Xfab 3d printer

DWS Systems | Additive manufacturing

DWS Systems | Additive manufacturing|

XFAB 2500HD |

XFAB 3500HD |

028J Plus |

029JL2 |

029X |

029XC |

XPRO S |

XPRO SL |

XPRO Q |

|

XFAB 2500PD |

XFAB 3500PD |

029JL2 |

029X |

029XC |

XPRO S |

XPRO Q |

DFAB |

LFAB |

|

XFAB 2500SD |

XFAB 3500SD |

029JL2 |

029X |

029XC |

XPRO S |

XPRO SL |

XPRO Q |

JEWELLERY & FASHION

DENTAL LAB & CLINIC

MANUFACTURING & DESIGN

MANUFACTURING & DESIGN

JEWELLERY & FASHION

DENTAL LAB & CLINIC

Proseguendo la navigazione, accetti l'utilizzo dei cookies di questo sito. Per maggiori informazioni consulta l'informativa..

CHIUDI

DWS Systems | Materials

MATERIAL FINDER

DOWNLOAD JEWELLERY BROCHURE

DOWNLOAD INDUSTRIAL BROCHURE

DOWNLOAD DENTAL BROCHURE

FUSIA SERIES: Lost wax casting materials

The Fusia series has been specially developed for lost wax casting of jewelry, fashion accessories, industrial and dental applications and is suitable for the construction of models and detailed parts where the highest possible resolution is required.

The Fusia series materials are developed and tested internally, ensuring precise and accurate details, and stands out among them Fusia DC900 with its red matt color.

In addition to supports removal, a washing cycle and a curing cycle with original DWS UV-curing devices are required.

Through the special XCLUSTER application, the combination of Fusia 445 material, printer and specially designed proprietary software, it is possible to produce lost wax fusing clusters making the workflow completely digital and automated.

THERMA SERIES: High temperature resistant materials

The Therma series includes nanoceramic materials developed for applications where thermal stress resistance is required. In jewelry and fashion accessories applications, the Therma series allows the creation of heat-resistant master models for the creation of rubber molds, both RTV and HTV. 3D molded models with Therma materials are characterized by high resolution, detailed and extra smooth surfaces.

Therma materials for orthodontic dental applications are specially developed for the thermoforming of invisible aligners.

Using Therma DM500 material it is possible to produce injection molds for thermoplastic injection molds with stereolithographic technology that are resistant to hundreds of molding cycles. This makes it possible to exploit digital technology directly in production processes.

VITRA SERIES: High definition transparent materialsThe Vitra series materials are developed by DWS to faithfully, solidly and accurately reproduce the characteristics of glass, crystal and plastic materials, capable of superior transparency, guaranteeing the best final performance, also in terms of dimensional stability, for single objects or components.

The Vitra series is composed of different solutions of hardness and resistance, all characterized by smooth and polished surfaces and accuracy of details. It can also be colored.

In the medical field, specific Vitra materials are suitable for medical imaging, whose transparency makes it possible to accurately visualize the anatomical structure of the patient in the smallest detail.

The IRIX series is composed of hybrid materials patented by DWS, called "digital stone".

Irix in color white, ivory, black and coral, reproduces the main characteristics of natural stones.

Irix A is a nanoceramic very pleasant to touch and able to recall the characteristics of handcrafted ceramics. It can be enameled, colored and sprayed.

Irix V, transparent and translucent, can reproduce faceted gemstones and ornaments of any shape and dimentions and is available in the colors that reflect precious gems.

Irix materials fully meet the needs of the fashion and fashion accessories sector, as they allow the on-demand production of jewelry through DWS 3D printers, avoiding the need for storage.

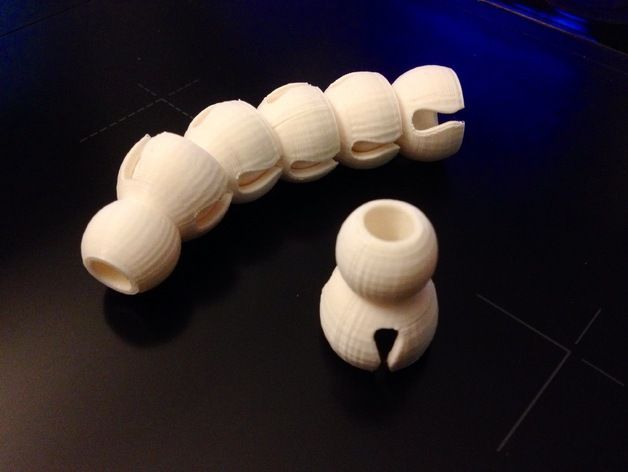

FLEXA SERIES: The most advanced solutions of elastomeric materials

The FLEXA series is the best answer to the need for rapid prototyping and production of objects and components of elastomeric products.

The performance of the models produced by the elastomers in black color or transparent from DWS 3D printers are at the highest levels of flexibility and elasticity making them durable over time and with defined surfaces.

For maximum flexibility of use, Flexa materials are available with different physical characteristics, colors and wear resistance.

PRECISA SERIES: precision, detail and high definition for aesthetic models and mockups

The Precisa series is designed for stereolithographic 3D printing of prototypes with ultra-smooth and detailed surfaces, which require high resolution and accuracy. In the prototype phase it is possible to verify shapes, dimensions and levels of detail by producing in an economical and flexible way.

The Precisa series is ideal for use in the dental industry, where models require both the highest dimensional accuracy and the highest level of detail. Similarly, in model making, the resolution in the smallest details is appreciated, which is also fundamental in jewellery and fashion accessories.

INVICTA SERIES: accuracy, range and performance for functional models and end-use parts

The INVICTA series was developed specifically for the use of 3D DWS printers for final production and prototypes of interlocking functional parts.

Precision and dimensional stability, together with impact resistance, distinguish the materials of the Invicta series, suitable for the digital manufacture of functional products.

The models produced with Invicta materials are characterized by the excellent durability of their physical and mechanical characteristics.

Invicta 2020, in particular, for end-use parts is recommended for industrial design, functional parts and aesthetic mockups.

BIOCOMPATIBLEMaterials for restorations and dentures

The Temporis and Irix series materials are developed by DWS for the production of permanent and temporary long-term restorations and are certified according to the strictest biocompatibility classes.

High quality, natural appearance and best-in-class technical features make the production of bridges, crowns, inlays and veneers possible.

DWS restorative materials are available in different colors and thanks to the exclusive Photoshade technology and the DFAB 3D printer, customized restorations with adaptive color gradient are achieved.

Materials for surgical guides and impression trays

They complete the range of biocompatible materials:

DS3000 is a transparent Class I biocompatible material for the realization of surgical guides, which require high precision, accuracy, stability and non-deformability, guaranteeing an impeccable fit to the anatomical topology of the patient, optimal condition for the effective and safe intervention.

DS3500 is a biocompatible Class I material ideal for printing individual impression trays. Rigid, stable and non-deformable, it is compatible with any specific impression material.

GL4000: Material for gingival masks and soft tissues

GL4000 is the material that realistically replicates the characteristics of gum and soft tissue by color, soft tissue texture and conformation.

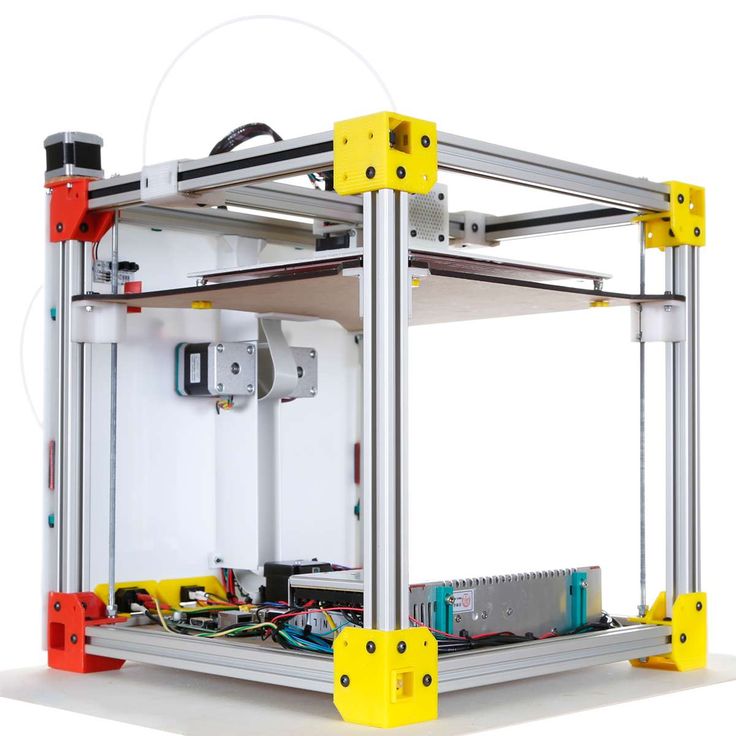

3D Printing Technologies - Antar Printing House in Khabarovsk

Automated production of three-dimensional figures based on their computer model was implemented quite a long time ago, back in the last century. After all, CNC milling or turning machines to some extent solved this problem. But 3D printing is considered a breakthrough in the technology of creating objects based on a virtual three-dimensional image. It is based on a completely different principle, when an object is formed not by processing the original workpiece, but by recreating it layer by layer in various ways.

This technology appeared quite a long time ago, in the 80s, and is now used almost everywhere. This is due to its significant reduction in price. If the first 3D printers were built tens and hundreds of thousands of dollars, now they have reached the level of almost household devices available to any consumer.

This is due to its significant reduction in price. If the first 3D printers were built tens and hundreds of thousands of dollars, now they have reached the level of almost household devices available to any consumer.

The history of 3D printing. Stereolithography

The study of this direction in technology began with the research of the American Charles Hull, who got excited about the idea of creating three-dimensional figures back in the late 40s. A method that he was able to patent only at 1986, was called stereolithography, and it was based on the process of creating objects using the photopolymerization of a liquid substance. The first industrial 3D printer was called that - a stereolithographic installation. This technology involved "growing" an object by superimposing layers of fractions of a millimeter on a continuously moving platform. The units produced by the Hull-founded 3D System were commercially successful, but limited in demand due to their considerable cost and bulkiness.

Modern 3D printing technologies

And only in the current century, around 2012, did a breakthrough occur in the 3D printer market, when compact and cheap consumer-grade models appeared. Buying them now is no problem, you can even order in the online store. The aforementioned 3D System company also started their production, but its printing technology is far from the only one.

LOM - sheet printing

Back in 1985, another method was proposed - by forming objects from thin sheets, connected using a heated press. It was invented by Mikhailo Feigen, and not only plastic, but also paper was used as a material. The three-dimensional models of the earth's surface created with its help look very impressive. However, this method, referred to as LOM, has some disadvantages associated with insufficient strength of the resulting sample.

SLS - powder plus laser

Around the same time, in 1986, a more advanced technology appeared that uses a laser and powder as a raw material. The principle of operation lies in its layer-by-layer sintering by a laser beam along a given contour in a special chamber. Accordingly, this technology is designated SLS, that is, selective laser sintering. The powder used can be made from polymers, ceramics, metal or foundry wax.

The principle of operation lies in its layer-by-layer sintering by a laser beam along a given contour in a special chamber. Accordingly, this technology is designated SLS, that is, selective laser sintering. The powder used can be made from polymers, ceramics, metal or foundry wax.

The advantage of this method, proposed by Carl Descartes, can be considered not only the use of various materials, but the possibility of simultaneous production of several items. The disadvantages include the porous structure of the obtained samples, as well as the need for regular cleaning of the chamber.

SGS - UV Curing

This method was developed by Gubital in Israel a year later. In it, as in stereolithography, photopolymerization is used, however, the technological process itself involves the preliminary formation of a template that covers a thin layer of photopolymer. After its exposure to ultraviolet irradiation, the material solidifies selectively (only under the template), the process is repeated cyclically.

The advantage of this technology is the possibility of stopping it, for example, to check the quality of workmanship. The disadvantage is the use of unique high cost polymers. The installation itself also costs a lot - hundreds of thousands of dollars. For this reason, 3D printers of this class have not received distribution in our country.

FDM - Filament Printing

In the early 90s, this technology made a splash in the market when Stratasys offered consumers $50,000 3D printers. Inventor Scott Crump received a patent for it at 1988, and the installation itself is somewhat similar to a conventional inkjet printer. After all, it uses a real print head, through which the melt of plastic, metal or wax (in the initial state - in the form of a thread) flows down and forms an object in even layers. The transition to the next layer is carried out after lowering the platform on which the sample is located.

Currently, all of the above methods are used for 3D printing, however, the invention of Charles Hull is considered the most promising. This is due to the fact that stereolithography has significantly less restrictions on the materials used. Regardless of the method used, the most important factor in the development of this technology is its penetration into various spheres of human activity. Today, they are not limited to industry, and 3D printing is confidently taking its place in construction, medicine, and even culinary.

This is due to the fact that stereolithography has significantly less restrictions on the materials used. Regardless of the method used, the most important factor in the development of this technology is its penetration into various spheres of human activity. Today, they are not limited to industry, and 3D printing is confidently taking its place in construction, medicine, and even culinary.

We can safely say that this is technology of the XXI century .

Bestfilament plastic for 3D printers Khabarovsk

-

New

Bestfilament Fluorescent PLA for 3D Printers, Yellow, 1kg (1.75mm)

More details

-

New

White Bflex plastic Bestfilament for 3D printers 0.

5 kg (2.85 mm)

5 kg (2.85 mm) More details

-

New

Yellow Bflex plastic Bestfilament for 3D printers 0.5 kg (2.85 mm)

More details

-

New

Green Bflex plastic Bestfilament for 3D printers 0.5 kg (2.85 mm)

Read more

-

New

Designer XL PRO 3D printer

More details

-

New

PICASO 3D Designer XL

More

-

New

MINI PACK (PLA+PETG+Watson)

More

-

New

Bestfilament Fluorescent PLA for 3D Printers, Blue, 0.5 kg (1.75 mm)

More details

-

New

Brass PETG plastic Bestfilament for 3D printers 1 kg (1.

75 mm)

75 mm) Read more

-

New

Copper PETG plastic Bestfilament for 3D printers 1 kg (1.75 mm)

More details

Specials

-

MINI PACK (PLA+PETG+Watson)

3 770

2 750 ₽

Read more

-

Transitional PLA plastic Bestfilament for 3D printers 1 kg...

2 190

1 550 ₽

Read more

- Learn more

- Best program to design 3d prints

- Best 3d printer for orthodontics

- 3D printing industry revenue

- 3D fabric printing machine

- 3D printing filament singapore

- 3D printer kaufen

- 3D printer silicone heated bed

- Xyzprinting 3d scanner software

- Diy 3d printer bed

- 3D printed grommet

- 3D printed theo jansen strandbeest