Handyscan 3d scanner cost

Creaform launches the HandySCAN Silver Series 3D scanner - technical specifications and pricing

0Shares

3D measurement system manufacturer Creaform has announced the launch of its latest handheld 3D scanner.

The HandySCAN 3D Silver Series is available in two models: the HandySCAN 307 at $19,990 and the higher-performance HandySCAN 700 at $29,900. Aimed at professional engineers and technology companies, the device is intended to provide repeatable metrology-grade 3D measurements for product development and reverse engineering applications.

“For the professionals who need to adapt quickly to their customers’ needs and provide better answers to their inquiries, a reliable 3D scanning solution is indispensable,” states Simon Côté, Product Manager at Creaform. “The possibilities presented by gathering such precise data can open doors to new projects and strengthen the partnerships with existing clients. It cannot be overstated how 3D scanning and 3D printing technologies have become vital for any small-to-medium sized company. ”

Professional 3D scanning with Creaform

Based in Québec, Creaform already has an extensive portfolio of professional 3D scanning devices. Go!SCAN, the company’s most affordable line, is capable of capturing full color 3D models with a setup time of just five minutes. With a focus on accessibility and ease-of-use, the entry-level range is designed to be usable by individuals of any background in a pick up-and-play manner.

For those looking for more in the way of performance, the HandySCAN and MetraSCAN ranges might be a little more suitable. Built for manufacturing and metrology professionals working in dynamic manufacturing environments, these premium 3D scanner lines offer high-precision measurements for engineering projects.

Scanning a Koenigsegg with the HandySCAN Silver Series. Photo via Creaform.The HandySCAN 3D Silver Series

The latest addition to the HandySCAN range is characterized by its precision and versatility. Operating on seven red laser crosses, the Silver Series provides users with a scan area measuring 275 x 250mm, an accuracy of up to 0.03mm, and a measurement resolution of up to 0.05mm. With a recommended part size ranging from 0.1 – 4m, the device is reportedly compatible with a whole host of object types, regardless of complexity, surface finish, or color.

Operating on seven red laser crosses, the Silver Series provides users with a scan area measuring 275 x 250mm, an accuracy of up to 0.03mm, and a measurement resolution of up to 0.05mm. With a recommended part size ranging from 0.1 – 4m, the device is reportedly compatible with a whole host of object types, regardless of complexity, surface finish, or color.

At 0.85kg, the Silver Series is lightweight and portable. Designed for both in-house and on-site use, the scanner fits comfortably in a small suitcase and can be set up in around two minutes. It triangulates its own relative position using in-built optical reflectors, meaning it can be used as a standalone device with no tripod or external tracking equipment. Featuring a simple UI and real-time visualization functionality, Creaform’s Silver Series boasts a “shallow learning curve” regardless of the user’s experience level.

The new Silver Series 3D scanning a helmet. Photo via Creaform.Technical specifications and pricing

Below are the technical specifications for the HandySCAN 3D Silver Series. The 3D scanner is available to order now, starting at $19,990.

The 3D scanner is available to order now, starting at $19,990.

| HandySCAN 307 | HandySCAN 700 | |

| Accuracy | Up to 0.04mm | Up to 0.03mm |

| Volumetric accuracy | 0.02mm + 0.1mm/m | 0.02mm + 0.06mm/m |

| Measurement resolution | 0.1mm | 0.05mm |

| Mesh resolution | 0.2mm | 0.2mm |

| Measurement rate | 480,000/s | 480,000/s |

| Light source | 7 red laser crosses | 7 red laser crosses + extra line |

| Laser class | 2M | 2M |

| Scanning area | 275 x 250mm | 275 x 250mm |

| Stand-off distance | 300mm | 300mm |

| Depth of field | 250mm | 250mm |

| Part size range | 0. 1 – 4m 1 – 4m | 0.1 – 4m |

| Weight | 0.85kg | 0.85kg |

| Dimensions | 77 x 122 x 294mm | 77 x 122 x 294mm |

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the new Silver Series 3D scanning a helmet. Photo via Creaform.

Tags Creaform HandySCAN 3D Silver Series Simon Côté

Kubi Sertoglu

Kubi Sertoglu holds a degree in Mechanical Engineering, combining an affinity for writing with a technical background to deliver the latest news and reviews in additive manufacturing.

Creaform HandySCAN 700 Elite review

Creaform HandySCAN 700 Elite (SILVER Series) review

In short, the HandySCAN 700 is an excellent product with a well-rounded, professional software suite.

This 3D scanner is a trailblazer on several levels. Its cable management system, colored LED distance indicator, and “thumb-accessible” buttons are innovations that have become standard on Creaform products and are now imitated by competing brands.

Its red-colored lasers provide great results, even on reflective surfaces, although we must say that the mandatory markers are a bit of a hassle. The “single beam” mode is a bit slow but performs very well on intricate details and geometries.

Read the full review

Pros

- The “Creaform experience”: great product quality and smooth workflow backed by the brand’s extensive expertise

- A complete software solution, honed by years of updates and upgrades

Cons

- Use of markers is mandatory

Creaform HandySCAN 700 Elite (SILVER Series) overview

The Creaform HandySCAN 700 Elite is a professional handheld 3D scanner made by Creaform, a leading manufacturer from Canada. It was originally launched in 2014. As of 2022, the SILVER Series now boasts blue lasers instead of red ones.

It was originally launched in 2014. As of 2022, the SILVER Series now boasts blue lasers instead of red ones.

This portable 3D scanner uses blue laser triangulation technology to 3D scan a wide variety of mechanical parts, mockups, and prototypes. It casts 7 blue laser crosses in “Cross grid” mode, and a single blue laser beam in “Single beam” mode to capture complex details and deep pockets.

We reviewed the HandySCAN 700 in 2016. Creaform has continued updating its lineup since then and re-launched this 3D scanner under the new, more affordable SILVER Series. For the occasion, and after the price drop (down to $29,900), we conducted another HandySCAN 700 review to evaluate its price-to-performance ratio.

This professional handheld 3D scanner suits various use cases, such as:

- reverse engineering

- all steps of design and manufacturing processes

- cultural heritage preservation

- restoration

- digital archiving

- entertainment

It comes with VXelements software for 3D scanning and 3D file optimization.

HandySCAN lineup

Creaform’s HandySCAN lineup includes:

- SILVER Series for less-demanding use cases

- HandySCAN 307

- HandySCAN 307 Elite

- HandySCAN 700 Elite

- BLACK Series for best-in-class metrology and precision

- HandySCAN BLACK

- HandySCAN BLACK Elite (full review here)

Creaform also manufactures the powerful Go!SCAN SPARK (full review here), which focuses more on speed and ease of use.

Creaform HandySCAN 700 price

Please contact us to obtain a free quote for this 3D scanner.

Discover all Creaform 3D scanners with our 3D scanner comparison engine.

non -contact 3D scanner - HandyScan Series - CreaForm

Add to the Favorite folder

Add more detailed information on the CreaForm

characteristics

300 mm (11. 8 in)

8 in)

20 µm

Description

The SILVER series is part of the HandySCAN 3D™ line, the industry standard for metrology-grade portable 3D scanners. This proven and reliable patented technology enables accurate and reproducible 3D measurements of any complex surface, anywhere. HandySCAN 3D Series | SILVER is optimized to meet the needs of technology innovators and engineering professionals who are looking for a powerful, affordable and reliable way to improve product development, reduce time to market and reduce development costs. HandySCAN 3D | The SILVER Series provides accurate and reliable 3D measurements regardless of the quality of measurement setup and user experience level. Thanks to dynamic linking, the scanner and part can move freely during scanning, and you can still get an accurate and high-quality image. Volumetric accuracy 0.020 ± 0.060 mm/m (0.0008 in. ± 0.0007 in./ft) High repeatability and traceable certificate High level of detail Offering the best value for money, HandySCAN 3D | SILVER Series is a smart buy due to its affordable price and high quality features. Designed and manufactured in North America and with over 5,000 users, this proven and reliable technology demonstrates Creaform's commitment to attentive service and reliability. Best Price/Performance Designed and manufactured in North America Over 5,000 users worldwide Supported by a global team of engineers and technicians Using triangulation on optical reflectors to determine its relative position to a part, this handheld 3D scanner is a standalone device that does not require a tripod or any external tracking device.

Designed and manufactured in North America and with over 5,000 users, this proven and reliable technology demonstrates Creaform's commitment to attentive service and reliability. Best Price/Performance Designed and manufactured in North America Over 5,000 users worldwide Supported by a global team of engineers and technicians Using triangulation on optical reflectors to determine its relative position to a part, this handheld 3D scanner is a standalone device that does not require a tripod or any external tracking device.

---

This is an automatic translation. (view original in English)

Catalogs

No catalogs are available for this product.

See all Creaform catalogs

Visit the Creaform website for more information

More Creaform products

PROFESSIONAL AND INDUSTRIAL PORTABLE 3D SCANNERS

See all Creaform products

duties and do not include additional costs associated with installation or commissioning. Prices are indicative and may vary depending on country, commodity prices and exchange rates.

Prices are indicative and may vary depending on country, commodity prices and exchange rates.

scopes and overview of models / Sudo Null IT News

3D laser scanning - creating a digital model of a physical body using a laser beam. The technology is non-contact, works at close and long distances, eliminates damage to objects during scanning. The principle of operation of 3D laser scanners: a directed laser beam is reflected from the surface of an object, forming a cloud of points. Each point has its own coordinates in space. The software identifies them and creates a finished 3D digital model based on this data.

From the overview you will find out where laser scanning is used and what equipment is used to solve related problems.

Purpose of laser scanners

Source: newequipment.com

Compared to traditional measurement methods, laser scanners have an important advantage - they can digitize objects with complex surfaces and work in hard-to-reach places for humans. The main areas of application of devices are input and output quality control in production, inspection of working devices in order to prevent and eliminate defects, reverse engineering and other areas.

The main areas of application of devices are input and output quality control in production, inspection of working devices in order to prevent and eliminate defects, reverse engineering and other areas.

Construction, renovation and renovation of objects

Source: ellisdon.com

During the preparation of the building project, it is necessary to evaluate the features of the site and the cost of the forthcoming works. With the help of 3D laser scanners, a landscape model is created, on the basis of which further work is carried out. During the construction process, intermediate control of the geometry of future buildings is required: walls, corners, openings, etc. Laser scanning copes with this task more accurately and faster than conventional measuring technologies.

The basis for an exterior or interior renovation is often an accurate digital model, on the basis of which changes and additions to the current interior or exterior are planned. Laser scanners are also indispensable in this area.

Laser scanners are also indispensable in this area.

Road networks and transport

Source: autodesk.com

Laser scanning is becoming an integral part of the planning and creation of urban and suburban road networks, tunnels, pedestrian sections, railways, ports. The technology is used to assess the current state of coatings, plan and estimate the cost of repairs, to obtain models of perennial structures, such as bridges. The equipment is involved in the design, manufacture, repair and tuning of cars, air transport and ships.

Public utilities

Source: 3dscanner.es

With the help of 3D laser scanners, it became possible to quickly digitize and document engineering communications. Scanning significantly saves time during maintenance and reconstruction. The devices work remotely, minimizing the risks of people when working in adverse conditions and in hard-to-reach areas.

Oilfield installations

Source: ramboll.com

Oil production complexes located in the water require constant monitoring of work processes. Objects are regularly exposed to adverse and changeable environmental influences: winds of different strengths and directions, currents, temperature changes, etc. 3D laser scanning is becoming an integral part of the inspection of oil production installations. The equipment allows you to quickly identify and fix deformations and other damage, control wear, calculate the timing of scheduled maintenance, and prevent accidents.

Forensic

Source: faro.com

Photographs and manual measurements in investigative processes and forensic examinations are being replaced by 3D laser scanning. The devices create three-dimensional models of scenes of incidents with accurate fixation of the location of objects and the distances between them. The data is used in the process of pre-trial and litigation.

The data is used in the process of pre-trial and litigation.

Other applications

Source: news.microsoft.com

3D laser scanners facilitate and optimize workflows in the following areas:

- In cartography and geodesy, when creating terrain plans, maps, geographic information systems (GIS).

- In archeology, when restoring and preserving ancient artifacts.

- In paleontology, to create missing parts of excavated skeletons.

- In medicine, including plastic surgery and dentistry.

Overview of models and manufacturers

FARO Focus

Source: ifworlddesignguide.com

FARO is one of the popular manufacturers of laser scanning devices. The new Focus3D S-series instruments stand out from other scanners in lightness and compact size, as well as the ability to work in bright sunlight and keep in touch with the location using GPS.

The FOCUS 3D S 150 scanner works at a distance of up to one hundred and fifty meters, with an accuracy of up to ±2000 microns at a maximum distance. The device is used in design, architecture and construction, for digitizing equipment and other objects.

You can learn more about this model on the website.

Source: youtube.com

Focus3D S 350 scans with the same accuracy as the previous device, but the distance to the measurement object is increased to 0.35 km. The device is designed for outdoor use.

Source: kkgeosystem.blogspot.com

SHINING 3D

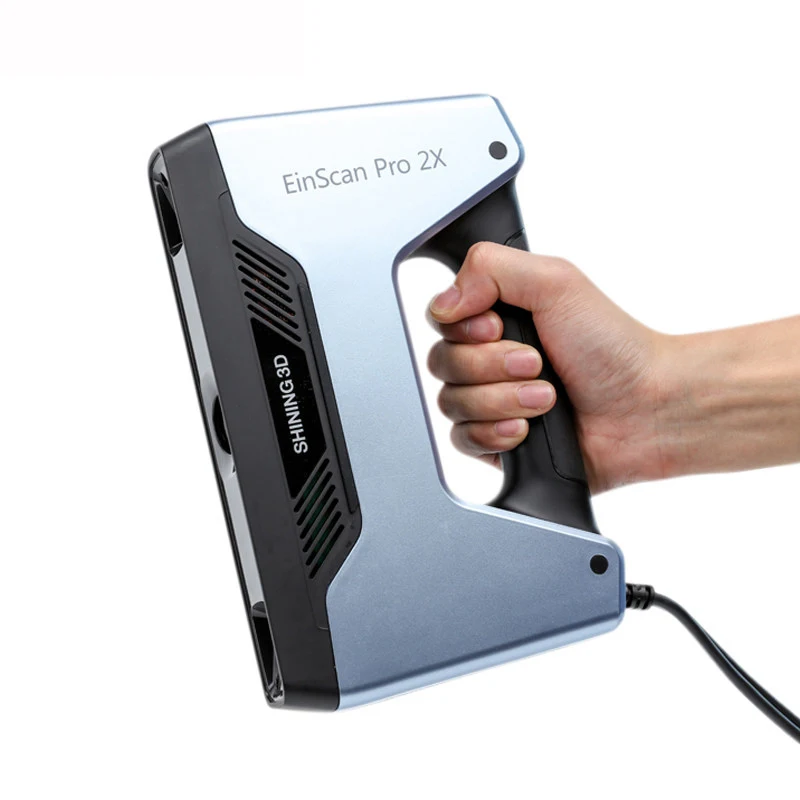

Source: shining3d.com

FreeScan is a line of well-known Chinese manufacturer of digital equipment SHINING 3D. These are universal laser handheld 3D scanners FreeScan X5 (X5+), FreeScan X7 (X7+) weighing up to 1 kg, with an excellent set of professional features.

Main parameters:

Specifications

Creaform

Source: foundry-planet.com

Creaform's SCAN 3D range is characterized by high scanning quality combined with ease of use. Portable laser scanners HandySCAN 3D, MetraSCAN 3D have a clear interface, do not require special skills and complex user training.

Instrument features:

ScanTech

Handheld range

Source: cmmxyz.com

The HandHeld Prince series uses blue and red laser beams to scan large and small objects with high accuracy. Scanners can operate in bright sunlight and low light conditions. Due to its compact size, high speed and detail, the equipment is widely used in reverse engineering, quality inspection, digitization of museum, archaeological and other objects.

Key features:

Composite series

Source: twitter. com

com

In addition to the dual scan mode, the KSCAN20 is equipped with a photogrammetry system, thanks to which the working area of the device is 2.5 m * 3 m with an accuracy of 35 µm / m.

Blue and red lasers provide high-speed scanning of up to 650,000 measurements per second with a resolution of 0.01 mm.

Key Features:

3D Laser Scanner Applications

Reduce construction costs and time with FARO Focus

Source: autodesk.com

US construction company Gilbane invested $60,000 in the purchase of a FARO Focus-S 350 laser scanner, software and employee training. At first glance, the amount seems too large for a small-scale firm. But, after making calculations, the company's management came to the conclusion that the investments would pay off in the shortest possible time.

According to Gilbane's director of 3D design, John Tocci Jr., after introducing the expensive new technology, the company began to use the equipment even in areas where it was not originally planned. The specialists managed to save $30,000 for one hour of Focus-S 350 and Autodesk Revit software.

The specialists managed to save $30,000 for one hour of Focus-S 350 and Autodesk Revit software.

Source: autodesk.com

Building a digital model of air ducts and other systems made it possible to avoid errors during the installation of physical objects, which could take several weeks. The use of FARO Focus in the assembly of plumbing, electrical and mechanical installations helped to optimize costs at all stages of work

Case “Modernization of the building of the University of Miami”

Source: elevar.com

At the time of the start of work, the architects had at their disposal drawings made 85 years ago, and a little more than 4.5 thousand square meters of the old building. Using a 3D laser scanner, Gilbane digitized the training areas in one day. The modernization of the load-bearing structures, as well as the main utility systems: plumbing, electrical and ventilation, was based on the data obtained from the scan.

Quality Inspection with ScanTech

Source: 3d-scantech.com

The advantage of metal stamping over forging and casting is the lower weight and thickness of the resulting parts. The use of molds gives high accuracy and maximum compliance of the obtained parts with the specified characteristics, but does not completely exclude deviations and deformations. Which, in turn, can lead to difficulties in assembling finished products and reducing product quality. Therefore, constant quality inspection is a necessary part of production.

Having understood the manufacturer's tasks, ScanTech suggested checking the quality of stamped parts using the PRINCE laser scanner. The ability to switch blue and red laser modes allowed the device to combine the functionality of traditional portable and metrological 3D scanners. The mode of operation with an active beam of a red laser provides fast digitization of objects. In the case of increased requirements for accuracy and detail, turn on the blue laser beam mode.

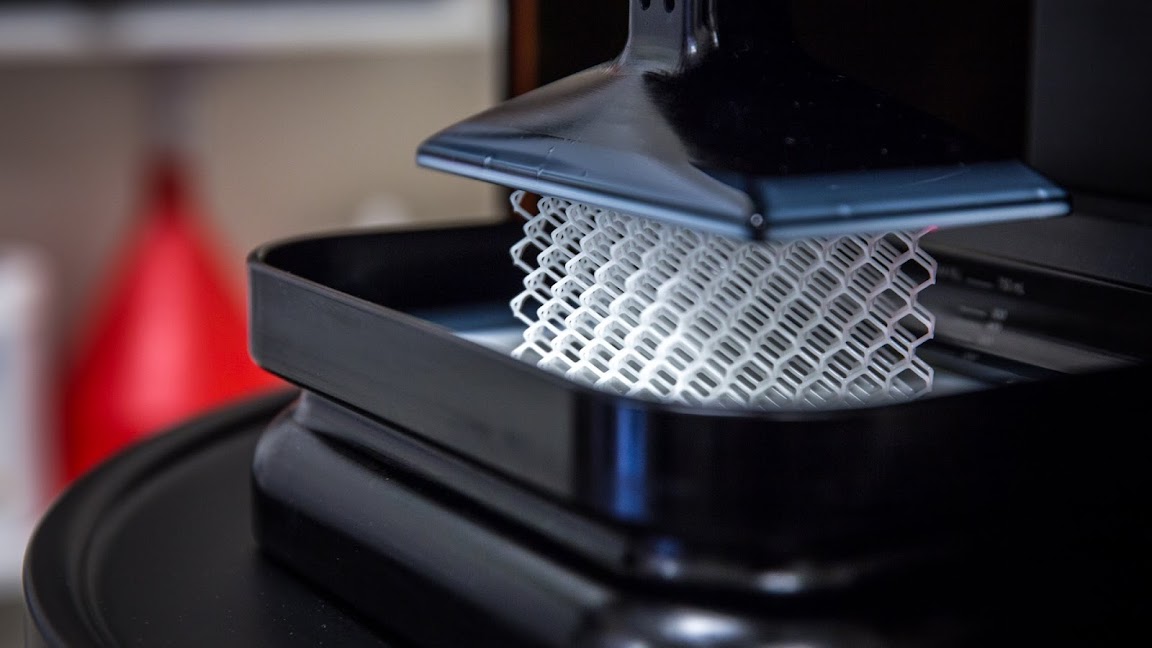

The photo shows the stages of work:

1. Installing markers - takes about two minutes.

Source: 3d-scantech.com

2. Digitizing a part takes about three minutes.

Source: 3d-scantech.com

Source: 3d-scantech.com

3. Identification of deviations - lasts 3 minutes.

Source: 3d-scantech.com

The digital model shows the parameters and deviations, allows you to correct errors at the design stage. The case clearly shows that the process required a minimum of time and effort.

Using FARO 3D Scanners on Justin Timberlake's World Tour

Source: disguise.one

Timberlake's "Man of the Woods" program features scenery brought to life on stage. First, the ScanLAB team digitized a number of corners of the forest in the US state of Oregon. Laser projectors then directed images over the auditorium and stage, painting amazing images of the Portland landscape on translucent canvases suspended in the air.

Laser projectors then directed images over the auditorium and stage, painting amazing images of the Portland landscape on translucent canvases suspended in the air.

Source: faro.com

Two Faro Focus X 330 laser scanners, Faro Scene 6.2 software were used to prepare visual effects. In total it took 40 digital copies and 1 working day in the concert hall.

Source: www.esa.int

Considering the limited preparation time, the large surface areas for displaying the image and the corresponding need for high image resolution, it was impossible to create visual effects in a short time without using the chosen technology.

Selection guide for 3D laser scanners

In the review, we introduced you to the equipment of market leaders with an excellent reputation. All the devices described have high performance, so we recommend that you pay attention to these devices for use in various fields:

FARO Focus: Focus3D S350, Focus 3D S150.