Light saber 3d print

Lightsaber best 3D printer files・Cults

georgestephanis Savi's Chassis mid tweak

Free

Master replicas Yoda Proffieboard Conversion Chassis v3.0

Free

Custom Lightsaber Grips

Free

Not another LEGO Lightsaber

Free

Lightsaber: Darth Nihilus (Lightsaber)

€12.50

Star Wars/laser saber/stormtrooper LED sign

€3.50

Custom Lightsaber

€3.06

Luke Sywalker Return of the Jedi Lightsaber

€9.65

Custom Lightsaber

€8.70

Light Saber Emitter

Free

Darksaber sword 1 12 scale black series 6 inch

€5. 65

Star wars Naga Sadow statue

Free

luke skywalker lightsaber

€9.52 -75% €2.38

Smolder Lightsaber

€2.82

Darth Vader ROTJ Stunt Saber AKA MoM

€40.11

Collapsing Luke Lightsaber (Removable Blade)

Free

Obi-Wan Kenobi Lightsaber

€15

LightSaber Wall Mount

€1.41

Four Lightsabers with parts to mix

Free

Grogu With Jedi training helmet

€5.16

Generic Light Saber Stand

Free

Soupcan13 5k follower appreciation saber

Free

Inquisitor Ripper Saber

Free

Anakin lightsaber ROTS

€5

Custom Lightsaber

€5. 16

16

Asoka Tano Lightsabers

€11.46

Custom Lightsaber

€5.16

Darth Vader Lightsaber

€5.73

Second Sister Lightsaber for Cosplay

€12.50

Second Sister Armor for Cosplay

€14.90

Second Sister Helmet for Cosplay

€14.90

Obi Wan Kenobi Lightsaber for Cosplay

€9.90

Obi Wan Kenobi Battle Armor for Cosplay

€19.90

Darth Star Killer Helmet for Cosplay

€14.90

Darth Star Killer Lightsaber Armor for Cosplay

€9.90

Darth Vaders lightsaber

Free

Lightsaber Hand Guard

€5. 64

64

Lightsaber guard

€3.75

Graflex Light Saber Chassis

€5.65

custom lightsaber

€4.35

Qui Gon Jinn Lightsaber - Tales of the Jedi

€5.88

Obi Wan Kenobi's First Lightsaber - The Phantom Menace

€5.88

Darth Vader Lightsaber

€1.88

Darth Maul's Lightsaber

€1.88

Count Dooku's Lightsaber

€1.88

Anakin Skywalker's Lightsaber

€1.88

Obi Wan Kenobi's Lightsaber

Free

Qui Gon Jinn Lightsaber - 3D Print .

STL File

STL File€4.13

3d Print Lightsaber - Etsy.de

Etsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

Find something memorable, join a community doing good.

(784 relevant results)

Do-it-yourself lightsaber or choosing transparent plastic for 3D printing Bringing what we see on the big screen to life in a believable way requires a lot of trickery, and with limited resources and budgets, creative skills are sharpened to the limit.

PapaTony's Shield&Hammer team offers their own solution to the task of making a lightsaber.

One of the rare materials is transparent tubes. They can be obtained in advertising workshops, where light structures are made. We conducted an on-duty call to all those involved in such a case within a radius of 500 kilometers around Krasnoyarsk. All that they could offer us was the certainty that some factory would put the required pipe into the production plan and it might be delivered in 3-4 months. Plus prepayment. Obviously not our choice.

Decided to do everything by hand.

In general, we did not make a Jedi sword, but the design is similar. So, to create a luminous blade, you need a strong transparent plastic.

For tests, we took materials already known to us and decided to master new ones:

- Natural PLA is a material widely known to everyone working with 3d printing. Differs in ease of the press, high rigidity.

- Natural Watson (SBS) is a very popular thin-walled plastic.

The ease of post-processing to give the product evenness and transparency has made this plastic the best choice for creating vases/bottles/dishes/lamps, etc. They are easy to print with moderate softness.

The ease of post-processing to give the product evenness and transparency has made this plastic the best choice for creating vases/bottles/dishes/lamps, etc. They are easy to print with moderate softness. - Natural PETG is a material that has recently gained popularity. It has excellent interlaminar adhesion. Practical experience with him is not enough, we will catch up.

- Transparent ABS is a very mysterious material. Natural ABS is ivory white with a slight warm yellowish tint. Apparently, transparency is achieved by adding some substance. According to the manufacturer, printing and processing is no different from conventional ABS.

A printer with a print height of 1 meter was also not found, and there was not enough time to assemble my own. Therefore, a test for bonding strength was added to the test for the strength of the structure itself.

Printing was done with the following settings:

- The print and bed temperatures for each material were selected closer to the upper limit of the manufacturer's recommendations - this way there is a higher probability of obtaining a stronger adhesion of the layers

- Nozzle 1.

2 mm, layer 0.6 mm, extrusion width 2.4 mm. Print mode - spiral vase.

2 mm, layer 0.6 mm, extrusion width 2.4 mm. Print mode - spiral vase. - Airflow is switched on from 3 layers even for ABS - there is a risk that a thick layer of plastic will not have time to cool and the structure will float.

- Print speed 15 mm/sec — you should not rush when printing such objects, the lower the speed, the better the sufficiently thick plastic layer cools down.

- Model - a simple cylinder with a diameter of 30 mm and a height of 200 mm (print height of the vast majority of popular printers).

PETG looks the most transparent in appearance due to the excellent adhesion of the layers. Next comes Watson. ABS and PLA are tied for third place.

Since the print height of the printer is not enough for a more or less decent sword, it remains only to glue:

- PLA - with dichloromethane.

- Watson - solvent or xylene (let's try both options).

- PETG - no solvents were found, so we will use cyanoacrylate (aka superglue).

- ABS - acetone.

When printing with a spiral vase, the tubes are smooth on one side, with a step on the other:

It is not necessary to cut the step - it is great for joining the two upper parts of the tube:

Cyanoacrylate hards due to moisture in the air, to accelerate the process, the moisturizer was included:

Ready for tube tests:

To begin with, all gluings were tested for static load. A package with dumbbells weighing 2 kg was suspended from the center of each rod.

PLA turned out to be the most rigid, 60 cm of the tube practically did not bend:

ABS confidently holds 2 position on the deflection

Petg slightly lags behind ABS

, Watson behaves softer than all

To evaluate the strength in the dynamics, we decided to break the trumpets of Sinai-a training sword sword for kendo.

All specimens withstood at least one well placed impact. The fragments were collected for study.

PLA parted along the seam in the first place of gluing, broke near the seam in the second:

Watson is split and broken:

PETG is half split at the joint, half cracked:

ABS is split at the bond. At the point of impact, a change in the transparency of the plastic is visible:

Subtotal: all plastics held up with dignity. To be honest, I expected that everyone would break with one blow.

Based on the test results, we chose transparent ABS in our project - in case of breakage, it is easily and quickly glued with acetone / dichloromethane and perfectly processed (were sanded so that the light from the LEDs was more uniform).

The resulting sword is:

A little about lighting. The problem with LED strips, and LEDs in general, is pointiness. Without tricky tricks it is impossible to create the effect of a uniform glow in any type of plastic:

However, if you add a frosted tube to the center, the lighting is evened out

.

Transparent ABS was a pleasant discovery for me - it retained the qualities of conventional ABS (easy to process, high strength, solvents available, high temperature resistance, great printing experience with this material) and at the same time expanded the boundaries of the material.

Thank you for your attention, and may the Force be with you.

15 epic 3D printable Star Wars models

Yoda, which one will you have on your desk? Laser sword hilt holder? Or a battery powered moving AT-AT? Get these epic Star Wars models with 3D printing.

Looking for a new model of Darth Vader or a roaming AT-AT? After all, a new episode of Star Wars is just around the corner - more precisely, in December - so it's time to prepare for it. What is the best way to do this? Stock up on 3D printed Star Wars items. Below is a list of amazing Star Wars 3D printable models.

1. Thermal detonator

This Star Wars thermal detonator can be 3D printed. The model has four holes for LEDs, allowing you to bring this support to the senses.

The model has four holes for LEDs, allowing you to bring this support to the senses.

2. Darth Vader head

Of course, this head is a 3D printed product. It can be used as a great accessory for any desktop. This model looks best for printing in black.

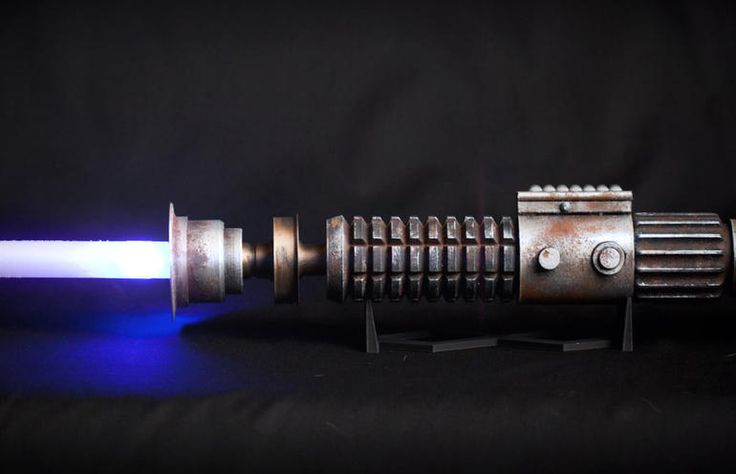

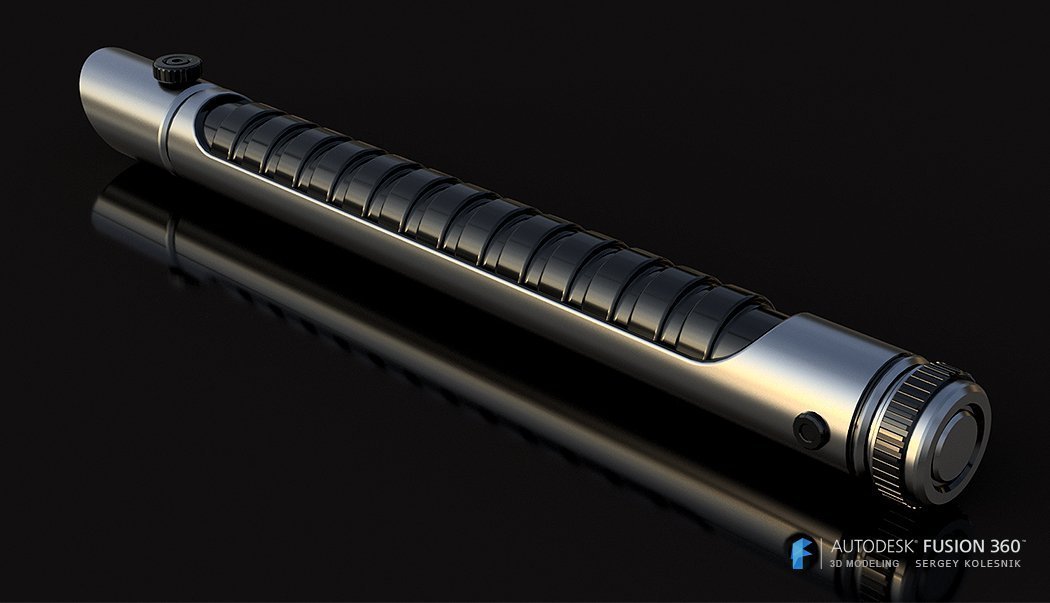

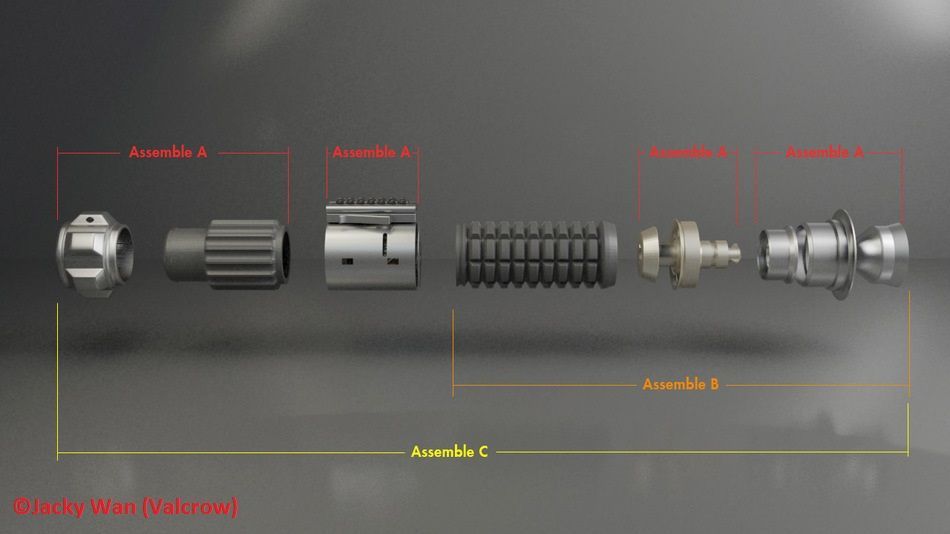

3. Luke Skywalker's lightsaber

This Star Wars model comes in eight separate parts. “I see that you are constructing a new lightsaber. Your skills are perfect. Surely you are strong, just as the Emperor foresaw." - Darth Vader.

4. Polygonal Yoda

3D printed bust of Yoda. The polygonal design perfectly conveys the character's character. The 3D print should take about seven hours using PLA and 20% infill at 100 microns. Patience must have! This is Yoda.

5. Large R2-D2

A beautiful remake of the R2-D2 droid. But R2-D2 is white, isn't it? An exact copy can just as easily be printed using a variety of colors. Make sure to save the plans for the Death Star in the R2-D2 droid.

6. Star Wars Emblem

When 3D printing the emblem, it is recommended to use two colors, preferably black and yellow, as in the photo.

7. Motorized AT-AT

This is a 3D printed AT-AT that can walk. How cool is that? This part of the movement has 69 parts and is powered by a 9-volt battery and a 90 rpm motor.

8.BB-8

3D printed version of BB-8, the ride droid from Star Wars Episode VII. Model BB-8 is designed for use with Sphero. Sphero is a controlled robot ball app that can roll at speeds up to 7 feet per second.

9. Blaster Han Solo

This blaster is known as the DL-44 blaster pistol. Han Solo used one of these pistols in the Star Wars movies. We suggest printing this Star Wars model with 10% infill and 200 micron quality.

10. K-2SO

3D printable model of the K-2SO robot seen in Rogue One. This is a witty robot who sacrificed his existence for the success of the mission - to steal the plans of the Death Star.