3D printed urn of loved ones head

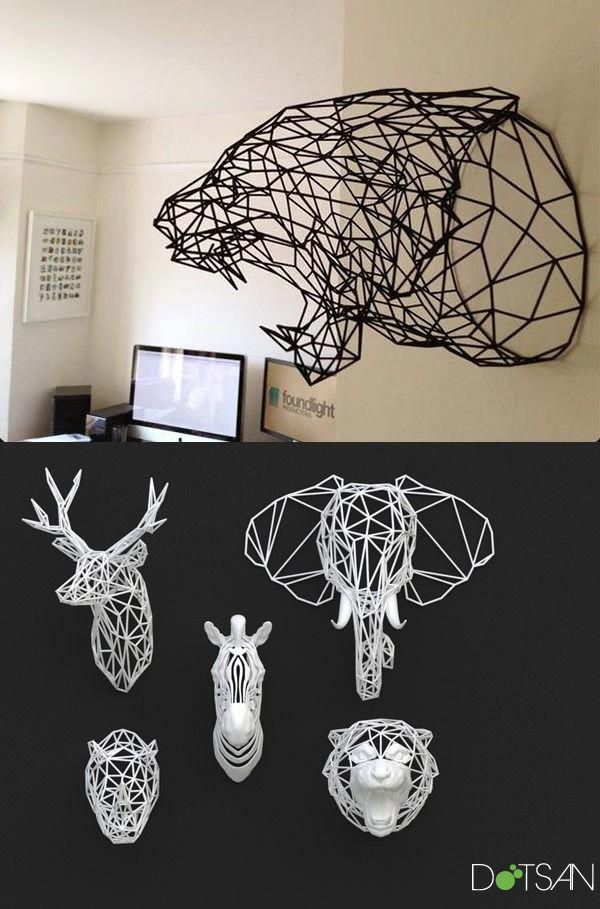

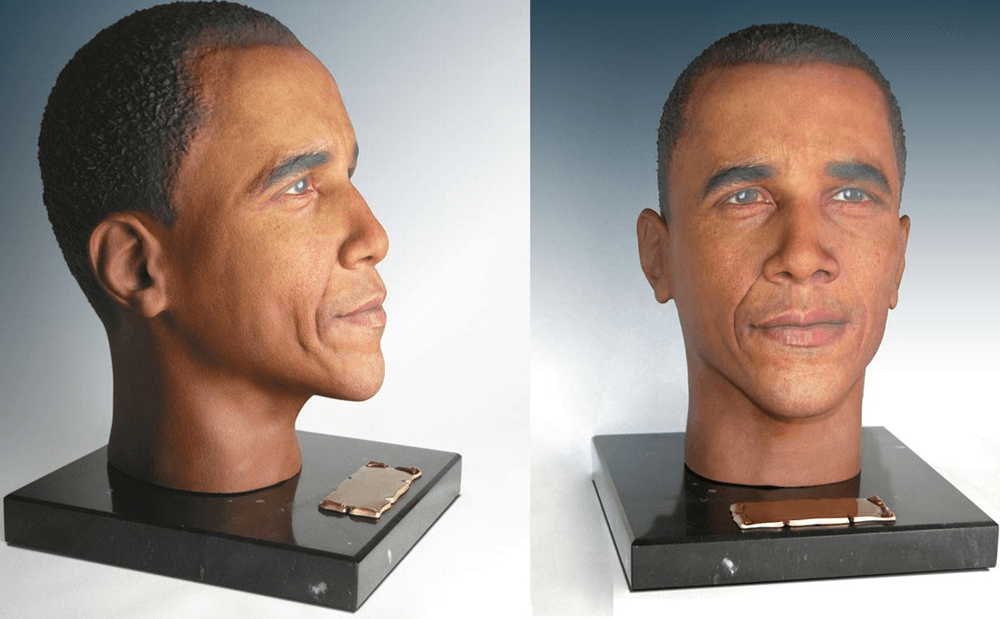

Strange 3D-printed cremation urns of the deceased's head to hold their ashes

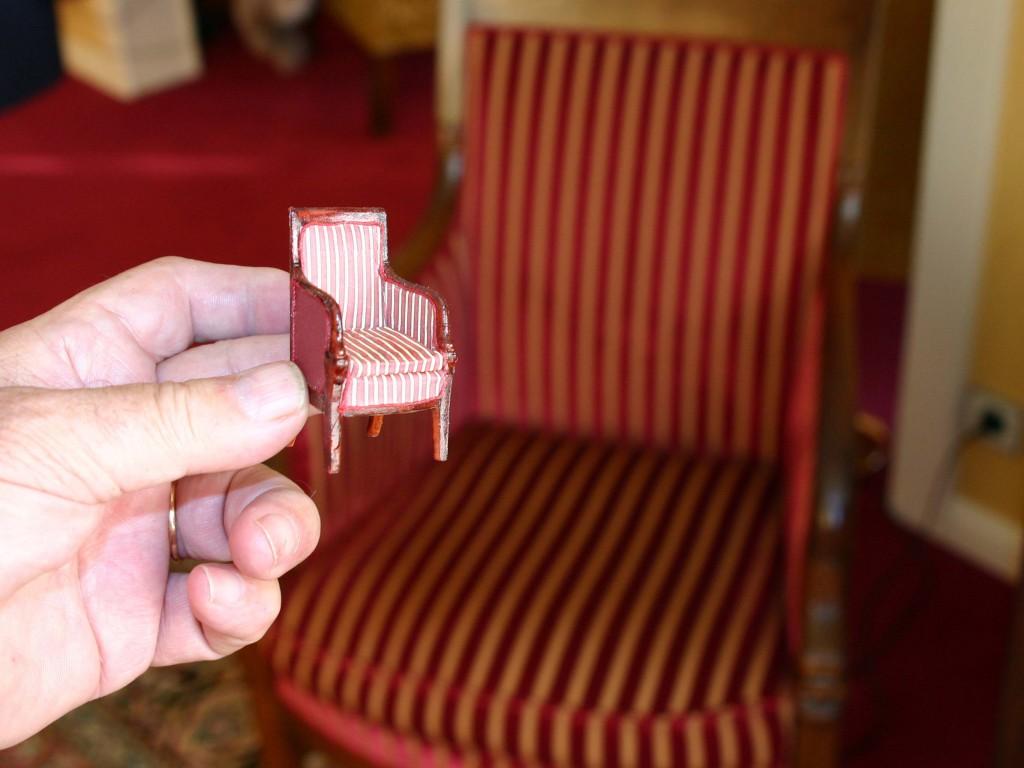

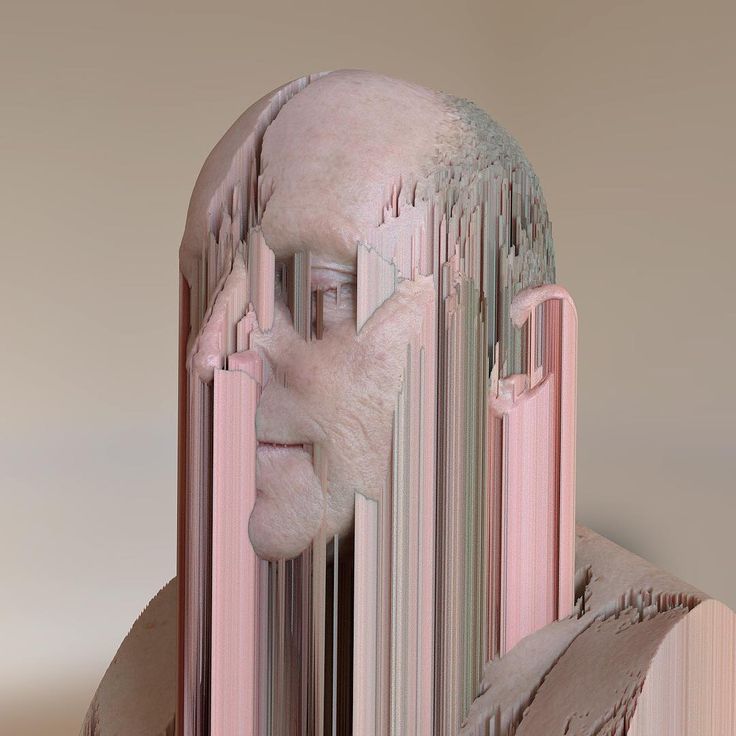

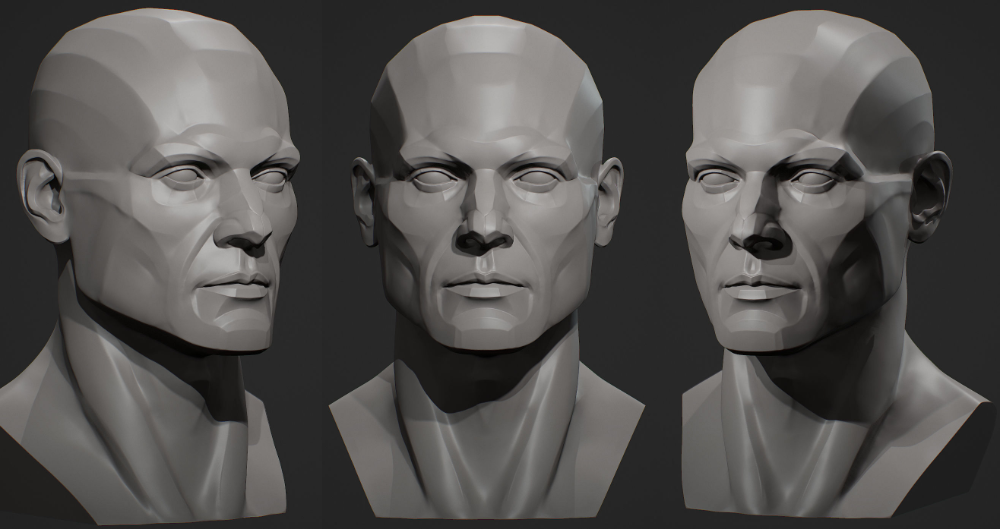

Cremation Solutions offers 3D-printed busts of the deceased's head to hold their ashes. The prices range from $600 to $2,600 depending on the size. Think of it as having your ashes scattered in the Uncanny Valley. From Print Media Centr:

The Vermont-based company informs customers on its website that the urn does not come with hair although it can be digitally added or wigs can be used. It writes: "Personal urns can be designed to look like anyone. We just need good pictures. We prefer one picture from the front and one from the side. Complexions can be adjusted in the final stages and customers get a chance to proof the results."

Prices range from $600 (£389) for the smaller cremation urn to $2,600 (£679) for a larger one. Bizarrely, the company illustrates the service with an urn made in the shape of President Barack Obama's head, explaining that you can also have the urn designed in the image of your hero.

![]()

(Thanks, Charles Pescovitz and Terry Donald!)

images: Creation Solutions

-

How cool is this? It's a 3D printed retro IBM PC. On it's working color monitor it displays a fully working version of Doom housed on an ESP32 chip inside. Details of the build can be found here. [Via Donald Bell's Maker Update.] READ THE REST

-

Abby is a musician, a YouTuber, and someone living with one hand. She has a full left arm and hand and a right arm to the elbow. On Abshow, her YouTube channel, she chronicles her adventure and challenges in living a full life with only one full arm and five fingers. Abby is a drummer… READ THE REST

-

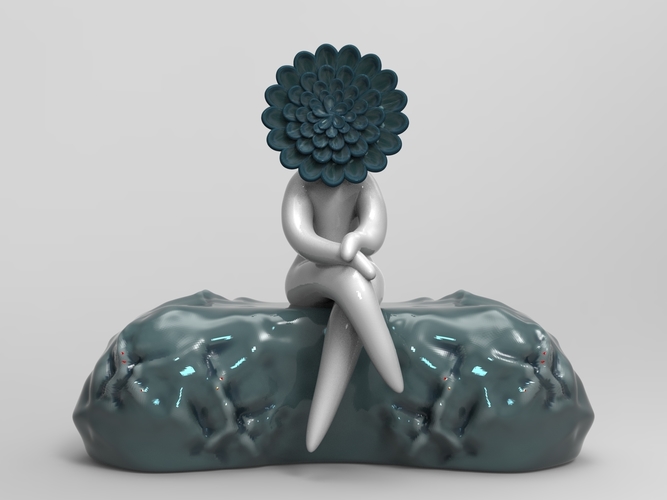

Viginia-based Miguel Zavala 3D artist as compiled a massive archive of printable files to make your own miniatures of nearly every creature in the Dungeons & Dragons bestiary.

They're pretty awesome: You can access all of the files for free, but Zavala also has a Patreon full of great perks to help support his efforts.… READ THE REST

They're pretty awesome: You can access all of the files for free, but Zavala also has a Patreon full of great perks to help support his efforts.… READ THE REST -

We thank our sponsor for making this content possible; it is not written by the editorial staff nor does it necessarily reflect its views. When New Year's Day rolls around, everybody starts examining their goals and intentions for the upcoming year. One great commitment to consider making? Well, more and more people are focusing on… READ THE REST

-

We thank our sponsor for making this content possible; it is not written by the editorial staff nor does it necessarily reflect its views. A new year is approaching, and that means it's the perfect time to take account of your goals! While a new year can be about all kinds of self-growth, one of… READ THE REST

-

We thank our sponsor for making this content possible; it is not written by the editorial staff nor does it necessarily reflect its views.

Flights are at an all-time high, and if you're planning to travel for the holidays, you're most likely experiencing sticker shock. Avoid the exorbitant prices and travel on a budget with The Dollar… READ THE REST

Flights are at an all-time high, and if you're planning to travel for the holidays, you're most likely experiencing sticker shock. Avoid the exorbitant prices and travel on a budget with The Dollar… READ THE REST

3D printers can copy your loved one's head - as a cremation urn

Printers

Published

By | Fox News

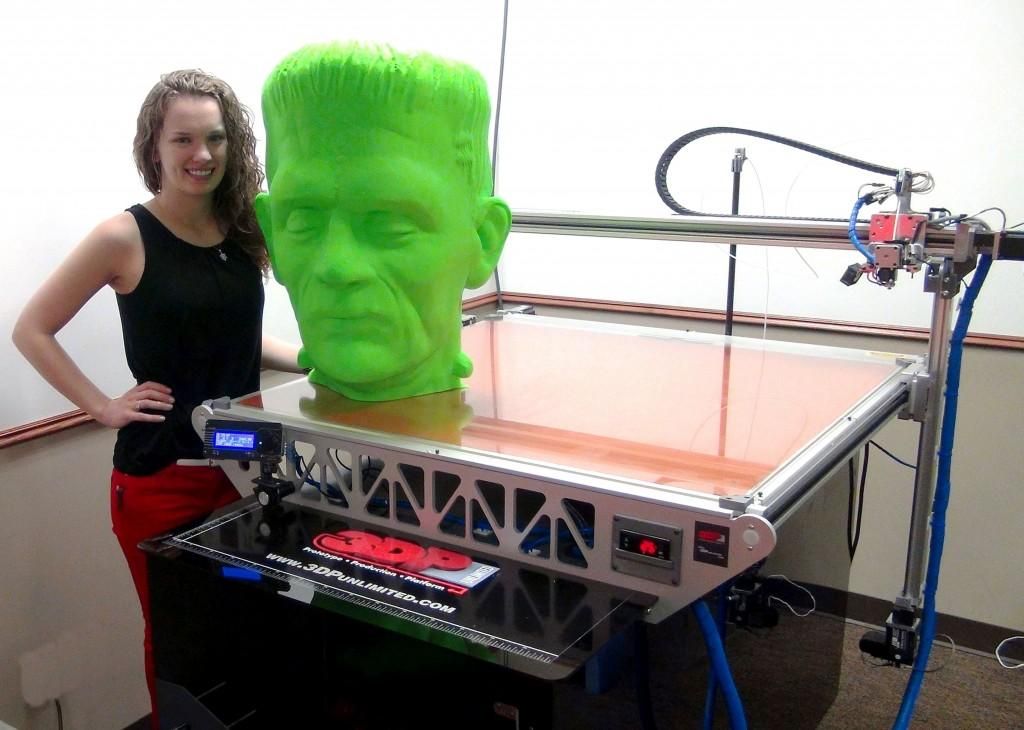

The 3D printer has been used in many surprising, strange ways, from “printing” cars to shoe burgers. The technology has even been used to create a three-dimensional replica of a fetus. Now, you can add cremation urns that possess the shape and features of your loved one’s head to that list. Yes, you read that correctly – cremation urns. Vermont-based Cremation Solutions now offers special customized, 3D printer-produced urns that can be made in “the image of your loved one or your favorite celebrity or hero, even President Obama,” according to the company’s website.

While traditional wooden or metal urns might be the gold standard for storing a loved one’s ashes, Cremation Solutions' new product promises a more memorable way to commemorate those who have passed away.

The company writes on its website that the “latest technology” is used to create the urns, building the closest likeness possible to the deceased using photographs and facial recognition software that “can transform your favorite two-dimensional image into a three-dimensional sculpture that captures the finest details.” To represent a loved one in the best possible light, the company offers to “erase blemishes” so that those who have passed “will look their best for all eternity.”

The urns come in two sizes – an 11-inch “full-size personal urn” that will hold all the ashes of an adult, as well as a “keepsake sized personal urn,” standing at 6 inches and only holding a portion of the remains. The urns aren’t cheap. The larger size is listed at $2,600, while the smaller version is priced at $600. Hair is not automatically included. That being said, the company can “digitally add hair” onto personal urns that depict those with short hair, while a wig can be added for those sporting a longer style.

Hair is not automatically included. That being said, the company can “digitally add hair” onto personal urns that depict those with short hair, while a wig can be added for those sporting a longer style.

While a strange use for 3D printing, the cremation urns represent the growing ubiquity of the three-dimensional technology. According to a 2013 Harvard Business Review article titled “3-D Printing Will Change the World,” the rise of 3D printing is leading to an emphasis on customization of goods to suit consumers’ specific needs and tastes.

For Cremations Solutions, customization is key. The company stresses on its website that not only can customers purchase these items for those who are long-since gone, but they can also customize urns for themselves. Planning on cremation down the line? The company’s website states that a customer can select a picture that shows him or her at the peak of youth.

“Whether you are planning your own funeral to take the burden off your family, or planning one after a death, these urns are a great way to hold onto a crisp and perfect image,” the product description reads. “They are the perfect way to secure and store the ashes of any loved one.”

“They are the perfect way to secure and store the ashes of any loved one.”

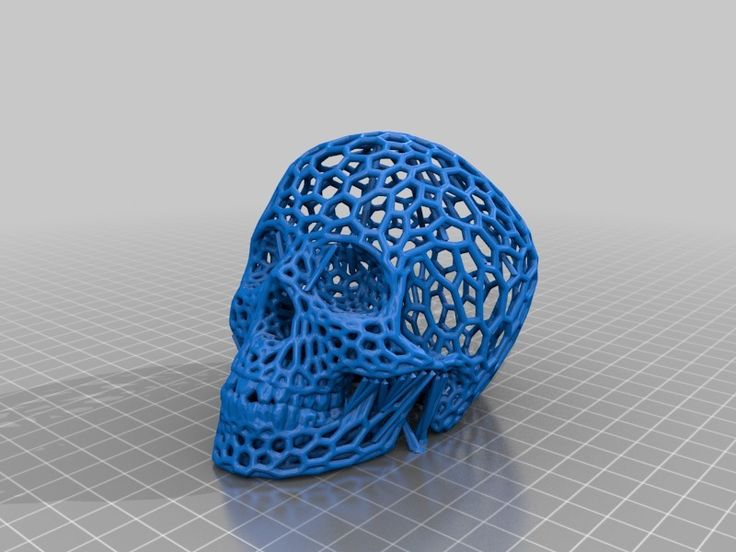

Scientists 3D-printed a skull and saved a child's life

Any surgical operation requires extreme caution from doctors - one wrong move can cause the patient's death. You have to be especially careful with newborn children, because their bones are not formed, and their internal organs are very poorly protected from external influences. In February 2022, in one of the maternity hospitals in the Polish city of Rzeszow, a girl was born, the fifth lobe of the bone part of the head of which was not formed. Due to the fact that one of the areas of the child's skull was practically absent, her brain tissue remained partially exposed - if damaged, the girl was at risk of acquiring many health problems. Fortunately, the company Sygnis came to the rescue, which printed on a 3D printer an exact copy of her skull based on photographs. The layout literally saved the girl's life, but how? Is the skull of a child half made of plastic? nine0003

A 3D-printed skull saved the life of a newborn girl

A child with an underdeveloped skull

A newborn girl from Poland did not have an occipital bone formed. It is located below, on the back of the head, and is needed to protect many parts of the brain - for example, under the occipital bone is the cerebellum. This part of the brain is responsible for coordinating body movements, regulating balance and muscle tone. The volume of the cerebellum is only 10% of the volume of the entire brain, but it contains most of all cells of the nervous system. nine0003

It is located below, on the back of the head, and is needed to protect many parts of the brain - for example, under the occipital bone is the cerebellum. This part of the brain is responsible for coordinating body movements, regulating balance and muscle tone. The volume of the cerebellum is only 10% of the volume of the entire brain, but it contains most of all cells of the nervous system. nine0003

Location of the bones of the skull

Based on the above, it turns out that a girl without an occipital bone could easily damage the cerebellum and in the future have problems with coordination of movements. The defect was not diagnosed during the mother's pregnancy - they learned about it only closer to the birth. The child was born, but was in a very dangerous position, so he was quickly transferred to a hospital in Krakow.

Related article: Scientists have found that appetite is controlled by the cerebellum

3D printed skull

Polish hospital specialists already knew that bone reconstruction was needed to save the girl's life. As noted at the beginning of the article, operations on children require careful care - surgeons needed to know exactly what shape the patient's brain has to within millimeters. Pictures cannot provide such accurate data, so the specialists turned to Sygnis, which has been engaged in 3D printing for a long time. It is reported that the firm has abandoned all its activities to make a model of the girl's head and help doctors save her life. nine0003

As noted at the beginning of the article, operations on children require careful care - surgeons needed to know exactly what shape the patient's brain has to within millimeters. Pictures cannot provide such accurate data, so the specialists turned to Sygnis, which has been engaged in 3D printing for a long time. It is reported that the firm has abandoned all its activities to make a model of the girl's head and help doctors save her life. nine0003

3D-printed skull helped save a girl's life

Sygnis said they started printing as soon as they received scan data from a newborn baby's head. To avoid mistakes, they created two models at once on two 3D printers using two different materials. The best option turned out to be polyamide, which has great strength and is not damaged by contact with surgical instruments. All this took them only 24 hours - speed in this matter was very important, because in order to save the girl's life, the operation had to be carried out as soon as possible. nine0003

nine0003

Surgeons have inserted a 3D-printed eye for the first time in history. Here are the details

How doctors saved a girl's life

A 3D printed model of the girl's skull showed the surgeons what they would have to deal with. Needless to say, she did not become part of the child's head, because with age, her skull will grow. On the created model, the surgeons conducted preoperative testing and, so to speak, "knocked their hand." Thanks to this training, the specialists successfully performed a bone reconstruction operation. More than six months have already passed since then, and it is known that everything is fine with the girl. This is another case where technology was able to save a person's life. nine0003

3D printing technology has long been used in medicine and saves lives

The skull model used for preoperative testing has been archived and will be used by students in the future. It is reported that after this incident, Sygnis produced another model - it helped with the treatment of a child with a hernia and scoliosis.

Be sure to subscribe to our Telegram channel. For almost 8 thousand people!

3D printing equipment has been actively used in medicine for a long time. Sometimes it is capable of seemingly impossible things. At the end of 2021, we talked about how scientists used human blood to heal wounds using a 3D printer. If you are interested in how it works, welcome to this material. nine0003

3D printing3D printersMedical

Related news

To send a comment, you must either

print your photos in 3D! - qbed

| Detailed instructions for 3D printing of lithophanes |

|---|

3D printed lithophane from kraftly.com

Modern 3D printers allow you to create many original and unique things, and one of them is 3D photo-lithophanes, which are gaining more and more popularity as a customized gift for loved ones or just an original product for sale. Let's take a look at what linophane is and how to print it. nine0003

Let's take a look at what linophane is and how to print it. nine0003

Article content:

What is lithophane?

Designing a lithophane

Selecting a photo

Converting a photo into a 3D model

Creating and printing a 3D model of a lithophane in Photoshop

How to slice a lithophane?

Seal of lithophane

What is lithophane?

Classic lithophane is a three-dimensional image on thin translucent porcelain that can only be seen when illuminated from behind by a bright light source (for example, the sun or an ordinary light bulb). The image will appear in gray tones. Traditionally, lithophanes were created in several stages: first, the image was cut out of wax, then, based on the wax model, a mold was created from plaster, into which porcelain was cast, after which the image was fired. nine0003

German lithophane of the 19th century, on the left - without illumination, on the right - with illumination. Photo — Diego Verger

Photo — Diego Verger

The first lithophanes appeared almost simultaneously in several cities of Europe — France, Germany, Prussia and England — at the end of 1820s and their three-dimensionality was strikingly different from the two-dimensional engravings popular at that time and daguerreotypes . The fact is that the quality and quantity of light interacting with lithophane significantly changes the characteristics of the image itself - such dynamism arouses great interest in the viewer. For example, lithophane inserts in windows change their appearance throughout the day depending on the quality and intensity of the sun's rays.

Modern 3D printers allow you to print lithophane from any high contrast photo. How? Varying the thickness of different sections of the 3D model to render different shades of gray when the lithophane is backlit: thin sections let in more light and look brighter, while dense parts of the print let in little light and create dark details in the image. Don't panic, you don't have to manually calculate the thickness of various sections of the digital model - there are many programs that create 3D models for lithophanes automatically and for free! Let's get down to business! nine0003

Don't panic, you don't have to manually calculate the thickness of various sections of the digital model - there are many programs that create 3D models for lithophanes automatically and for free! Let's get down to business! nine0003

Back to Contents

Designing the Lithophane

First we need to create a digital model of the lithophane.

Choosing a photo

The first step towards a great printout is choosing a suitable photo , because not all images will look good in the form of a lithophane.

-

Firstly, the finished lithophane will be displayed in grayscale, so images where color plays an important role or where there is a lot of color detail will not work. nine0017 You can try converting the photo to b / w in Photoshop or any other program to make sure that you like the picture even if there are no colors.

-

Secondly, it is better to give preference to contrasting photos - so the printed linofan will look more interesting (unlike the image, where adjacent details will merge due to lack of contrast).

Again, you can add contrast to the selected photo in Photoshop or any other program. nine0003

Again, you can add contrast to the selected photo in Photoshop or any other program. nine0003

An example of a low-contrast image, not quite suitable for lithophane printing. Photo — Christina Ryumina

-

Thirdly, avoid photos consisting only of small details , it can be difficult for the printer to print them. For lithophanes, images with large contrasting details, such as portraits, are more suitable. Images with a single-color background without details are also good, for example, portraits against a backdrop or against a clear sky. You can clean up the background or create a color fill instead of an existing background in Photoshop or any other program. nine0003

Contrast photo on a plain background is ideal for printing lithophane. You can further clean up the background and add photo contrast in any post-processing program. Photo — Christina Ryumina

You can further clean up the background and add photo contrast in any post-processing program. Photo — Christina Ryumina

An example of a photo with many details is not the best choice for creating a lithophane. Photo — Christina Ryumina

nine0002Of course, you don't have to follow these tips. If you print on a high-quality printer with high resolution, then you can handle any details! For example, SLA printers allow you to print smaller details than their FDM counterparts (read more about 3D printing methods here), so a photo for printing on an SLA printer may contain small elements.

Convert photo to 3D model

There are several ways to convert your photo into a 3D model for printing lithophane:

-

You can convert photo with free online Image to Litophane converter.

-

Models for lithophanes can be created in Photoshop CC by downloading a special Operation (Action) from the official website (read detailed instructions below), or in Blender: these programs have more options to edit the model.

It is worth considering that a subscription to Photoshop CC is paid.

It is worth considering that a subscription to Photoshop CC is paid.

-

Cura software (version 13.11 and higher) from Ultimaker will also work. The program is easy to use and allows you to smooth the model, but it does not have the ability to edit the image and create a frame around it. nine0075

-

Customizable Lithopane from printer manufacturer MakerBot on Thingeverse can be used. Here you can add a hole in the frame of the lithophane so you can hang your masterpiece, but in this application your photo resolution will be compressed to 100x100 pixels. Another disadvantage: the application can be quite slow, because the Thingeverse website Customizer creates a model and STL file instead of your computer.

-

There is also a free 2D to STL converter for Windows. There are options for smoothing the model, but no way to edit the image. nine0075

-

You can create a model for lithophane in a paid Photo to Stereolithographic file converter.

This program allows you to create lithophanes on spheres, cubes and other shapes, but the interface here is not the most understandable.

This program allows you to create lithophanes on spheres, cubes and other shapes, but the interface here is not the most understandable.

-

There is a nice free Portuguese converter where the language can be changed to English after installation by going to the Iniciar menu, then Idioma and finally selecting English. Here is a link to download the program. In this converter, you can create a frame for the image, edit it before creating a 3D model, and also enlarge / reduce the image. The converter generates models quite quickly, so you can experiment with 3D model settings until you are completely satisfied with the result. nine0003

The list of programs, of course, is not exhaustive. You can use any converters of 2D files to 3D models that support export to STL. In this article, we will be using Photoshop CC to create a 3D model from a photo.

Create and print a 3D model of Lithophane in Photoshop

Attention! The operation only works if the interface language in your Photoshop CC is English. nine0017 You can change the language by going to menu Photoshop CC → Preferences → Interface.

nine0017 You can change the language by going to menu Photoshop CC → Preferences → Interface.

To add an action in Photoshop, go to the program, go to the top menu in Window → Actions or click the icon Play in the side menu (see screenshot below).

Going into the Actions panel in Photoshop

Opening the operations panel, click on the menu icon (see screenshot below) and select the command "Load Actions..." . We go to the location where your downloaded Lithophane folder and the operation itself "Make Lithophane.atn" are located and select it. The operation is now available in your Photoshop.

Loading the operation "Make Lithophane.atn"

Operation "Make Lithophane. atn" is ready to go

atn" is ready to go

Open the image you are about to print. You can convert it to black and white, add contrast and make any changes, then print the visible layers into one by pressing Ctrl + Shift + Alt + E (English), or simply merge the layers through the menu Layers (in any case , you will be prompted to merge layers when starting the operation). In the layers panel (marked in blue in the screenshot below), select the layer with the final version of your image and name it Background (or select the Background itself directly if you haven't changed anything). Then open the "Make Lithophane" operation folder, select "Make 100mm x 6.25mm Lithophane" (marked in red in the screenshot), press Play (marked in green in the screenshot). The operation automatically converts the 2D image into a 3D printable object: Photoshop converts the image to Grayscale, inverts the tones, creates a 3D depth map, as well as a frame and a flat surface on the back of the image. nine0003

nine0003

Starting the operation of creating a digital model of lithophane

Litophane in Photoshop CC

To print a 3D object, click on the top menu 3D → 3D Print (marked in red in the screenshot below) or click on the print icon (marked in pink). Next, you will see the 3D printing settings panel (see screenshot below). Select a printer (or specify Printer: STL File if you want to export the model as STL), set Printer Units , Detail Level . Determine the size of the model by setting the X / Y / Z values. Option Scale to Print Volume will create the largest printout that will fit in your printer's camera.

Click on the icon marked in green in the screenshot below to have Photoshop prepare your model for printing. Photoshop will analyze the object and show you a print preview with supports in a new window (supports are turned on and off by ticking Scaffolding ). From the same window, we can print or export the model.

Photoshop will analyze the object and show you a print preview with supports in a new window (supports are turned on and off by ticking Scaffolding ). From the same window, we can print or export the model.

Preparing the model for printing/export

Print/Export Model

Do not forget that the size and thickness of the lithophane, as well as the amount of detail in the photo and model, affect the printing time. Depending on these settings, it may take 30 minutes or 5 hours to print. nine0003

How to slice lithophane?

The slicer will help convert our model into a printer-friendly G-code (read more here). To open a 3D model in a slicer, you need to export it as STL file . To do this, in the Photoshop 3D printing settings panel, select Printer: STL File , export the model as described above, and open it in your slicer to set up the location of the model on the platform and set other parameters. You can also export photos to STL from any of the other converters mentioned above and then open the file in a slicer. nine0003

You can also export photos to STL from any of the other converters mentioned above and then open the file in a slicer. nine0003

To achieve optimal printing results, it is recommended to slice the lithophanes as follows:

-

Set straight infill to 100% at an angle of 30-35°. 100% infill will provide the best quality lithophane, as there will be no honeycomb inside the layers, which will spoil the tones in the printout.

-

Set the minimum layer height that your printer supports. This way you will ensure high resolution details and the maximum number of shades of gray in your lithophane. nine0075

-

Print as slowly as possible. Speaking of FDM, slow printing will help you avoid retraction problems, because most of the print is created with little extrusion, which can provoke a huge amount of retraction. To prevent your printer from smearing your printouts with unwanted material smudges and your extruder from clogging due to fast retractions, it's best to print as slowly as possible.

-

Select the optimal lithophane slicing parameters available in your slicer. Different slicers provide different options. Choose the slicer you like, however, be aware that some slicers take longer to layer the model than others, for example, Cura usually slices faster than Slic3r. Experiment!

-

Do not scale the model in the slicer. The model should be scaled in Photoshop or other converters mentioned so as not to lose resolution when printing. nine0003

Litophane Printing

Now it remains to load our STL file into the printer via USB or SD card (or any other methods available in your printer). The faster the connection, the better, since lithophanes can contain a lot of detail, and some types of connection may not be fast enough to send the entire G-code to the printer, and the printer will begin to slow down and smear material on the printout.