Exone 3d printer cost

Desktop Metal launches affordable new ExOne S-Max Flex 3D printer: technical specifications and pricing

0Shares

Industrial 3D printer manufacturer Desktop Metal (DM) has announced the launch of an accessible new binder jetting system.

Built using the combined technologies and expertise of Desktop Metal and its subsidiary ExOne, the S-Max Flex is specifically designed to provide foundries with a robust, low-cost means of creating sand tooling for metal casting applications.

As ExOne’s most affordable unit to-date, the Flex effectively makes S-Max technology available to a wider base, and in doing so, allows more users to rapidly cast complex metal parts for clients, including those operating in the aerospace, automotive and energy sectors, amongst others.

“We designed the all-new S-Max Flex from the ground up leveraging Single Pass Jetting (SPJ) technology with the idea of making premium sand 3D printing accessible to every foundry, so that more companies can take advantage of the benefits of AM 2. 0, such as distributed, local production, and remain competitive for the long-term,” said Ric Fulop, Co-Founder and CEO of Desktop Metal.

“To achieve our vision of Additive Manufacturing 2.0, we need to make production 3D printing practical in terms of speed, cost, and material availability for a broad range of applications.”

Desktop Metal’s expanding portfolio

Since it was founded in 2015, Desktop Metal has established itself as one of the leaders in the binder jet 3D printing space. One way the firm has managed to achieve this is via the sale of machines fitted with its Single Pass Jetting technology, a process which sees the steps behind binder jetting combined into the pass of a single, integrated carriage.

Desktop Metal’s current 3D printer portfolio includes the Shop System and Production System, and it continues to expand on their material compatibility as a means of growing its accessible markets. Just last year, the company became the first to qualify 4140 low-alloy steel for use with binder jetting, shortly after launching a sustainable wood 3D printing technology via its Forust subsidiary.

In the aftermath of Desktop Metal’s SPAC merger in late-2020, it has also sought to accelerate its growth trajectory via a string of acquisitions. This strategy has seen the firm buy recoater system developer Aerosint, acquire hydraulic power specialist Aidro, snap up EnvistionTEC (now ETEC) for $300 million, and most significantly purchase ExOne for $575 million, one of its key binder jetting rivals.

Having bought ExOne, Desktop Metal has now not only carried out some rebranding, adding the InnoventX, X25Pro and X160Pro to its ‘X-Series,’ but it has now poured the firms’ combined expertise into the design of a new low-cost digital casting solution.

Introducing the S-Max Flex

According to Desktop Metal, foundries are enjoying a period of strong demand for castings, but they’re struggling when it comes to finding labor. Citing data provided by the American Foundry Society, the firm says that 90% of surveyed foundries are therefore seeking to take advantage of this trend, by making capital investments over the next year.

This is where the S-Max Flex comes in, as by packing SPJ technology into a more affordable architecture, it’s designed to offer a new value proposition to foundries seeking to expand their capabilities. Through teaming an industrial robot with an all-new end effector, the system is able to selectively deposit binder into a 1900 x 1000 x 1000 mm telescoping build box, at a rate of up to 115 liters per hour.

As a result, just like the more premium S-Max and S-Max Pro models, the Flex offers users the opportunity to reliably churn out parts, while achieving a rapid return on investment. The build box itself is also available in larger volumes up to 4700 x 1000 x 1000 mm in size, in addition to taller 1000 x 2500 x 2400 mm variants, enabling foundries to adopt a machine that’s tailored to meet their specific needs.

The build box itself is also available in larger volumes up to 4700 x 1000 x 1000 mm in size, in addition to taller 1000 x 2500 x 2400 mm variants, enabling foundries to adopt a machine that’s tailored to meet their specific needs.

Application-wise, given the system’s large size and ability to jet a variety of powders into parts with a dimensional accuracy of +/- 0.5 mm, Desktop Metal says it could soon address “industries beyond metalcasting.” For now, early adopters of the Flex include Founders Service & Manufacturing Co. and HTCI Co, while Desktop Metal’s Forust brand is also set to use it to print large, cost-effective wooden parts.

A set of sample parts produced via the ExOne S-Max Flex 3D printer. Photo via Desktop Metal.Technical specifications and pricing

Below are the technical specifications for the ExOne S-Max Flex 3D printer. The system is set to debut at the CastExpo 2022 metal casting trade show from April 23-26 in Columbus, Ohio. In the meantime, those interested in acquiring the system can contact Desktop Metal for a quote.

In the meantime, those interested in acquiring the system can contact Desktop Metal for a quote.

| Binder System | Furan |

| Job Box | 1,900 x 1,000 x 1,000 mm |

| Build Volume | 1,900l |

| Build Rate | Up to 115 l/h |

| Layer Height | 0.28 to 0.5 mm |

| Dimensional Accuracy | +/- 0.5 mm |

| Exhaust Air | 26 m³/h |

| External Dimensions | 8.5 x 4.9 x 4.9 m |

| Weight | 5,900 kg |

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

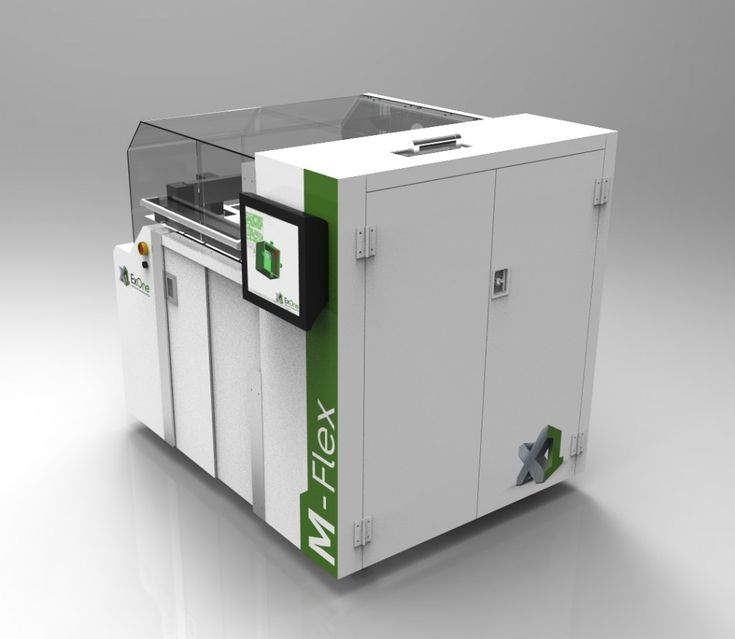

Featured image shows Desktop Metal’s new ExOne S-Max Flex 3D printer. Photo via Desktop Metal.

Tags aerosint Aidro American Foundry Society CastExpo 2022 Desktop Metal ETEC Exone Forust Founders Service & Manufacturing Co HTCI Co Ric Fulop S-Max Flex

Paul Hanaphy

Paul is a history and journalism graduate with a passion for finding the latest scoop in technology news.

X-Series | Desktop Metal

Team DM

Platforms

Metal and composites 3D printing 3D printing solutions for health care Industrial-grade polymer 3D printing™

Sand and tooling 3D printing solutions 3D printers for sheet metalMaterials

Breakthrough photopolymer development Advancing 3D printed upcycled woodApps & More

The hydraulic additive manufacturing experts Multi-material powder recoating technology Driving digital transformation in dentistryBinder jet 3D printing featuring patented Triple ACT for excellent surface quality and specialty materials, including both metals and ceramics.

Systems Overview

-

— 01

InnoventX

The most compact binder jet 3D printer for the production of metal, ceramic or composite parts.

Launched in 2018, this easy-to-use system features Triple ACT and a piezoelectric printhead. It’s suitable for education, research, prototyping, rapid product development, and short-run production of small components.

Launched in 2018, this easy-to-use system features Triple ACT and a piezoelectric printhead. It’s suitable for education, research, prototyping, rapid product development, and short-run production of small components. InnoventX

InnoventX

The most compact binder jet 3D printer for the production of metal, ceramic or composite parts. Launched in 2018, this easy-to-use system features Triple ACT and a piezoelectric printhead. It’s suitable for education, research, prototyping, rapid product development, and short-run production of small components.

[SPECS]

Download Spec SheetInnoventX

Print Technology

Triple Advanced Compaction Technology™

Print direction

Uni-directional

Build box size

160 x 65 x 65 mm (6.

3 x 2.5 x 2.5 in)

3 x 2.5 x 2.5 in)Max build rate (65μm layer thickness)

54 cc/hr

Binder Systems

AquaFuse™, CleanFuse™, FluidFuse™, PhenolFuse™

External dimensions

1203 x 1016 x 1434 mm (47.4 x 40.0 x 56.5 in)

-

— 02

X25Pro

This mid-volume advanced binder jet 3D print system is already being used globally for the production of metal, ceramic and composite parts.

Launched in 2020, this system features Triple ACT and a piezoelectric printhead. It’s suitable for research, prototyping, rapid product development, short-run production or continuous 24/7 production.

Launched in 2020, this system features Triple ACT and a piezoelectric printhead. It’s suitable for research, prototyping, rapid product development, short-run production or continuous 24/7 production.X25Pro

X25Pro

This mid-volume advanced binder jet 3D print system is already being used globally for the production of metal, ceramic and composite parts. Launched in 2020, this system features Triple ACT and a piezoelectric printhead. It’s suitable for research, prototyping, rapid product development, short-run production or continuous 24/7 production.

[SPECS]

Download Spec SheetX25Pro

Print Technology

Triple Advanced Compaction Technology™

Print direction

Uni-directional

Build box size

400 x 250 x 250 mm (15.

75 x 9.84 x 9.84 in)

75 x 9.84 x 9.84 in)Max build rate (65μm layer thickness)

1,200 cc/hr

Binder Systems

AquaFuse™, CleanFuse™, FluidFuse™, PhenolFuse™,

External dimensions

2300 x 1800 x 2300 mm (90.5 x 70.9 x 90.5 in)

-

— 03

X160Pro

The world’s largest binder jet 3D printer for the production of metal, ceramic or composite parts.

This system features Triple ACT and a piezoelectric printhead. It's designed for continuous 24/7 production, yet supports short-run production, rapid product development, and even research and prototyping

This system features Triple ACT and a piezoelectric printhead. It's designed for continuous 24/7 production, yet supports short-run production, rapid product development, and even research and prototypingX160Pro

X160Pro

The world’s largest binder jet 3D printer for the production of metal, ceramic or composite parts. This system features Triple ACT and a piezoelectric printhead. It's designed for continuous 24/7 production, yet supports short-run production, rapid product development, and even research and prototyping

[SPECS]

Download Spec SheetX160Pro

Print Technology

Triple Advanced Compaction Technology™

Print direction

Uni-directional

Build box size

800 x 500 x 400 mm (31.

5 x 19.7 x 15.8 in)

5 x 19.7 x 15.8 in)Max build rate (65μm layer thickness)

Up to 3,120 cc/hr

Binder Systems

AquaFuse™, CleanFuse™, FluidFuse™, PhenolFuse™,

External dimensions

3300 x 3300 x 2700 mm (130 x 130 x 107 in)

Applications by Industry

_Industries

Explore applications for 3D printing across a range of industries.

Keep Up with the Latest News

ExOne 3D printers. 3D printing with sand. Production of sand molds

When buying a 3D printer DISCOUNT on plastics and polymers up to 10%

There are 7 products

Sort:- Default

- Default

- Most popular

7 Prices: cheaper 9000 9000

Price on request

on order

Number

Number

In the favorites

Compare

Quick View

EXONE

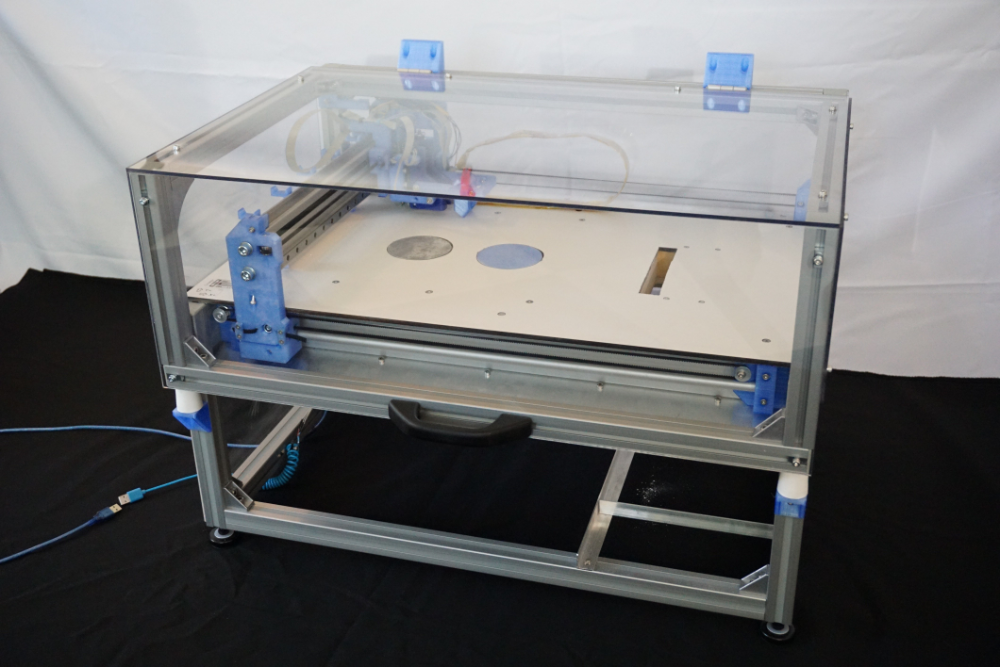

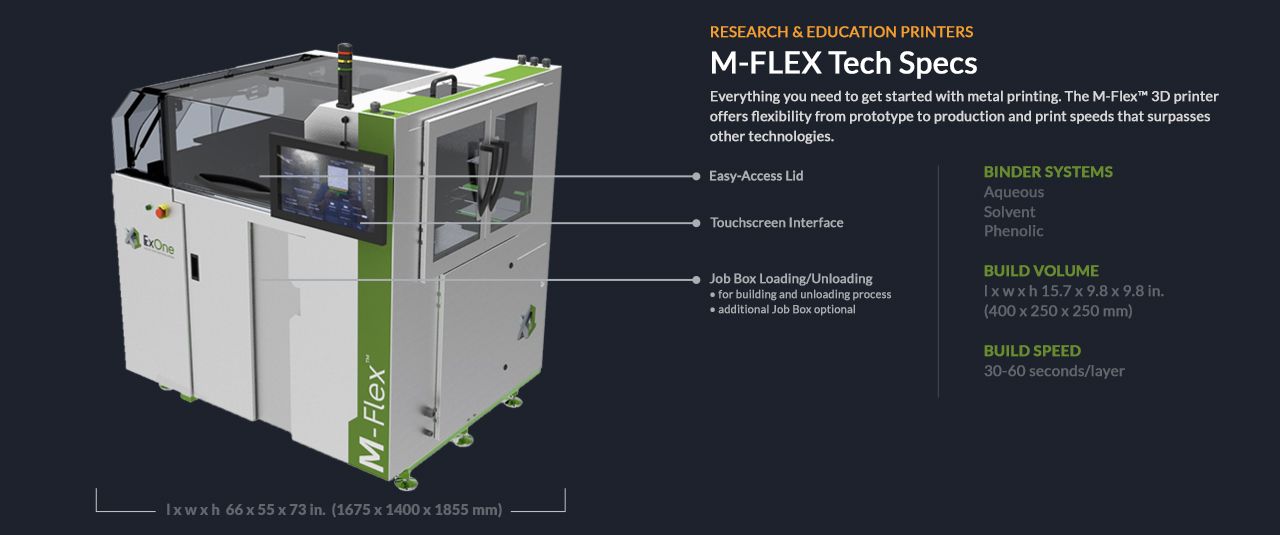

3D EXONE M-FLEX

price 0 out of 5

(0 reviews)

On order

- Print technology - SLM

- Print material - Metal

- Print field - 400x250x250 mm

Price on request

on order

Number

Number

In the favorites

Compare

Quick View

EXONE

3D EXONE X1 160PRO

2 out of 5

(0 reviews)

On order

- Print technology - MIM

- Print material - Metal

- Print field - 800x500x400 mm

Price on request

on order

Number

Number

In the favorites

Compare

Quick View

EXONE

3D EXONE X1 25PRO

9000 9 out of 5

(0 reviews)

On order

- Print technology - MIM

- Print material - Metal

- Print field - 400x250x250 mm

Price on request

on order

Number

Number

In the favorites

Compare

Quick View

EXONE 9000 0 out of 5

(0 reviews)

Custom order

- Print technology - SBJ

- Print material - Sand

- Print field - 1800x1000x700 mm

Price on request

on order

Number

Number

In favorites

Compare

Quick View

EXONE 9000 0 out of 5

(0 reviews)

On order

- Printing technology - SBJ

- Printing material - Sand

- Printing area - 1800x1000x700 mm; 400H (With box-in-box system)

Price on request

on order

Number

Number

In the favorites

Compare

Quick View

EXONE

3D EXONE S-PRINT

price 9000 9000 0 out of 5

(0 reviews)

Custom order

- Print technology - SBJ

- Print material - Sand

- Print field - 800x500x400 mm

Price on request

On order

Quantity

Quantity

ExOne's history dates back to 1995 when Extrude Hone ProMetal was founded to develop metal 3D printers.

In 1998, Extrude Hone released the world's first commercial inkjet metal 3D printing machine, developed at MIT, the ProMetal RTS-300. The system printed with a mixture of metal powder with a binder, which was subsequently melted in a high-temperature furnace and sintered the metal particles together. The first ProMetal RTS-300 system was installed at Motorola.

Read more…

In 2002, Extrude Hone launched a sand 3D printer for 3D printing molds for metal casting. This process is sometimes referred to as "indirect" 3D printing because the printed molds are used to create finished metal products by casting.

In 2013, the company was restructured and changed its name to ExOne Company, in addition, the firm completed a successful initial public offering on the Nasdaq in the same year.

By 2019, ExOne has launched more than 12 models of industrial 3D printers for printing with metals, sand, ceramics and composite materials. About half of the ExOne machines installed worldwide are used for 3D printing of molds for metal casting, the other half are used for direct 3D printing with metal, ceramics and composite materials.

Today ExOne is the undisputed world leader in the production and supply of additive systems using binder jetting inkjet technology. Hundreds of ExOne pieces of equipment have been installed in industrial plants, research centers, medical educational institutions for the production and development of finished products and test prototypes.

One of the main advantages of 3D printing on ExOne equipment is the ability to combine several metal parts into a single product, which is manufactured in one production cycle, previously, when manufacturing a similar product using traditional methods, it was necessary to produce several parts, which were then assembled into a single assembly by fastening, welding and other types of connection.

3D Printers ExOne Company, LLC

Purpose

Purpose

Professional

Industrial

Personal

Commercial

3D printer type

3D printer type

Tabletop

Food

Professional

For home

Chocolate

Jewelry

Russian

Reprap

Dental

Full color

Industrial

Not expensive

Medical

For training

Material type

Material type

Plastic

606

Metal

50

Photopolymer

245

Other

144

Manufacturer

Manufacturer

3D Systems

84

PICASO 3D

8

Stratasys Ltd

38

Leapfrog BV

6

EnvisionTEC

51

Myriwell

4

3D-Experts

3

PrintBox3D

4

FELIXrobotics

11

Solidoodle

8

WANHAO

32

ROKIT

5

SeeMeCNC

4

mUVe 3D LLC

1

RepRapPro

5

Formlabs

9

Afinia

1

Airwolf 3D

6

Type A Machines

2

iRapid

1

RoBo 3D Printer

3

Mixshop Inc

4

IonCoreLtd

1

Old World Laboratories

1

XYZprinting

13

Panowin Technologies Co. , Ltd.

, Ltd.

2

MiiCraft

7

Portabee 3D Printer

2

Zeepro

1

Pirate 3D

1

Qualup SAS

2

BEETHEFIRST

3

Heacent

2

Robot Factory

2

Kuhling&Kuhling

1

3Dfactories

3

Tangible Engineering USA Corporation

1

DWS Lab

1

Sedgwick

2

3DJoy

4

Futura Elettronica

1

Makible Ltd

2

ALT Design

1

Active 3D

2

Trinitylabs

1

Sumpod Ltd.

4

Brahma3

1

Hyrel 3D

5

Omni3D

4

BCN3D Technologies

7

Boots Industries

2

ORD Solutions

2

Ironvault

1

2PrintBeta

3

Unique Design

3

Hot Proceed

1

3DD Plas

2

York3dPrinters

1

Code-P

4

Deezmaker

3

Ruian Maitian Network Technology Co

2

CB-Printer

1

Print Technologies Pty Ltd.

5

MaukCC

1

Choc Edge Ltd

2

Shenzhen WeisTek Co.,Ltd

5

Delta Tower

2

Tegelbeckers Ltd

1

Deltaprinter

1

MindKits

1

Robot Co, Ltd

1

Romscraj

2

Fabmaker

1

Peerbhai Robotic

1

Sintermask GmbH

1

KL Services Group Inc

1

Fochif Mechatronics Technology Co. , Ltd

, Ltd

4

Teil3

1

Maker's Tool Works, LLC.

2

Gaminu

1

re:3D

1

inDimension3

4

Acuity Design

1

Essential Dynamics

1

Isis3D

1

Velleman

1

Kentstrapper

4

Blue Eagle Labs

1

Gubbels Engineering

2

Zortrax

8

3dBotic

1

MakerGear, LLC

1

Jelwek

1

it is 3D

2

Cablysa Systems, S. L.

L.

3

Ac123Dc

1

E3D Online

1

Hydraraptor

1

MakerBot Industries, LLC

8

Delta Micro Factory Corporation

3

Ultimaker B.V.

11

Solidscape Inc.

8

MBot3D

4

B9Creations

4

Jinhua Flashforge Technology Co., Ltd

26

Tinkerine Studio Ltd

3

Aleph Objects Inc.

4

DeltaMaker

1

Reprap Austria

3

IC3D LLC.

1

Ultibots, LLC.

2

Intelligent Machine Inc.

1

Metamaquina

1

Shenzhen Mootooh Engineering Co., Ltd.

1

Multitec GmbH

3

German RepRap GmbH

3

Sharebot

17

Nova 3D

1

QU-BD Inc.

4

RDMCU

1

Full Spectrum Laser LLC

1

PieceMaker Technologies

1

Printbot, Inc.

7

Terawatt Industries

1

botObjects

1

Lunavast

2

MakerFarm

3

NWRepRap

1

eMotion Tech

1

Printed Worlds

1

Reprapsource

1

Twelvepro Co

1

Replicator Warehouse

1

Stellamove Inc.

1

Make Mendel

6

Rapide 3D

2

Makealo

1

Crew Ltd.

1

Open cube

1

3D Kits

1

Coombes Solutions Ltd.

1

SHARK Limited Partnership

1

Smartfriendz

1

3D Monster

1

Kikai Labs

2

THY3D

1

Tantillus

1

RepRap Diffusion

1

QSQM International Co.

1

Tumaker

1

Makism 3D Corp.

3

3dBotZ

1

ZMorph 3d

1

Eckertech Inc.

1

Imec Proto

6

miniFactory Oy Ltd

1

printMATE 3D

1

CMET Inc.

5

Arcam AB

6

3Geometry Manufacturing Systems Pvt Ltd

8

Electro Optical Systems

15

Trump Precision Machinery Co. , Ltd

, Ltd

4

Wuhan Binhu Mechanical & Electrical Co., Ltd.

11

Optomec Inc.

1

Shaanxi Hengtong Intelligent Machine Co., Ltd.

9

Matsuura Machinery Corporation

1

ExOne Company, LLC

6

Concept Laser GmbH

9

Instrument Tech Co, Ltd

7

UnionTech

8

Renishaw plc

2

D-MEC Ltd.

3

Realizer GmbH

5

SLM Solutions GmbH

5

Fabriconic LLC

3

Mark Forged

8

Keyence Corporation

2

SYS + ENG

1

Lithoz GmbH

1

DWS s.r.l.

12

Beijing TierTime Technology Co. Ltd

17

Carima

3

Mcor Technologies Ltd.

3

Asiga

11

Rapid Shape GmbH

14

solido ltd.

1

Blueprinter ApS

1

Kevvox Pte Ltd.

2

JER Education Technology Co., Ltd

1

Azuma Engineering Machinery Inc.

2

Space Monkey

1

Trimaker

1

Most Fun

1

Iniciativas 3D

1

IdeaLab 3d

1

MendBot Labs

Bonsai Lab

2

MakerDreams

1

i3Dbot Co.:quality(80)/images.vogel.de/vogelonline/bdb/649100/649117/original.jpg) , Ltd

, Ltd

2

Natural Machines

1

Cyrus3D

ITALYmaker

Something3D

Cagelli Distribution

E Crew Vis

BigRep GmbH

2

Voxeljet Technology GmbH

5

Sciaky Inc.

Mankati

4

F&B rapid production

3

3DQuality

17

Workshop Churyumov

2

Unimix

2

Center for Additive Technologies

3

ENNOVA

1

Exclusive Solutions

2

Magnum

5

SHEKLA

1

D-Force

3

BigRep

4

Roland

1

ABC 3D

2

MAKEX

1

3D Master Kit

7

Shining 3D

25

3NOVATICA

3

AVS Robotics

1

IMPRINTA

11

Createbot

5

AIO Robotics

1

RK-3D

1

SPETSAVIA

3

3DiY

14

Wonwall

1

Apium Additive Technologies

3

3DSUN

1

Cheap3D

1

3rd

1

EGL3D

1

Creality 3D

42

UNIMATECH

2

VolgoBot

3

ZVER 3D

3

Zenith

2

MicroFactory

1

Hewlett Packard

2

Shenzhen Anet Technology Co Ltd

15

MASS PORTAL SIA

11

Cyberon

2

PHOTOCENTRIC

2

TotalZ

11

3dcon

2

Raise3D

6

OOO RUSSIAN ENGINEER

1

Vortex-3D

5

Flying bear

11

Print3D

5

ROBOINO

1

SoloPrint

1

Fun Distribution

1

Alekmaker

2

Cronos

2

TEVO 3D

9

3D printers from China

2

ZAV 3D printer

4

Epo3d

1

FLSUN 3D

3

WINBO

19

PROTOTYPE

1

UNIZ TECHNOLOGY

2

W2P Engineering GmbH

4

MAESTRO

1

Pi 3D printer

1

Shenzhen Tronxy Technology Co

23

Kelandi

1

Geeetech

21

3DCeram

2

Omaker

1

Builder 3D Printers

6

Creatable Labs

1

ROBOZE

3

Desktop Metal

1

Sintratec

2

CreatBot

10

ANYCUBIC

29

3dlaboratorio

2

OOO SPC "Lasers and Equipment"

2

Prusa Research

6

Prismlab

3

ivilol

2

Geralkom-3D

7

EqMex

1

Tsar3D

2

Zhuhai CTC Electronic Co. , Ltd

, Ltd

3

Shenzhen Aurora Technology Co., Ltd

6

Monoprice

1

Shenzhen Salon Technologies Co., Ltd.

1

Shenzhen Sundystar Technology Co., Ltd

2

Shenzhen Easythreed Technology Co., Ltd

1

WOW Innovation Technology Co., Ltd.

2

Jinhua Xingzhe 3D Technology Co., Ltd

1

Shenzhen Zhongxin Microscience Software Co., Ltd.

1

Shenzhen Yaying Trading Co. , Ltd

, Ltd

5

Z Bolt Co.

2

Anisoprint

1

Shanghai 3D ARTEL Science and Technology Co.

3

FABERANT 3D printers

1

Self-assembly 3D printers

4

Z Rapid Tech

21

Zonestar

13

3DGence

3

BLB Industries

1

Hard Light

1

Stereotech

2

TPM3D

7

Artillery

4

Phrozen Tech Co.