes sense to focus on the “standard” print area. And even if the part you need to print is larger than the working area of your 3D printer, you can always cut it in a special editor, and then print 2 parts of the model and glue them together.

There are printers on the market with a large print area (1m x 1m x 1m), and with a very small one (100mm x 100mm x100mm). But for most tasks, a certain standard has already developed. This is the printable area within 200 x 200 x 200 mm. With slight fluctuations in size in one direction or another. Most 3D printers have exactly this size of the working area. This volume is enough to solve 95% of any tasks. But options are possible ... If you plan to manufacture small parts, then a smaller size will probably be enough for you. But if your work will be related to manufacturing, for example, a master model for casting, or large prototypes, then only then it makes sense to pay attention to a printer with a large print area. In other cases, the size of the print area larger than the standard is nothing more than a nice bonus. But as they say, you have to pay for everything. Therefore, most often it makes sense to focus on the “standard” print area. And even if the part you need to print is larger than the working area of your 3D printer, you can always cut it in a special editor, and then print 2 parts of the model and glue them together.

Nuance 3 : Decide on the complexity of the products

You should decide for yourself how complex models you will print on a 3D printer. If you plan to manufacture complex prototypes, or complex art models, then you need a 3D printer that can print with two materials. This is necessary so that your printer can print supports from soluble material. If the models are not the most complex, then you can get by with one extruder and save the budget. A complex model is a model with a large number of elements suspended in the air, or a model whose elements have angles of more than 30 degrees.

Point 4: Decide on the list of materials to be used.

Another important point. You must immediately determine for yourself a list of possible materials with which you are going to print. This primarily applies to materials with a high degree of shrinkage, such as ABS and Nylon. In order to print with such materials, a heated table is clearly required in a 3D printer. And it is very desirable to have a closed case to provide a thermal circuit around the model. If you plan to print only with PLA plastic. You don't need a heated table. But still it is better that the printer has a heated table. Now the difference in the cost of printers with a heated table is practically the same as the cost without it. But you get a universal solution with which you can perform the full range of tasks facing a 3D printer. One more moment. Ability to print with flexible materials Quite a number of 3D printers face the problem of printing with flexible materials. Of course, printing with various Flexes and Rubbers is very interesting at first glance. But the use of these materials in life is not very common. Usually, for most people, this happens like this: A couple of models are printed, and the understanding comes that this is not a fast and rather complicated process. And this is where the acquaintance with flexible materials ends.

In order to print with such materials, a heated table is clearly required in a 3D printer. And it is very desirable to have a closed case to provide a thermal circuit around the model. If you plan to print only with PLA plastic. You don't need a heated table. But still it is better that the printer has a heated table. Now the difference in the cost of printers with a heated table is practically the same as the cost without it. But you get a universal solution with which you can perform the full range of tasks facing a 3D printer. One more moment. Ability to print with flexible materials Quite a number of 3D printers face the problem of printing with flexible materials. Of course, printing with various Flexes and Rubbers is very interesting at first glance. But the use of these materials in life is not very common. Usually, for most people, this happens like this: A couple of models are printed, and the understanding comes that this is not a fast and rather complicated process. And this is where the acquaintance with flexible materials ends. Therefore, it makes sense to demand such an opportunity from the printer if printing with such materials is very necessary.

Therefore, it makes sense to demand such an opportunity from the printer if printing with such materials is very necessary.

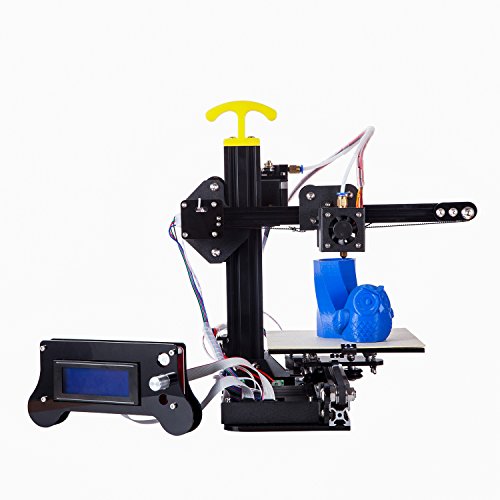

Nuance 5: Construction and kinematics

Next, you need to pay attention to the design of the 3D printer. Even if you are not a great specialist in technology, you can immediately see that some printers have an open design. And others are closed. As they like to be called in the Russian-speaking community "cubes". What does the appearance say? Printers with an open design, usually have kinematics with a horizontally moving table (based on Prusa 3D printers). This kinematics has some inherent flaws. Such as, not the highest print speed and possible print quality problems associated with the complexity of the settings. First of all, this is the so-called wobble. Also, the lack of a closed case can cause print quality problems with high shrinkage plastics (ABS, Nylon). The main advantage of printers of this design is their price. It is usually lower. But as you know, you have to pay for everything. In this case, the worst performance. The so-called "cubes" today, is the main design, which is represented by leading manufacturers on the market. Such printers are built according to the lifting table scheme. And they lack most of the shortcomings that are inherent in printers from the previous group. “Cubes” usually have a closed body, which allows the highest quality printing with plastics with a high degree of shrinkage. Closed case printers are more rigid. This results in better quality printing. The kinematics of moving the print head is represented by various designs. They have their pros and cons. But most of them have advantages over moving table printer circuits.

The main advantage of printers of this design is their price. It is usually lower. But as you know, you have to pay for everything. In this case, the worst performance. The so-called "cubes" today, is the main design, which is represented by leading manufacturers on the market. Such printers are built according to the lifting table scheme. And they lack most of the shortcomings that are inherent in printers from the previous group. “Cubes” usually have a closed body, which allows the highest quality printing with plastics with a high degree of shrinkage. Closed case printers are more rigid. This results in better quality printing. The kinematics of moving the print head is represented by various designs. They have their pros and cons. But most of them have advantages over moving table printer circuits.

Nuance 6: Diameter and changeable nozzle

Most 3D printers on the market come with 0. 3-0.4mm nozzles. This is enough to solve the vast majority of tasks facing a 3D printer. Some of the printers have the ability to install a nozzle of a different diameter, others do not. As we wrote above, the need to print with nozzles with a diameter other than 0.3-0.4 mm arises very infrequently. This mainly concerns, or personal experiments, or some very specific tasks. If you do not plan to do this, then this opportunity is not so necessary. What do we mean by specific tasks? This is especially true for printing large items, where it is very important to reduce the printing time. This can be achieved by using large diameter nozzles. For example, with a diameter of 0.6-0.8 mm, or even a diameter of 1 mm. For printers with a large printable area, the ability to change nozzles is already a vital necessity. Therefore, here, as in the case of a heated table, the ability to change nozzles is a good bonus. It is not mandatory, but very useful if you do not have to pay extra for it.

3-0.4mm nozzles. This is enough to solve the vast majority of tasks facing a 3D printer. Some of the printers have the ability to install a nozzle of a different diameter, others do not. As we wrote above, the need to print with nozzles with a diameter other than 0.3-0.4 mm arises very infrequently. This mainly concerns, or personal experiments, or some very specific tasks. If you do not plan to do this, then this opportunity is not so necessary. What do we mean by specific tasks? This is especially true for printing large items, where it is very important to reduce the printing time. This can be achieved by using large diameter nozzles. For example, with a diameter of 0.6-0.8 mm, or even a diameter of 1 mm. For printers with a large printable area, the ability to change nozzles is already a vital necessity. Therefore, here, as in the case of a heated table, the ability to change nozzles is a good bonus. It is not mandatory, but very useful if you do not have to pay extra for it.

Nuance 7: Print thickness

It is important to understand that most models on a 3D printer are printed with a layer of 0. 1-0.2 mm. These are the optimal values that allow you to achieve quality and acceptable print speed. There are a certain number of printers that allow you to print with a layer of less than 0.05 mm, and get very high quality prints. But then there is the problem of a sharp increase in print time. And if such print quality is important to you, then it probably makes sense to turn your attention to 3D printers, which we talked about at the very beginning of the article. These are 3D printers using SLA or DLP technology.

1-0.2 mm. These are the optimal values that allow you to achieve quality and acceptable print speed. There are a certain number of printers that allow you to print with a layer of less than 0.05 mm, and get very high quality prints. But then there is the problem of a sharp increase in print time. And if such print quality is important to you, then it probably makes sense to turn your attention to 3D printers, which we talked about at the very beginning of the article. These are 3D printers using SLA or DLP technology.

Nuance 8: Extruder type

Today there are two main types of extruder. This is a direct extruder in which the bar feed motor is located in the printhead itself. And the so-called Bowden extruder, where the plastic feed motor is located on the body. And the plastic itself is fed to the extruder through a fluoroplastic tube. What are the advantages and disadvantages of each type of extruder? Bowden extruder, due to the lack of a motor on the print head, has less weight. And therefore, it has greater positioning accuracy, which affects the print quality. And a higher speed of movement, which, accordingly, has a positive effect on the speed of printing. But it has one drawback. It is usually difficult to print with flexible plastics on a Bowden extruder. Such as Rubber or Flex. All its positive features, this extruder reveals when using plastic with a diameter of 2.85-3.00 mm. But this type of plastic is less common than the now standard plastic with a diameter of 1.75 mm. And therefore, users of printers with such plastic are often deprived of the opportunity to use new types of materials. Which are primarily produced in the most common form factor of 1.75mm. The direct extruder usually doesn't have such big problems with flexible plastics. Easier to set up, but due to the greater mass of the print head, it is inferior to the Bowden extruder in terms of speed and positioning accuracy. What to prefer? This is the user's choice. We just wanted to talk about the pros and cons of these extruder types.

And therefore, it has greater positioning accuracy, which affects the print quality. And a higher speed of movement, which, accordingly, has a positive effect on the speed of printing. But it has one drawback. It is usually difficult to print with flexible plastics on a Bowden extruder. Such as Rubber or Flex. All its positive features, this extruder reveals when using plastic with a diameter of 2.85-3.00 mm. But this type of plastic is less common than the now standard plastic with a diameter of 1.75 mm. And therefore, users of printers with such plastic are often deprived of the opportunity to use new types of materials. Which are primarily produced in the most common form factor of 1.75mm. The direct extruder usually doesn't have such big problems with flexible plastics. Easier to set up, but due to the greater mass of the print head, it is inferior to the Bowden extruder in terms of speed and positioning accuracy. What to prefer? This is the user's choice. We just wanted to talk about the pros and cons of these extruder types. Of course, there are many more nuances when choosing a 3D printer. But we think that even our small list will force you to look and study some points that you may not have thought about more closely. And it will save you time and money when choosing a 3D printer. 3Dtool company has extensive experience in the 3D equipment market. We work with leading Russian and foreign manufacturers, offering high-quality equipment for a reasonable price. Our service center is staffed by highly qualified specialists who are able to solve any problem in the shortest possible time, and all offered 3D printers come with a 1-year warranty.

Of course, there are many more nuances when choosing a 3D printer. But we think that even our small list will force you to look and study some points that you may not have thought about more closely. And it will save you time and money when choosing a 3D printer. 3Dtool company has extensive experience in the 3D equipment market. We work with leading Russian and foreign manufacturers, offering high-quality equipment for a reasonable price. Our service center is staffed by highly qualified specialists who are able to solve any problem in the shortest possible time, and all offered 3D printers come with a 1-year warranty.

In our assortment you can always find 3D printers for your tasks:

1) Budget 3D printers

2) 3D printers for business

3) Large area 3D printers

4) SLA and DLP 3D printers

Do you have any questions?

Call: +7 (495) 324-07-90 (Moscow) and 8 (800) 775-86-69 (toll-free in the Russian Federation) or write to the mail: sales@3dtool.