Drexel 3d printer

Coronavirus News: Drexel University launches 3D printing project for face shields

WATCH LIVE

Welcome,

Your Account

Log Out

Coronavirus

Wednesday, April 1, 2020

EMBED <>

More Videos<iframe src="https://6abc.com/video/embed/?pid=6069171" frameborder="0" allowfullscreen></iframe>

Drexel students and faculty are making 3D face shields to help healthcare workers.

PHILADELPHIA (WPVI) -- Philadelphia's tech community is really stepping up to help healthcare workers fill the gap on scarce supplies.

Drexel University, a long-time technology leader, has turned it's 3D printing power to making face shields for several hospitals.

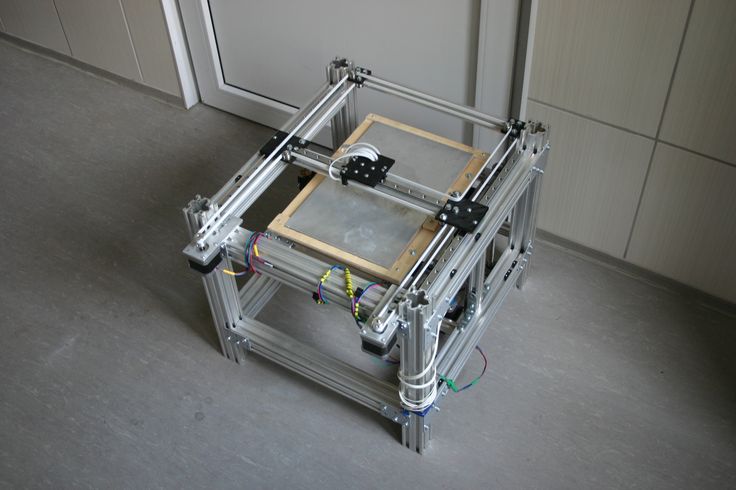

After sitting idle since the university closed, printers are now humming again, making headbands for the shields.

Michele Marcolongo, Ph.D., the department head in Materials Science, began the project Sunday at the request of a friend who is an emergency room physician at Einstein Medical Center.

She enlisted colleagues, students and others in the 3D printer community.

They made 60 masks in about three days, but hope to do 200 by the end of the week.

"We have at least 25 going throughout the region, some at Drexel, some in students' basements, and at apartments... just trying to do as much as we can," said Marcolongo.

"It feels really good to be useful and everyone that we've asked to participate on this project has accepted," she says.

They're now looking for a manufacturer to scale up production.

But in the short run, they're looking for more printers at homes, in organizations, or companies, so they can help the Temple University and Jefferson health systems, too.

If you can help, contact Dr. Marcolongo at [email protected].

Report a correction or typo

Copyright © 2022 WPVI-TV. All Rights Reserved.

Related Topics

HEALTH & FITNESS PHILADELPHIA HEALTHCHECK CORONAVIRUS HELP CORONAVIRUS CORONAVIRUS OUTBREAK TECHNOLOGY DREXEL UNIVERSITY COVID 19 PANDEMIC COVID 19 OUTBREAK VIRUS

Coronavirus

Some antibiotics in short supply as respiratory illnesses spread

32 minutes ago

Doctors decode the differences between RSV, flu and COVID

How China's zero-COVID policy threatens the US economy

Hospitals brace for more flu, COVID, RSV cases

Top Stories

Police ID suspect wanted in Delco attempted homicide, Philly shooting

1 hour ago

Teen shot dead after attending birthday party

2 hours ago

3 charged with kidnapping, assaulting 22-year-old

Phillies, SS Trea Turner reach 11-year, $300M deal: ESPN source

43 minutes ago

Some antibiotics in short supply as respiratory illnesses spread

32 minutes ago

Local Tuskegee Airman, one of few remaining, passes away

2 hours ago

Cape May County Zoo needs your help naming two new toucans

2 hours ago

Coronavirus PPE: Drexel University Engineers Creating Hundreds Of 3D-Printed Face Shields For Hospitals

Local News

/ CBS Philadelphia

PHILADELPHIA (CBS) -- Hundreds of new medical face shields are being made for hospitals in the Philadelphia region by engineers at Drexel University. Hospitals have been desperate to find protective equipment for medical teams treating patients with COVID-19.

Hospitals have been desperate to find protective equipment for medical teams treating patients with COVID-19.

Engineering professors and students at Drexel found a way to help fill the void.

Coronavirus Update: Latest On COVID-19 Cases, School Closings And Cancellations Across Delaware Valley

For the engineers at Drexel, figuring out how to make these coveted face shields was a no-brainer.

"It's a pretty simple design, altogether. Just trying to make them as fast as possible and get them out to all the health care workers who need them," said Drexel professor Michele Marcolongo.

Marcolongo got the request from a Philadelphia doctor a week ago and Drexel's engineering ingenuity quickly sprang into action.

"We have lots of people working many hours a day," she said. "Nobody has been sleeping much."

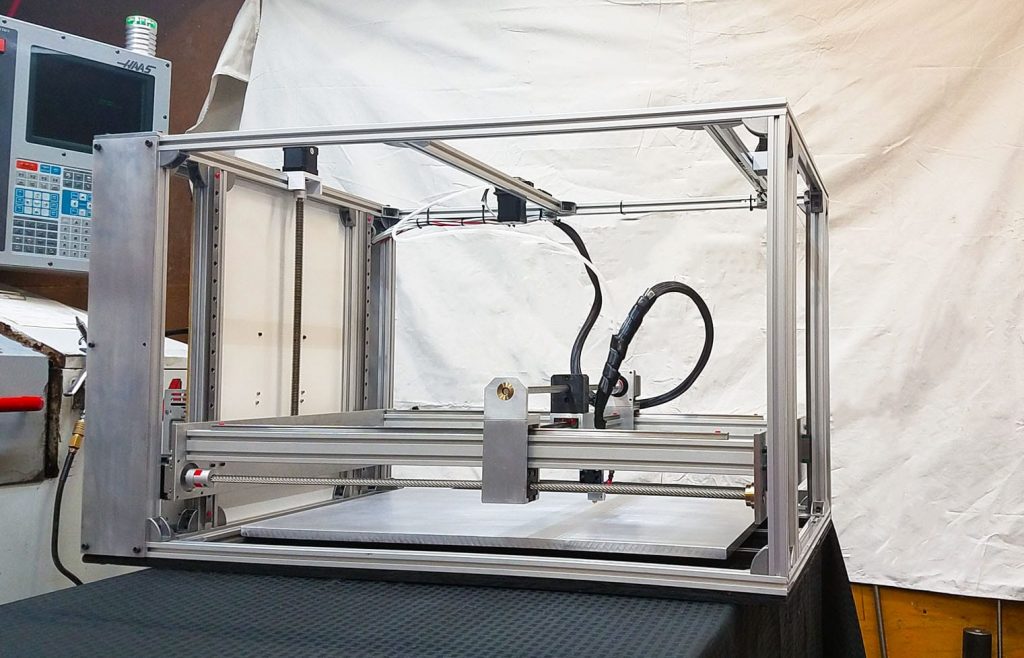

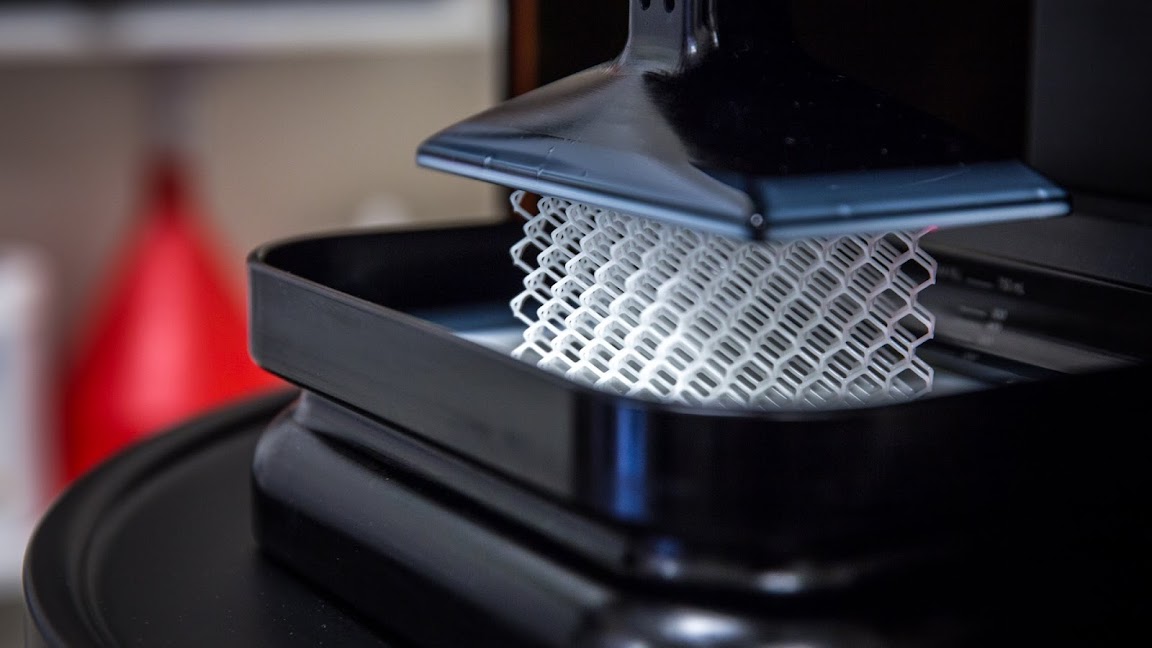

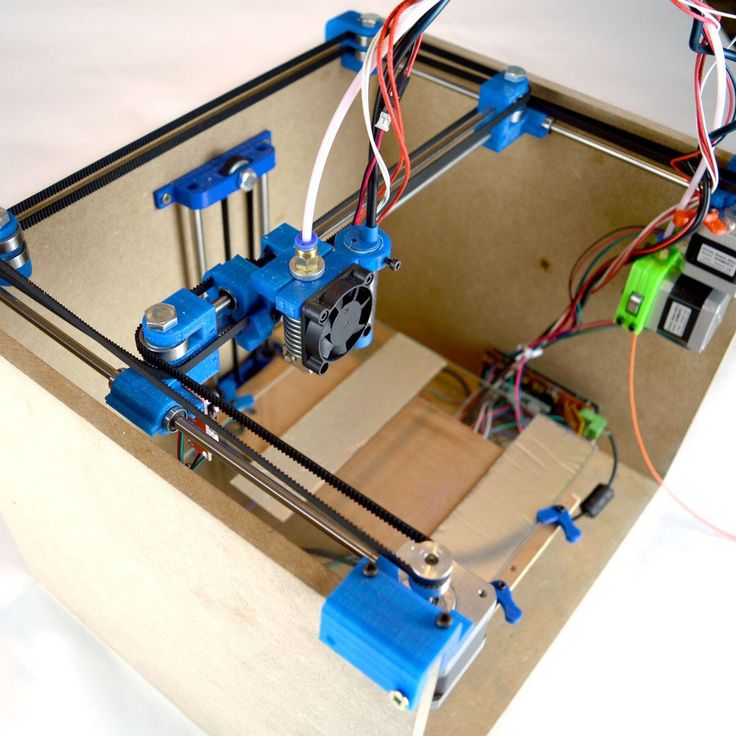

(credit: CBS3)The engineers created a prototype for the headband to make them with 3D printers.

"The 3D printer has a jet of polymer and it lays down row-by-row a layer of polymer, until it builds up into this thick structure," Marcolongo said.

The head piece is outfitted with a plastic shield and a flexible band. There's even a piece of padding for the forehead that was donated.

"It's been a wonderful show of community and really in the City of Brotherly Love," Marcolongo said. "It's been amazing."

The shields are being sent to area hospitals running low on protective supplies, where they can be life-saving for medical teams treating patients with COVID-19.

"It feels like we're making a contribution in that way," Marcolongo said. "I think engineers, in general, that's how we work, we try to give people what they need to do their jobs well."

LATEST CORONAVIRUS STORIES

Using about 20 3D printers, Drexel is hoping to make about 400 shields a week.

"It's rewarding to be an engineer, especially at this time to be able to move quickly. Within a week to have a whole product from request to manufacturing, it's unprecedented," Marcolongo said.

Within a week to have a whole product from request to manufacturing, it's unprecedented," Marcolongo said.

The Drexel team is looking for partners and hopes to team up with manufacturers to help create more face shields, which have been vetted by doctors and area especially critical when patients have to be intubated, and that is happening with a growing number of COVID-19 patients.

- In:

- Headlines

- Philadelphia

- Drexel University

First published on April 1, 2020 / 4:50 PM

© 2020 CBS Broadcasting Inc. All Rights Reserved.

Thanks for reading CBS NEWS.

Create your free account or log in

for more features.

Please enter email address to continue

Please enter valid email address to continue

15 incredible things printed on a 3D printer

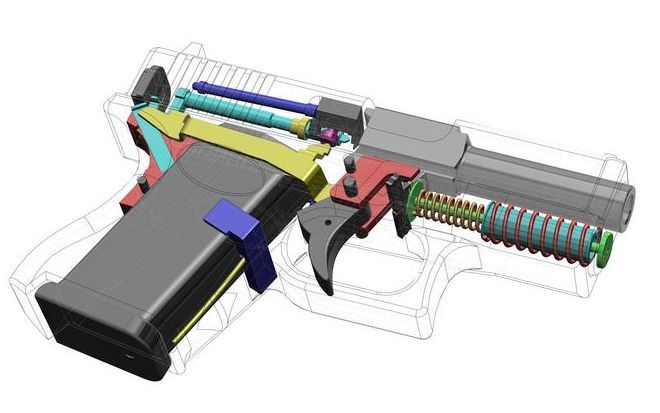

Most likely, you have already heard that a modern 3D printer can print firearms. But what do you say when you find out that the latest 3D printers are capable of recreating a human liver or a prosthetic arm? We invite you to get acquainted with the list of the most incredible things that can be printed on a modern 3D printer!

But what do you say when you find out that the latest 3D printers are capable of recreating a human liver or a prosthetic arm? We invite you to get acquainted with the list of the most incredible things that can be printed on a modern 3D printer!

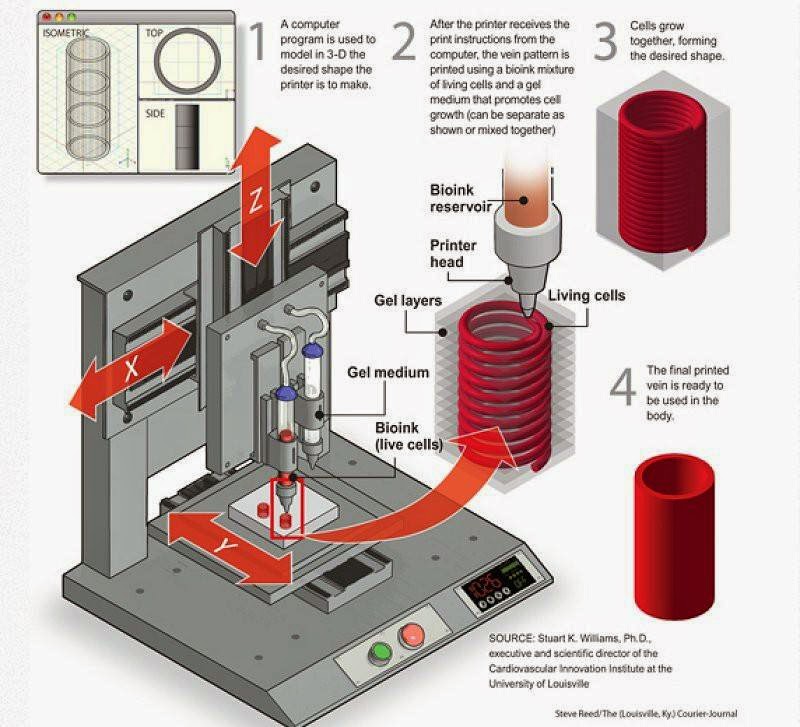

Parts of the human body

It is unlikely that a 3D printer can print a working human liver yet, but developers are already making attempts to create such a technology. A scientist at Organovo, San Diego, has successfully used biomass as a consumable to print human liver tissue.

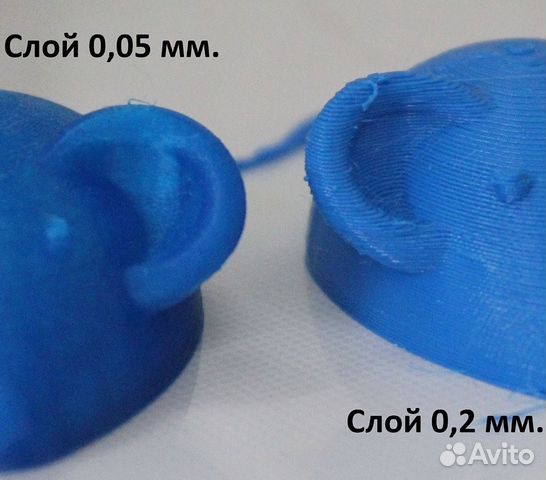

The head of the project is sure that in the future they will be able to recreate an exact copy of the human organ. Note that scientists from Cornell University have already been able to create a copy of the human ear, which can be implanted in a living person.

Prostheses for humans and animals

Who said that prostheses are ugly? Bespoke Innovations is a San Francisco-based company that makes beautiful "packages" for dentures.

Thanks to such “clothing”, prostheses look like human limbs. They can even be tattooed! Imagine what will happen if you combine the Robohand project and Bespoke Innovations? Many disabled people will have the opportunity to restore damaged fingers, and even whole hands. This technology also makes it possible to create artificial limbs for animals.

Dinosaur Skeletons

How about a printout of a life size dinosaur skeleton? Scientists from Drexel University, Philadelphia have developed a technology that allows you to print real-size dinosaur bones.

In the future, they plan to create "robosaurs" from these bones and force them to take over the planet. Joke! Note that the total mass of such a "robotosaurus" will be 80 tons.

Dead people

If endangered species of animals can be printed, why can't an exact copy of a dead person be created? Scientists from a British university have successfully recreated an exact copy of King Charles III, who died in 1485.

Residents of the island nation are planning to "clone" several more important figures in the history of England.

Meat and leather

If you don't like the world of the dead, we offer printed meat products and leather. Modern 3D printers can actually print a steak for your breakfast!

Modern Meadow, Columbia, is working to improve the printing technology for meat and leather products.

Fast food and snacks

Don't eat meat? What about printed fast food? NASA and Cornell University researchers are improving the technology to recreate different types of food. Cookies, oysters and gelatin have already been successfully opened and eaten. All participants in the experiment are alive and well.

It remains to remember the famous student from New York, Mark Manricos, who developed a 3D printer for making delicious burritos.

Legal drugs

After smoking legal drugs, you always want to eat and here the above described burritos may be needed.

By the way, the Thingiverse society produces hookahs, grinders and boats printed using a 3D printer.

Intimate goods

If the production of hookahs using 3D printers did not impress you, then Maker Love offers you to purchase sex toys.

You can come up with the design of the "device" yourself or download samples from the site.

Cars

Cars can also be 3D printed, and there is nothing surprising here. Today, many car manufacturers use 3D printing technologies to create car body or engine parts.

Also, 3D printers are already being used to create a full-sized electric car that has a "futuristic design."

Drones

Modern 3D printing has already taken to the skies. The University of Southampton in the UK has developed the first radio-controlled aircraft SULCA, which was printed in 10 minutes on a 3D printer.

The SULCA mini plane operates on autopilot and is capable of flying for half an hour non-stop at speed 90 mph.

Houses on the Moon

It's unlikely that we can get any practical benefit from a drone, but we could use a new house. A professor at the University of Southern California, who currently works for NASA, is developing a project to create houses so that people can live on the moon.

All objects will be 3D printed. The researchers note that such buildings will be cheap and durable.

Clothes

3D printing has long been used in the world of fashion and jewelry. However, there is one more element of the wardrobe that the modern woman may like - a 3D printed bikini!

The creator of this bikini also offers to wear glasses that were created in a similar way.

Human masks

You already know that with the help of modern 3D printing technologies it is possible to recreate an approximate copy of a human face. However, New York City professor Heather Dewey-Hagborg used his knowledge of human DNA research and was able to develop a printer that prints accurate sculptures of people's faces.

Crazy professor collects cigarette butts and chewing gum from students, extracts DNA samples and creates an image on the computer!

An exact replica of the soon-to-be-born baby

Don't want to look at the printed face of a person? What about an exact copy of the baby in the womb? Brazilian company Technologia Humana3D uses 3D printers to print replicas of small, unborn babies.

Perhaps this service will be of interest to parents who are expecting a child.

Surfboard

Unique surfboards have never been so cheap! One of the most important advantages of modern 3D printing is that it allows you to independently design any thing for everyday use. The MADE organization from Chicago has developed a special chip that is inserted into the surfboard.

While riding the waves, it reads the details of your way of "riding on the sea surface" and helps to create a board shape that is ideal for the client.

Article prepared exclusively for 3dtoday.ru

3D printer and cancer treatment

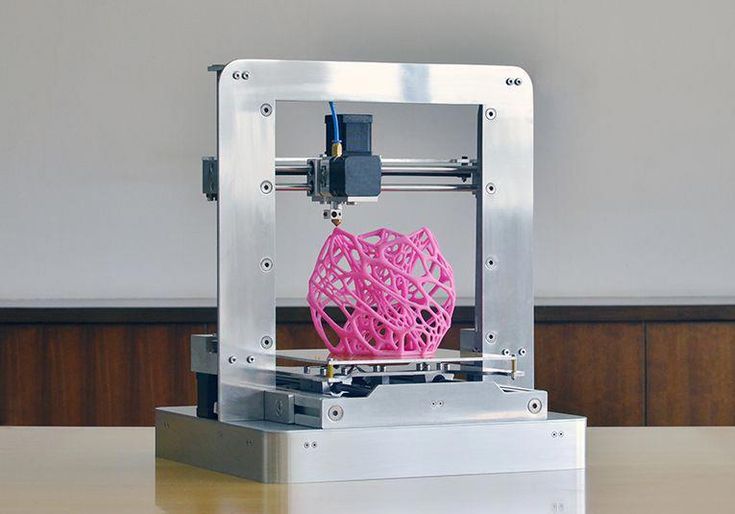

Recently, 3D printers have become more and more active in our lives, allowing us to create three-dimensional models of any objects. They are used in everyday life, as well as in various types of production - foundry, construction, weapons, etc. But only a few know that this device will soon become an effective assistant to doctors in the treatment of cancer in Israel.

Currently, when planning radiation therapy in the leading clinics of the world, virtual models of a malignant tumor to be irradiated are used. However, scientific and technological progress does not stop there: scientists from different countries are trying to create a kind of “clone” of a tumor using 3D printers. Similar experiments were carried out earlier, when models of implants of bones or various organs affected by malignant tumors were made using a 3D printer for planning surgical operations. Now this innovation has come to oncology, and scientists from different countries: the USA, Great Britain, China, etc., are studying the use of 3D printing in various fields related to the study and treatment of cancer.

Now this innovation has come to oncology, and scientists from different countries: the USA, Great Britain, China, etc., are studying the use of 3D printing in various fields related to the study and treatment of cancer.

One of the areas of work with 3D printing, carried out at the Institute for Cancer Research and the Royal Marsden Hospital (London), is the creation of three-dimensional tumor models for calculating radiation doses for radiotherapy. These models accurately replicate the shape of the tumor and adjacent organs of a real patient. This simulation helps doctors achieve the perfect balance between killing cancer cells and preserving healthy tissue.

By creating a tumor model, British scientists intend to improve radioisotope therapy. Such a model makes it possible to fill the tumor model with the same radioactive liquid that will be injected into the patient, and to "calculate" the effect of treatment as accurately as possible.

Initially, such models were made by hand, but 3D printing technology makes it possible to significantly improve the accuracy of dosing the radioisotope - for example, in thyroid cancer, neuroendocrine tumors in adults, neuroblastomas in children, and prostate cancer with bone metastases.

Treatment of prostate cancer in Israel: reviews

“We are already seeing that 3D printing can be used in orthopedics and surgery, and this study shows that it can also improve cancer treatment by helping us make all the calculations in radiotherapy more accurately,” says Glen Flux, PhD, head of the radioisotope department. Therapy of the Joint Department of Physics of the Institute for Cancer Research and the Royal Marsden Hospital. “We are optimistic about this technology and its potential for personalized cancer treatment using precisely targeted radiation.”

Ichilov Clinic

Get a treatment program and an exact price

Live tumor models

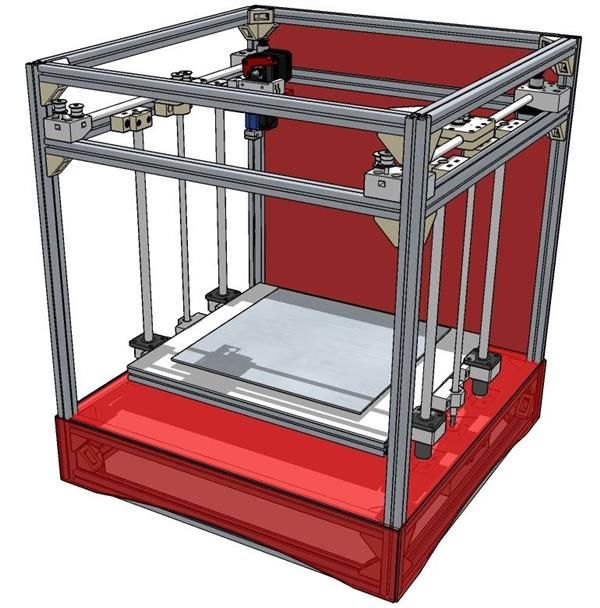

Another revolutionary use of 3D printing in oncology is the creation of 3D tumor models containing living cells. For the first time, such a model was created by a team of scientists from Drexel University (Philadelphia), led by Ph.D. Wei Song.

During this project, an artificial 3D tumor sample was grown (such samples have been created before, but they were all 2D).