Balco 3d printers

Matching PLA filament for the BALCO 3D printer

Sort byRelevanceBestsellersCustomer ReviewsPrice, Low to HighPrice, High to LowNew arrivalsHighest Discount

-

3DJAKE magicPLA Metallic Emerald 4 Model types- Shimmering colours

- ecoPLA base

- Made in EU

-

3DJAKE magicPLA Deep Space 4 Model types- Shimmering colours

- ecoPLA base

- Made in EU

-

3DJAKE ecoPLA - Black 10 Model types- Made in EU

- High quality

- Easy to print

-

Polymaker PolyTerra PLA Charcoal Black 2 Model types- More environmentally friendly

- Easy processing

- Good rigidity

-

3DJAKE ecoPLA White 10 Model types- Made in EU

- High quality

- Easy to print

-

3DJAKE ecoPLA - Glow in the Dark 6 Model types- Made in EU

- High-Quality

- Easy to Print

-

3DJAKE ecoPLA Matt Black 6 Model types- Made in EU

- High-quality

- Matt finish

-

3DJAKE ecoPLA White & Black Economy Set 2 diameters- 2x 1000g ecoPLA

- Made in the EU

- High-quality materials

-

3DJAKE ecoPLA - Light Grey 6 Model types- Made in EU

- High quality

- Easy to print

-

Polymaker PolyTerra PLA Cotton White 2 Model types- More environmentally friendly

- Easy processing

- Good rigidity

-

3DJAKE ecoPLA - Sky Blue 6 Model types- Made in EU

- High quality

- Easy to print

-

3DJAKE ecoPLA - Transparent 6 Model types- Made in EU

- High quality

- Easy to print

-

3DJAKE ecoPLA Red 6 Model types- Made in EU

- High quality

- Easy to print

-

Fillamentum PLA Extrafill Wizard's Voodoo 2 diameters- Variety of colours

- Easy to print

- High accuracy in production

-

3DJAKE ecoPLA - Dark Blue 6 Model types- Made in EU

- High quality

- Easy to print

-

3DJAKE ecoPLA - Yellow 6 Model types- Made in EU

- High quality

- Easy to print

-

3DJAKE magicPLA Sunset Sky 4 Model types- Shimmering colours

- ecoPLA base

- Made in EU

-

3DJAKE ecoPLA Glitter Blue 6 Model types- Made in EU

- High-quality

- Easy to print

-

3DJAKE ecoPLA - Orange 6 Model types- Made in EU

- High quality

- Easy to print

-

3DJAKE ecoPLA - Bronze 6 Model types- Made in EU

- High quality

- Easy to print

-

3DJAKE ecoPLA - Light Green 6 Model types- Made in EU

- High quality

- Easy to print

-

3DJAKE ecoPLA - Neon Green 6 Model types- Made in EU

- High quality

- Easy to print

-

3DJAKE ecoPLA Matt White 6 Model types- Made in EU

- High-quality

- Matt finish

-

3DJAKE ecoPLA - Neon Yellow 6 Model types- Made in EU

- High quality

- Easy to print

All prices incl. VAT.

balco 3d printer - Buy balco 3d printer with free shipping

balco 3d printer - Buy balco 3d printer with free shipping | Banggood ShoppingBrands

SEE MORE

RC Drone Spare Parts

Plug Type

Working Type

Printer Filament Material

Printing Size

3D Printer Function

Application

Bag Type

-

Home

- "" 543 Results

Price -

OK

Ship From

Filter for the right parts for your vehicle

Add vehicle

Total 10 pages

Go to Page

Go

Confirm your age

You must be at least 18 years of age to enter this section.

I AM UNDER 18 I AM OVER 18

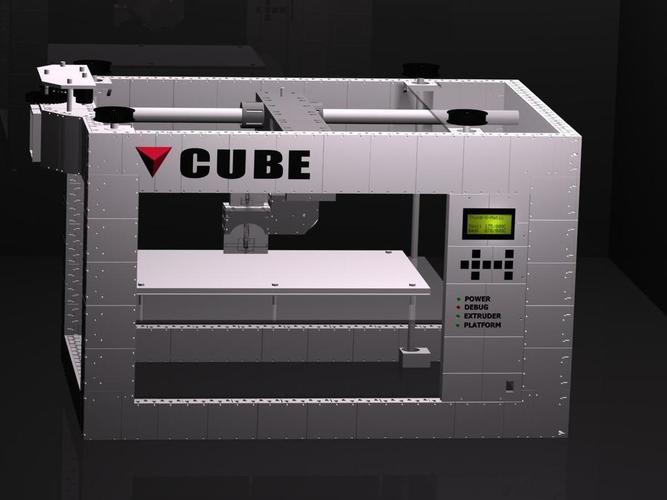

How to build a printer. Design and calculation of the X-axis beam for deflection.

Let's continue to trample on the feelings of believers in the perfect 3D printer.

The last publication received a lot of responses, albeit not always unambiguous - there were both “so, through the knee of a drunken octopus, across the bench and whipped”, and “well, you can’t be so disloyal”, and for the mentoring and guiding tone. All opinions are valid. I will only say that in a professional environment, in addition to the widely represented serpentarium and unhealthy competition, I usually welcome neutral relations with a direct indication of your mistakes or shortcomings, without equivocations, with the acceptance of criticism at your own discretion, and I am not used to crumbling in curtsy. However, I do not pretend to absolute knowledge, but I have some qualifications that allow me to draw some conclusions. nine0003

Well, let's go "disassemble" the neophyte's CREATION and promote the YouTuber further?

The general organization of CoreXY / H-Bot portal printers, as well as some Cartesian printers with a moving Z axis, requires the organization of an X axis beam.

Let's take the popular ZAV line as a basis. The pictures, albeit without permission, are taken from the manufacturer's website, to which I have absolutely nothing to do, and are presented for reference only as visual aids.

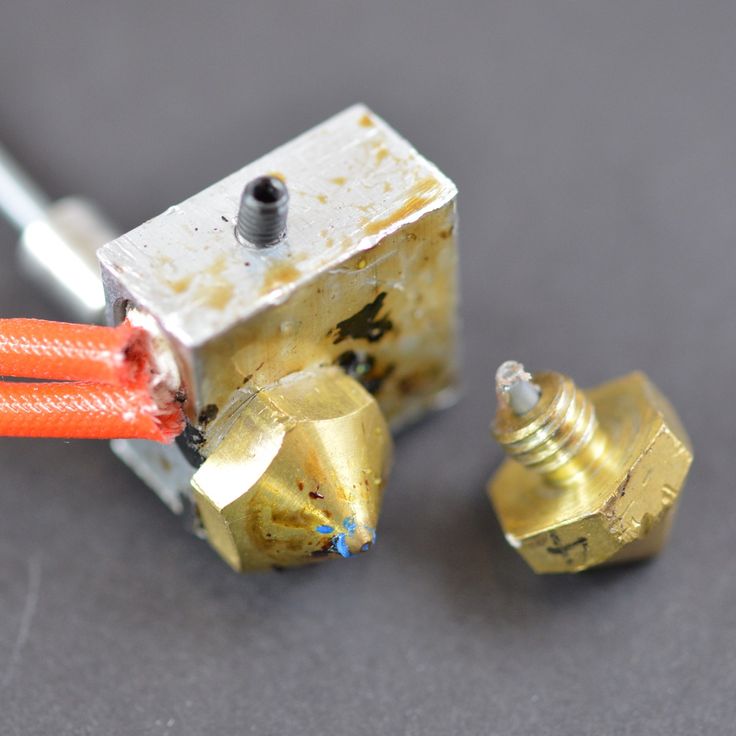

X-axis beam (hereinafter referred to as X-beam) on a medium-sized printer with a build volume of 200 mm along the X axis looks like this:

As you can see, the axis rail is rigidly fixed to the profile beam, which, in turn, is fixed to the Y-axis carriages. ZAV-mini models from THIS POST comrade. Dagov 'a:

. nine0003

Art. Chucha HERE more than once criticized my knowledge of mechanics (in terms of rigidity), but somehow got away from the proposed dispute in order to measure the amount of knowledge in this part :))), which is not surprising to expect from a person who measures the rigidity of a structure (hereinafter - I quote ):

The self-assembly frame is assembled very rigidly and it is not possible to deform it diagonally, I checked this, and after installing panels 1mm thick, even more so.And I’m a small person, but I press 110 kg on my chest without problems, so by the way. nine0029

The note of comrade. termosintez:

It is enough to pick up a micron indicator and the whole world will turn upside down before his eyes.The micron indicator is an engineer's horror.And organoleptic measurement methods should be left aside.

*

Let's continue - the X-beam at the "self-assembly" of the author looks like this:

X-beam - self-supporting.

*

The distance between the Y-axis carriages, judging by the dimensions of the frame, is 450 mm:

And the "rail" is located horizontally with a 12 mm wide plane.

In technical mechanics, the most such calculation scheme corresponds to a beam with a concentrated load and hinged fastening in extreme positions:

Moment of inertia relative to deflection for a 12[W] X 7.

5[H] rectangle is: 92 / 6 = 112.5 mm3

Beam length : l=450 mm

Two types of force act on the beam - the weight of the beam itself and the weight of the carriage with a hotend, additionally loaded with a flexible cable channel.

We neglect the absence of the beam body in the sections from its ends to the carriages (and the rigidity of 2 mm plates in this area is much less than the X-beam itself, but we conditionally assume that it is compensated by the part where the X-beam is screwed to these plates).

Beam weight, or distributed load is: 0.65 kg/m or 6.5 N/m according to Hiwin

X-axis bottom bracket and slider weight is: 352 g or 3.6 N mm, is 230 g/m of the channel itself. A little less than a meter is spent on such styling, for good measure, let's take the weight of 300 g and divide it in half, because. it is fixed at two points. Those. the carriage has an additional 150 g or 1.5 N.

In total, we have q=6.5 N/m distributed load and F=3.

6+1.5 = 5.1 N concentrated load on the middle of the beam to calculate the deflection. nine0003

Also, for simplification, we consider that drilled holes for fastenings weaken the rigidity of the structure with a coefficient k=0.8

The stiffness modulus of steel is taken I have a beam deflection of more than 200 microns, or 0.2 mm in the center. To check, you can use the ONLINE CALCULATOR

Which shows the total deflection under 0.25 mm.

What does this lead to? Curve X-beam portal over with a flat table will show a "virtual" deflection and the inability to print large parts without scanning the grid of the table surface.

That is why, in the design of the IDEX printer with an enlarged construction area, the load-bearing X-beam was located in the XY plane with a narrow 7.5 mm side with the rejection of the flexible cable channel, which showed a calculated deflection of about 80 µm. And this knot still causes some concerns for me and I am considering options for retrofitting the beam with a bent profile of an angular section.

nine0003

In my opinion, I have enough basic knowledge of strength of materials and tech-mech, which I have proven many times, and, in the spirit of bloodlust and my own causticity, I suggest comrade. Chucha to assign, in addition to the title "sofa practitioner", also "miracle engineer" .

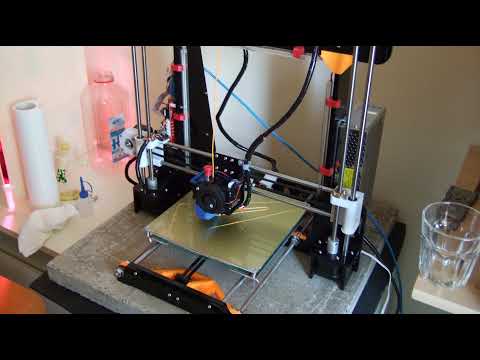

Will the 3D printer become my personal balcony factory? / Sudo Null IT News

Broke, for example, my cabinet handle. I search Google for a similar 3D model or even make my own design, go to the balcony, turn on my native 3D printer, and after a few hours I get a warm new part. Is this a myth or the near future? At least, scientists have already proposed a method for at least doubling the strength of 3D products. It is based on the study of the relationship between the temperature parameters of the printing process and the properties of the finished part. nine0003

The method proposed by NUST MISIS scientists and even published in the international scientific journal Rapid Prototyping Journal, in principle, opens up a real prospect of creating necessary household items at home, comparable in quality to factory ones.

The printing process is not even polymer - clayToday, additive manufacturing machines are dominated by relatively simple and inexpensive desktop format devices, usually classified as open source hardware and operating on the principle of distributing a thermoplastic polymer melt. nine0003

These are the very ubiquitous 3D printers that have become an integral part of the modern hackspace or the youth circle of technical creativity, settled in the garages and kitchens of enthusiastic makers. Despite its modest dimensions and low cost, the average desktop 3D printer has a very decent production potential. The annual productivity of the device exceeds 100 kg of polymer products. This is about 2 times more than the number of polymer products produced by factories per inhabitant of the planet annually. nine0003

And here - printing with plastic, that is "thermoplastic polymer melt distribution"

In other words, theoretically, a personal 3D printer can fully cover the needs of its owner in plastic products.

At the same time, there is no noticeable use of desktop 3D printers for the production of consumer products, and my neighbors on the balconies do not print stools.

One of the reasons for such an underestimation of the potential of this class of devices is the lack of confidence in them on the part of designers and engineers. There is a widespread (and, to be honest, not unreasonable) opinion that the strength of polymer products obtained by desktop 3D printing is incomparably small compared to the strength of similar objects produced traditionally in a factory. nine0003

NUST MISIS Fab Lab digital production lab residents believe that this is, to put it mildly, not a progressive point of view.

“It's all about attitude,” says Vladimir Kuznetsov, head of the NUST MISIS Fab Lab – If you stop treating a desktop device like a printer, that is, a device with which you can get a “printout” - a three-dimensional replica of a computer model and start treating it as a program-controlled and three-axis moving extruder, that is, a production machine, then the paradigm itself will change.nine0127 An ideal printer should have only one button = print, all the processes of turning a computer file into a "printout" are hidden from the user. The ideal production machine, on the other hand, should give the user full control over the technological parameters of the process.”

NUST MISIS Fab Lab team

Young engineers and scientists of the NUST MISIS Fab Lab adhere to a similar principle and are actively working on transforming an ordinary 3D printer into a real production tool. nine0003

“In a published work, we have shown that it is possible to significantly increase the strength characteristics of a polymer product by providing a sufficiently high temperature at the boundary between the layer of the part being formed and the layer that precedes it,” says one of the co-authors of the study, postgraduate student of the Department of Materials Science of Non-Ferrous Metals Azamat Tavitov , — V In turn, we can influence the temperature at the layer boundary by changing the nozzle temperature, printing speed, airflow intensity of the part, and even the number of simultaneously printed products.nine0002 Another key parameter that affects the adhesion strength between layers and, accordingly, the strength of the entire product is the extrusion efficiency. By optimizing these parameters, we will improve the adhesion between the layers of the part, that is, we can bring the strength at the interlayer boundary very close to the strength of the material itself. As the study on specific cases has shown, regardless of the geometry of the product or the method of loading, the optimization of the temperature parameters of the process gives noticeable results - the strength of parts compared to the reference printed according to default parameters increases up to two times. nine0003

Vladimir Kuznetsov and Azamat Tavitov

Twice is probably not enough to print not a handle, but, for example, a plastic window sash. However, there is a trend. Currently, the team continues to move towards distributed production and conducts experimental research on polymer printing, studying the relationship between the geometry of a computer model and the strength of the finished product.

Learn more