Best 3d printer for orthodontics

Choosing the Best 3D Printer for In-Office Aligners

You are here: Home / Orthodontics / Choosing the Best 3D Printer for In-Office Aligners

Dr. Melissa Shotell, DMD, MS · ·

A question that comes up on a regular basis by clinicians is… “what is the best 3D printer for in-office clear aligners?” Great question, let’s dive into it!!

We live a time and era where there is a race to quantify ‘the best technology available’ in dentistry and many clinicians look to formulas or recipes for success when implementing new technology and workflows into practice. Frankly, our brains are programmed from dental school to choose that elusive ‘best’ option at all times. When it comes to 3D printing, the true struggle when selecting a printer for an office is that what is best in my office and workflow may not be best in another doctors office. My solution to this question is to ask the inquiring doctor “what do you want to print, and then choose what will work ‘best’ in your workflow?

When selecting a 3D printer we must first look at a broad array of factors that will influence our decision in selecting our “best” option. I have selected my top five factors to consider when selecting a 3D printer. Some of the many factors to evaluate when looking at 3D printers include:

- Physical size of the 3D printer and laboratory space available

- Types of resins available

- Size of build platform

- Speed and accuracy

- Print production capability start to finish

While some of these factors may seem self-explanatory, it is important to evaluate each factor individually and how these will contribute to 3D printer selection for in-office clear aligner in an orthodontic office or general practice.

1. Physical size of the 3D printer

In many dental offices, space is a hot commodity and if the laboratory area is small, a printer with a large footprint may not fit conveniently into the space allocated. Be careful about printer size too, it’s also important to consider the resin wash and/or light curing stations when mapping out a new 3D printing digital workspace.

With many of the new desktop style 3D printers these can be conveniently placed in a small laboratory. Smaller units, such as the WhipMix Veribuild LCD printer is small and compact for desktop style use yet has a small build-platform.

Medium sized desktop units like the Formlabs Form3 and SprintRay Pro are larger overall in size but have a large build platform for higher volume printing.

Multiple 3D Printers in a Dental OfficeDimensions of Form3 Printer (Courtesy Formlabs)Dimensions of Nextdent 5100 Printer (Courtesy 3D Systems)Fitting in desktop-industrial printers such as the Nextdent 5100 3D Printer or the Asiga Max 4k Pro Printer units may be extremely challenging in many dental offices.

2. What types of resins are available for the 3D printer

One of the first questions to ask yourself is: “What do I want to print?” It is important to know what we want to print because this will dictate the type of resins the printer needs to be capable of printing. For a clinician or technician looking to print surgical guides and clear aligner models this doctor will need a printer capable of printing not only model resin for aligner models but also biocompatible resins.

For a clinician or technician looking to print surgical guides and clear aligner models this doctor will need a printer capable of printing not only model resin for aligner models but also biocompatible resins.

Many 3D printers use proprietary resins specific for the printer and most printers have a limited number of resin types available. 3D printing for clear aligner models is typically done with model resins and almost all 3D printers available in the dental space have model resins available but it is important to consider the color and type of resin prior to purchasing a 3D printer and if the doctor will use these models as presentation models with the patient.

Collection of 3D Printed Resins for Various PrintersWhen considering printing biocompatible resins for use in the mouth with occlusal guards, dentures, surgical guides, etc. a clinician and/or technician must determine what they want to print as not all resins are available to each type of printer. The nice thing is that when it comes to printing for in-office clear aligners, we do not have to worry about biocompatible resins since all clear aligners are created by vacuum forming. This comes in handy if one wants to integrate a Formlabs 3D printer as the non-dental version Form3 is $1,500 less expensive than the dental version Form3B. The difference? The more expensive dental version can print resins that are considered biocompatbile such as their Dental SG or Dental LT resin line, however, the less expensive version can print Grey resin for clear aligner models! The key is to figure out “what do I want to make” prior to purchasing and to make sure if you want to utilize only one printer for multiple tasks, it critical to check resin availability prior to purchasing the 3D printer.

The nice thing is that when it comes to printing for in-office clear aligners, we do not have to worry about biocompatible resins since all clear aligners are created by vacuum forming. This comes in handy if one wants to integrate a Formlabs 3D printer as the non-dental version Form3 is $1,500 less expensive than the dental version Form3B. The difference? The more expensive dental version can print resins that are considered biocompatbile such as their Dental SG or Dental LT resin line, however, the less expensive version can print Grey resin for clear aligner models! The key is to figure out “what do I want to make” prior to purchasing and to make sure if you want to utilize only one printer for multiple tasks, it critical to check resin availability prior to purchasing the 3D printer.

3. Size of build platform

When considering different 3D printers for an office it is important to look at the size of the build platform to see if the build platform can accommodate all sizes of models that will need to be printed. One important aspect to consider is that footprint size of the printer and size of the build platform are not always correlated! Some of the largest 3D printers in the dental space have relatively small build platforms.

One important aspect to consider is that footprint size of the printer and size of the build platform are not always correlated! Some of the largest 3D printers in the dental space have relatively small build platforms.

Many of the 3D printers in the dental space can print at least two models printed in a horizontal orientation, but this will not provide the volume typically needed for in-office clear aligners. The work around for this solution is to print models in the vertical orientation as described in an earlier article on the topic that I wrote comparing horizontal vs vertical 3D printing for clear aligner cases.

Looking at some of the larger build platforms for production style printing in in-office clear aligners the SprintRay Pro and Form3 offer larger style build platforms in a desktop size printer.

Size of Sprintray Pro Build Platform (Courtesy Sprintray)4. Speed and accuracy of printer:

Speed and accuracy do not always go hand-in-hand in the 3D printing world. Typically, if looking to print models quickly there is a trade-off in accuracy and printing at slower speeds allows for more detailed accurate models. When printing for in-office clear aligners and retainers my preference is to print at 50 microns to capture a high level of detail in the models, printing at this level of detail will take longer than printing at 100 microns so when speed is needed for a same-day retainer or aligner I will often print at the lower resolution to gain speed.

Typically, if looking to print models quickly there is a trade-off in accuracy and printing at slower speeds allows for more detailed accurate models. When printing for in-office clear aligners and retainers my preference is to print at 50 microns to capture a high level of detail in the models, printing at this level of detail will take longer than printing at 100 microns so when speed is needed for a same-day retainer or aligner I will often print at the lower resolution to gain speed.

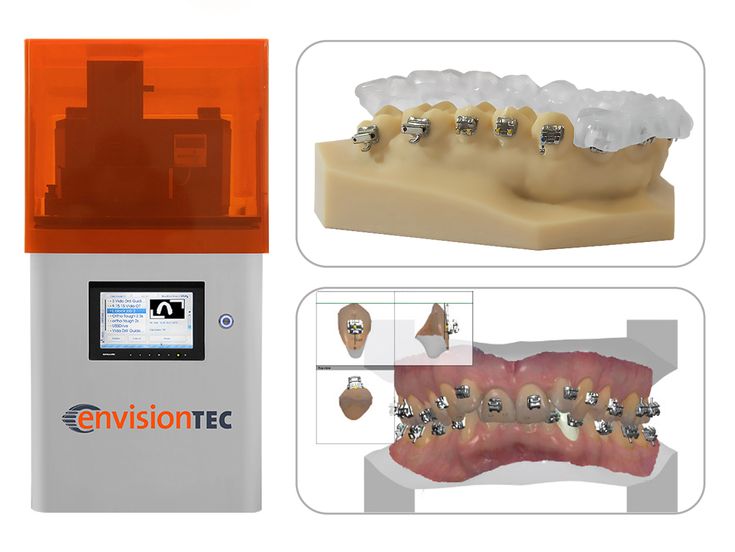

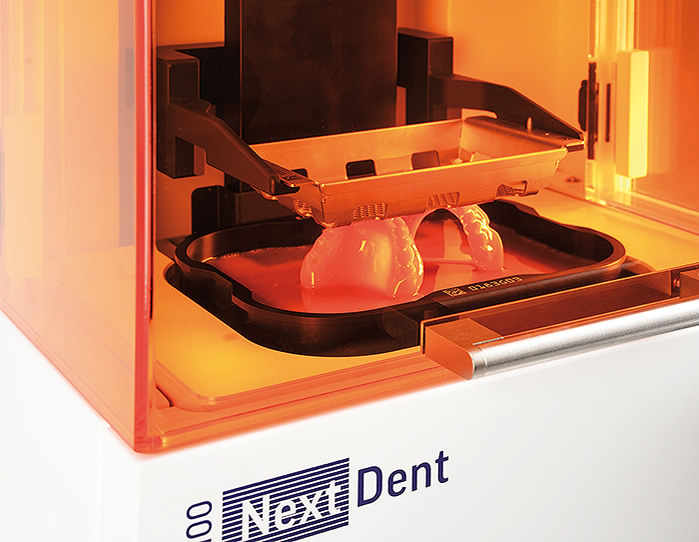

While it is more difficult to print at a high rate of accuracy when printing fast some 3D printers have found a great balance between these two properties. The NextDent 5100 printer by 3D Systems has managed to harness the capabilities of speed at a high levels of accuracy.

I often turn to the NextDent 5100 for same-day aligners and retainers where I can produce high quality models in approximately ten minutes. While the NextDent 5100 can print at incredible speeds the trade-off is the small build platform, although you can stack up to 40 models in a single print using the Nextdent printer.

The SprintRay Pro while not as fast as the NextDent printer, it has a large build platform and is able to print aligner and retainer models in under an hour. The Form3 by Formlabs fills a space in the market that looking for incredible print quality with a smooth finish, the Form3 has a large build platform and can produce aligner models in under two hours.

5. Print volume in the office

When printing for in-office clear aligners print volume become important to minimize the number of model batches printed per print which adds up over the course of a day, week, or month. With a larger build platform or printing in the vertical orientation a larger volume of models can be printed at a time, minimizing the labor of monitoring the printers and restarting batches.

Multiple Arches Printed on Form2 3D Printer for Clear Aligner TherapyThe large build platforms of the SprintRay Pro and medium sized build platform of the Form3 lend well to printing large volumes of models.

The unique stackable printing of the NextDent 5100 printer allows for up to forty models at a time to be printed in a single print cycle with the stacked formation. This unique stacked printing function creates a high-volume laboratory environment for large busy practices.

When evaluating all of the 3D printers I have in my laboratory all are capable of printing for in-office clear aligners but I turn to different printers at different times depending on the requirements of the printing job.

Interested in learning more? I put together this video discussing the topic in a bit more detail, check it out:

Are you interested in getting into clear aligner therapy but unsure if they really work? Are you a general dentist interested in getting into orthodontics but not know where to start? Check out our comprehensive fast-track clear aligner course featuring diagnosis and treatment planning, how to get started with clear aligner laboratories, the differences in technology, step-by-step clinical procedures from taking records to delivering aligners and monitoring your patients until case completion. We cover the basics to getting you started with clear aligner treatment using traditional and digital methods for recording taking, step-by-step clinical and laboratory workflows, insurance/billing and growing your clear aligner practice through innovative marketing strategies. The clear aligner course is eligible for up to 12 hours of continuing education credits.

We cover the basics to getting you started with clear aligner treatment using traditional and digital methods for recording taking, step-by-step clinical and laboratory workflows, insurance/billing and growing your clear aligner practice through innovative marketing strategies. The clear aligner course is eligible for up to 12 hours of continuing education credits.

Interested in 3D Printing your own clear aligners? Check out our step-by-step 3d printing course featuring creating your own branded in-house clear aligners by designing and 3D printing your aligner cases. We teach you the secrets, step-by-step on how to set-up your cases (or outsource setup!) and then 3D print models for aligners, vacuum forming aligners, and then finishing and delivering them to the patient! The clear aligner course includes the entire fast-track clear aligners course mentioned above and is eligible for up to 27 hours of continuing education credits.

Digital Dentistry, Orthodontics 3d printing, formlabs, nextdent, sprintray, whipmix

About Dr. Melissa Shotell, DMD, MS

Dr. Melissa Shotell is a Board Certified Orthodontist and practices in a multi-specialty practice in Sonora, CA focusing on the interplay of Orthodontics and restorative treatment. Dr. Shotell received her DMD at Nova Southeastern University and advanced hospital training a General Practice Residency Certificate from The Ohio State University. After spending years in general practice treating a broad range of patients, Dr. Shotell returned to complete a certificate and master’s degree in Orthodontics from Loma Linda University. At Loma Linda University, Dr. Shotell focused her training on cutting-edge three dimensional imaging technology for diagnosis and treatment planning for interdisciplinary dentistry. Dr. Shotell considers education to be her passion and regularly consults and lectures on dental technology, clear aligner therapy, orthodontics, office efficiency and workflow, and teamwork.

LCD Resin Printers for Crowns and Other Dental Appliances from China etc

Since the introduction of the first 3D printing technology in 1986, additive manufacturing has been showing impressive growth in the constantly increasing range of industries adopting the cutting-edge technologies. Dentistry is among those taking all the benefits of 3D printing most willingly and rapidly.

Credit: placervilledentistry.com

This is Top 3D Shop, and in this article, we are going to discuss different aspects of digital dentistry and find out which 3D printing solutions are the best fit for this application.

Biocompatible dental 3D printing for labs and clinics

Credit: dentalhospitalthailand.com

The traditional workflow in dentistry implies the cooperation of two parties involved in the process — dental clinics on the one side and prosthesis laboratories on the other, the interaction between the two requiring quite a lot of time and logistics. Since every patient has a unique dentition, dental labs mostly use manual production methods which are usually slow and assume the work of highly skilled dental technicians, still leaving a lot of room for probable imperfections in the final result. The use of 3D printing provides wide opportunities for low-cost mass customization, saving time and ensuring extremely high precision of printed models. A wide range of dedicated biocompatible materials with various properties allows for the creation of orthodontic models, crowns and bridges, surgical guides, aligners, retainers, splints, dentures, and other dental products that perfectly match the patient’s anatomy.

Since every patient has a unique dentition, dental labs mostly use manual production methods which are usually slow and assume the work of highly skilled dental technicians, still leaving a lot of room for probable imperfections in the final result. The use of 3D printing provides wide opportunities for low-cost mass customization, saving time and ensuring extremely high precision of printed models. A wide range of dedicated biocompatible materials with various properties allows for the creation of orthodontic models, crowns and bridges, surgical guides, aligners, retainers, splints, dentures, and other dental products that perfectly match the patient’s anatomy.

Applications of 3D printing in dental industry

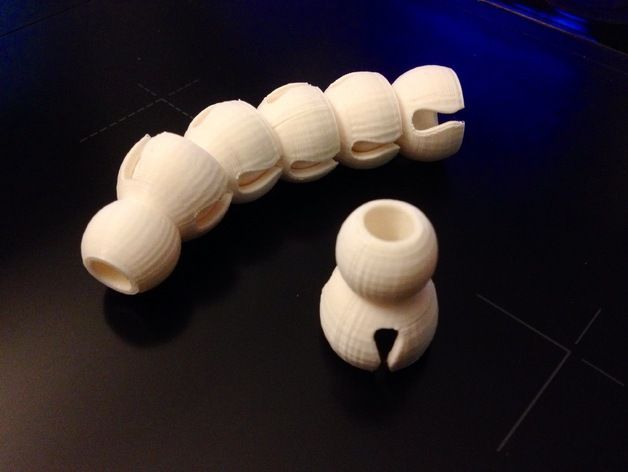

Aligners

Credit: china-ortholab.com

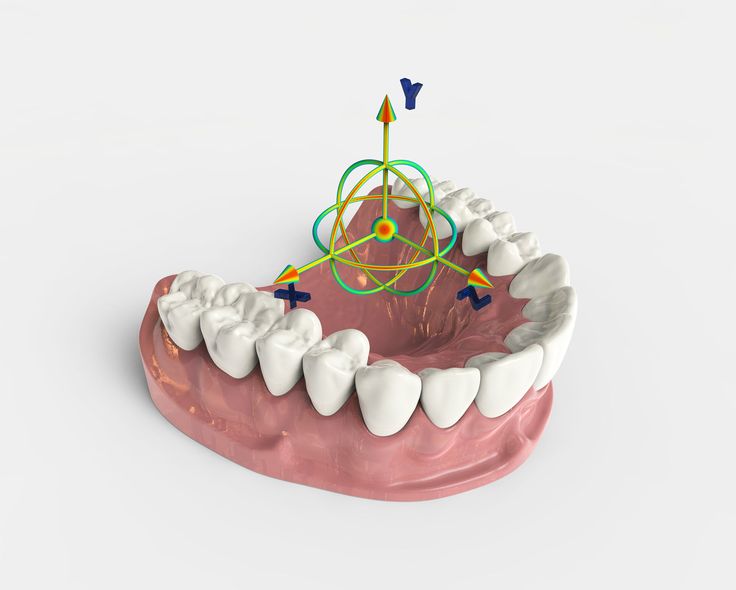

Aligner production is an example of using 3D printing as a bridge to traditional manufacturing methods. First the dentist takes the impression of the patient’s mouth by means of intraoral scanning with further converting the scanned data to a CAD model, which is then edited to specify the stages of desired teeth shifting. When this is done, the model for each stage is printed, usually employing SLA technology. After that each printed model is placed into a thermoforming machine where a clear aligner is wrapped around it creating the patient-specific set of aligners.

When this is done, the model for each stage is printed, usually employing SLA technology. After that each printed model is placed into a thermoforming machine where a clear aligner is wrapped around it creating the patient-specific set of aligners.

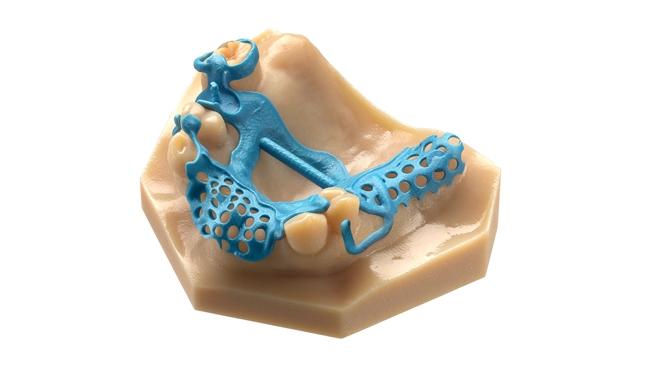

Surgical guides

Credit: creativedentistry.ca

Surgical guides are used in medicine, dentistry in particular, to assist the surgical procedures. In dentistry surgical guides are of great help in implantation as they ensure the precise placing and fitting of the implant. The guides are placed directly over the patient's teeth and then removed during or after the surgery when no longer needed. Surgical guides not only increase the accuracy of the procedure, but also make it faster and less invasive thus shortening the recovery time. Different manufacturers offer special surgical guide resins to ensure the best printing results.

Crowns

Credit: dentalimplantxperts.com

3D printed dental crowns are becoming more widespread with the development of new biocompatible materials. First additive manufacturing was used only as a bridge to investment casting process helping create accurate casting patterns. Now there are a variety of materials, from special permanent crown resins, like Formlabs Digital Dentures Resin, to various metal alloys, that allow printing high-quality permanent crowns taking all the advantages 3D printing provides.

First additive manufacturing was used only as a bridge to investment casting process helping create accurate casting patterns. Now there are a variety of materials, from special permanent crown resins, like Formlabs Digital Dentures Resin, to various metal alloys, that allow printing high-quality permanent crowns taking all the advantages 3D printing provides.

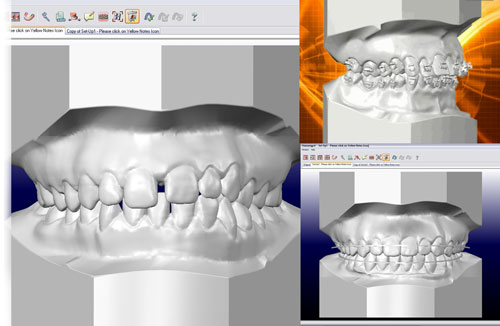

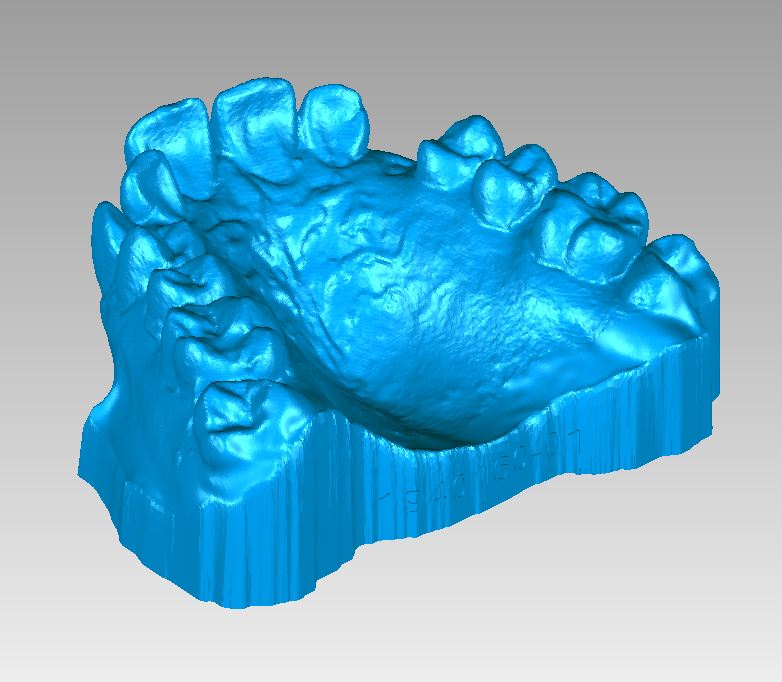

Dental models

Credit: dental.formlabs.com

Dental full arch or crown and bridge models with removable dies help dentists while planning denture restoration. Dental models are printed based on the digital impression of the patient's mouth so they are indispensable when it comes to checking fixed prosthetics that will be later used in a patient's treatment. Special materials, like Formlabs Dental Model Resin allow for precise models with matte smooth surface and a high level of detail.

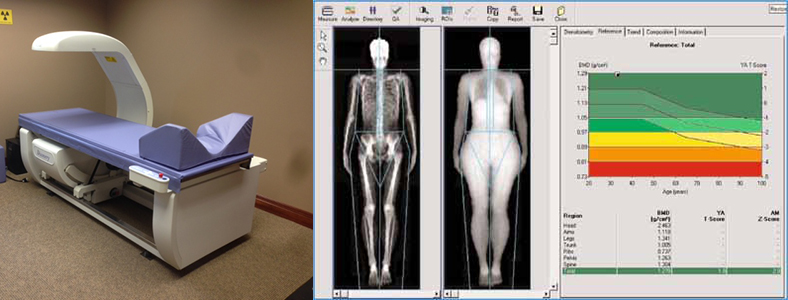

How are dental models 3D printed?

The process of 3D printing in dentistry always starts with the dentist taking a digital impression of a patient’s mouth with an intraoral or desktop scanner. The obtained data is converted to a CAD model which can be saved and then used as a basis for creating dental print models when needed. The digital model is sliced using appropriate software and sent to the printer. Once printed, dental parts usually require some post-processing steps depending on the technology and type of material used.

The obtained data is converted to a CAD model which can be saved and then used as a basis for creating dental print models when needed. The digital model is sliced using appropriate software and sent to the printer. Once printed, dental parts usually require some post-processing steps depending on the technology and type of material used.

Does dental 3D printing require special training?

The process of dental 3D printing is mainly automated and generally requires less special skills than dental technician’s work. Still, certain training is required, especially for those not familiar with additive manufacturing technologies in general. 3D printing equipment and material manufacturers usually offer training programs and support for their customers. In fact, digital dentistry allows for chair-side creation of some patient-specific dental products, while more complex parts have to be printed in dental labs by skilled professionals.

How to get digital models for a 3D printer

As mentioned, a dental 3D scanner (for example, Shining 3D Aoralscan 3) is used to capture the patient’s dental anatomy and take a digital impression of their teeth and gums. This digital impression is converted to a CAD file that is edited to create a digital model of the specific dental product, for example, a crown, depending on the particular case and treatment plan.

This digital impression is converted to a CAD file that is edited to create a digital model of the specific dental product, for example, a crown, depending on the particular case and treatment plan.

How to print dental custom trays

In traditional dentistry trays are used to get a patient's teeth impression, usually with plaster. The implementation of 3D technologies offers much more convenient and precise digital impressions made with an intraoral scanner. Yet impression trays are still widely used in dentistry either by those who prefer conventional methods, or in cases when digital scanning is impossible for some reason. The use of standard trays has always been a compromise as they can not guarantee the necessary precision which a custom-made 3D printed tray provides. The process of printing is the same as with other dental products, and the final result ensures getting highly precise dental products in a shorter time. Different manufacturers offer special resins for impression trays production.

Credit: dental.formlabs.com

Criteria for top dental 3D printers

Precision

Print precision is one of the key points to be considered when choosing a dental 3D printer. If you are going to print not only educational models just to show your patients the treatment process in detail (in that case almost any desktop 3D printer will do), but working dental products, then you should look for a high resolution device, as even subtle discrepancy can lead to a completely unsatisfying result.

Speed

Speed is always of great importance when it comes to business. High print speeds are helpful, whether we speak about dental labs or in case of chair-side printing in dental clinics, where rapid printing helps minimize the number of a patient’s appointments with the dentist.

Biocompatible materials support

It’s by far the main feature the printer should possess to be called dental. All dental products that come in contact with the patient’s mouth or skin should be certified biocompatible in your area, so it’s highly recommended to check the material compatibility list while choosing a dental 3D printer.

Dental printing materials

For today, the most popular technology for dental 3D printing is vat photopolymerization, which includes SLA, DLP and LCD-based processes, all of them using liquid resins that are cured by a light source. Hence the choice of special dental resins in the market is really vast. All dental resins are biocompatible and can be used for printing temporary or permanent dental parts with required properties.

Credit: megadas.com

Metal 3D printers are becoming more and more widespread in dentistry as they work with different metal and metal alloy powders, for example, titanium or cobalt chromium, traditionally used for fabrication of crowns, dentures, and stents. DMLS printers are capable of producing durable extremely precise models in a short time.

Another popular technology for dental 3D printing is material jetting that prints with liquid materials — plastics or polymers — which are cured by UV light. The technology boasts the exceptional accuracy of the printed models, but the printers utilizing this technology are usually bulky and expensive.

As for FDM printing, despite its popularity in a lot of other industries, it has not been widely used in dentistry, as FDM machines usually demonstrate lower accuracy than the other technologies mentioned above. However, new FDM 3D printer models show much higher resolution, accuracy, and dimensional stability, compared to their predecessors, and now dental industry can take advantage of all the benefits of FDM technology.

Best dental 3D printers 2022

Resin 3D printers

Phrozen Sonic 4K 2022

The Phrozen Sonic 4K 2022 is a desktop LCD-based resin 3D printer equipped with a monochrome 4K (3840 x 2160) LCD screen with the resolution of 772 PPI and the lifespan of 2000 hours. Due to the upgraded dedicated ParaLED Matrix 3.0 technology, the device can print layers at a minimum height of 10 microns. Together with the XY resolution of only 35 microns, it allows creating incredibly accurate precise models with a perfectly smooth surface finish. The Sonic 4K 2022 is a reliable and fast 3D printer capable of building a single layer in just two seconds. It can be operated via PC or a built-in 5" touchscreen and boasts wide connectivity options including Ethernet, USB, and Wi-Fi interfaces. The Phrozen Sonic 4K 2022 is designed to meet all the dental printing requirements. Apart from common for the Phrozen 3D printers ChiToBox slicer compatibility, the Sonic 4K 2022 comes with the proprietary Phrozen Dental Synergy Slicer targeted specifically at dental applications.

The Sonic 4K 2022 is a reliable and fast 3D printer capable of building a single layer in just two seconds. It can be operated via PC or a built-in 5" touchscreen and boasts wide connectivity options including Ethernet, USB, and Wi-Fi interfaces. The Phrozen Sonic 4K 2022 is designed to meet all the dental printing requirements. Apart from common for the Phrozen 3D printers ChiToBox slicer compatibility, the Sonic 4K 2022 comes with the proprietary Phrozen Dental Synergy Slicer targeted specifically at dental applications.

Credit: @bellwoodlab / Instagram

Pros

- High resolution and accuracy

- Fast print speed

- Sturdy aluminum construction

- Wide connectivity options

- 5" operating touchscreen

Cons

- The build volume is not very large

Phrozen Sonic XL 4K 2022

The Phrozen Sonic XL 4K 2022 is a professional desktop resin 3D printer designed specifically for the dental industry. The model is a larger version of the Phrozen Sonic 4K 2022 with a more spacious build volume of 200 x 125 x 200 mm. This allows printing fairly large parts or multiple dental models in one go for efficient time saving. All other printer specs are similar to the previous model, with the only difference in the XY resolution of 52 microns, compared to 35 microns of the Sonic 4K 2022, due to the larger build volume of the Sonic XL 4K. Despite this, the device is capable of producing astonishingly detailed precise parts with a flawlessly smooth surface finish at a high speed of 2 mm per layer. The printer is compatible with ChiToBox and comes with the designated Phrozen Dental Synergy Slicer. The Phrozen Sonic XL 4K can be successfully used not only for dental applications, but in jewelry fabrication and any other industry where the quality of the parts is of paramount importance.

The model is a larger version of the Phrozen Sonic 4K 2022 with a more spacious build volume of 200 x 125 x 200 mm. This allows printing fairly large parts or multiple dental models in one go for efficient time saving. All other printer specs are similar to the previous model, with the only difference in the XY resolution of 52 microns, compared to 35 microns of the Sonic 4K 2022, due to the larger build volume of the Sonic XL 4K. Despite this, the device is capable of producing astonishingly detailed precise parts with a flawlessly smooth surface finish at a high speed of 2 mm per layer. The printer is compatible with ChiToBox and comes with the designated Phrozen Dental Synergy Slicer. The Phrozen Sonic XL 4K can be successfully used not only for dental applications, but in jewelry fabrication and any other industry where the quality of the parts is of paramount importance.

Credit: @ALICEADMD / Twitter

Pros

- Large build volume

- Fast print speed

- High print quality

- Open material system

- Wide connectivity options

Cons

- The XY resolution is a bit lower compared to the Sonic 4K 2022

Uniz Slash 2

The Uniz Slash 2 is a professional desktop LCD 3D printer with a 8. 9" 4K LCD screen. The device boasts an amazing print speed of up to 200 mm/h ensuring extremely high time-efficiency of the printing process. The minimum layer height of 10 microns allows for highly detailed accurate models with flawless look and feel. With a sizable build volume of 192 x 120 x 200 mm you can print either large models or small runs of smaller parts at a time. The printer is equipped with an effective heat management system and a proprietary liquid cooling mechanism. All these features make the Uniz Slash 2 an indispensable tool for dentistry, jewelry, or any other industry with strict part quality requirements.

9" 4K LCD screen. The device boasts an amazing print speed of up to 200 mm/h ensuring extremely high time-efficiency of the printing process. The minimum layer height of 10 microns allows for highly detailed accurate models with flawless look and feel. With a sizable build volume of 192 x 120 x 200 mm you can print either large models or small runs of smaller parts at a time. The printer is equipped with an effective heat management system and a proprietary liquid cooling mechanism. All these features make the Uniz Slash 2 an indispensable tool for dentistry, jewelry, or any other industry with strict part quality requirements.

Credit: @coutelas_v / Instagram

Pros

- Incredibly high speed

- Automatic bed leveling

- High print quality

- Durable resin tank

- Cloud-based services

Cons

- No control screen

Uniz NBEE

The Uniz NBEE is a resin LCD-based 3D printer designed specially for the dental industry. The NBEE features extremely high print speed, being able to produce six dental models in 5 minutes. The printer’s build volume is 192 x 120 x 180 mm. With the minimum layer height of 25 microns, the device prints aligners, removable dies, surgical guides, crowns, bridges, and other dental appliances with exceptional quality. The NBEE can print either with a wide range of special Uniz photosensitive dental resins or with third-party materials.

The NBEE features extremely high print speed, being able to produce six dental models in 5 minutes. The printer’s build volume is 192 x 120 x 180 mm. With the minimum layer height of 25 microns, the device prints aligners, removable dies, surgical guides, crowns, bridges, and other dental appliances with exceptional quality. The NBEE can print either with a wide range of special Uniz photosensitive dental resins or with third-party materials.

Credit: uniz.com

Pros

- Extremely high speed

- High print quality

- Wide range of compatible dental resins

Cons

- High price

Formlabs Form 3B+

Credit: dental.formlabs.com

The Formlabs Form 3B+ is based on proprietary LFS (Low Force Stereolithography) technology that is aimed at improving the surface finish of the prints. The Form 3B+ is designed for digital dentistry and can print with minimum layer thickness of 25 microns. The build volume of the printer is 145 x 145 x 185 mm. The device can come alone or with post-processing equipment, including the Form Wash and Form Cure machines. Formlabs offers a wide range of biocompatible resins for different dental appliances (for example, Formlabs Dental LT Clear Resin).

The build volume of the printer is 145 x 145 x 185 mm. The device can come alone or with post-processing equipment, including the Form Wash and Form Cure machines. Formlabs offers a wide range of biocompatible resins for different dental appliances (for example, Formlabs Dental LT Clear Resin).

Credit: dental.formlabs.com

Pros

- High print quality

- Wide range of biocompatible resins

- Can be a part of a complete solution

Cons

- Compatible only with proprietary materials

- Lower print speed, compared to LCD models

Nexa3D NXE400

The NXE400 is an industrial resin 3D printer based on proprietary Lubricant Sublayer Photo-curing (LSPc) technology. Due to this technology, the NXE400 is by far one of the fastest resin 3D printers in the market. The machine features a large build volume of 274 x 155 x 400 mm. The print quality the NXE400 is capable of is incredibly high. The NXE400 can be regarded as a reliable 3D printer for a dental lab, as now it supports all biocompatible photopolymer dental resins by Keystone Industries. Apart from that, the NXE400 is compatible with a wide range of other resins, including xPeek, xABS, and xFlex.

The NXE400 can be regarded as a reliable 3D printer for a dental lab, as now it supports all biocompatible photopolymer dental resins by Keystone Industries. Apart from that, the NXE400 is compatible with a wide range of other resins, including xPeek, xABS, and xFlex.

Credit: 3dprint.com

Pros

- Extremely high print speed

- High-quality prints with smooth surface finish

- Large build volume

- Wide range of compatible materials

- Dental biocompatible resins support

Cons

- Price can be too high for small companies

FDM 3D printers

Raise3D E2

The Raise3D E2 is an industrial desktop FDM 3D printer featuring the Independent Dual Extrusion System (IDEX) which opens up versatile printing opportunities, from dual-material and dual-color printing to using mirror and duplication modes that allow you to double the production volume. The E2 can print with the maximum nozzle temperature of 300 °C and is compatible with a wide range of filaments, such as PLA, ABS, HIPS, PC, TPU, TPE, Nylon, PETG, ASA, PP, PVA, glass and carbon fiber filled composites, and others. Featuring the auto bed leveling function and a flexible removable heated build plate, the E2 provides perfect first layer adhesion for high-quality accurate printing. The minimum layer height of 20 microns makes for detailed accurate parts with the quality perfectly suitable for printing dental models.

Featuring the auto bed leveling function and a flexible removable heated build plate, the E2 provides perfect first layer adhesion for high-quality accurate printing. The minimum layer height of 20 microns makes for detailed accurate parts with the quality perfectly suitable for printing dental models.

Credit: @priamond.de / Instagram

Pros

- IDEX system

- Auto bed leveling function

- Wide range of compatible materials

- Enclosed chamber with a HEPA filter

- Minimum layer height of 20 microns

- Flexible removable build plate

Cons

- Auto bed leveling can take pretty much time

Creality CR-5 Pro High-temp Version

The Creality CR-5 Pro High-Temp version industrial-grade FDM 3D printer sports a fully-enclosed impressively large build chamber of 300 x 225 x 380 mm. The extruder is equipped with a 0.4 mm nozzle with the maximum temperature of 300 °C and a cooling fan that helps prevent stringing and warping issues. The CR-5 Pro High-temp is compatible with a wide range of filaments, including high-temp materials, such as PLA, TPU, and ABS. Proper first layer adhesion is provided by the high-quality carbon glass heated print bed. A bunch of advanced features, such as auto bed leveling, filament run-out sensor, or print resume function make for consistent reliable printing experience.

The CR-5 Pro High-temp is compatible with a wide range of filaments, including high-temp materials, such as PLA, TPU, and ABS. Proper first layer adhesion is provided by the high-quality carbon glass heated print bed. A bunch of advanced features, such as auto bed leveling, filament run-out sensor, or print resume function make for consistent reliable printing experience.

Credit: Just Vlad / YouTube

Pros

- Large build volume

- Wide range of compatible materials, including high-temp filaments

- Carbon glass heated print bed

- Auto bed leveling function

- Filament runout sensor

- Print resume function

Cons

- 100 microns minimum layer height

Metal 3D printers

Farsoon FS121M

The Farsoon FS121M is an MLS (metal laser sintering) printer that can perform as a reliable and efficient device for a number of industries, dentistry being one of them. The FS121M sports a large build volume, which is a cylinder of ⌀ 120 x h 100 mm, and a high build speed, allowing for the production of up to 160 dental crowns in 3 hours. The device is equipped with a single 200W fiber laser, used in the Flight series printers. The Farsoon FS121M is a fully open system, providing compatibility with a great number of proprietary and third-party metal powders, including 316L, 17-4PH, Maraging Steel Grade 300, HX, Cu, CuSn10, CoCrMoW, and CoCrMo.

The FS121M sports a large build volume, which is a cylinder of ⌀ 120 x h 100 mm, and a high build speed, allowing for the production of up to 160 dental crowns in 3 hours. The device is equipped with a single 200W fiber laser, used in the Flight series printers. The Farsoon FS121M is a fully open system, providing compatibility with a great number of proprietary and third-party metal powders, including 316L, 17-4PH, Maraging Steel Grade 300, HX, Cu, CuSn10, CoCrMoW, and CoCrMo.

Pros

- Large build volume and compact footprint

- High print quality

- Fast print speed

- Use of more powerful and durable fiber laser

- Open system

BLT-A160D

The BLT-A160D is an industrial-grade SLM metal 3D printer designed specifically for the dental industry. The machine can print with Titanium and Cobalt Chromium alloys that are widely used in dentistry for producing high-quality stents and dentures. The A160D features a build volume of 160 x 160 x 100 mm and can print 20 cobalt chromium brackets for 7 hours or 20 two-way titanium alloy stents for 4 hours. The minimum layer height of 10 microns allows printing durable parts with smooth surface finish. Two 200W lasers ensure fast and accurate printing. The intelligent software provides real-time monitoring of the printing process, a safety interlocking mechanism, and a self-diagnostics function.

The A160D features a build volume of 160 x 160 x 100 mm and can print 20 cobalt chromium brackets for 7 hours or 20 two-way titanium alloy stents for 4 hours. The minimum layer height of 10 microns allows printing durable parts with smooth surface finish. Two 200W lasers ensure fast and accurate printing. The intelligent software provides real-time monitoring of the printing process, a safety interlocking mechanism, and a self-diagnostics function.

Credit: xa-blt.com

Pros

- High print quality

- Fast print speed

- Intelligent software

- Build plate construction for fast loading

- Water-injection filter

Cons

- Build volume is quite small for large-scale manufacture

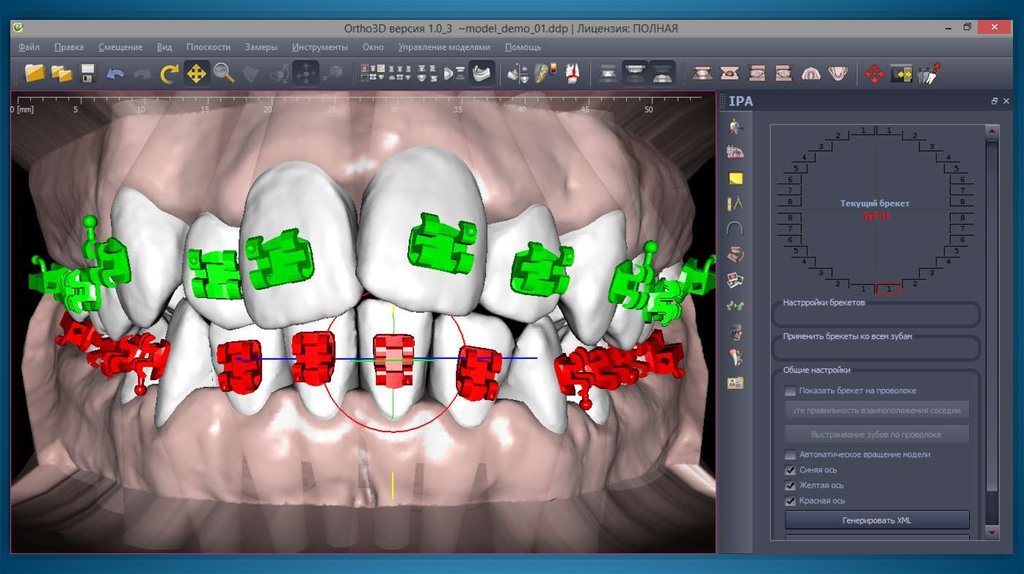

Dental 3D printing software

Almost all dental 3D printing solutions include proprietary software specially designed for dental practices and labs. It usually guides the user through all the stages starting with uploading a 3D scan to a CAD file with the following creation of a 3D digital model of the custom-tailored dental product. The slicer converts the CAD model to a printable file, usually STL, and prepares the model for printing. When the task is done, the software sends the print job to the printer.

The slicer converts the CAD model to a printable file, usually STL, and prepares the model for printing. When the task is done, the software sends the print job to the printer.

Credit: uniz.com

The use of dedicated software recommended by the manufacturer provides maximum compatibility and ensures the best results without any downtimes.

Post-processing equipment

Printing with resins, which is the most popular material in digital dentistry, always implies several post-processing steps; that is why a lot of dental printers can be purchased as part of a complete solution, including, besides the printer itself, machines for washing and post-curing the printed parts.

Credit: anycubic.com

Is dental 3D printing expensive?

Compact dental resin 3D printers suitable for in-office printing can cost about a few thousand dollars, while industrial-grade large machines’ price can be as high as tens of thousands dollars and more. Such devices are good for dental labs with big production volumes as they allow for fast continuous printing thus providing the fast ROI.

Such devices are good for dental labs with big production volumes as they allow for fast continuous printing thus providing the fast ROI.

Pros and cons of dental 3D printing

Pros

- Digital dentistry is capable of producing highly accurate dental appliances that can be easily customized at no additional cost.

- 3D printing saves a lot of time both for patients and practitioners.

- The cost per part is in many cases lower for 3D printed models compared to those produced by traditional methods.

- The dental technician’s work requires much more expertise than creation of digitally printed models.

- The process of dental 3D printing is usually highly automated.

- The final result in dental 3D printing is more predictable and reliable than in traditional dentistry.

Credit: dentalproductsreport.com

Cons

-

The startup price is rather high.

-

Dental 3D printing requires special training (usually provided by the printer’s manufacturer).

-

Not all materials can be used for 3D printing (though the existing variety is already wide enough and growing constantly).

Bottom line

Dental 3D printing is one of the most rapidly growing additive manufacturing industries, and its popularity among both practitioners and patients is easily explained. Digital dentistry saves time and money, provides much higher quality of the printed dental appliances, and makes the treatment less painful and invasive for the patient and more convenient for the dentist.

All about a 3D printer in dentistry: features, applications, technologies

The first attempts to use 3D printing in dentistry were made by specialists from Align Technology in the 1990s. Using a 3D printer, mouth guards were made, which served as a start for the development of this technology in the dental industry. The process of making teeth was looked at from a radically new point of view.

The process of making teeth was looked at from a radically new point of view.

But development did not progress as fast as we would like: it took almost 20 years to achieve satisfactory print quality and optimize performance. The first implant was printed by Layer Wise in 2012. In the same year, for the first time, it was possible to implant a patient with a titanium lower jaw, which was made using a 3D printer. Since then, the technology has evolved and raised the quality bar.

The advantages of using a 3D printer in a short time to solve almost any problem. With a dental 3D printer, a significant number of required instances can be modeled in a single session. All projects are saved in files, so in the future you can re-make the same model if necessary.

It is no longer necessary to send the patient for 2-3 days to wait for the production of plaster models. Now everything happens much faster: the doctor builds a 3D model in a few minutes using an intraoral scanner and instantly transfers the data to the laboratory, where printing also does not take much time. Speed and maximum precision increase the level of treatment and really save resources and time.

Speed and maximum precision increase the level of treatment and really save resources and time.

What you can print

Let's highlight the most common uses of 3D printing in dentistry. Using the printer, you can create:

- demonstration and collapsible models of the jaw, sectoral reproduction of the upper and lower jaws in the occlusion;

- ashless constructions, caps, bases for crowns and bridges, clasp prostheses;

- surgical guides for implantation, individual trays, guides for maxillofacial surgery.

Such a promising direction as the printing of permanent and temporary orthopedic structures, removable denture bases is actively developing.

About the types of printing

As we have already found out, the main task of a 3D printer for dentistry is to reduce the time of manufacturing restorations and reduce the cost of production without loss of quality and accuracy. We will understand the printing technologies and their features.

We will understand the printing technologies and their features.

Stereolithography (SLA or SL). With this technology, a laser beam selectively impacts a container of liquid resin through the printable area. Thus, the resin hardens in layers in specific places and forms a three-dimensional figure.

Stereolithography gives the best surface finish on parts and is most commonly used in today's 3D printer models. SLA machines provide a large area of restoration construction and work with a wide range of materials designed for a variety of tasks.

To switch from one material to another, it is enough to change the cartridge and the resin bottle. Relatively compact dimensions, ease of workflow and affordable price make SLA printers the best choice for dental laboratories. An example of SLA models - Form 2 and Form 3 from Formlabs, SLASH PLUS from Uniz Technology, Basic Dental from Omaker, Asiga PICO2.

Digital LED projection (DLP). Here, the chemical process is similar to SLA, but a digital projector is used instead of a laser as a light source to cure the resin. DLP printers have a simple interaction process, a fairly modest footprint, and a good selection of material options, but at a higher price compared to SLA.

Here, the chemical process is similar to SLA, but a digital projector is used instead of a laser as a light source to cure the resin. DLP printers have a simple interaction process, a fairly modest footprint, and a good selection of material options, but at a higher price compared to SLA.

Due to the nature of the illumination of the LED projector, there is a tendency for voxel lines-layers formed by small rectangular bricks of material. Models made by DLP have inferior surface quality to SLA models. But it is worth noting that DLP printers print much faster than laser ones. Examples of DLP printers include Varseo S by Bego, AccuFab-D1 by Shining 3D, D2-150 by Veltz 3D, Versus by Microlay.

PolyJet technology. The process is similar to that of a regular inkjet printer, but instead of inkjet drops on paper, the 3D printer blows layers of liquid resin onto the printable area. The layers harden when exposed to light.

Once upon a time PolyJet gained popularity in the dental industry, but its development was slowed down by two factors: the high cost of equipment and the impressive dimensions of the devices. Models made using PolyJet technology require long post-processing and are again inferior to SLA in terms of surface quality.

Models made using PolyJet technology require long post-processing and are again inferior to SLA in terms of surface quality.

PolyJet systems produce parts very quickly, but are limited in scope due to expensive proprietary consumables. Therefore, in the context of our industry, it is better to buy a dental 3D printer with SLA technology.

SLS and EBM. Allows titanium printing of ready-made elements for replacement of jaw parts. These technologies work on the principle of laser sintering of metal clay, a special metal powder for dentistry. So, the SLS and EBM systems allow you to work with a biocompatible titanium alloy. Since pure metal powder does not require a binder filler, the finished models do not differ in porosity. To achieve the required mechanical strength, the products do not require additional firing. An example of a printer capable of printing with metals is the EP-M150T from Shining 3D.

Filament printing. Technology is not relevant in dentistry and now we will explain why.

Technology is not relevant in dentistry and now we will explain why.

Printed with filament, a material similar to fine garden trimmer wire. The wound filament is charged directly into the 3D printer head, which moves on three axes.

Compared to other materials for 3D printing, this filament is quite inexpensive, but gives low accuracy compared to powders. The most popular types of filament are ABS and PLA plastic.

Comparison of the main 3D printing technologies used in dentistry

To clearly show the main pros and cons of each technology, we compare them in a table format.

| Stereolithography (SLA) | Digital Light Processing (DLP) | PolyJet Technology | SLS and EBM technologies | |

| Precision | ★★★★★ | ★★★★★ | ★★★★★ | ★★★★★ |

| Surface finish | ★★★★★ | ★★★★☆ | ★★★☆☆ | ★★★★☆ |

| Print speed | ★★★★☆ | ★★★★★ | ★★★★★ | ★★★☆☆ |

| Availability of materials | ★★★★★ | ★★★★★ | ★★★★☆ | ★★☆☆☆ |

| Metal printing | ||||

| Benefits |

|

|

|

|

| Drawbacks | Slow single print speed |

|

|

|

Our CV

PolyJet technology is becoming a thing of the past due to high cost and imperfect print results. SLS and EBM are more relevant for large laboratories than ordinary clinics. Therefore, it is worth considering SLA and DLP printers for everyday tasks. For example, take a closer look at Bego Varseo S, Formlabs Form 2. These devices have already proven themselves in the dental market and provide guaranteed high-quality results. You can see all 3D printers presented in StomShop.pro here.

SLS and EBM are more relevant for large laboratories than ordinary clinics. Therefore, it is worth considering SLA and DLP printers for everyday tasks. For example, take a closer look at Bego Varseo S, Formlabs Form 2. These devices have already proven themselves in the dental market and provide guaranteed high-quality results. You can see all 3D printers presented in StomShop.pro here.

← General requirements for the placement of portable X-ray machines | TOP 5 Illuminated Physiodispensers →

Dental 3D Printer Review 2019 Part 2

Digital Dentistry is the perfect business choice. Judge for yourself: a combination of high quality, patient-friendliness, low unit costs and optimized workflows. 3D printing, like the icing on the cake, perfectly complements the digital manufacturing process in the clinic. This market is growing rapidly, bringing the technology within reach of most manufacturers. But what technologies are relevant for dentistry? How do you compare printers in terms of quality, accuracy, and throughput? Why do some cost less than $5,000 and others $80,000 or more?

We continue to analyze the Russian market of 3D printers for dentists. Read the first part of the review here .

Read the first part of the review here .

Photon S by Anycubic

This printer certainly made a splash when it was released to the market in 2019. The novelty offered the user something more than the usual typical budget desktop 3D printer. In addition to a user-friendly user interface with a clear structured menu, large icons and buttons, the model stands out for greater stability and improved UV LED performance due to the directional lenses that have been added to the design. The printer is easy to use, ready to use immediately after unpacking, and also perfectly combines high print quality and reasonable cost.

Table rails provide high stability when printing. The manufacturer has a fairly large range of photopolymer resins, but you can use materials from other manufacturers.

- Print technology: LCD;

- Print speed: 10-20 mm/h;

- Print area: 115 x 65 x 155 mm;

- Layer thickness: 10 µm;

- Dimensions: 23 x 20 x 40 cm.

WHERE TO BUY

Shuffle by Phrozen

A concise, easy-to-operate model that provides the specialist with high quality reproducible objects. This is ensured by a unique optical drive that improves the speed and quality of printing.

Specially developed LED matrix system provides increased light transmission and high-quality illumination. The printer is distinguished by high reliability of parts and design as a whole, namely, it has a reinforced Z axis, due to which the possibility of oscillations during the printing process is completely eliminated.

The printer does not need to be connected to a computer, the job can be sent via Wi-Fi. Management is carried out through the touch screen. Additionally, it should be noted the built-in activated carbon filtration system.

- Print technology: LCD;

- Printing area: 120 x 68 x 200 mm;

- Layer thickness: from 10 µm;

- Dimensions: 28 x 28 x 42 cm.

WHERE TO BUY

Duplicator 8 from Wanhao

In terms of characteristics, it is somewhat similar to its counterpart, Duplicator 7 PLUS, but there is still a difference. The D8 has a large print area. The convenient touch screen displays all printing options in real time. Calibration is required, however, it is a very simple and quick manipulation that can be easily controlled and performed using a sheet of white paper. The printer has a fairly high contrast ratio compared to most LCD printers. In addition, the print bath and film are fairly easy to install.

The printer is excellent for printing full size models. You can control the first stages of printing, thanks to the presence of a viewing hole. The printer is surprisingly quiet considering that four cooling units are running during printing.

- Print technology: DLP;

- Print speed: up to 30 mm/h;

- Printing area: 192 x 120 x 180 mm;

- Layer thickness: 35-100 µm;

- Dimensions: 45 x 45 x 55 cm.

WHERE TO BUY

Liquid Crystal Precision 1.5 by Photocentric

This printer is great for printing fine details and has long been in demand among dentists and jewelers. About the British manufacturer Photocentric and their patented DPP technology, which will help you save money, we have already mentioned in the first part of the review. I must say, the model is so successful that according to the authoritative publication 3D Printing Industry it was recognized as the best desktop non-FFF 3D printer of the year. The printer successfully combines high printing accuracy and minimum layer thickness.

Consumables are fairly affordable and there are plenty to choose from. For example, photopolymer resins for printing burn-out models (crowns, bridges, clasp prostheses) and equipment for the manufacture of aligners. The control is carried out using a touch screen with a diagonal of 7 inches.

- Print technology: DPP;

- Print speed: 0.

1 mm/4-11 sec;

1 mm/4-11 sec; - Print area: 121 x 68 x 160;

- Layer thickness: 25-100 µm;

- Dimensions: 38 x 35 x 58 cm.

WHERE TO BUY

FORM 3 from Formlabs

A compact and functional printer using the new low power stereolithography method is able to create almost any object, even with very fine detail. This method is based on the use of a tunable tank and linear illumination.

The advantage is that the printer produces objects with a smoother surface than some similar machines. Thus, you spend less time on the subsequent processing of the product. Automated washing and final polymerization also speed up the production process. The printer works with a wide range of print materials.

A special application allows you to control the process from anywhere in the world and manage several printers at the same time. Calibration is carried out in a closed loop. Part of the nodes can be easily replaced by yourself, switching between cartridges with materials will also not cause problems.

- Print technology: LFS;

- Print speed: 200 mm/h;

- Print area: 145 x 145 x 185 mm;

- Layer thickness: 25-300 µm;

- Dimensions: 40.5 x 37.5 x 53 cm. Nobel Superfine by XYZPrinting Very compact, ergonomic model equipped with an LCD screen for control. The printer is left already calibrated, and belongs to the category of Plug and Play equipment - unpack and work.

- Print technology: DLP;

- Print area: 64 x 40 x 120 mm;

- Layer thickness: 25/50/100 µm;

- Dimensions: 29 x 35.

7 x 42.7 cm.

7 x 42.7 cm. - Print technology: LCD;

- Print speed: 200 mm/h;

- Printing area: 192 x 120 x 400 mm;

- Layer thickness: from 20 µm;

- Dimensions: 35 x 40 x 73 cm.

- Print technology: DLP;

- Print speed: up to 25.4 mm/h;

- Print volume: 130 x 80 x 200 mm;

- Layer thickness: from 20 µm;

- XY resolution: 100 µm;

- Dimensions: 38 x 38 x 50 cm.

- Print technology: LCD;

- Print area: 68 x 120 mm

- Layer thickness: 25-100 µm;

Also worth noting is the ability to automatically create structural supports to support overhanging parts at the stage of model building. Print projects can be sent via WiFi. A definite plus is the openness of the system and the ability to work with materials from different manufacturers, including photopolymer resins for further burning and creating molds for casting, as well as materials that have the necessary medical certification.

According to CONTEXT, XYZprinting is the world's leading supplier of desktop 3D printers in 2017 and 2018.

WHERE TO BUY

Slash Pro by UNIZ

Great desktop printer for professional 3D printing. This model has twice the print area of the SLASH PLUS, allowing you to create larger jobs, while the new LCD stereolithography model building technology provides high productivity and low production cost, while maintaining high quality and print detail.

The printer is highly reliable and can become a full participant in an automated workflow. The software allows you to manage multiple printers simultaneously and combines the printer and media into a powerful, easy-to-use system for industry-leading professional results.

This model uses water cooling to maintain high print speeds without loss of quality and extend the life of the printer. The Slash Pro is quite service friendly: easy refilling, calibration and bath cleaning. In addition, the printer works with materials from different manufacturers.

WHERE TO BUY

Moonray S by SprintRay

Dedicated dental DLP resin 3D printer provides the user with affordable high quality 3D printing. The model has a high print speed that exceeds SLA - from 3.8 to 25.4 mm per hour, depending on the thickness of the layer, and at any infill - even at 100% filling of the print volume with details (in SLA, the speed is highly dependent on the size and quantity printed parts).

The printer prints diagnostic, orthopedic and orthodontic models, surgical templates, trays, burn-outs, temporary crowns and works with third-party materials such as NextDent and their profiles.

The Rayware software that comes with the printer has both a convenient auto mode and many manual settings; among other things, it allows you to add optimal support and manage multiple printers from a single computer. The RayOne UV projector responsible for curing the photopolymer in the printer is rated for 50,000 hours of operation.

Polymer bath has an increased resource (50 L) and can work with different materials. A plus is also a fully automatic setup and calibration of the printer.

WHERE TO BUY

Creo C5 from Planmeca

The model was made specifically for dental clinics, with the involvement of leading industry experts, and tailored for the production of dental structures. High stability, precision and speed - the perfect combination for any dentist and technician. The print speed depends on the media. The device has a fairly large weight, which ensures stability during operation. Only manufacturer's materials can be used for printing, however, the advantage is the fact that the entire range is sharpened exclusively for dentistry and is designed to meet any requirements of a specialist.

Printing of models, surgical templates, caps, aligners, collapsible models is now available on the printer. Currently, the company is developing materials for temporary constructions (crowns, bridges, etc.), as well as material in disposable capsules. Capsules provide a long shelf life of the material and are conveniently inserted into the container. In addition, they are color-coded and equipped with a QR code, which eliminates the risk of confusing materials.

Controlled by touch screen. Material settings are pre-programmed and optimized. No calibration required before first run, just a quick pre-setup. The printer does not require regular annual maintenance.

WHERE TO BUY

Mlab cusing R from Concept Laser

The printer is designed for printing small detailed works from metals: clasp and bridge frames, crowns, individual abutments.