Lab 3d printer

Bambu Lab | Unleash Your Creativity with Bambu Lab 3D Printers

Bambu Lab Gallery

Share your prints on social media with #bambutiful or #bambuseful for a chance to be seen here.

Model created by @Toymakr3d

Printed by @BambuLab

70 hours

X1-Carbon

「Kaiju」

Model created by @Thing-O-Fun

Printed by @BambuLab

8.5 hours

X1-Carbon

「Ossum Rear Axle Mk III」

Model created by @Thing-O-Fun

Printed by @BambuLab

4.5 hours

X1-Carbon

「Differential Gear」

Model created by @Malolo

Printed by @BambuLab

5.5 hours

X1-Carbon

「Raspberry Pi 4 Case & Stands」

Model created by @Catiav5ftw

Printed by @BambuLab

36 hours

X1-Carbon

「Jet Engine」

Model created by @3Dsets

Printed by @BambuLab

19. 5 hours

X1-Carbon

「Jeep」

Model created by @Toymakr3d

Printed by @BambuLab

70 hours

X1-Carbon

「Kaiju」

Model created by @Thing-O-Fun

Printed by @BambuLab

8.5 hours

X1-Carbon

「Ossum Rear Axle Mk III」

Model created by @Thing-O-Fun

Printed by @BambuLab

4.5 hours

X1-Carbon

「Differential Gear」

Model created by @Malolo

Printed by @BambuLab

5.5 hours

X1-Carbon

「Raspberry Pi 4 Case & Stands」

Model created by @Catiav5ftw

Printed by @BambuLab

36 hours

X1-Carbon

「Jet Engine」

Model created by @3Dsets

Printed by @BambuLab

19.5 hours

X1-Carbon

「Jeep」

Model created by @Toymakr3d

Printed by @BambuLab

70 hours

X1-Carbon

「Kaiju」

Model created by @Thing-O-Fun

Printed by @BambuLab

8. 5 hours

5 hours

X1-Carbon

「Ossum Rear Axle Mk III」

Model created by @Thing-O-Fun

Printed by @BambuLab

4.5 hours

X1-Carbon

「Differential Gear」

Model created by @Malolo

Printed by @BambuLab

5.5 hours

X1-Carbon

「Raspberry Pi 4 Case & Stands」

Model created by @Catiav5ftw

Printed by @BambuLab

36 hours

X1-Carbon

「Jet Engine」

Model created by @3Dsets

Printed by @BambuLab

19.5 hours

X1-Carbon

「Jeep」

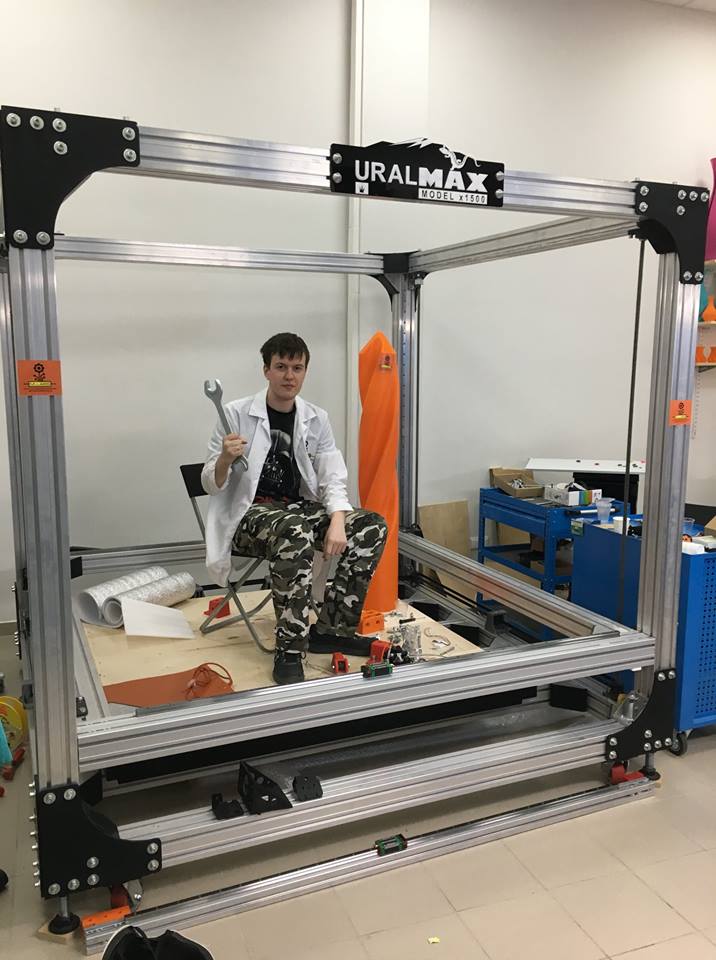

We hated 3D printing as much as we loved It.

We set 5 goals before we set off on this journey, and we are still far from our final destination. We made the first step, a very daring leap leading to a new era in 3D printing.

Bambu Lab P1P | Your one of a kind 3D printer

Bambu Lab P1P

• Preorder Delivery in Early January

• 2023 Early Bird Gifts ($60 Value)

with First Batch Purchase

“Almost every 3D printing maker started with a fantasy of printing amazing things. With the new Bambu Lab P1P, it has never been easier to 3D print your dream and customize your own 3D printer.”

With the new Bambu Lab P1P, it has never been easier to 3D print your dream and customize your own 3D printer.”

Current Time 0:00

Duration Time 0:00

Progress: NaN%

Made by Bambu Lab Created by You

Customize and 3D print the side panels of P1P with your magic touch. Select a Modplate template to print or design your one-of-a-kind side panels.

Pixel Modplate

Flowing Flame

Autumn Flowers

Pegboard

White

Black

Armor Modplate

Lake Blue

Meteorite Grey

Hot Rod Red

Earth Brown

Artistry Modplate

Bambu Lab Edition

Lily

Main Features

Designed for Efficiency

CoreXY up to 20000 mm/s² Acceleration

The Bambu Lab P1P inherits the proven kinematics and motion control system of the Bambu Lab Flagship printer. It prints with a top speed of 500 mm/s, the acceleration from zero to 500 mm/s takes just 0.025 seconds.

Vibration Compensation & Pressure Advance

The active vibration compensation (XY) algorithm and pressure advance guarantees extra smoothness and gets you good prints.

Direct-drive Extruder

With the design that the motor is directly connected to the extruder, P1P has better control on the extrusion and retraction of flexible filaments. Precise and consistent extrusion for smooth and no-blur prints.

Succeed with a Perfect First Layer

The automatic bed leveling(ABL) sensor calibrates and levels the bed properly, making you a perfect first layer for every 3D print.

Bambu Studio & Bambu Handy

Connect with Bambu slicing software and mobile app to control your printer and monitor the prints.

Advanced Technologies

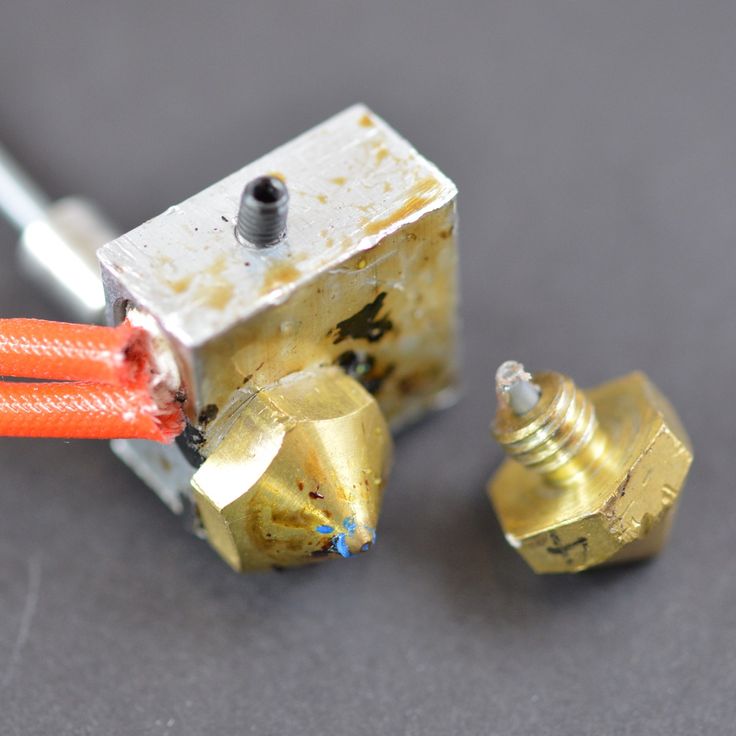

All-metal

Hotend

Durable material made to support long-time 3D printing filaments including ABS, carbon fiber at high temperatures. It provides accurate and smooth extrusion to achieve quality printing performance.

Filament Run-out

Sensor

Eliminate the problem of empty spools during printing. Change filament when empty and Resume.

Power Loss

Recovery

Worry-free from a power cut-off, you can resume the print from where it left off.

Semi-automatic

Belt Tensioning

The tension of the belt is essential for ensuring dimensional accuracy. Resonance frequency identification runs every time to help maintain the correct tension.

Fans with

Speed Feedback

The speed feedback sensor monitors the fan's speed ensuring that the fan is able to operate at its optimal speed at all times.

Time-lapse

Video

Upgrade P1P with a chamber camera to easily monitor and capture awesome prints.

Advanced Upgrades Available

Upgrade P1P with advanced parts to make it even better. Get essential electronic components from the official store and 3D print the other parts to assemble them yourself.

Tech Specs

| Item | Specification | |

| Printing Technology | Fused Deposition Modeling | |

| Body | Build Volume(W×D×H) | 256*256*256 mm³ |

| Chassis | Steel | |

| Shell | Printable | |

| Tool Head | Hot End | All-Metal |

| Extruder Gears | Steel | |

| Nozzle | Stainless Steel | |

| Max Hot End Temperature | 300 ℃ | |

| Nozzle Diameter (Included) | 0. 4 mm 4 mm | |

| Nozzle Diameter (Optional) | 0.2 mm, 0.6 mm, 0.8 mm | |

| Filament Cutter | Yes | |

| Filament Diameter | 1.75 mm | |

| Hot bed | Build Plate (Included) | Bambu Dual-Sided Textured PEI Plate |

| Build Plate (Optional) | Bambu Cool Plate Bambu Engineering Plate Bambu High Temperature Plate | |

| Max Build Plate Temperature | 100℃ | |

| Speed | Max Speed of Tool Head | 500 mm/s |

| Max Acceleration of Tool Head | 20 m/s² | |

| Max Hot End Flow | 32 mm³/s @ABS(Model: 150*150mm single wall; Material: Bambu ABS; Temperature: 280℃) | |

| Cooling | Part Cooling Fan | Closed Loop Control |

| Hot End Fan | Closed Loop Control | |

| Auxiliary Part Cooling Fan | Optional | |

| Supported Filament | PLA, PETG, TPU, ASA, PVA, PET | Ideal |

| PA, PC, ABS | Capable | |

| Carbon/Glass Fiber Reinforced Polymer | Not Recommended | |

| Sensors | Chamber Monitoring Camera | Low Rate Camera 1280 x 720 / 0. 5fps (Optional) 5fps (Optional)Timelapse Supported |

| Filament Run Out Sensor | Yes | |

| Filament Odometry | Optional with AMS | |

| Power Loss Recover | Yes | |

| Physical Dimensions | Dimensions(W×D×H) | 386*389*458 mm |

| Net Weight | 9.65kg | |

| Electrical Parameters | Input Voltage | 100-240 VAC, 50/60 Hz |

| Max Power | 1000W@220V, 350W@110V | |

| USB Output Power | 5V/1.5A | |

| Electronics | Display | 2.7-inch 192x64 Screen |

| Connectivity | Wi-Fi, Bluetooth, Bambu-Bus | |

| Storage | Micro SD Card | |

| Control Interface | Button, APP, PC Application | |

| Motion Controller | Dual-Core Cortex M4 | |

| Software | Slicer | Bambu Studio Support third party slicers which export standard G-code such as Superslicer, Prusaslicer and Cura, but certain advanced features may not be supported.  |

| Slicer Supported OS | MacOS, Windows | |

Ways to Get Started

Your one-of-a-kind 3D Printer

$699

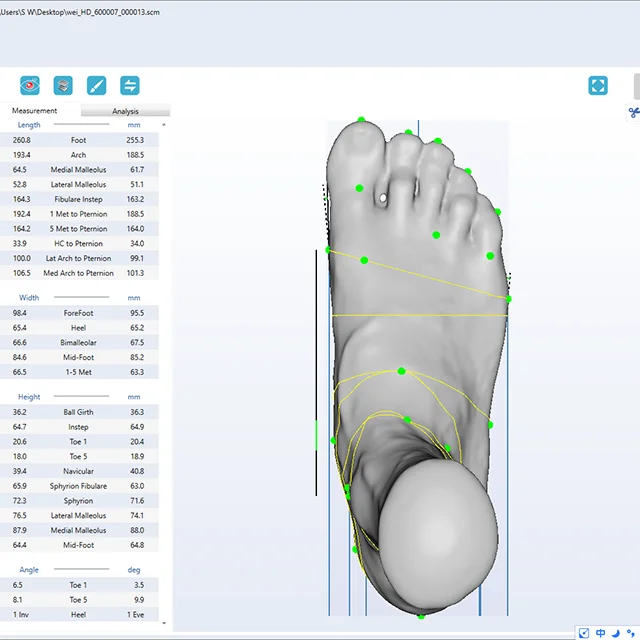

using 3D printing in dentistry to make dentures

Modern additive printing technologies allow the production of a wide variety of products for an incredible range of applications. Medicine, in particular the field of dentistry, has long been no exception and is using the achievements of technological progress for the benefit of its patients with might and main, becoming digital.

Benefits of using a 3D printer

Clinics everywhere are moving to intraoral scanning, abandoning analog, uncomfortable for the patient methods of impression making. Some are not limited to diagnostic manipulations at all, transferring the stages of modeling and manufacturing of single works under their own roof and partially refusing laboratory services. In this case, a 3D printer for dentistry is indispensable in the manufacture of orthodontic and temporary orthopedic structures. Mouth guards, night guards, surgical templates for operations and even the printing of dentures, whether they be single crowns, bridges or even removable basic dentures - all this is under the power of dental 3D printing. nine0003

Mouth guards, night guards, surgical templates for operations and even the printing of dentures, whether they be single crowns, bridges or even removable basic dentures - all this is under the power of dental 3D printing. nine0003

Comparison of the main 3D printing technologies used in dentistry

Laboratories are not left behind and are improving the manufacturing methods and range of dental products and services. The use of laboratory scanning eliminates the error that may occur during the manufacture of a plaster model. If desired, the model can be produced on a dental printer from a photopolymer, which is always less troublesome and faster. Gingival masks, individual trays, and any orthopedic constructions - the 3D printer opens up new horizons for dental laboratories. nine0003

If we talk about the main methods of manufacturing dental products on a 3D printer, these will be:

- SLA, or the so-called stereolithography, in which the laser beam polymerizes the material, quickly passing through each point of the object;

- DLP, or layer-by-layer illumination process, in which the projector illuminates the photopolymer layer by layer using ultraviolet radiation, transforming it into a future product.

Regardless of the printing method, the final properties of the work will depend on the material from which it is made, the very "resin". nine0003

Speaking of photopolymers, one cannot but mention NextDent. The company is a subsidiary of the Dutch manufacturer of plastics for prosthetics Vertex. NextDent pioneered the field of biocompatible 3D printing resins and was soon bought out by global additive technology giant 3D Systems.

With 30 unique NextDent photopolymers, the widest range of any dental material supplier. A range of aesthetically accurate colors enable dental labs and clinics to achieve a close match of finished products to the patient's teeth and gums. 3D printing materials from NextDent are biocompatible and certified in accordance with the requirements of the European Union, which makes them widely used. Photopolymers meet the requirements of the European Medical Device Directive (93/42/EEC), approved by the Food and Drug Administration (USA) and certified in many other countries.

With such a promising line of dental resins in its portfolio, 3D Systems, as the inventor of 3D printing and a recognized industry leader, could not do without using its own revolutionary technologies in a new field for itself. This is how the first 3D printer for dentists NextDent 5100 appeared, specially designed for the manufacture of products from biocompatible photopolymers. nine0003

Its hallmarks are speed and ease of use. Incredibly fast in the production of dental work of any complexity, the NextDent 5100 will allow you to print more than 70 temporary crowns in 25 minutes. Or to make a whole prosthesis in front of the patient in just an hour.

NextDent Denture 3D+, a class IIa biocompatible material, was created for the fabrication of removable denture bases. This material has significantly less shrinkage than the already used, standard PMMA materials. Shrinkage can be avoided using software, resulting in a perfectly suitable base for a removable denture. Excellent mechanical properties make it possible to surpass the quality of traditional methods of manufacturing removable dentures. Available in the following shades: dark pink, light pink, opaque, reddish pink and transparent pink. Biocompatible, non-cytotoxic, non-mutagenic, does not cause redness and swelling, does not have sensitizing properties, does not cause systemic toxicity. nine0003

Available in the following shades: dark pink, light pink, opaque, reddish pink and transparent pink. Biocompatible, non-cytotoxic, non-mutagenic, does not cause redness and swelling, does not have sensitizing properties, does not cause systemic toxicity. nine0003

NextDent C&B Micro Filled Hybrid is a class IIa biocompatible material designed for the production of single crowns and bridges. The balance between inorganic fillers and resin gives the material its high strength and wear resistance. This material is easy to polish and can be tinted with any composite paint. Due to the excellent balance between opacity and translucency, printed crowns blend perfectly with the patient's natural teeth. Available in the following shades: BL, N1, N1.5, N2, N2.5, N3 and T1. Biocompatible, non-cytotoxic, non-mutagenic, does not cause redness and swelling, does not have sensitizing properties, does not cause systemic toxicity. nine0003

The combination of these two materials allows you to quickly and accurately produce a base, crown, bridge and even a removable denture. Perfectly polished and individualized, absolutely not capable of causing rejection in the patient, do not contain methyl methacrylates.

Perfectly polished and individualized, absolutely not capable of causing rejection in the patient, do not contain methyl methacrylates.

The future has already arrived. Join the future and you! Let's change dentistry together!

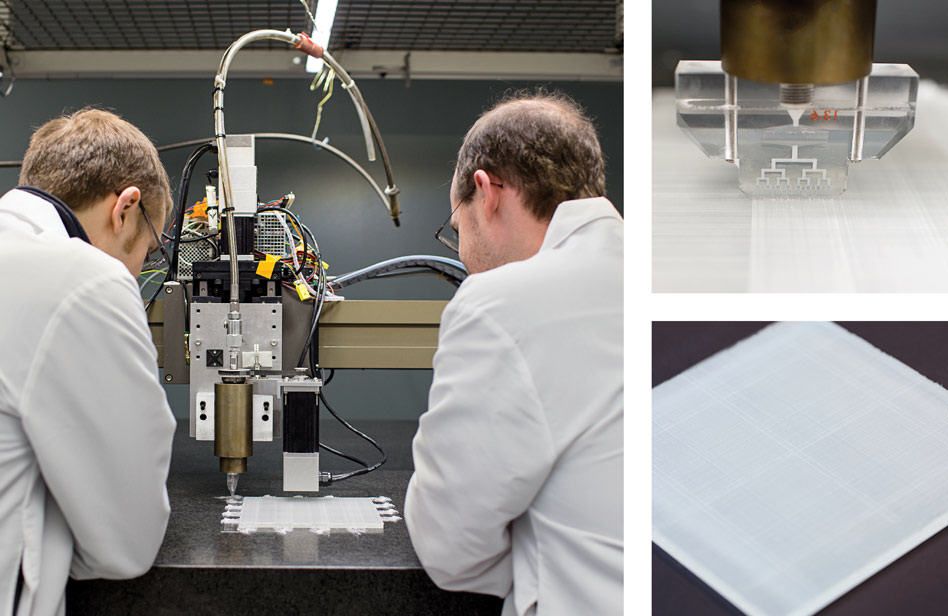

Lab 3D Ceramic Printer

News

Follow Author

Subscribe

Don't want

5

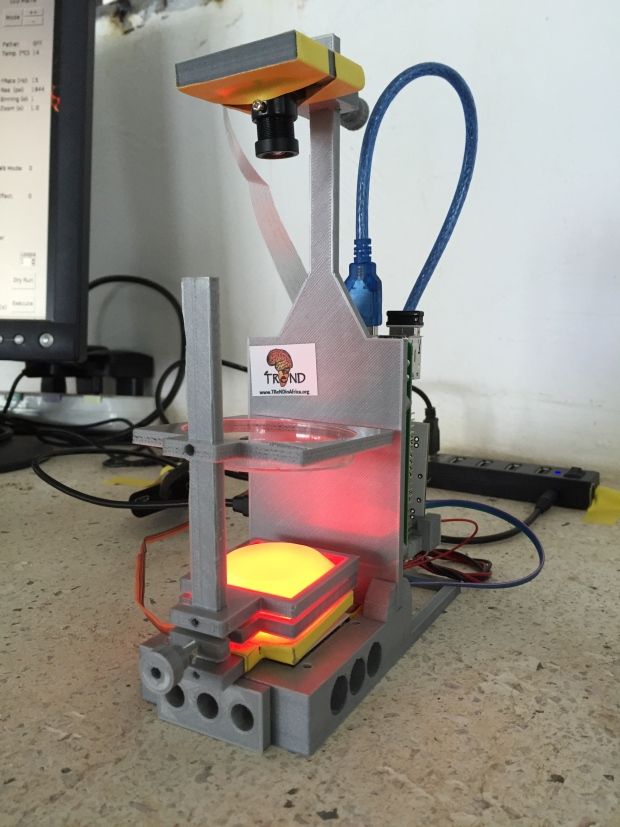

The Austrian company Lithoz offers the CeraFab Lab L30 3D printer for photopolymer 3D printing of ceramic blanks. The new "laboratory" additive system is aimed at increasing affordability for the benefit of consumables developers and research institutions that do not need more expensive industrial-grade 3D printers.

CeraFab designs stereolithographic 3D printers specifically for 3D printing with ceramic-filled photopolymers, with the expectation of subsequent debinding and sintering of workpieces into full-fledged ceramic products. This requires the use of highly viscous resins with a high filler content, which in turn necessitates tricks such as heating the consumable and occasional mixing. One of the most interesting systems in the Lithoz range is the CeraFab Multi 2M30 3D printer, which allows you to print with two materials at once. nine0003

One of the most interesting systems in the Lithoz range is the CeraFab Multi 2M30 3D printer, which allows you to print with two materials at once. nine0003

In addition to 3D printers, the company also offers specialized consumables, including:

- LithaLox HP 500 and LithaLox 350. High purity aluminum oxide materials (up to 99.99%) with high stiffness, corrosion and heat resistance;

- LithaCon 3Y 210. Zirconia ceramic with high mechanical properties and biocompatibility;

- LithaNit 770. Silicon nitride based ceramic with high strength, corrosion and thermal shock resistance; nine0018

- LithaBone TCP 300 and LithaBone HA 400. Materials based on beta-tricalcium phosphate and hydroxyapatite used in the manufacture of bone implants due to high biocompatibility and effective osseointegration.

- LithaCore 450. Silicon ceramic with alumina and zirconium for the production of foundry cores.

The problem is that not all potential customers require industrial grade 3D printers. In particular, this concerns developers of consumables, who usually work with small portions of photopolymers and composites, as well as researchers who are more interested in 3D printing of miniature products. For them, the new CeraFab Lab L30 system is designed - a relatively inexpensive 3D printer that takes full advantage of Lithoz's developments. nine0003

In particular, this concerns developers of consumables, who usually work with small portions of photopolymers and composites, as well as researchers who are more interested in 3D printing of miniature products. For them, the new CeraFab Lab L30 system is designed - a relatively inexpensive 3D printer that takes full advantage of Lithoz's developments. nine0003

The CeraFab Lab L30 uses a digital projector and a proprietary rotary mixing and leveling system for small amounts of consumables. The size of the construction area is 76x43x170 mm, and the minimum required volume of photopolymer is only 15 ml. For comparison, the industrial version of CeraFab S230 has a working volume of 192x120x320 mm. The layer thickness varies within 25-100 microns, the productivity is enough for curing up to one hundred layers per hour. nine0003

The 3D printing settings are open so that users can experiment with a variety of materials. At the same time, the system is distinguished by rather compact dimensions, which is important in cramped laboratory conditions.