Vader systems 3d printer

Xerox acquires Vader Systems, steps into $8 billion 3D printing industry

0Shares

Xerox, the American manufacturer of printers and photocopiers, has acquired Vader Systems, a New York-based manufacturer of the liquid metal jet 3D printers.

As previously reported by 3D printing industry, most recently in October 2018, Xerox has long had eyes on additive manufacturing opportunities.

After years of anticipation on its expansion into the 3D printing industry, Xerox made the brief announcement at its Investor’s Day 2019 conference in New York. This acquisition is part of the company’s innovations strategy which aims to access a Total Addressable Market (TAM) of $8 billion for additive/digital manufacturing.

Xerox and Vader Systems declined to provide further details on the acquisition or the longer term strategy for 3D printing covered by Joanne Collins Smee and Steve Hoover during the investor day.

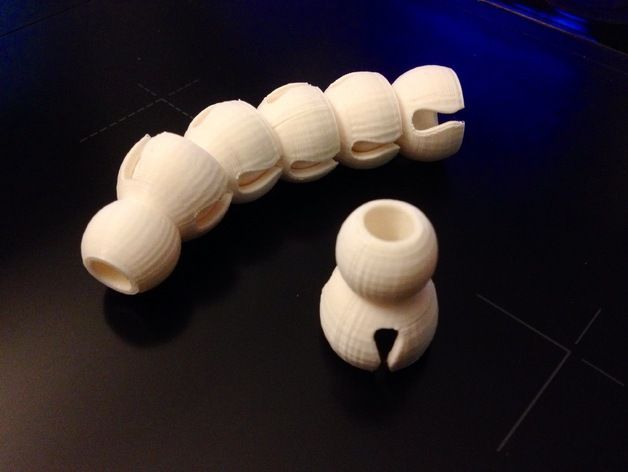

The Mk 1 Experimental metal 3D printer from Vader Systems.Xerox and 3D printing

In 2016, Janos Veres, the leader of the Palo Alto Research Center (PARC) Novel and Printed Electronics Program at XEROX, explained that the company’s planned transformation would involve 3D printing and Industry 4.0 technologies.

Then in 2017, PARC, was selected by US Defense Advanced Research Projects Agency, DARPA, to develop “a new computational paradigm” that goes beyond the limitations of existing 3D design platforms.

Following this, John Visentin CEO of Xerox announced on an investor call last year that the company is “developing a roadmap to participate in 3D printing.” Visentin stated:

“We are developing a roadmap to participate in 3D printing. We currently manufacture 3D printouts that we OEM where we have differentiated capabilities around print technologies, materials, toner and software that will enable 3D printing to move to the next level of adoption for the production of end-use industrial products.

”

Presently, according to the Investor’s Day presentation, Xerox intends to broaden the current offering of 3D printing,i.e., the prototyping market with the new acquisition.

Xerox’s Roadmap for the next 3 years shared at the company’s Investor Day Conference. this particular strategy will leverage Vader Systems’ 3D printing technology to develop new materials and processes for industrial additive manufacturing. Image via Xerox.Vader Systems Magnet-o-jet technology

Founded in 2013, Vader Systems developed and patented metal 3D printing technology referred to as Magnet-o-Jet. This process, as described by Zach Vader, co-founder of Vader Systems, “takes in metal wire feedstock that gets melted into a ceramic nozzle.”

“This makes a small pool [weighing] about 2 grams, the metal is always molten in the nozzle and then we use electromagnetism to induce a current and a radial inward force that produces a droplet.”

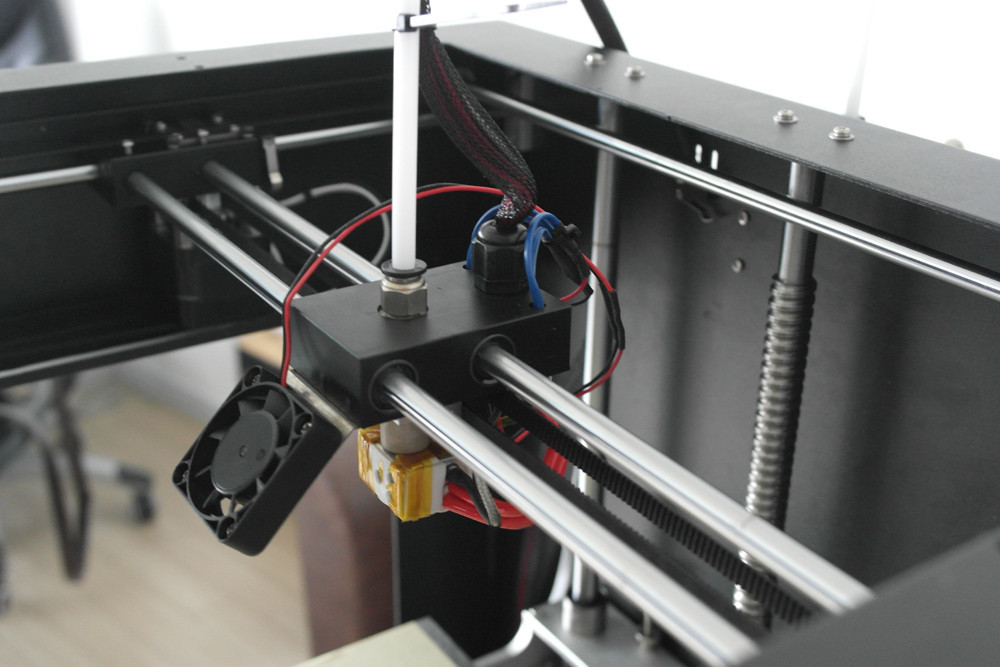

The magnet-o-jet liquid metal 3D printing subsystem. Image via Vader Systems,

Image via Vader Systems,This is done on each droplet using an electrical pulse at a rate of 1000 times a second, which results in a high deposition rate. The technology is integrated into the company’s first system, the MK1 Experimental metal 3D printer, and its three newer systems, the Vader Polaris, the Magnet-o-Jet Subsystem, and the Ares Microsphere Production System.

Magnet-o-jet technology is said to expand the range of conductive metals used within metal additive manufacturing. Such limitations within industrial additive manufacturing are also being addressed by the University of Nottingham, who established an additive manufacturing research lab in 2015 with custom metal-jetting systems. While the metal prints from Vader Systems remain near net shape, results seen by 3D Printing Industry from the metal jet technology under development in Nottingham are significantly more advanced.

Vader Systems Polaris metal 3D printing solution. Image via Vader Systems.For more updates on the Vader Systems acquisition by Xerox, subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

Also, nominations for the 3D Printing Industry Awards 2019 are open. Let us know the enterprises, technology and individuals leading the additive manufacturing sector.

Why not visit 3D Printing Jobs to commence your career in additive manufacturing?

Featured image shows the magnet-o-jet liquid metal 3D printing subsystem. Image via Vader Systems.

Tags Desktop Metal idc Janos Veres John Visentin Keith Kmetz PARC Tuan TranPham University of Nottingham Vader Systems xerox Zach Vader

Tia Vialva

Tia holds a BA in journalism, and has a background in writing news and features and is a senior journalist at 3D printing industry.

#3DStartup: Vader Systems and 3D Liquid Metal Printing

Published on June 6, 2018 by Alexandrea P.

In 2013, Vader Systems presented us with their prototype for their first 3D printer, the Mark 1, which was based on Liquid Metal Jet Printing technology. Created by Scott Vader and his son Zach, the startup wanted to make metal additive manufacturing more accessible. A few years later, they introduced the MK1, a machine based on the patented MagnetoJet technology that manipulates a liquid metal through magnetism. Like the Inkjet process, the Vader Systems solution propels droplets of liquefied metal, which helps to increase the speed of printing and lower the costs. We met with Jenae Pitts, the startup’s strategic advisor, to learn more about the solutions developed and the benefits that they offer.

Created by Scott Vader and his son Zach, the startup wanted to make metal additive manufacturing more accessible. A few years later, they introduced the MK1, a machine based on the patented MagnetoJet technology that manipulates a liquid metal through magnetism. Like the Inkjet process, the Vader Systems solution propels droplets of liquefied metal, which helps to increase the speed of printing and lower the costs. We met with Jenae Pitts, the startup’s strategic advisor, to learn more about the solutions developed and the benefits that they offer.

3DN: Can you introduce us to Vader Systems?

Vader Systems is the inventor of the MagnetoJet technology, which enables metal 3D printing for commercial use, making the technology of tomorrow available today.

Jenae Pitts

Vader’s technology is available in three platforms that provide system solutions to address the needs and requirements of the rapidly growing additive manufacturing market. These solutions include the Vader Polaris™ liquid metal 3D printing system, The MagnetoJet Subsystem for integration into hybrid manufacturing equipment, and the Are Microsphere Production System which produces Vaderite on demand – a small-batch powder for specialty additive. This innovative approach provides the market with the flexibility to use the most dynamic and innovative technology for countless customized applications.

This innovative approach provides the market with the flexibility to use the most dynamic and innovative technology for countless customized applications.

Vader works collaboratively with customers to understand their unique application and is positioned to create customized solutions. This intuitive approach delivers engineered solutions that are cost-effective while satisfying unique customer problems that can be solved by the platform of Vader’s technologies.

3DN: Can you tell us more about the MagnetoJet technology?

Vader Systems’ MagnetoJet technology represents a revolutionary advancement in 3D printing — eliminating the many issues inherent in legacy processes. Vader’s patented MagnetoJet technology employs the control and precision of an electromagnetic field to propel liquefied metal droplets and to produce high integrity, high-density parts faster and for less.

The Vader System delivers up to 1,000 droplets per second with micron-level accuracy, while more than doubling the speed of conventional 3D powder bed metal printers. The input material for a Vader System is metal wire, which is up to 96% less expensive than specialty metal powders used in powder bed machines.

The input material for a Vader System is metal wire, which is up to 96% less expensive than specialty metal powders used in powder bed machines.

3DN: What are the advantages of your technology?

The Polaris is a turnkey system used to print metal 3D parts from conceptualization to realization utilizing Vader’s patented liquid metal process. Vader is excited to announce that it can now print the most sought-after aluminum alloys in the market, including 6061 and 7075. Producing parts at rapid speeds with low-cost material and virtually no waste creates high value for customers. These advantages are compounded when also considering the safety of utilizing non-hazardous input materials, which stand in strong contrast to the substantial requirements that come with operating a powdered metal 3D printing machine.

The MagnetoJet customized subsystem is designed to integrate into hybrid manufacturing systems such as CNC and machine center equipment. By eliminating the use of powdered metal, the MagnetoJet system allows manufacturers to produce parts and precisely finish them all in one system. Vader collaborates closely with customers to assure its MagnetoJet subsystem is customized to work within existing or planned equipment and workflow. As with the Polaris System, the benefits are significant – including isotropic material properties, enhanced safety, and finished parts with near full density.

Vader collaborates closely with customers to assure its MagnetoJet subsystem is customized to work within existing or planned equipment and workflow. As with the Polaris System, the benefits are significant – including isotropic material properties, enhanced safety, and finished parts with near full density.

The Ares “Powder” System produces highly uniform and consistent metal microspheres for on-demand usage. The microspheres have been tested by a leading national lab and show best-in-class results. Printing powder on demand eliminates the need to carry powder inventory and enables a wide variety of small batch applications. The microspheres are extremely consistent with a very narrow particle distribution size. These attributes allow for excellent flowability, nearly 100% material usage, and more reliable results.

3DN: Who are your customers today and in what industries can your technology be applied to?

We focus on three markets: industrial, defense and aerospace, and research and development. Within the industrial space, we are working with customers interested in hybrid solutions that integrate our technology into current technologies, like CNC mills. We have drawn great interest from the automotive and casting industries.

Within the industrial space, we are working with customers interested in hybrid solutions that integrate our technology into current technologies, like CNC mills. We have drawn great interest from the automotive and casting industries.

Because Vader’s process does not require gravity (is not sensitive to vibration) and does not use powders, we are working with several aerospace and defense partners. Applications for this technology within this market include in-theater manufacturing, sustainment (replacement or repair of discontinued parts for land and sea craft), vertical integration of the supply chain, and printed circuit boards, for example.

The MK1 printer

3DN: What do you see in the future for metal additive fabrication?

We know the fourth industrial revolution is coming and that 3D metal printing augmented by web connectivity will be a part of it. Vader Systems’ solutions offer real value to commercial manufacturers, now, that will help the industry prepare.

What do you think about Vader Systems solutions? Let us know in a comment below or on our Facebook and Twitter pages! Don’t forget to sign up for our free weekly Newsletter, with all the latest news in 3D printing delivered straight to your inbox!

Super functional 3D printed suit

top sellers

-

Bearing 604UU U604ZZ

U-bearing U604ZZ 604UU 4*13*4

35.00 UAH

-

Thermal mat for 3D printing 200 x 200 mm

3D printing thermal pad

150.

00 UAH

00 UAH -

Buy epo3d+ 3D printer

Epo3d+ Ukrainian FDM 3D printer on HIWIN rails. Thanks to reliable...

UAH 35,000.00

-

ABS granules

ABS granules for extrusion

400.00 UAH

-

PLA

PLA environmental plastic from Plexiwire. 100% advance payment....

UAH 375.00

-

Buy ABS plastic (ABS)

ABS plastic from Plexiwire.

100% prepayment. Free shipping...

100% prepayment. Free shipping... UAH 220.00

-

Mini motor reducer 12v 100 rpm

high torque mini electric motor. Its size...

150.00 UAH

-

Nozzle for 3D printer 1.75 mm, for E3D and MK8 hotends

3D printer nozzle 1.75 mm 0.2/0.3/0.4/0.5

35.00 UAH

-

PETG plastic for 3D printer

PETG plastic from Plexiwire. 100% prepayment. Free...

UAH 360.00

-

SHF-20 shaft support

SHF-20 shaft support is used for CNC

60.

00 UAH

00 UAH -

A4988 stepper motor driver

35.00 UAH

-

Buy epo3d 3D printer

Ukrainian epo3d 3D printer built on the basis of modern kinematics...

UAH 18,000.00

All best sellers

Information

3D Printed Super Functional 3D Suit

Star Wars is undoubtedly one of the most popular movies and Darth Vader is perhaps the most iconic character. Fans will soon be able to dress up as a Sith warrior in a super realistic, functional Darth Vader costume.

The Darth Vader costume is far from new to fans of the Star Wars fandom, but a Vancouver high school music and design teacher is raising the bar. Aaron Warbinek designed and constructed a life size Sith Lord with a ventilation system, lighting, sound effects and a voice changer.

Aaron Warbinek designed and constructed a life size Sith Lord with a ventilation system, lighting, sound effects and a voice changer.

The entire suit, except fabric, electronics and lenses, is 3D printed and can be printed on most consumer 3D printers. Its creator plans to launch a 3D printable file pack and detailed instructions for fans.

The complete suit is actually quite complex and well thought out, consisting of custom printed circuit boards to keep electrical complexity to a minimum. It also has magnetically mounted parts for a comfortable fit and spring-loaded shoulder pads for a comfortable fit.

Most of the components of this suit are 3D printed, from the shoulder pads to the helmet. Other parts of the costume, such as the cape, lenses, and even the electronics, are custom-made for this project, mostly by the creator himself. In fact, the entire project was carried out by Aron alone, in his spare time, over the course of a year, including prototyping 3D printed components from scratch, developing electronics, and creating instructional material.

The suit is powered by a Tesla battery that maintains all functions for several hours. The presentation is planned at the Maker Faire festival in Vancouver.

When buying a 3D printer at home, we plan to create small models like vases, toys or lamps. But sometimes the process is so addictive that grandiose projects are obtained. And you realize that you are no longer a music teacher, but perhaps the creator of Hollywood costumes, and a 3D printer changes your life.

Vader Systems demonstrates prototype 3D hot metal printer

News

Follow author

Subscribe

Don't want

5

Vader Systems continues to develop 3D printers for printing with metal melts. The creators promise high performance and safety along with the possibility of using cheap consumables.

Vader Systems is a family run startup formed by father and son Scott and Zachary Vader. Since 2012, the company has been trying to create 3D printers for printing with metals and alloys. The developers are guided by an unusual scheme involving the application of drops of metal melts using a magnetohydrodynamic dispenser.

Since 2012, the company has been trying to create 3D printers for printing with metals and alloys. The developers are guided by an unusual scheme involving the application of drops of metal melts using a magnetohydrodynamic dispenser.

At the RAPID + TCT show in Fort Worth, the startup announced an additive system called "Polaris" that can print various aluminum alloys, including 4043, 6061 and 7075, as well as copper and bronze. The prototype certainly works, but so far the system is only capable of producing fairly rough workpieces.

Although developers claim the possibility of growing complex geometric shapes, there are limitations associated with the complexity of building suspended structures. Most likely, this will require growing supports, similar to FDM printing, which will complicate post-processing and increase waste. However, the technology shows high productivity, allegedly reaching 0.45 kg / h, and uses cheap welding wire as consumables.

The size of the construction area of the Polaris 3D printer reaches 305x305x305 mm, although the company intends to offer a specialized Magnet-o-Jet head separately, for installation on robotic arms or integration into machining centers. A head with a ceramic hot end heats up a metal wire to 750°C, and the resulting melt is squeezed out drop by drop by a pulsating electromagnetic field at a rate of about 1000 drops per second. Low residual stress and high density exceeding 99%, eliminate the need for additional heat treatment.

One of the prototypes has been running since July last year at the Additive Technology Center at the Rochester Institute of Technology (RIT). When to expect to enter the commercial market and how much such 3D printers will cost, the developers have not yet disclosed. Additional information can be found on the official website of Vader Systems at this link. See how it works below:

Do you have interesting news? Share your developments with us, and we will tell the whole world about them! We are waiting for your ideas at [email protected].

Follow the author

Subscribe

Don't want

5

More interesting articles

7

Subscribe to the author

Subscribe

Don't want

Startup NewStep of the North-Western Nanocenter has developed and patented the first system in Russia for device...

Read more

6

Subscribe to the author

Subscribe

Don't want

We summarize the results of the #Obzor2022 contest and announce the winner.