Get started with 3d printing

gettingstarted - 3dprinting

- Getting Started

- Why 3D Printing?

- Getting started with 3D Printing

- Where to get a model printed

- What printer to get

- Where to find models

- Material Choices

- Slicers

- Printing and Troubleshooting

- Post Processing

- How to make models

- Further Info

| If you're new around here, welcome! We thought we'd put a few links together to springboard your foray into the fabulous (and sometimes frustrating!) world of 3D printing. :) |

|---|

| If you are contributing to this wiki please keep this page incredibly concise and extremely high level, keep further detail for the Detailed Info pages. |

Why 3D Printing?

3D printing (a.k.a Additive Manufacturing) is now pretty well established in industry as a prototyping tool, and is becoming more common as a process for creating finished custom or low-run parts.

In the home, printers can be a marvelous tool for solving practical household problems for example by repairing items, or creating new items that are fully customised for their position or use case. They also can be used for fun, and are popular for making tabletop gaming minis, and toys.

For inspiration browse the top posts of this subreddit.

Getting started with 3D Printing

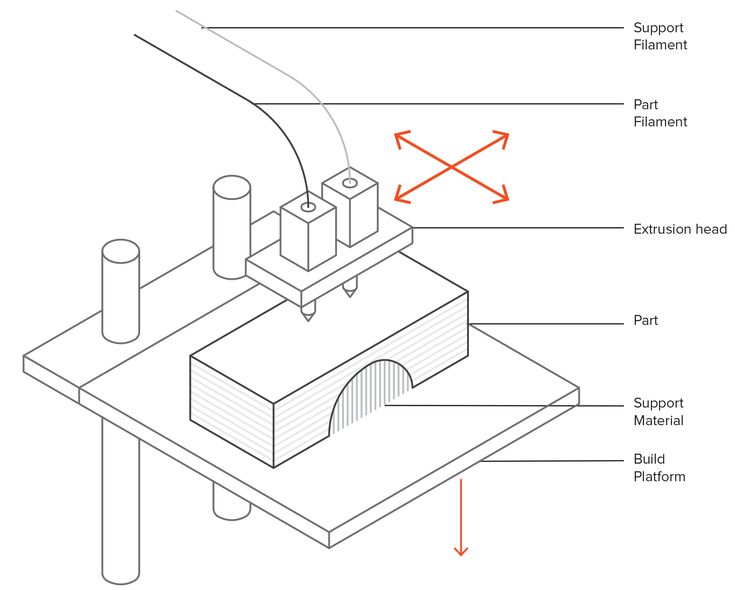

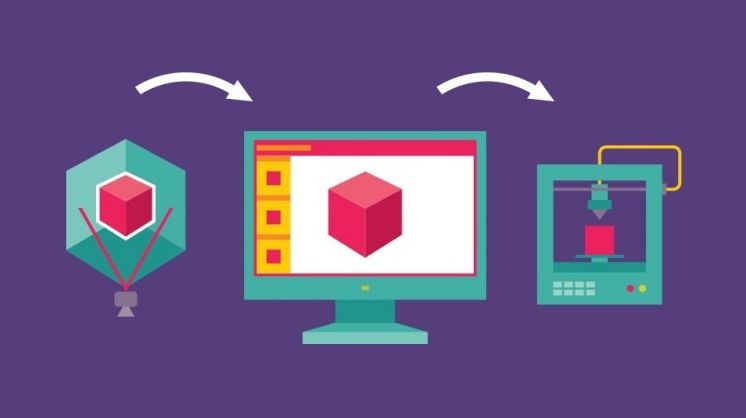

The various types of 3D printing technologies all create real-world three-dimensional objects from digital models via the addition of material. These processes are able to produce novel structures that other manufacturing techniques cannot. Usually the 3D printing process looks like this:

Get a digital 3D model (by downloading or making one)

Slice it (use a program to generate instructions for the printer)

Print it (and troubleshoot it)

Post-process it (remove support material, clean up areas, paint etc)

Where to get a model printed

If you don't want to buy a printer (and you just want to have something printed), you can engage the help of a 3D printing service. Some popular choices include:

Some popular choices include:

For a full list of service-providers (including design and model hosting services), please see the Services page.

What printer to get

If you're totally new to printing, the best place to ask for help when deciding what printer is right for you is our stickied monthly Purchase Advice Megathread.

Generally personal printers come in two main categories;

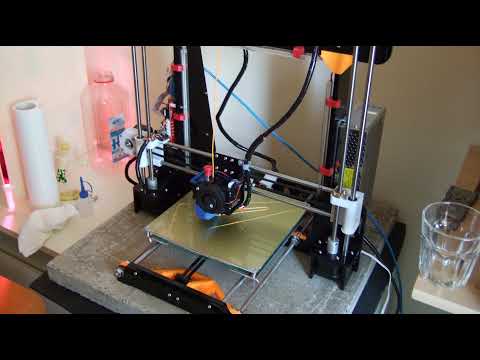

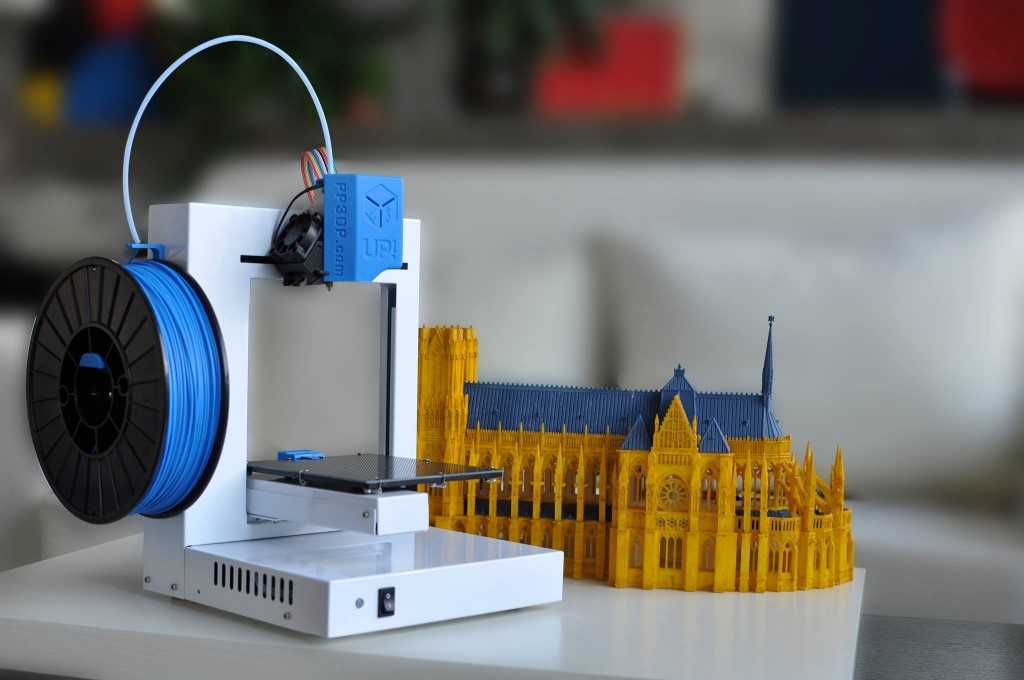

FDM (FFM) printers are best suited to larger objects and functional parts and work a bit like a like a hot glue gun that moves around, extruding plastic filament and building up an object layer by layer.

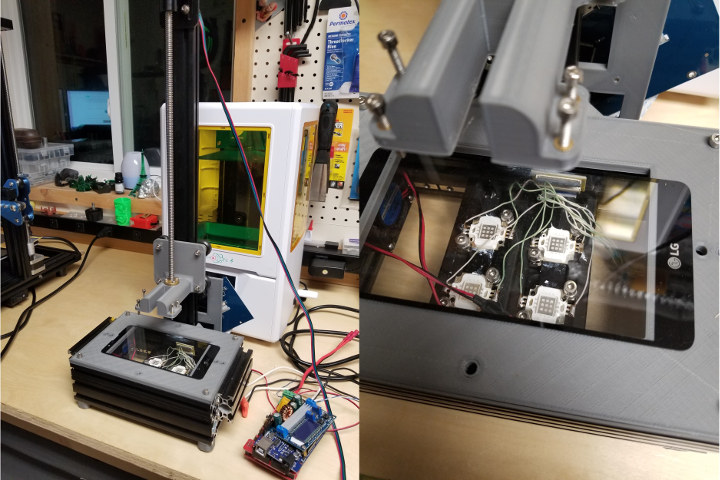

DLP (Layer Masking) printers are best suited to extremely detailed prints, and use light to cure resin in layers, masking it with an LCD screen.

There are, however, many other types of 3D printing technologies, which are explained here.

Where to find models

If you don't want to make your own models to print, there are many sites that host models for download. The more popular ones are:

The more popular ones are:

Printables: upcoming and community-focused, feature-rich

Thingiverse: biggest model host, often buggy

Thangs: free models, which can be searched by geometry

My Mini Factory: free and paid models, guaranteed to print

GrabCad: functional/ technical models

YouMagine: Open source models

pinshape: free and paid models

yeggi: 3D model aggregator/search

CGTrader: free and paid models, not all of them made to be printed

A community-curated list of model host services can also be found on the services page.

The RepRap foundation also keeps a list of printable model-host services here.

When selecting a model you need to ensure they are manifold, here's an explanation of what that means and guide on fixing them. You can also try these free, automated services; Netfab, and Microsoft's tool

Material Choices

When you are just starting out with FDM 3D printing PLA is the recommended choice. It's very easy to work, relatively strong, with and comes without many of the safety concerns of other materials. A deeper discussion of materials can be found here.

It's very easy to work, relatively strong, with and comes without many of the safety concerns of other materials. A deeper discussion of materials can be found here.

If you are starting on a resin printer, check out our Resin Info page.

Slicers

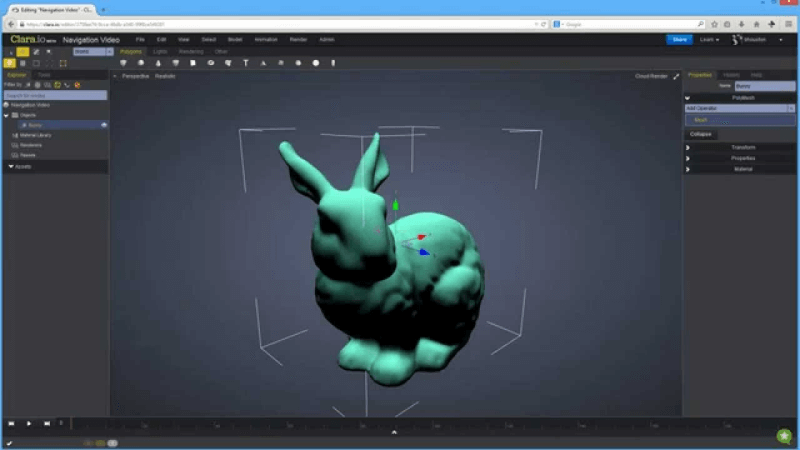

Slicing software takes a 3d model and turns it into instructions for the 3D printer. The instructions are generally exported in GCode which essentially is a list of locations to move to, amount of filament to extrude, etc.

The popular choices for slicing software are:

Ultimaker Cura: free, open source, highly customisable. Getting Started, Full Manual

Prusa Slicer (Based on Slic3r), Beginning with Prusa Edition (old version)

There are, however, many other options, most of which are discussed here

Be sure to check the layer preview to see if it makes sense in your slicer before printing (no unsupported overhangs, no parts missing, etc). More info on the Slicers Page

Printing and Troubleshooting

Follow your manufacturer's instructions in setting up your printer and starting your first print. It's a good idea to print a test print first (usually printers come with one).

It's a good idea to print a test print first (usually printers come with one).

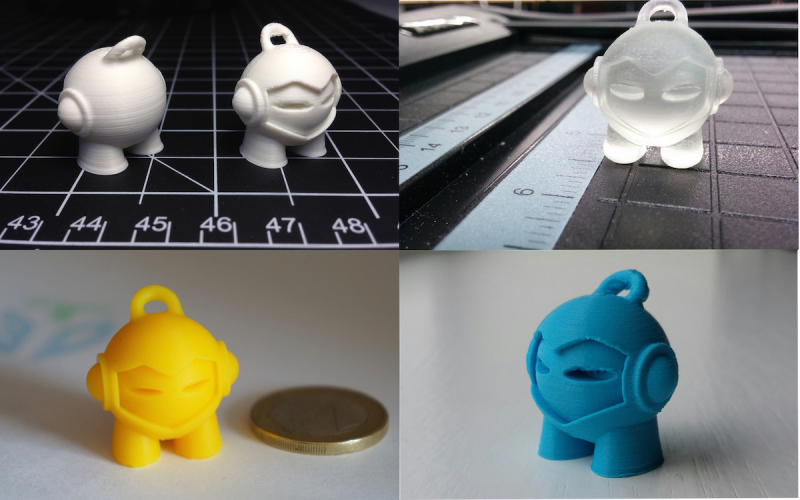

If it succeeds congrats on your first print! You can now start slicing and printing your own models or some calibration prints

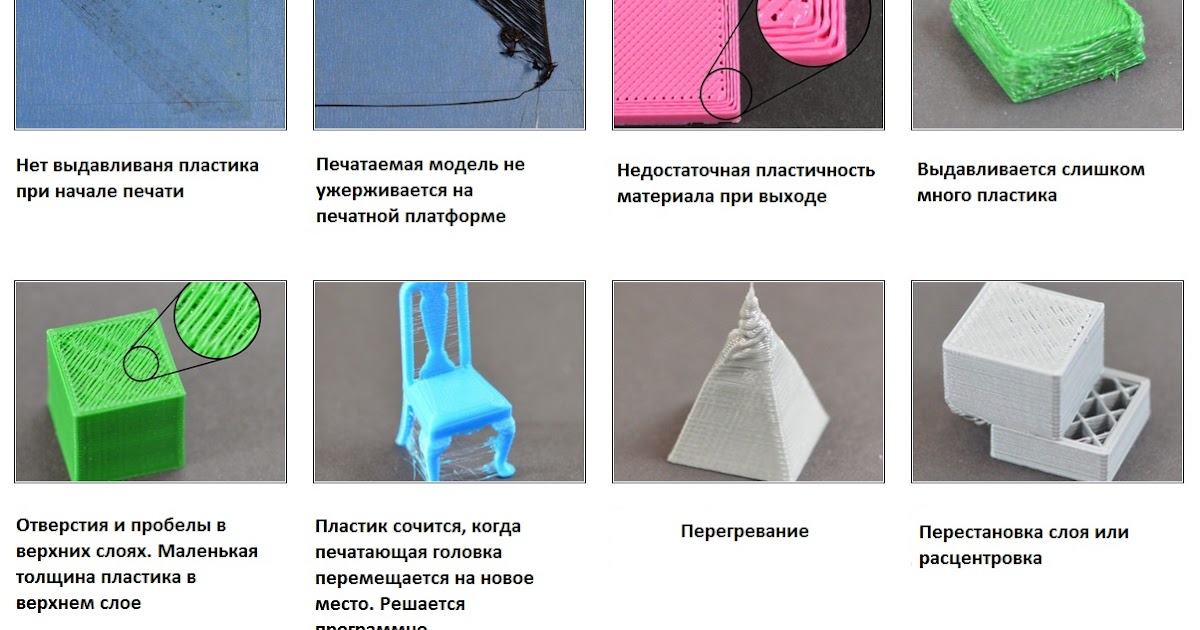

If your print fails you can begin troubleshooting.

This video helps you get to know the parts of your machine, so you know what we're talking about! :)

By far the most common reason for prints failing is an issue with levelling/tramming:

Full-resolution printable copy can be found here.

This visual reference, and this video may also help.

Once you have your prints sticking and printing, these guides can help you identify and solve any other issues you're experiencing:

Our Troubleshooting and Calibration wiki page

A Printa Pro PrintaGuide

rigid.ink poster and visual guide

Matterhackers Troubleshooting Guide

Simplify 3D Visual Troubleshooting Guide

Ultimaker Visual Troubleshooting Guide

RepRap Wiki Pictorial Troubleshooting Guide and Descriptive Troubleshooting Guide, these are a bit more technical/ advanced

It's also worthwhile seeking information from the manufacturer of your machine.

You can try searching for similar issues that other folk have experienced in the following communities: /r/3Dprinting, /r/FixMyPrint, the 3D Printers Discord

If the above suggestions don't solve your issue then it's time to seek help from the community:

This video is a great overview on how to seek help with prints.

The best places to ask for help are here on /r/3Dprinting, /r/FixMyPrint, the 3D Printers Discord. When asking for help be sure to provide the following:

- A highly descriptive title (even if you don't know exactly what everything is officially called, please do your best to describe the issue in plain English. This not only helps you get the help you want, but also helps the rest of the community by keeping the sub searchable, so others can benefit from the help you receive.)

- Photos of the issue, screengrabs of the layer view in your slicer, screengrabs of the model itself.

- A description of what the machine was doing as it produced this issue.

- Your basic settings such as: nozzle and bed temperature, speed, nozzle/line width and later height, the printer you're using and the material you're printing in. Or better yet, a screengrab or an export of your settings (you can upload files free without an account here)

- Any other information you think could be relevant such as modifications or hypotheses.

Post Processing

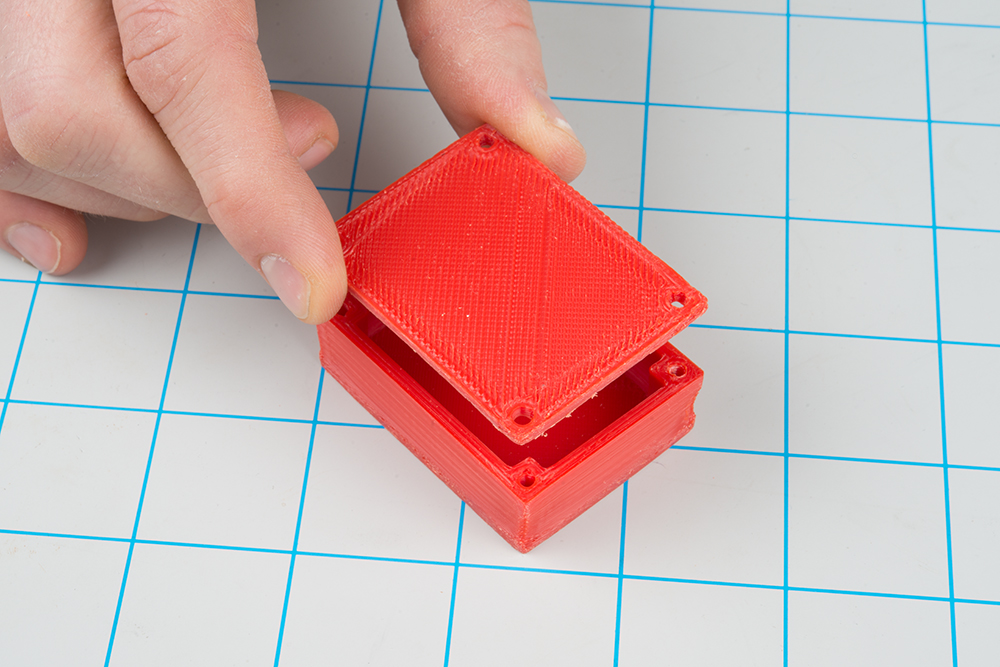

Most prints need some work after they come off the printer to turn them into a finished part. Supports need to be removed, and surfaced may need to be smoothed. Here are some tutorials:

- How to finish 3D Prints guide

More info on the Post Processing page

How to make models

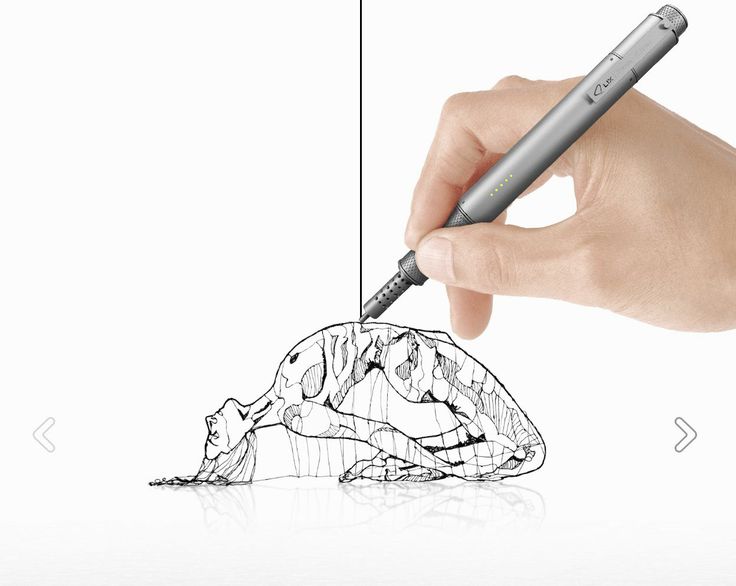

Can't find what you want online? Why not design and make it? Model-making software is split into 4 main categories, depending on your goal:

Full-resolution, printable copy here

These are just the top picks, model making is discussed in more depth on the Making Models page

More communities:

/u/Devtholt keeps a Multireddit of all 3d printing subreddits including some specifically for help, or tailored to certain printers or printer manufacturers.

Also has some subs that are related to 3D printing peripherally, such as /r/lasercutting and /r/CNC

Also has some subs that are related to 3D printing peripherally, such as /r/lasercutting and /r/CNC3D Printers Discord great platform for troubleshooting and socialising.

RepRap Forums

gettingstarted/%23wiki_why_3d_printing.3f - 3dprinting

gettingstarted/%23wiki_why_3d_printing.3f - 3dprintingLooks like you're using new Reddit on an old browser. The site may not work properly if you don't update your browser ! If you do not update your browser, we suggest you visit old reddit .

Press J to jump to the feed. Press question mark to learn the rest of the keyboard shortcuts

Search all of RedditFound the internet!

Feeds

Popular

Topics

ValheimGenshin ImpactMinecraftPokimaneHalo InfiniteCall of Duty: WarzonePath of ExileHollow Knight: SilksongEscape from TarkovWatch Dogs: Legion

NFLNBAMegan AndersonAtlanta HawksLos Angeles LakersBoston CelticsArsenal F. C.Philadelphia 76ersPremier LeagueUFC

C.Philadelphia 76ersPremier LeagueUFC

GameStopModernaPfizerJohnson & JohnsonAstraZenecaWalgreensBest BuyNovavaxSpaceXTesla

CardanoDogecoinAlgorandBitcoinLitecoinBasic Attention TokenBitcoin Cash

The Real Housewives of AtlantaThe BachelorSister Wives90 Day FianceWife SwapThe Amazing Race AustraliaMarried at First SightThe Real Housewives of DallasMy 600-lb LifeLast Week Tonight with John Oliver

Kim KardashianDoja CatIggy AzaleaAnya Taylor-JoyJamie Lee CurtisNatalie PortmanHenry CavillMillie Bobby BrownTom HiddlestonKeanu Reeves

Animals and PetsAnimeArtCars and Motor VehiclesCrafts and DIYCulture, Race, and EthnicityEthics and PhilosophyFashionFood and DrinkHistoryHobbiesLawLearning and EducationMilitaryMoviesMusicPlacePodcasts and StreamersPoliticsProgrammingReading, Writing, and LiteratureReligion and SpiritualityScienceTabletop GamesTechnologyTravel

Create an account to follow your favorite communities and start taking part in conversations.

r/

3Dprinting

"gettingstarted/%23wiki_why_3d_printing. 3f" does not exist

3f" does not exist

This page uses a restricted URL and can not be used as a wiki page

Wiki home

About Community

/r/3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

Created Mar 4, 2010

Related Communities

r/resinprinting

37,886 members

r/ender3

188,051 members

r/PrintedMinis

98,080 members

r/anycubic

13,789 members

r/prusa3d

49,236 members

r/PrintedWarhammer

37,848 members

r/ender5plus

7,956 members

r/Ender3Pro

21,312 members

r/3Dmodeling

203,117 members

r/SCREENPRINTING

55,344 members

Useful Links before Posting

Before Posting for Help, consider searching if your issue hasn't already been answered, or look for answers in our Wiki sections

r/3dprinting Rules

Posts must be 3D-printing-related

Requests for purchase advice must go in the stickied megathread

Less than 10% self-promotion

Community Behavior

Monday is Meme Day. You can only post Memes on Monday

You can only post Memes on Monday

First layer Fridays, Spaghetti Saturdays

No Karma/Repost Bots

Filter by Flair

News

Project

Discussion

Troubleshooting

Meta

Question

No File

Paid Model

Meme Monday

Moderators

Moderator list hidden. Learn More

ImpressumReport NetzDG Content

helpTransparency report

User AgreementPrivacy policy

Content policyModerator Code of Conduct

Reddit Inc © 2023. All rights reserved

Reddit and its partners use cookies and similar technologies to provide you with a better experience.By accepting all cookies, you agree to our use of cookies to deliver and maintain our services and site, improve the quality of Reddit, personalize Reddit content and advertising, and measure the effectiveness of advertising.By rejecting non-essential cookies, Reddit may still use certain cookies to ensure the proper functionality of our platform. For more information, please see our Cookie Notice and our Privacy Policy .

For more information, please see our Cookie Notice and our Privacy Policy .

Advertisement

instruction how to work from scratch for beginners and dummies, how

looks likeThree-dimensional printing has become increasingly introduced into our daily lives. Thanks to new technologies, it has become possible to easily print from a small detail to a large building. The range of products is also pleasing - today you can find a lineup that includes both affordable devices and more expensive ones. But how to work with a 3D printer? This is a completely normal question that any beginner will have, it is for this reason that we will try to answer it as simply and accessible as possible. nine0003

What is a 3D printer and how does it work?

The 3D device consists of the printer itself and a computer that controls all processes. The principle of operation of such a design is to create 3D models by superimposing layers of liquid material. There are a large number of printer models - from large industrial ones to compact ones, but they all have the same principle of operation and component parts:

There are a large number of printer models - from large industrial ones to compact ones, but they all have the same principle of operation and component parts:

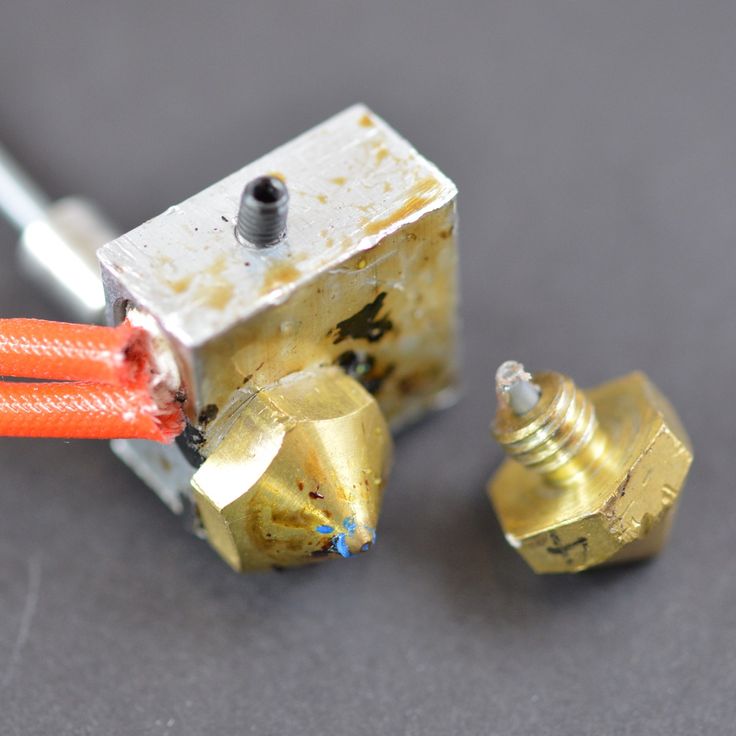

- Extruder - the print head through which the thread passes. The head heats the thread to a semi-liquid state and evenly supplies the material to the working surface. nine0010

- Work surface - a printing platform on which a 3D model is formed.

- Motors - mechanisms responsible for the accuracy of movement and speed of printing.

- Sensors are electronic devices that limit moving parts to specified coordinates.

- The frame is the structure that connects all parts of the printer.

How a 3D printer works: features

Work with the aim of building a three-dimensional model begins with a sketch, which is created in a special program. After that, the software independently generates a plan for the movement of the print head and a print sequence. The 3D model is reproduced by strongly heating the plastic and distributing it evenly. nine0003

nine0003

3D printers are used in many areas. Let's list some of them:

- Architecture - creation of models of buildings.

- Medicine - dental prosthetics, making models of organs for study.

- Construction - production of houses using 3D printing technology.

- Education - a visual aid for learning 3D printing.

- Automotive - creation of tuning parts, prototype layouts and other products.

This is a small list of industries where 3D printing is actively used. Today, almost every entrepreneur and just an enthusiastic person can afford a printer. nine0003

The following printers are distinguished by design features:

- RepRap - self-reproducing printers that can create their own copies.

- DIY-kit - the device comes disassembled with instructions, the assembly of which will take a sufficient amount of time.

- Completed - Models are delivered assembled and ready to use.

- Commercial and Industrial - devices capable of printing metal, concrete, polymers and other materials. nine0010

How to use a 3D printer: tips for beginners, where to start

Mastering the technique of 3D printing is not difficult if you follow the recommendations and tips. Especially for those who plan to learn the basics of 3D modeling, an up-to-date list of questions and detailed answers to them has been prepared.

Printer Installation

To begin, you will need to carefully unpack the box and remove any stops. The next step is to install the printer on the surface using the building level. This will allow you to place the device as evenly as possible, which will provide better printing. nine0003

Note. Some 3D printers come with a level for installation.

Next, you will need to connect the printer to your computer and install the necessary drivers. The software disc comes with the 3D device.

Preparation for work

To get started, you need to calibrate the working surface - without this, printing quality products is impossible. This process is carried out automatically or manually. The attached instructions have detailed information on how to perform manual calibration. nine0003

Extruder patency test

The next important step is setting up the extruder. First of all, you will need to check its nozzle. If the printer has already been used, the nozzle should be cleaned of solidified particles that will interfere with the throughput of the material. Refueling the 3D printer The thread is fed into the extruder directly from the spool. But there is one caveat - for this you must first warm it up. To thread the thread, you will have to make a small effort in order to loosen the presser mechanism. nine0003

Working with models

Models can be created using a variety of 3D modeling programs. The process of manufacturing three-dimensional parts is creative, requiring careful preparation. The better and more detailed the model is drawn, the better the 3D layout will be at the output.

The better and more detailed the model is drawn, the better the 3D layout will be at the output.

Start printing

After creating the model in the program and preparing the printer for work, you need to send the file for printing and wait for the result. The print speed varies depending on the printer model and specifications, as well as the media used. nine0003

Processing the finished product

3D printed products usually do not please the user with an ideal appearance: the parts have an uneven surface. But this is typical for models of 3D printers on FDM, SLA and DLP devices, which are distinguished by higher print quality. Owners of FDM printers should not despair - a simple processing of products will give products an attractive appearance and make the surface smooth.

Several powerful ways to post-process 3D printed parts:

- Mechanical - carried out by sanding the surface with sandpaper or a special sponge for grinding.

- Chemical - Surface treatment with aggressive solvents such as acetone and dichloroethane.

- Mixed - In this case, the above two processing methods are used.

What are the possible errors and how to avoid them?

Even a novice can master the technology of 3D printing, but, despite this, the production of the first products causes excitement for the user. Simple operation, detailed instructions and recommendations on the Internet will allow everyone to deal with almost any printer model. But there are a few useful life hacks, the knowledge of which will help you avoid typical beginner mistakes:

- Calibrate and test the 3D printer before starting work.

- Be sure to use the correct file extension for quality printing.

- Do not remove the finished product from the printer immediately after it has been processed: this may damage the part and cause defects.

- If errors occur during the 3D printing process, try restarting the device - this usually helps.

- If restarting the printer still does not help, try changing the settings or re-entering the model. nine0010

- When assembling the 3D printing devices, follow the enclosed instructions carefully.

- Use only the correct materials for your 3D printer.

- Subscribe to useful 3D printing channels and articles.

Following the above tips will allow you to set up your 3D printer, get it ready for operation and, most importantly, print your first 3D products. Choose a model according to your budget and capabilities, and it will not be difficult to master the basics of 3D modeling and get the first details if you follow the instructions and recommendations. nine0003

- March 21, 2021

- 8835

Get expert advice

Learn how to get started with ceramic 3D printing・Cults

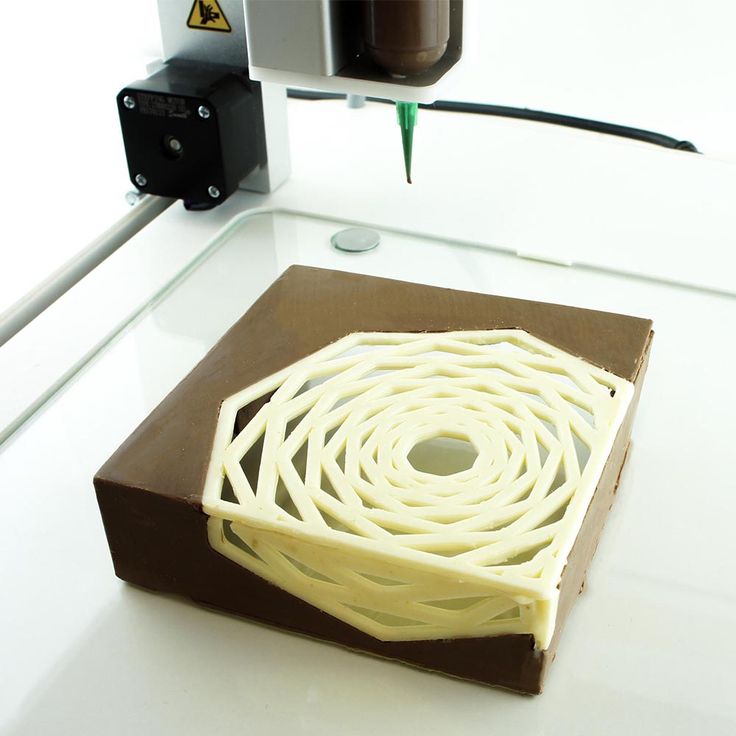

This is a guest blog post about ceramic 3D printing by Takeum Lee, a multidisciplinary artist. He is currently an Assistant Professor of Graphic Design at Appalachian State University in Boone, North Carolina. In his latest research, he is exploring non-traditional methods for creating 3D type. This includes working with materials and techniques unique to typography, such as ceramics and various analog and digital craft techniques. As part of his research, he built a 3D printer and developed his own paste extruder to produce complex 3D ceramic objects and types. nine0003

He is currently an Assistant Professor of Graphic Design at Appalachian State University in Boone, North Carolina. In his latest research, he is exploring non-traditional methods for creating 3D type. This includes working with materials and techniques unique to typography, such as ceramics and various analog and digital craft techniques. As part of his research, he built a 3D printer and developed his own paste extruder to produce complex 3D ceramic objects and types. nine0003

Since the summer of 2015, I have been interested in combining 3D printing and ceramics to create complex fonts and other objects. Desktop 3D printing is especially attractive because it requires much less space and equipment than a conventional clay studio. Using a delta printer and a custom screw extruder, I can print small to medium sized ceramic objects up to a width and height of 300mm.

My ceramic printer started out as a RepRap kit. RepRap, which stands for rapid replication, is one of the most popular open source 3D printing projects. It allows you to quickly and cheaply print many of the frame parts needed to make another 3D printer. It also allows you to customize the machine to suit your needs. Starting with the RepRap printer, I set it up to use ceramic as the material. nine0003

It allows you to quickly and cheaply print many of the frame parts needed to make another 3D printer. It also allows you to customize the machine to suit your needs. Starting with the RepRap printer, I set it up to use ceramic as the material. nine0003

At first I tried to make a clay extruder using glue dispensers, but they didn't work very well. I decided to make my own PVC pipe (Note: PVC pipes can be dangerous when working at high PSI. Other materials such as steel, copper or aluminum are recommended to avoid injury). An air compressor pushes the ceramic through the PVC pipe, where it is eventually forced out through a nozzle. It took several trials to find the optimum air pressure and slicing configuration for efficient printing. nine0003

After creating my first kit, I wanted to build my own printer specially optimized for printing large ceramic parts. On my first machine, I printed many of the components needed for a larger printer. There were many technical and mechanical issues, as Delta printers are particularly difficult to calibrate. After several months and 40 different firmwares tested, I was able to get my ceramic printer to work properly.

After several months and 40 different firmwares tested, I was able to get my ceramic printer to work properly.

Clay is a particularly tricky material to work with because you need to get the right viscosity for printing, making sure it's not too thin or too viscous. I started with low temperature white clay and printed various clay bodies. I added more water to soften it up a bit. The small models were relatively easy to print, but when printing larger and more complex layers, I had a problem with layers breaking. I started by using a heat gun to dry the layers faster and recently installed three 120mm fans to dry the piece. One of the benefits of working with clay is the ability to reuse material from discarded impressions. nine0003

Early versions of my extruder only worked by pneumatically forcing clay through PVC pipes, but I wanted to make a new version that would allow me to print more complex shapes. I have designed an extruder with a screw system to extrude the clay more precisely. I have tested over 60 different augers and 10 different housings. Using this custom extruder, I have developed several different Delta printers. One is the size of the trip, and I have participated in a workshop at universities such as Detroit College of Creative Studies, North Carolina State University in Raleigh, and San Diego State University. I will be bringing it to other workshops. nine0003

I have designed an extruder with a screw system to extrude the clay more precisely. I have tested over 60 different augers and 10 different housings. Using this custom extruder, I have developed several different Delta printers. One is the size of the trip, and I have participated in a workshop at universities such as Detroit College of Creative Studies, North Carolina State University in Raleigh, and San Diego State University. I will be bringing it to other workshops. nine0003

Most of my 3D models are designed in Rhinocerous 5, although for more organic shapes I use Sculptris. I also use Microsoft Kinect and the Skanect software when I want to get scans of human figures or objects. The gcode for the printer is created in a program that many of you may be familiar with, Repetier Host.

The general process for printing on clay is as follows.

- Create your design with your choice of CAD 9 tool0010

- Create an STL or OBJ file for your design

- Cut out the design and generate Gcode with Repetier Host.

Learn more