Handyscan 3d laser scanners

HandySCAN 3D, GoSCAN 3D & MetraSCAN 3D

Creaform develops highly accurate industrial 3D scanners.

Our handheld 3D scanners have been designed to accelerate the time-to-market with your product development workflows, all while helping you meet your quality control requirements in non-contact 3D measurements. Discover how our 3D scanners can help you gain a competitive edge, cut the time and costs associated with product development, and optimize production processes.

HandySCAN 3D | BLACK Series

Metrology-grade portable 3D scanners

View more

HandySCAN 3D | BLACK Series is the fastest portable metrology-grade 3D laser scanner on the market, offering the highest measurement rate and accuracy available. It’s ideal for product development and quality control.

Accuracy

0.025 mm

Resolution

0.025 mm

HandySCAN 3D | SILVER Series

Professional 3D laser scanners

View more

Made in North America, this professional-grade 3D scanner offers the perfect mix between unbeatable performance at a great price. Based on trusted and patented metrology-grade 3D scanning technology.

Accuracy

up to 0.030 mm

Resolution

0.050mm

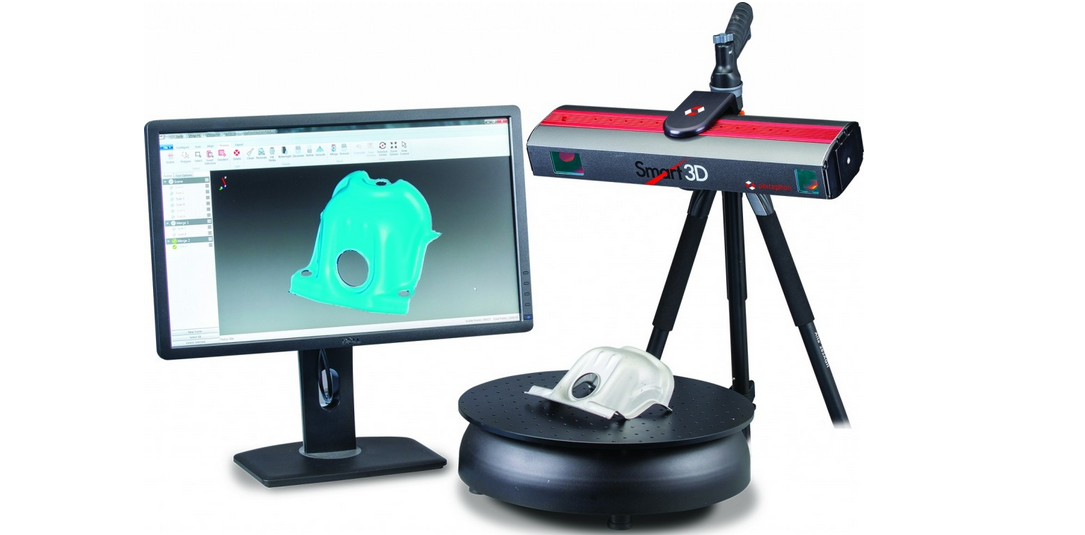

Go!SCAN 3D

Professional portable 3D scanner

View more

Go!SCAN 3D enables easiest 3D scanning experience, generating fast and reliable measurements for all your design and prototyping needs. Effortlessly capture the 3D shape and color of any object.

Accuracy

up to 0.050 mm

Resolution

0.100 mm

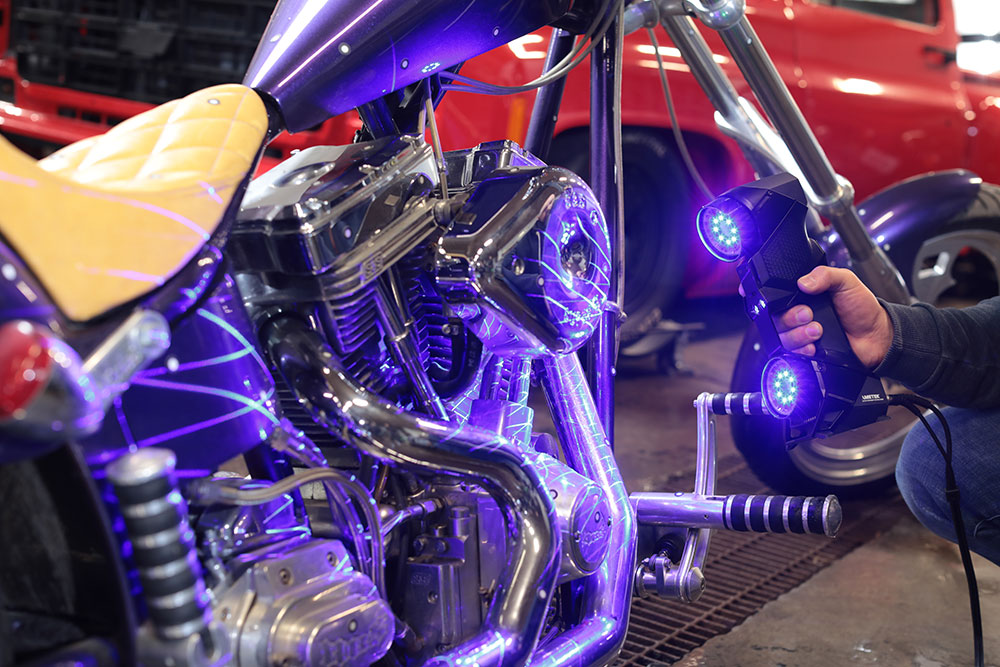

MetraSCAN 3D

Optical CMM 3D scanners and probe

View more

The most complete 3D scanners for metrology-grade measurements on all materials, MetraSCAN 3D is a powerful inspection solution that is insensitive to instabilities and harsh environments.

Accuracy

0.025 mm

Resolution

0.025 mm

Which portable 3D scanner is right for you?

No matter what type of industrial 3D scanner you are looking for, Creaform has the widest breadth of 3D measurement technologies for any workflow or project. Easy to use, they deliver unmatched performance.

Easy to use, they deliver unmatched performance.

| Accuracy | Up to 0.030 mm(0.0012 in) | Up to 0.050 mm(0.0020 in) | 0.025 mm(0.0009 in) | 0.025 mm (0.0009 in) | ||||

|---|---|---|---|---|---|---|---|---|

| Probing | X | |||||||

| Color Acquisition | X | |||||||

| Light Source | 7 red laser crosses(+ 1 extra line) | White light (99 stripes) | 11 blue laser crosses(+ 1 extra line) | 15 blue laser crosses(+ 1 extra line) | ||||

| Accreditation | ISO 17025 | ISO 17025 | ||||||

| Price | + | + + | + + + | + + + + | ||||

| View the full specs | View the full specs | View the full specs | View the full specs |

Find the best portable 3D scanner on the market

Talk to one of our metrology experts to determine which Creaform 3D scanner meets your unique needs.

Contact us today

VXelements software platform

Discover a fully integrated 3D software platform and application suite that powers Creaform’s entire fleet of 3D scanners and 3D measurement technologies. It offers all the essential tools in a user-friendly environment for real-time visualization and complete 3D scanning experience.

VXinspect™

Dimensional inspection software module for first article inspections or quality control

Get the details

VXmodel™

Scan-to-CAD software module to finalize and prepare 3D scan data for use in any 3D printing or CAD solution

Get the details

Pipecheck™

NDT pipeline integrity assessment software

Get the details

SmartDENT 3D™

3D scanning solution for aircraft quality control

Get the details

3D Measurement solutions designed for manufacturers’ unique needs

Creaform’s 3D scanners address the 3D measurement requirements for each stage of the manufacturing process.

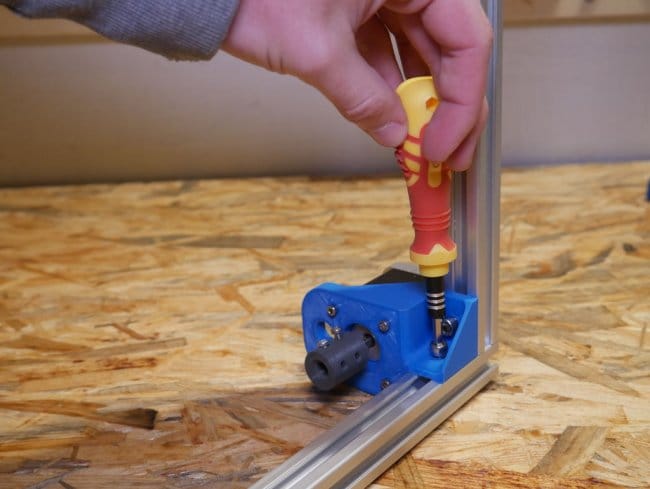

Product development and design

Creaform’s portable 3D scanners help engineers and designers to develop innovative new products and push product development further—all while minimizing design iterations and accelerating manufacturers’ time to market.

Read more application cases

Quality assurance and quality control

Thanks to our portable 3D scanning technologies, quality assurance and quality control teams can minimize the risk of delivering defective and non-compliant products to customers. Our 3D scanners enable manufacturers to reduce their total costs of quality.

Read more application cases

Maintenance, repair and overhaul

Maintenance, repair and overhaul (MRO) companies around the world benefit from Creaform’s industrial 3D scanners for accurate, repeatable and reliable 3D measurements to cater to the demanding needs and regulations of OEM and airline customers.

Read more application cases

Non-destructive testing for oil and gas

Robust, easy to use and featuring lightning-fast speed, Creaform’s 3D scanners and pipeline assessment software help non-destructive testing (NDT) service companies and inspectors safeguard pipelines’ state of health—and the security of local communities.

Read more application cases

Reverse engineering

Creaform’s handheld 3D scanners and scan-to-CAD software are the tools engineers and industrial designers need to quickly and accurately generate 3D models of existing parts, assemblies and their surrounding environments for a wide range of reverse engineering workflows.

Read more application cases

Explore all of our 3D measurement applications

See more

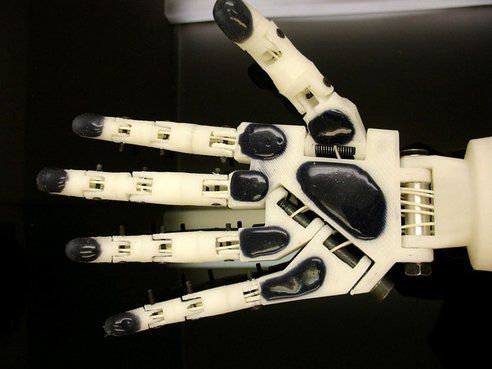

Portable 3D scanners for the healthcare and educational sectors

Explore our 3D scanning solutions for healthcare, with our Healthcare Partner 3D scanner, and for education, with Creaform ACADEMIA.

3D scanning in healthcare

Creaform’s Healthcare Partner 3D scanner is the ideal device for healthcare and 3D scanning for body measurement, including orthotics, prosthetics, cranial scanning, podiatrics, plastic survey and more. Contrary to traditional measurement methods, such as plaster casts, our 3D scanner enables fast and highly accurate data acquisition.

Learn more

3D scanning in education

Teachers and researchers can help educate the engineers and designers of tomorrow thanks to Creaform ACADEMIA. Whether you need to teach students about metrology or conduct advanced research, our professional-grade 3D scanners are designed with educational purposes in mind.

Learn more

Creaform’s customer success stories

Find out about some of our latest customer satisfaction testimonials and learn how our clients are taking advantage of our 3D measurement technologies.

« Not only in the sport industry but in any kind of industry, when designing new products, we have to give the designers a base to work with. The HandySCAN 3D allows us go from the handmade prototype to the 3D models much faster. »

Bertrand Didier, Chief Engineer Sports division, SCOTT Sports

« After benchmarking all available measurement systems, we felt that Creaform’s products and solutions fitted best with our demanding requirements and environment, as they are less sensitive to movements during scanning. »

»

Jon Gunner, Technical Director, Koenigsegg Automotive AB

« With the MetraSCAN 3D scanner, we have a dynamic production development process with a common work basis for QC and design/construction. We can now make adjustments to components where we had not previously thought was possible before. »

Sebastian Witt, Quality control motorsport, KTM

« The automotive industry benefit highly from the MetraSCAN 3D optical CMM scanner line-up in the ability to scan in real time, get a precise image of what is going on with our parts and solve those critical quality issues. It ensures we provide good parts for our customer. »

Aaron Boyer, Global director – CAD/CAE, Flex-N-Gate

Effective and efficient 3D scanning is at your fingertips

Creaform’s continuous innovations in 3D measurement technologies gives you peace of mind knowing you are relying on proven 3D scanning solutions that get the job done.

Find out how

HandySCAN 3D Scanners | Portable 3D Scanning & Metrology

CREAFORM

An Accurate and Portable 3D Scanning Solution

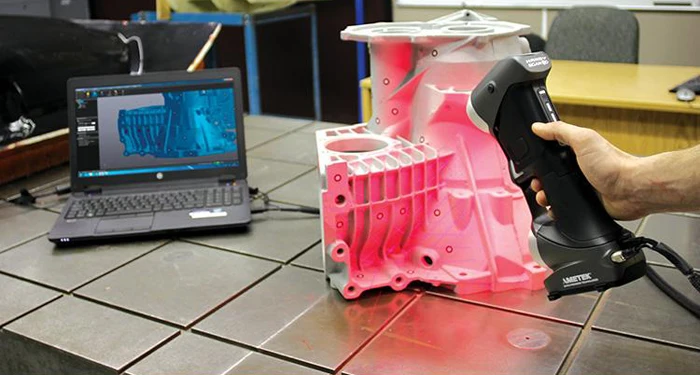

Creaform's flagship 3D scanner is now more portable than ever and is faster at delivering accurate and high resolution 3D scans while remaining simple to use. With dynamic referencing you can take the system anywhere and have accurate and repeatable 3D scanning results in any environment. It is the perfect tool for reverse engineering and inspection across the entire product development lifecycle.

View Video Brochure Request Demo Request a Quote

- Overview

- Key Features

- Key Features

- Advantages

- Applications

- Software

- Specifications

- Request a Quote

Faster, More Accurate, & Redesigned for the Best Metrology Experience

The HandySCAN 3D handheld scanners from Creaform have been optimized to meet the needs of product development and engineering professionals on the lookout for the most effective and reliable way to acquire 3D measurements of physical objects

Explore the HandySCAN 3D by watching the video

TRUaccuracy

Achieve precise, metrology-grade measurements in real life operating conditions. Get consistent and repeatable results across all work conditions and environments without the need for a rigid setup.

TRUportability

Take 3D scanning wherever you need to go. Ditch external positioning systems, arms and fixtures for a high-tech stand-alone device that weights under 1kg and small enough to fit inside a carry-on case.

TRUsimplicity

It’s as simple as it gets. This user-friendly device carries a short learning curve and is up and running in less than 2 minutes- regardless of the user’s experience level.

New Features

- 25 times faster than the previous generation

- 40% more accurate

- improved ergonomy:

- 35% lighter

- 50% smaller

- Greater freedom of movement

- Multi-function buttons for easier interaction with the software

Accuracy

Metrology-Grade Measurements: Accuracy of up to 0. 030 mm (0.0012 in.), resolution of up to 0.050 mm (0.002 in.), high repeatability and traceable certificate.

030 mm (0.0012 in.), resolution of up to 0.050 mm (0.002 in.), high repeatability and traceable certificate.

Accuracy in real-life conditions: Regardless of environment conditions, part set-up or user.

No rigid setup required: Optical reflectors are used to create a reference system that is “locked” to the part itself, so users can move the object any way they want during scanning sessions (dynamic referencing). Changes in surrounding environment have no impact on data acquisition quality or accuracy.

Self-positioning: The HandySCAN 3D scanner is a data acquisition system and its own positioning system. This means that no external tracking or positioning devices is required. It uses triangulation to determine its relative position to the part in real time.

Reliable: Consistent and repeatable results across all work conditions or environments.

On-demand user calibration: The 3D scanner can be calibrated as often as necessary (day-to-day basis or before each new scanning session). Calibration takes about 2 minutes and guarantees optimal operation

Calibration takes about 2 minutes and guarantees optimal operation

TruPortability

Stand-alone device: There is no need for an external positioning system, arms, tripod or fixture.

On-the-go scanning: You can take it from place to place or use it in-house or on site.

Lightweight: Weighs under 1 kg.

Small: Fits into a case the size of a carry-on.

Easy access to confined spaces: Thanks to its small size and flexible stand-off distance.

Speed

Fastest 3D Scanner on the Market: 25 times faster than the previous generation

Highest measurement rate among all laser scanners: 480,000 measure/s.

Automatic mesh output: Ready-to-use files, right as you complete acquisition.

Quick workflow integration: Usable scan files can be imported into RE/CAD software without post-processing.

TruSimplicity

User Friendly: Very short learning curve, regardless of the user’s experience level.

Quick Setup: Up and running in less than 2 minutes.

Direct Mesh Output: No complicated alignment or point cloud processing.

Real-Time Visualization: Look at the computer screen to see what you are doing and what is left to be done.

Versatile: Virtually limitless 3D scanning – no matter the part size, complexity, material or color.

Applications

HandySCAN 3D scanners present opportunities for process improvement across all the stages of the product development lifecycle; from concept development through to design, prototyping, manufacturing and after sales support and servicing. Let our team guide you in integrating this technology into your current workflow

Concept Development

and Early Stage Prototyping

Requirements and Specifications

| Concept Design

| Concept Prototyping

|

Design, Rapid Prototyping

and Simulation

CAD Design

| Rapid Prototyping

| Testing, Simulation and Analysis

|

Manufacturing

Tooling Design

| Assembly and Production

| Quality Control

|

After Sales Support & Servicing

Product Documentation

| Maintenance, Repair, and Overhaul (MRO)

| Replacement and Recycling

|

Scan with Confidence

The new HandySCAN 3D performs 25 times faster- the fastest 3D scanner on the market. The device also carries the highest measurement rate among all laser scanners at 480,000 measures per second, allowing it to be 40% more accurate than previous generations.

The device also carries the highest measurement rate among all laser scanners at 480,000 measures per second, allowing it to be 40% more accurate than previous generations.

Improved Ergonomics

The new HandySCAN 3D performs 25 times faster- the fastest 3D scanner on the market. The device also carries the highest measurement rate among all laser scanners at 480,000 measures per second, allowing it to be 40% more accurate than previous generations.

Two Variants

The HandySCAN 3D scanners feature two distinct models to suit the needs of your organization. The HandySCAN 300 is the most efficient device to reverse engineering and/or design, achieve quick and accurate scans from a reliable tool.

The HandySCAN 700 features increased accuracy and resolution and is the most versatile 3D scanner on the market for inspection and reverse engineering.

Speed, Accuracy and Comfort All in One Reliable Tool

VXelements: 3D Software Platform

The HandySCAN 3D scanners come with VXelements, a fully integrated 3D software platform that powers our entire fleet of 3D scanning and measurement technologies. The user-friendly software thrives off a sleek and simple working platform. gathering essential elements, including real-time visualization, it creates the best scanning experience.

The user-friendly software thrives off a sleek and simple working platform. gathering essential elements, including real-time visualization, it creates the best scanning experience.

Upon completing the scan, an optimized file is automatically created, significantly reducing the time involved in your inspection/design process.

VXscan: Scan Software Module

VXscan is entirely dedicated to the acquisition and optimization of 3D scanning data. It delivers high performance for that specific task, yet it is simple and user-friendly enough to suit any user’s experience level.

- User-friendly interface: VXelements was designed to simplify the whole scanning process to its essential core, through a powerful and simple process.

- Surface optimization algorithm: avoids the creation of multiple scan layers and ensures a more accurate mesh without any post-treatment;

- Direct mesh output: an optimized mesh can be exported in all standard formats, right as you complete acquisition.

No complicated alignment or point cloud processing needed;

No complicated alignment or point cloud processing needed; - No limitation to the scan resolution: you simply need to input a resolution value, independent from the size of the scanned object. Resolution can be changed at any time before/after the scan;

- Real-time visualization: the user can view the 3D surface as the object is being scanned;

- Scan results enhancement: hole filling, smart decimation, boundary filters, etc.

- Compatible Software: 3D Systems (Geomagic), InnovMetric (Polyworks), Dassault Systèmes (CATIA V5, SolidWorks), PTC (ProEngineer), Metrolog X4 and V5, Simens (NX and Solid Edge), Autodesk (Inventor, Alias, 3ds Max, Maya, Softimage)

VXinspect

3D Inspection Software Designed for Article Inspection and Quality Control

Learn More

VXmodel

Seamlessly integrate 3D scan data into your CAD & 3D printing process

Learn More

VXremote

Remote Access Software Application for 3D Measurements in the Field

Learn More

Industries

The versatility of HandySCAN 3D scanners mean that they can be applied to applications across various industries regardless of environments. Explore some of the advantages in your industry or call us to speak with one of our industry experts.

Explore some of the advantages in your industry or call us to speak with one of our industry experts.

HandySCAN 300 | HandySCAN 700 | |||

Weight | 0.85 kg [1.9 lbs] | 0.85 kg [1.9 lbs] | Weight0.85 kg [1.9 lbs] | |

Dimensions | 12.2 x 7.7 x 29.4 cm [4.8 x 3.0 x 11.6 in] | 12.2 x 7.7 x 29.4 cm [4.8 x 3.0 x 11.6 in] | Dimensions12.2 x 7.7 x 29.4 cm [4.8 x 3.0 x 11.6 in] | |

Measurement Rate | 205,000 measures/s | 480,000 measures/s | Measurement Rate205,000 measures/s 480,000 measures/s | |

Scanning Area | 225 x 250 mm [8.8 x 10 in] | 275 x 250 mm [10.8 x 10 in] | Scanning Area225 x 250 mm [8.8 x 10 in] 275 x 250 mm [10.8 x 10 in] | |

Light Source | 3 Laser Crosses | 7 Laser Crosses (+1 extra line) | Light Source3 Laser Crosses 7 Laser Crosses (+1 extra line) | |

Laser Class | II (eye-safe) | II (eye-safe) | Laser ClassII (eye-safe) | |

Resolution | 0. 10 mm [0.004 in] 10 mm [0.004 in] | 0.05 mm [0.002 in] | Resolution0.10 mm [0.004 in] 0.05 mm [0.002 in] | |

Volumetric Accuracy | 0.020 mm + 0.025 mm/m [0.0008 in. + 0.0003 in./ft] | 0.020 mm + 0.025 mm/m [0.0008 in. + 0.0003 in./ft] | Volumetric Accuracy0.020 mm + 0.025 mm/m[0.0008 in. + 0.0003 in./ft] | |

Stand-off Distance | 300 m [12 in] | 300 m [12 in] | Stand-off Distance300 m [12 in] | |

Depth of Field | 250 mm [10 in] | 250 mm [10 in] | Depth of Field250 mm [10 in] | |

HandySCAN 3D laser scanners | Creaform

HandySCAN 3D handheld scanners are optimized for the needs of pipeline integrity engineers and provide the most efficient and reliable way to obtain 3D measurements of physical objects.

Creaform's flagship metrology scanners have been redesigned. They're lighter and deliver high-resolution 3D scans faster, while still being just as easy to use.

They're lighter and deliver high-resolution 3D scans faster, while still being just as easy to use.

The Creaform Pipecheck system offers a choice of two models of 3D laser scanners depending on the required level of accuracy.

A COMBINATION OF PRECISION AND PORTABILITY. INTRODUCING HANDYSCAN 3D SCANNERS.

Looking for the most efficient way to accurately quantify material loss and mechanical damage ? HandySCAN 300 is a reliable tool that will solve this problem.

HandySCAN 700 provides high accuracy and resolution. It is the most versatile 3D scanner for checking available on the market. The data collection speed of the HandySCAN 700 will pleasantly surprise you.

- Benefits

- Operating sequence

- Applications

- Accessories

- specifications

TRUaccuracy (True Accuracy)

- Dynamic coupling between tube and scanner maintains accuracy and resolution in all conditions, including high vibration conditions.

- The system generates accurate, reproducible high resolution 3D data (0.040-0.050 mm).

- Improved virtual level gauge capabilities. The transmitter is configured to provide the most accurate measurements close to welds.

- Comparison of Internal Pipe Condition Data : Access inspection results by comparing internal pipe inspection data and data from tools with data from the Pipecheck system. This helps operators to more accurately identify areas where earthworks need to be done.

- Depth of Corrosion Within a Mechanical Fault : Unique and innovative tools for determining the depth of corrosion within a mechanical fault.

TRUsimplicity : A very simple 3D scanning process

- Scanning and analysis are accurate, intuitive to use and independent of operator skill.

- Very fast learning, regardless of user experience.

- Launch and start in less than 2 minutes.

- Simplicity: simple and fast learning.

- The ability to change the working distance allows access to isolated areas.

- Visualization of the scanned surface in real time.

TRUportability : 3D scanning where you need it

- Portable from place to place and used both indoors and outdoors.

- Weight 0.85 kg; possibility of use in limited spaces. Fits in a portable case.

- The mass of the scanner is approx. 1 kg.

Pipecheck: Your best ally in all phases of your pipeline integrity program

SCAN

- Corrosion

- High definition image capture for all areas showing signs of corrosion

- Fast surface imaging for increased efficiency

- Improved scanning of fine details such as pitting

- Mechanical damage

- High resolution mesh files for analysis optimization

- Quick measurements to check any surface finish

- Comparison of pipe internal inspection data

- Skill-independent high-precision measurements for more accurate matched data

- Improved performance to cover more area and get more accurate statistical trends

ANALYSIS

- Corrosion

- Troubleshooting using real pipeline geometry

- Automatic application of interaction rules

- Estimated Burst Pressure Calculation

- Improved virtual level gauge for working near welds and obstacles

- Mechanical damage

- Automatic maximum depth detection

- Automatic creation of a 2D cross profile in both directions at maximum depth

- Measuring the maximum depth in both directions with straightedge

- Lug section available

- Comparison of pipe internal inspection data

- Automatic detection of coincidences when overlapping surfaces

- Manual match function

- Axial and circular offset function for optimum overlap

REPORT

- Corrosion

- Excel report including worst case profile and predicted fault evolution

- Ability to export to CSV format for further analysis

- Ability to export coordinate grid

- Configurable Pass/Fail criteria

- Photographic device for 3D report

- Mechanical damage

- Excel report with ovality measurements

- Detailed cross section (axial and cylindrical)

- Depth mesh export to CSV format

- Ability to export coordinate grid

- Excel report with ovality measurement results (diameter measurement with caliper)

- Dat, maximum depth point

- Dat, 90° from maximum depth point

- Dmax

- Comparison of pipe internal inspection data

- Visual overlay of pipe internal inspection data and faults detected by scan

- General Graph for Evaluating the Performance of Sizing, Maximum Depth and Estimated Burst Pressure Tools

- List of coordinated and inconsistent functions

- Piping corrosion assessment

- Assessment of mechanical damage to pipelines

- Estimation of hail damage to aircraft

- 3D Simulation for Phased Array Inspection - Aerospace

- 3D Simulation for Phased Array Inspection - Energy

Rugged field kit with wireless tablet

For companies looking for optimal performance in the field, Creaform has developed a complete set of accessories. Our rugged field kit includes a wireless tablet for real-time visualization of scanned surfaces.

Our rugged field kit includes a wireless tablet for real-time visualization of scanned surfaces.

It also offers a choice of three compatible power sources: Creaform battery with charger*, 110/220V direct input or car battery.

Package includes:

- Wireless tablet powered by VXremote

- Pelican rugged laptop case

- Creaform battery with charger

- Magnetic support for scanner

- Magnetic tablet support

- USB 3.0 cable, 8m

Accessories:

- Emergency power cables for car battery

*When used with a Creaform rechargeable battery, the rugged field kit provides 8 hours of battery life.

3D Scanner Power Bank: Takes portability to a whole new level

Lightweight 3D scanner power bank with three hours of battery life improves data acquisition efficiency. Ideal for short term projects and applications where the object is accessed with a tether and provides complete freedom of movement. Combined with HandySCAN 3D, you can use the scanner wherever you are. The small weight and size guarantee a new level of portability! Offered at a reasonable and affordable price, the rechargeable battery is ideal for working in confined spaces as well as outdoors!

Combined with HandySCAN 3D, you can use the scanner wherever you are. The small weight and size guarantee a new level of portability! Offered at a reasonable and affordable price, the rechargeable battery is ideal for working in confined spaces as well as outdoors!

- Autonomy: 3 hours of continuous scanning

- Dimensions: 180x110x20 mm / 7.1x4.3x0.8 inches.

- Weight: 0.52 kg / 1.14 lb

- Charging time: 4 hours

VXremote™: Remote Access Software

VXremote improves field efficiency by providing quick and easy remote access to Pipecheck. This software guarantees fast start-up and configuration without any hardware. All 3D scanner functions are at your disposal... Only available with Creaform Certified Rugged Tablets!

Complete solution includes:

- Handyscan 3D Laser Scanner

- Pipecheck software license

- Calibration plate

- Pointer with protective cover

- USB 3.

0 cable, 4m

0 cable, 4m - Power supply

- 4 sets of 500 alignment marks

- One year parts and labor warranty

Accessories

- Certified Notebook PC

- Sample Pipecheck

https://www.creaform3d.com/ru/sistemy-nerazrushayushchego-kontrolya/lazernye-skanery-handyscan-3d/tehnicheskie-harakteristiki

Overview of HandySCAN Black and Black Elite 3D scanners / Sudo Null IT News We have devoted this review to professional high-precision scanners Creaform HandySCAN Black Elite and Creaform HandySCAN Black, used in many industries. These are handheld 3D scanners with laser illumination. Read the article to find out more.

Source: top3dshop.ru

In the article we will introduce you to the technical characteristics of the equipment and the range of tasks solved using Creaform HandySCAN Black.

Contents

- About

- Technical data Creaform HandySCAN Black

- General information

- Equipment

- Preparing for work

- Software package

- Consumables

- Cases Creaform HandySCAN

- Automotive transmission housing

- Helicopter design

- Scan Cadillac Escalade

- Aerospace use

- Compare Creaform HandySCAN Black and ScanTech PRINCE 335

- Advantages and disadvantages of

- Conclusion

About the manufacturer

Source: creaform3d. com

com

Creaform was founded in Canada in 2002. The main activity is the development, production and sale of professional 3D scanners. The company's management has chosen an original development path that differs from a number of competitors. In addition to its own developments and hiring highly qualified specialists, Creaform bought companies that are effectively operating in the same industry.

Source: facebook.com

The strategy paid off: a few years later, in 2005, the company's office was opened in France and the first mobile 3D scanner was launched on the market. The next decade was marked by the release of devices in different price niches: from the basic UNIscan model to the full-color VIUscan 3D scanner. In the same period, InSpeck, a leader in the production of scanners for 3D human scanning, was bought, representative offices were opened in different countries.

Source: facebook. com

com

Since 2013, Creaform has become part of the American AMETEK holding. The reputation of the company has grown every year. Exhibitions, competitions, awards. For example, the Product Design 2017 title was awarded to MetraSCAN 3D. Scanners Go!SCAN SPARK and HandySCAN BLACK were among the leaders in the Red Dot Award.

Specifications Creaform HandySCAN Black

Source: creaform3d.com

General Information

The Creaform HandySCAN Black and Black Elite 3D scanners are designed for professional use in various industrial applications.

Examples of tasks to be solved:

- Inspection of main pipelines for mechanical damage and corrosion;

- Reverse engineering - creating a CAD model based on a finished object;

- Quality control of finished parts;

- Compliance with the accuracy of the dimensions of the finished product to the technical specifications;

- Digitization of objects for various purposes.

HandySCAN Black scanners are based on the principle of “plug-and-play” ease of use. To start the scanning process, you need to connect the scanner to your laptop, turn on the device and run the program. The user has the opportunity to pause at any time, analyze the indicators on the monitor and continue working.

The difference between the models lies in the number of working beams:

- HandySCAN Black - 14 beams;

- HandySCAN Black Elite - 22.

Due to the larger number of beams, the Elite's speed is higher. The first model can use 1 beam in operation. This increases the duration of the scan, but deepenings, holes and other complex areas of objects are worked out in more detail. The cameras of both models have a resolution of 0.025 mm. The devices are absolutely safe for eyesight, due to the use of class 2M technology.

Source: facebook. com

com

Before starting work on the surface of the object, you need to evenly place magnetic or adhesive stickers - scanning marks. They are used to determine the scanner in space and improve the accuracy of the data. During operation, the marks in the program are highlighted in different colors, by which you can adjust the distance to the object:

- blue color indicates too much distance;

- green - optimal removal;

- red - too short distance between the scanner and the object.

Source: creaform3d.com

For the convenience of digitizing objects with non-standard surfaces, HandySCAN Black provides 2 functions.

Auto-tuning

Used to scan parts with a mirror surface. To configure, you need to turn on the device and fix it in one position for a few seconds. Laser sensors will automatically adjust to work with the object. This is one of the important advantages of Creaform HandySCAN Black over competitive models that require matting spray on glare objects.

HDR mode

Works when shooting light details or large pale objects with smooth outlines against a light background. In the software, the user selects automatic or HDR mode. The function enhances the image contrast during data processing by the instrument.

Equipment

The case with the scanner contains:

- USB cable;

- power cable;

- USB stick with program files;

- sticker packs;

- folder with calibration panel.

Getting Started

Takes a few minutes. Creaform HandySCAN Black and Black Elite are connected to a laptop and mains power. The scanner is directed to the calibration panel and the program is launched on the laptop/computer. After a minute of scanning the calibration panel, the device is completely ready for use.

Software package

The VXelements application package consists of modules selected by the user depending on the tasks:

- VXinspect - for checking the quality of products, detecting deviations;

- VXmodel - for digitizing objects.

For highly specialized industries, developers offer separate applications.

For example, Pipecheck helps inspect main pipelines, and SmartDENT 3D assesses the degree of wear of aircraft body parts.

Consumables

Source: facebook.com

Scanning consumables are labels - special stickers. Magnetic or adhesive marks are evenly placed on the part, on the table, when working with small objects - on bulky objects located around.

Creaform HandySCAN Cases

Automotive Transmission Housing

In this case, an EMS3D specialist used HandySCAN Black to digitize a car's transmission case. He received the model in just a few minutes. Just as quickly, the device coped with scanning the chrome plated disk of the car.

Helicopter design

The American helicopter company Bell is working on a unique project. Engineers develop air taxis. To study metal products for the possibility of warping, experts turned to HandySCAN Black equipment. According to Bell employees, the use of Creaform scanners guarantees high data accuracy and saves up to 35 percent of time compared to other technologies.

Engineers develop air taxis. To study metal products for the possibility of warping, experts turned to HandySCAN Black equipment. According to Bell employees, the use of Creaform scanners guarantees high data accuracy and saves up to 35 percent of time compared to other technologies.

Digitization Cadillac Escalade

To create a drawing of a film that protects the paintwork, it was necessary to completely digitize the car. The combination of different surfaces, chrome and black parts, could create difficulties in scanning. However, Creaform HandySCAN Black was able to capture accurately, process the information and provide a high quality model.

Aerospace use

In this case, it was necessary to digitize a part of a complex design used in the aerospace industry. The pipe had a shape with bends and turns, the exact transmission of which was important for the project. Creaform HandySCAN Black scanned the object, despite the non-standard shape, in a matter of minutes.

Comparison of Creaform HandySCAN Black and ScanTech PRINCE 335

Source: 3d-scantech.com

The Chinese-made ScanTech PRINCE 335 model is similar to the Canadian HandySCAN devices in many technical characteristics. The scanning accuracy of the PRINCE 335 is the same, but the model is slightly slower due to fewer laser beams. The ScanTech scanner is used for digitizing objects, quality control and reverse engineering, but its software does not provide for solving highly specialized tasks - monitoring the condition of pipelines or aircraft skins. Similar in functionality, scanners have different capabilities due to software.

Advantages and disadvantages

Advantages:

- High speed and accuracy of information processing;

- Comfort in operation;

- A powerful software package for highly specialized tasks.

Cons: