Hersheys 3d chocolate printer

3D chocolate printing has bright future, says Hershey

Last year, Hershey entered a joint development agreement with 3-D printing specialists 3D Systems. In December, the chocolate firm debuted a 3-D Chocolate Candy Printing at Hershey’s Chocolate World Attraction in Pennsylvania.

“One of the goals of our exhibitions has been to gather consumer insights on price point and designs as we build out our commercialization plan for Hershey 3-D printed chocolate,” Jeff Mundt, Hershey’s senior marketing manager of technology, told ConfectioneryNews.

A permanent fixture in Hershey retail stores?

Hershey's 3-D chocolate printing exhibit features an interactive touchscreen that allows the company survey the public on their customization preferences. The data will help Hershey to develop its business model for a commercial 3-D candy printing experience.Mundt said that 3-D printing had an exciting future as consumers increasingly looked for customized food.

“3-D printed chocolate could become a permanent fixture at our retail stores in the near term, for example,” he said. “Consumers will be able to design their own piece of chocolate, have it printed before their eyes and take it home as a special souvenir.”

Hershey says the principal advantage of 3-D chocolate printing is that every item from the printer can be completely unique.

Can it replace chocolate molding?

Mundt said the technology was not currently a good substitute for mass production because it was far slower than traditional chocolate molding . “That being said, with each iteration the technology becomes faster and more precise so we’ll have to see what the future holds.”

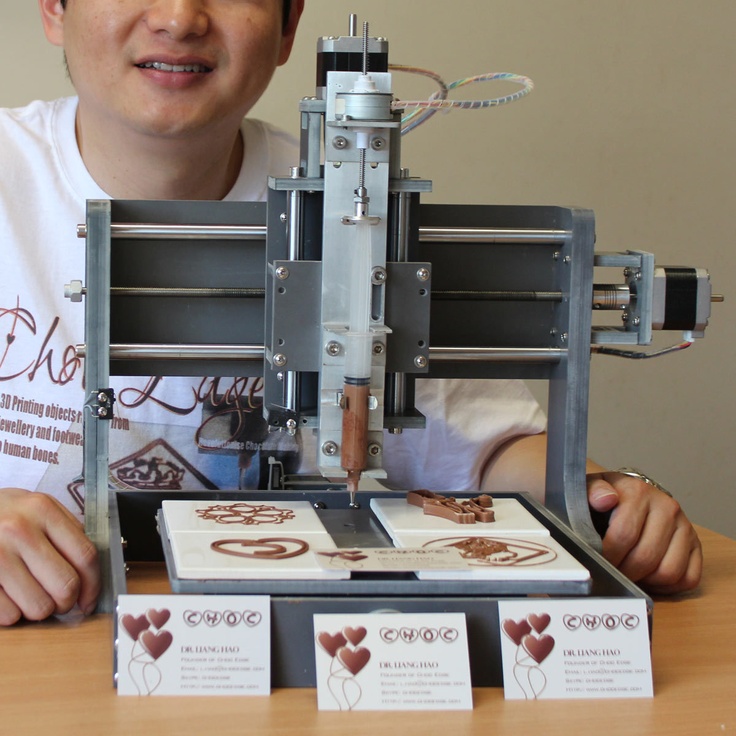

Liang Hao, a senior lecturer of Engineering at the University of Exeter and founder of 3-D printing firm Choc Edge previously told this site that he expected industrial 3-D chocolate printing within 3-5 years.

Industrial potential beyond capabilities of molding

Mundt said that printing times depended completely on the amount of chocolate needed for the design.

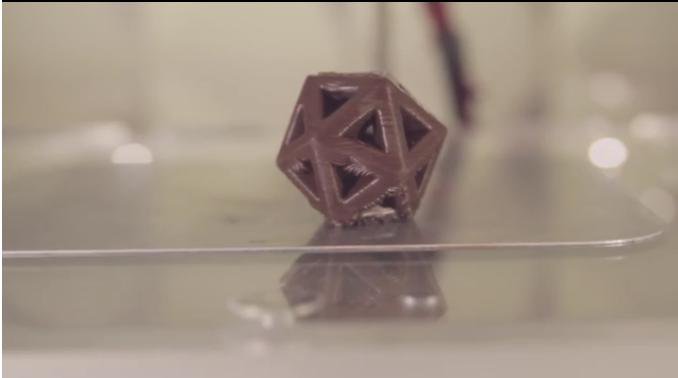

“A standard 40 gram chocolate bar would take about an hour, but if it was a complex lattice that 3-D printers are capable of making you could print something the ‘size’ of a standard chocolate bar in much less time,“ he said.

“It doesn’t make sense to use the 3-D printing today to make a standard bar when we have such strong manufacturing competency, but it does make sense to make something that you couldn’t make with a mould, like a lattice or other design that would be totally unique and delightful to consumers.“

How does the printer know what to print?

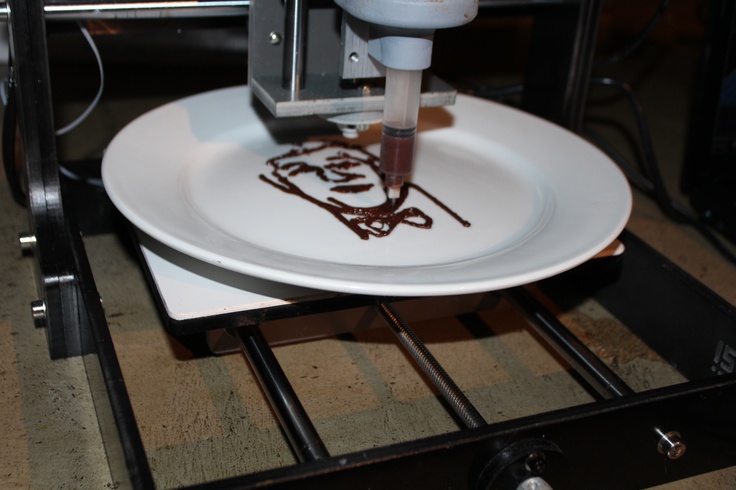

3-D printer print a design according to a 3-D design file. Hershey’s Jeff Mundt said: “The file could be a CAD file you download from a sharing site like Quickparts or a 3-D scanned image of your face, a photo of your dog or your company’s logo. Also, with the advent of the low cost, high resolution scanning technology available today, you no longer need to be a CAD designer to create your own unique designs and print them out. The possibilities are truly limitless.”

The possibilities are truly limitless.”

Are 3-D printers set to boom?

Basic 3-D printers currently sell for upwards of $5,000. The price may be prohibitive for many households, but Mudnt said that things could change rapidly.

3-D chocolate printers are capable of producing edible faces that are retrived from real-life photos. Pictured is a 3-D chocolate version of Hershey founder Milton Hershey.“We are living in an exponential world with technology making progress much more rapidly than anticipated, so it is very likely that each of us will one day have a 3-D printer in our homes sooner than we think. Remember how revolutionary the microwave oven was when it was first offered commercially, today it is ubiquitous,” he said.

He added that the 3-D printing exhibit space at the Consumer Electronics Show had doubled between this year and last, showing how interest was mounting among inventors.

3D Systems exhibited its latest printer –the Hershey/3D Systems CocoJet 3-D Chocolate printer – at the show earlier this month. The company also showcased its full-color ChefJet Pro printer, which features Digital Cookbook software to create intricate candies and sweets. It will be commercially available in the second half of 2015.

The company also showcased its full-color ChefJet Pro printer, which features Digital Cookbook software to create intricate candies and sweets. It will be commercially available in the second half of 2015.

Taste the Future: 3D Printing Chocolate at Hershey

Additive Manufacturing in the Food Industry

Growing up watching The Jetsons, I could have never fathomed a world in which the press of a few buttons actually resulted in real food – at least not in my lifetime. Well, that moment is here. Additive manufacturing, also known as 3D printing, may have had its roots in plastics and metals, but it is now being used in the food industry as well [1]. Growing at a 38.5% CAGR, the 3D food printing industry is projected to reach $525.6 million by 2023 [2]. While still in its very early days, 3D food printing has massive potential to revolutionize the food industry: from improving nutritional properties, to creating food for those with dietary restrictions, to customization in gastronomic experiences, to feeding the hungry and even aiding in disasters where food is unavailable, the possibilities are endless [3]. No discussion about food, however, would be complete without chocolate, right? Enter Hershey.

No discussion about food, however, would be complete without chocolate, right? Enter Hershey.

[4]

How Hershey is Innovating with Additive Manufacturing

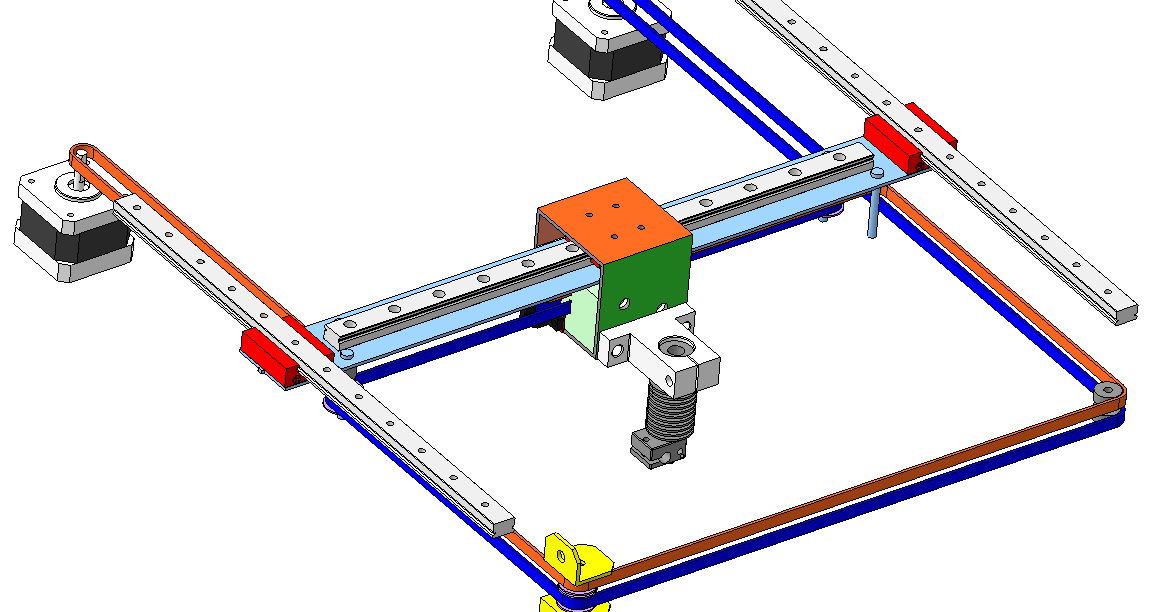

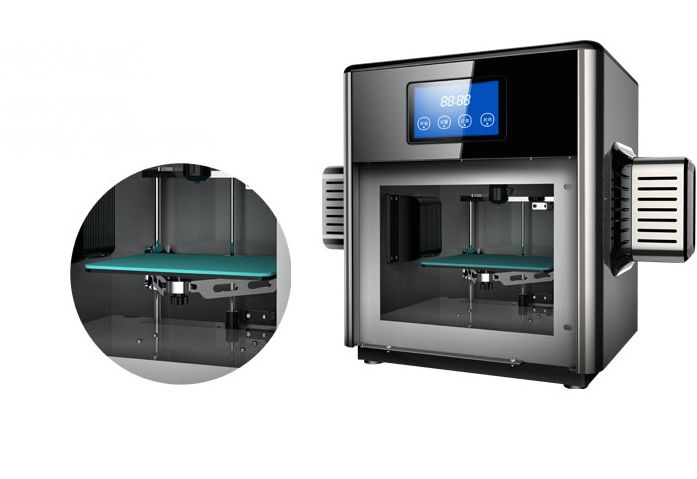

The Hershey Company, one of the largest chocolate manufacturers in the world, and 3D Systems, one of the leading manufacturers of 3D printing equipment, collaborated to create CocoJet, a chocolate 3D printer [5]. “The CocoJet printer is designed to print milk, dark, and white chocolates in a user defined design fed into it through a computer aided design (CAD) file” or scanning technology [5]. The CocoJet can not only personalize existing Hershey products, but also “print chocolates in various shapes, sizes, and geometries” [5]. Hershey embarked on this journey in the 3D food printing space to allow customization of its products to consumers. As such, the CocoJet was first revealed and debuted in December 2014 at Hershey’s Chocolate World Attraction in Hershey, PA [6].[7]

Visitors to Hershey’s Chocolate World Attraction can customize their chocolate bars with personalized messages through a CAD file or even a picture of their faces recreated through CocoJet’s scanning technology [7]. One of the several limitations the additive manufacturing field currently faces, however, is time. Printing a full size Hershey Chocolate Kiss (pictured above) takes approximately one hour and twenty-six minutes [7]. Therefore, what Hershey is currently offering the public with their 3D printer is actually two dimensional design customization, which takes only a few minutes [7]. The idea is for customers to interact and buy; anything longer would likely “detemper [customer] enthusiasm” [7].

One of the several limitations the additive manufacturing field currently faces, however, is time. Printing a full size Hershey Chocolate Kiss (pictured above) takes approximately one hour and twenty-six minutes [7]. Therefore, what Hershey is currently offering the public with their 3D printer is actually two dimensional design customization, which takes only a few minutes [7]. The idea is for customers to interact and buy; anything longer would likely “detemper [customer] enthusiasm” [7].

Additionally, “the printers have an interactive touchscreen that allows the company to survey the public on their customization preferences” [8]. This customer feedback can help inform the company of how to proceed with their technology as they continue innovating.

What’s Next for Hershey and 3D Printing?

While “it’s too soon to say how their work will translate into real world applications”, Hershey continues to explore how they can leverage the technology they have developed with 3D Systems [8]. Hershey and 3D Systems continue investing in R&D both internally and externally [8]. For example, the companies have established a partnership with the Culinary Institute of America (CIA), one of the world’s top culinary schools [8].

Hershey and 3D Systems continue investing in R&D both internally and externally [8]. For example, the companies have established a partnership with the Culinary Institute of America (CIA), one of the world’s top culinary schools [8].

They have installed the technology at the culinary school giving access to current CIA students, alumni, and culinary professionals so that they can continue to innovate using the printer and help find real world applications for it in the culinary world. The companies’ hope is that “this will help [them] to better understand how user friendly the technology is and to see how far [they] can push its capabilities to create chocolate shapes otherwise not achievable through traditional molding techniques” [8].

The more hands on deck – or kitchen counter – the better; “with each iteration the technology becomes faster and more precise so we’ll have to see what the future hold[s]” [8].

Recommended Areas for Growth

So where does Hershey go from here?

“The technology [of 3D food printing] makes it possible to create complex, reproducible 3D structures impossible to make by hand alone, and can also help with more customized nutritional requirements” [9].

In addition to customizing products through personalization, shapes, and sizes, I believe using 3D printing to customize the nutritional property of chocolate represents a huge growth opportunity for Hershey to develop a line of products to significantly expand its target market.

Other research areas of 3D food printing include the development of creating lower sugar products, such as cookie doughs [9]. Similar work is being done in hospital care where 3D food printing is also being used to customize and tailor the nutritional properties to each patient’s needs [10].

Hershey could create a range of lactose free or low sugar products for individuals who are lactose intolerant, suffer from diabetes, or have other dietary restrictions.

What Challenges Does Hershey Face?

The biggest challenge Hershey and others innovating in the 3D food space is, “how do we scale from here?”

(799 words)

References

[1] McCue, TJ. “3D Food Printing May Provide Way To Feed The World.” Forbes, October, 30, 2018. https://www.forbes.com/sites/tjmccue/2018/10/30/3d-food-printing-may-provide-way-to-feed-the-world/#5bb669be5817, accessed November 2018.

“3D Food Printing May Provide Way To Feed The World.” Forbes, October, 30, 2018. https://www.forbes.com/sites/tjmccue/2018/10/30/3d-food-printing-may-provide-way-to-feed-the-world/#5bb669be5817, accessed November 2018.

[2] “Global 3D Food Printing Market: Focus on Technology (Fused Deposition, Selective Sintering, and Powder Bed Binder Jetting), Vertical (Commercial, Government, and Hospital), and Food Type (Confections, Meat, and Dairy) – Analysis & Forecast 2018-2023.” Research and Markets, June 2018. https://www.researchandmarkets.com/research/j3kmz7/global_525?w=4, accessed November 2018.

[3] Abidi, Sam. Phipps, Jarrod. Porter, Kim. Szepkouski, Adam. “3D Opportunity Serves it Up:

Additive Manufacturing and Food.” Deloitte Insights, June 18, 2015. https://www2.deloitte.com/insights/us/en/focus/3d-opportunity/3d-printing-in-the-food-industry.html, accessed November 2018.

[4] “The Jetsons Future of Technology.” March 4, 2014. https://www.youtube.com/watch?v=2m7szptyYPY, accessed November 2018.

[5] “3D Printing in the Food Industry – Advanced Manufacturing TechVision Opportunity Engine.” Frost & Elliot, November 4, 2016.

[6] Halterman, TE. “3D Systems Unveils CocoJet Chocolate 3D Printer At 2015 CES.” 3D Print, January, 6, 2015. https://3dprint.com/35081/culinary-printing-3d-systems/, accessed November 2018.

[7] “How Hershey’s is Using 3-D Printers to Make Chocolate Kisses.” Bloomberg, May 7, 2015. https://www.youtube.com/watch?v=9FajGAeJ840, accessed November 2018.

[8] Eagle, Jenny. “Hershey continues to explore the possibilities of 3D printing.” Confectionery News, December 4, 2017. https://www.confectionerynews.com/Article/2017/12/04/Hershey-continues-to-explore-the-possibilities-of-3D-printing, accessed November 2018.

[9] Saunders, Sarah. “Using 3D Printing to Reduce the Amount of Sugar in Cookies…Without Making Them Inedible.” 3D Print, October 6, 2018. https://3dprint.com/227364/3d-printing-to-reduce-sugar-in-cookies/, accessed November 2018.

[10] University of Copenhagen. “3D printed food to help hospital patients.” Faculty of Science, October 3, 2017. https://www.science.ku.dk/english/press/news/2017/3d-printed-food-to-help-hospital-patients/, accessed November 2018.

Hershey will create a chocolate 3D printer

Komsomolskaya Pravda

Smart things: Gadget of the day

Anya Sklepova

January 18, 2014 15:49

The largest manufacturer of chocolate bars in North America intends to make their sweets a product of the future

Hershey chocolate 3D printer Photo: GLOBAL LOOK PRESS

Hershey is working with 3D systems to develop a 3D printer for chocolate and other products. nine0004

The largest candy bar maker in North America has yet to disclose the amount of the deal or when the invention will be available to consumers.

However, the representative of the company spoke about how three-dimensional chocolate products are created. To do this, chocolate is melted, heat-treated and placed in a 0. 05 mm thick layer into a mold.

05 mm thick layer into a mold.

- Chocolate is a fairly difficult material to 3D print due to the need to constantly control its temperature and viscosity, Hershey explained. nine0004

“Whether we are creating a new form of sweetness or manufacturing technology, we plan to use modern technologies such as 3D printing to make our timeless sweets products of the future,” said William Papa, Vice President and Head of Research and Development. Hershey designs.

Hershey isn't the first company to make food-printing gadgets, according to The Telegraph.

Last week at the International Consumer Electronics Show, which constantly brings to the attention of the public strange and wonderful devices, this gadget was presented that will delight all sweet teeth: a 3D printer that can print food. The gadget, named "ChefJet", prints the most real, edible and very tasty sweets. Using sugar and water, he creates glazes of all kinds, shapes and sizes. nine0004

And the British company Choc Edge claims to be able to create a chocolate replica of your face using a 3D printer. Such a copy will cost from £50 to £80.

Such a copy will cost from £50 to £80.

Photoshop users today can create, edit and print an image on their computers. It is possible that soon we will also be able to print food in our kitchens of the future.

Age category of the site 18+

Online publication (website) registered by Roskomnadzor, certificate El No. FS77-80505 dated March 15, 2021

CHIEF EDITOR OLESIA VYACHESLAVOVNA NOSOVA.

EDITOR-IN-CHIEF OF THE SITE - KANSK VICTOR FYODOROVICH.

THE AUTHOR OF THE MODERN VERSION OF THE EDITION IS SUNGORKIN VLADIMIR NIKOLAEVICH.

Messages and comments from site readers are posted without preliminary editing. The editors reserve the right to remove them from the site or edit them if the specified messages and comments are an abuse of freedom mass media or violation of other requirements of the law. nine0004

JSC "Publishing House "Komsomolskaya Pravda". TIN: 7714037217 PSRN: 1027739295781 127015, Moscow, Novodmitrovskaya d. 2B, Tel. +7 (495) 777-02-82.

2B, Tel. +7 (495) 777-02-82.

Exclusive rights to materials posted on the website www.kp.ru, in accordance with the legislation of the Russian Federation for the Protection of the Results of Intellectual Activity belong to JSC Publishing House Komsomolskaya Pravda, and do not be used by others in any way form without the written permission of the copyright holder. nine0004

Acquiring copyright and contacting the editors: [email protected]

3D chocolate printing: advantages and pitfalls

You are here

Home

Chocolate is a sweet, the first historical records of which date back to 350 BC. Already in those days they knew about the existence of cocoa and other chocolate drinks. Today, chocolate is not only a favorite sweet for many, but also a raw material for 3D printing.

Additive manufacturing has made a difference in many food markets, so it's no surprise that 3D printing has affected the chocolate industry as well. Companies such as Hershey, Nestlé, Mars Inc. and Mondelez International have been experimenting with 3D printing chocolate over the past few years. As a result, edible chocolate creations of art appeared on the market.

Companies such as Hershey, Nestlé, Mars Inc. and Mondelez International have been experimenting with 3D printing chocolate over the past few years. As a result, edible chocolate creations of art appeared on the market.

How it works?

Most chocolate 3D printers work with CAD files like other 3D printers. Instead of filament, chocolate 3D printers use a syringe filled with chocolate. The extruder head moves and deposits the molten chocolate in the desired shape in layers. Chocolate cools down over time and becomes hard. The syringe loading system is food safe, ensuring the safety of sweet raw materials. nine0004

Printing Difficulties

Resin is much easier to print than chocolate. The sweet mass has completely different melting and cooling properties, so melted chocolate cannot harden as quickly as plastic.

The type of chocolate used also matters. Milk, black and white chocolate have different viscosities. For best results, it is recommended to use high quality and tempered chocolate (such as Belgian dark). In some cases, makers add significant amounts of pectin to make 3D printing easier. Since chocolate cannot be rolled into a hard thread due to its too soft texture, the melted chocolate is stored in a cartridge and pressed with a syringe. nine0004

In some cases, makers add significant amounts of pectin to make 3D printing easier. Since chocolate cannot be rolled into a hard thread due to its too soft texture, the melted chocolate is stored in a cartridge and pressed with a syringe. nine0004

The main problem with chocolate 3D printers is temperature control. The printing process can take a long time due to temperature complications. The chocolate must be hot enough to melt, and at the same time, it must be cold and dry enough to retain its shape.

Advantages of

The first advantage is, of course, the ability to print sweets of any shape. In other words, additive manufacturing enables ultra-personalization of finished chocolate products. nine0004

3D printing makes almost any idea a reality. In this case, it is recommended to print not very large models. You should also avoid printing sweets with small details, too steep corners. Otherwise, the model will have to be edited. To print complex chocolate objects, you will need to slow down the print speed to give the chocolate more time to dry and harden.