3D printing podcast

Digital Manufacturing From Design to Print on Apple Podcasts

28 episodes

The 3D printing industry has gone through a lot of major innovations since the first WTFFF episode was recorded, more than six years ago. When one of the 3D industry leaders, HP, asked hosts, Tom Hazzard and Tracy Hazzard to take a new look at where the 3D print industry is today, they jumped at the chance to get an inside tour into global trends, education, creativity, and design, and an opportunity to cover all aspects of the HP Create Ecosystem from design to print, including 3D design, XR visualization and digital manufacturing. Meet some of the most brilliant, amazing people who are passionate about 3D design and improving the creative workflow for themselves and for their customers. Whether you’ve used HP 3D printers before or not, there is something in this series for everyone. Join the conversation and send in your questions and comments! We’re talking ingenuity, innovation, and creation – the whole process!

In collaboration with HP, Tom and Tracy Hazzard have put together this 25-episode special series that invites you to explore the 3D Design and Create Ecosystem. The series will feature interviews of people who have been working in 3D Creative Workflow behind the scenes with HP 3D Print and Z By HP or some of its partner companies, as well as some updates on older WTFFF?! episodes that have topics and guests that are still very relevant today. In the spirit of change, Tom and Tracy also take the podcast to a whole new level by doing video for the first time. Make sure to watch and subscribe!

Your Podcast hosts, Tracy Hazzard and Tom Hazzard, co-founders of Hazz Design Consulting have collectively designed and developed 250+ products generating almost $1 Billion in revenue for their retail clients. Their flagship 3D Print Twist Tie Design won Outstanding Work from the China World 3D Printing Tech Alliance. They hold over 37 utility and design patents with an unprecedented 86% commercialization rate – double the USPTO-reported national average. Their entrepreneurial experiences are taught in a Harvard Business Review course in 26 universities around the world. The 3D Printing Podcast WTFFF?! ranked #1 on iTunes and Stitcher. They originally began the WTFFF?! 3D Printing Podcast to help scale the steep learning curve, advocate for more 3D design and product focus, and to help people figure out their what.

The 3D Printing Podcast WTFFF?! ranked #1 on iTunes and Stitcher. They originally began the WTFFF?! 3D Printing Podcast to help scale the steep learning curve, advocate for more 3D design and product focus, and to help people figure out their what.

With almost 600 episodes, the WTFFF?! 3D Print Podcast and its website 3D Start Point has loads of tools, tips, tactics, resources, and insightful interviews to choose. After you listen to this Special Series Sponsored by HP 3D Print and Z by HP, work your way backwards through the three Archive Volumes also available here on your favorite podcast player.

Tracy and Tom have been featured in the Harvard Business Review, Forbes, Wired, Fortune Small Business, and CNN Money, Tracy penned a weekly featured Inc. column on innovation for 4 years. They are graduates of Rhode Island School of Design with degrees in Industrial Design and Textile Design respectively. Tracy has worked directly for design-leading companies like Milliken and Herman Miller. Tom built and managed design teams for three ready-to-assemble furniture companies. They have worked as ghost designers behind both secret and well-known brands such as Martha Stewart Living, X-Rocker, Bayside Furnishings, Herman Miller, Steelcase, and Better Homes & Gardens. Their best-selling product – a mesh office chair has been in Costco for over 8 years straight.

Tom built and managed design teams for three ready-to-assemble furniture companies. They have worked as ghost designers behind both secret and well-known brands such as Martha Stewart Living, X-Rocker, Bayside Furnishings, Herman Miller, Steelcase, and Better Homes & Gardens. Their best-selling product – a mesh office chair has been in Costco for over 8 years straight.

Tune in to discover what exciting changes are taking place in the 3D printing industry. The WTFFF?! Special Series features reviews, guest contributors, expert viewpoints, and useful tips and tools to help you realize your opportunity as this disruptive technology changes the future. Take a deep dive into 3D printing and the whole 3D creative workflow with us here on the WTFFF?! Special Series sponsored by HP 3D Print and Z by HP with Tom and Tracy Hazzard!

The 3D printing industry has gone through a lot of major innovations since the first WTFFF episode was recorded, more than six years ago. When one of the 3D industry leaders, HP, asked hosts, Tom Hazzard and Tracy Hazzard to take a new look at where the 3D print industry is today, they jumped at the chance to get an inside tour into global trends, education, creativity, and design, and an opportunity to cover all aspects of the HP Create Ecosystem from design to print, including 3D design, XR visualization and digital manufacturing. Meet some of the most brilliant, amazing people who are passionate about 3D design and improving the creative workflow for themselves and for their customers. Whether you’ve used HP 3D printers before or not, there is something in this series for everyone. Join the conversation and send in your questions and comments! We’re talking ingenuity, innovation, and creation – the whole process!

When one of the 3D industry leaders, HP, asked hosts, Tom Hazzard and Tracy Hazzard to take a new look at where the 3D print industry is today, they jumped at the chance to get an inside tour into global trends, education, creativity, and design, and an opportunity to cover all aspects of the HP Create Ecosystem from design to print, including 3D design, XR visualization and digital manufacturing. Meet some of the most brilliant, amazing people who are passionate about 3D design and improving the creative workflow for themselves and for their customers. Whether you’ve used HP 3D printers before or not, there is something in this series for everyone. Join the conversation and send in your questions and comments! We’re talking ingenuity, innovation, and creation – the whole process!

In collaboration with HP, Tom and Tracy Hazzard have put together this 25-episode special series that invites you to explore the 3D Design and Create Ecosystem. The series will feature interviews of people who have been working in 3D Creative Workflow behind the scenes with HP 3D Print and Z By HP or some of its partner companies, as well as some updates on older WTFFF?! episodes that have topics and guests that are still very relevant today. In the spirit of change, Tom and Tracy also take the podcast to a whole new level by doing video for the first time. Make sure to watch and subscribe!

In the spirit of change, Tom and Tracy also take the podcast to a whole new level by doing video for the first time. Make sure to watch and subscribe!

Your Podcast hosts, Tracy Hazzard and Tom Hazzard, co-founders of Hazz Design Consulting have collectively designed and developed 250+ products generating almost $1 Billion in revenue for their retail clients. Their flagship 3D Print Twist Tie Design won Outstanding Work from the China World 3D Printing Tech Alliance. They hold over 37 utility and design patents with an unprecedented 86% commercialization rate – double the USPTO-reported national average. Their entrepreneurial experiences are taught in a Harvard Business Review course in 26 universities around the world. The 3D Printing Podcast WTFFF?! ranked #1 on iTunes and Stitcher. They originally began the WTFFF?! 3D Printing Podcast to help scale the steep learning curve, advocate for more 3D design and product focus, and to help people figure out their what.

With almost 600 episodes, the WTFFF?! 3D Print Podcast and its website 3D Start Point has loads of tools, tips, tactics, resources, and insightful interviews to choose. After you listen to this Special Series Sponsored by HP 3D Print and Z by HP, work your way backwards through the three Archive Volumes also available here on your favorite podcast player.

After you listen to this Special Series Sponsored by HP 3D Print and Z by HP, work your way backwards through the three Archive Volumes also available here on your favorite podcast player.

Tracy and Tom have been featured in the Harvard Business Review, Forbes, Wired, Fortune Small Business, and CNN Money, Tracy penned a weekly featured Inc. column on innovation for 4 years. They are graduates of Rhode Island School of Design with degrees in Industrial Design and Textile Design respectively. Tracy has worked directly for design-leading companies like Milliken and Herman Miller. Tom built and managed design teams for three ready-to-assemble furniture companies. They have worked as ghost designers behind both secret and well-known brands such as Martha Stewart Living, X-Rocker, Bayside Furnishings, Herman Miller, Steelcase, and Better Homes & Gardens. Their best-selling product – a mesh office chair has been in Costco for over 8 years straight.

Tune in to discover what exciting changes are taking place in the 3D printing industry. The WTFFF?! Special Series features reviews, guest contributors, expert viewpoints, and useful tips and tools to help you realize your opportunity as this disruptive technology changes the future. Take a deep dive into 3D printing and the whole 3D creative workflow with us here on the WTFFF?! Special Series sponsored by HP 3D Print and Z by HP with Tom and Tracy Hazzard!

The WTFFF?! Special Series features reviews, guest contributors, expert viewpoints, and useful tips and tools to help you realize your opportunity as this disruptive technology changes the future. Take a deep dive into 3D printing and the whole 3D creative workflow with us here on the WTFFF?! Special Series sponsored by HP 3D Print and Z by HP with Tom and Tracy Hazzard!

-

Jeffrey McGrew On Adapting 3D Print Furniture Techniques To Today's Demands

Jeffrey McGrew On Adapting 3D Print Furniture Techniques To Today's Demands

3D print furniture is perhaps the best solution to get beds, chairs, tables, and more in the easiest and fastest way possible. This also allows homeowners to help reduce waste and build sustainable properties. Jeffrey McGrew takes this process to another level by achieving more personalized outputs and making customers more involved with their creation.

Joining Tom Hazzard and Tracy Hazzard, he shares the different 3D printing methods they are using at Model-No. to produce custom-made but still ergonomic furniture. He talks about the advantages of focusing more on quality over mere quantity, as well as maximizing the limits of wood integration and subtractive fabrication.

Joining Tom Hazzard and Tracy Hazzard, he shares the different 3D printing methods they are using at Model-No. to produce custom-made but still ergonomic furniture. He talks about the advantages of focusing more on quality over mere quantity, as well as maximizing the limits of wood integration and subtractive fabrication.Love the show? Subscribe, rate, review, and share!

Here’s How »

Join the WTFFF?! 3D Printing movement today:

3DStartpoint.com3D Startpoint Facebook3D Startpoint LinkedInHazz Design Twitter3D Startpoint YouTube -

Finally An Easy Toy 3D Printer And Ecosystem Anyone Can Use With Ben Baltes of Toybox

Finally An Easy Toy 3D Printer And Ecosystem Anyone Can Use With Ben Baltes of Toybox

Imagine having the freedom to create and being able to make your own toys at home with the push of a button.

Toybox lets you do just that! Redefining the 3D printing experience, Toybox enables the average consumer to 3D print without any prior knowledge. On today’s podcast, Tom Hazzard and Tracy Hazzard bring on Ben Baltes, the Cofounder and CEO at Toybox. Recently, Ben and his company has been featured live on CNN, Yahoo Finance, ABC News, and on the front page of the Wall Street Journal. Today, he shares how the idea of Toybox was conceived and the path they took to get Toybox to the marketplace.

Toybox lets you do just that! Redefining the 3D printing experience, Toybox enables the average consumer to 3D print without any prior knowledge. On today’s podcast, Tom Hazzard and Tracy Hazzard bring on Ben Baltes, the Cofounder and CEO at Toybox. Recently, Ben and his company has been featured live on CNN, Yahoo Finance, ABC News, and on the front page of the Wall Street Journal. Today, he shares how the idea of Toybox was conceived and the path they took to get Toybox to the marketplace. -

Virtual 3D Print Education That Inspires Girls of All Ages with Mary Hadley, CEO of Makergirl

Virtual 3D Print Education That Inspires Girls of All Ages with Mary Hadley, CEO of Makergirl

The times are changing, and the 3D print industry is no longer just for men. Women, too, are great assets and bring different perspectives and ideas to the table.

Continuing with advocating for the growth of women in the industry, Tom Hazzard and Tracy Hazzard start them young by inviting Mary Hadley, the CEO of MakerGirl, to talk about virtual 3D print education that inspires girls of all ages. Mary shares with us the MakerGirl workshop and how they are conducting it virtually amidst this pandemic. What is more, Tracy also invites her eleven-year-old daughter, Lannea, to share her experience taking the virtual MakerGirl workshop.

Continuing with advocating for the growth of women in the industry, Tom Hazzard and Tracy Hazzard start them young by inviting Mary Hadley, the CEO of MakerGirl, to talk about virtual 3D print education that inspires girls of all ages. Mary shares with us the MakerGirl workshop and how they are conducting it virtually amidst this pandemic. What is more, Tracy also invites her eleven-year-old daughter, Lannea, to share her experience taking the virtual MakerGirl workshop.More About HP:

Capture and Create with Z by HP, Inspiring you for your next creative breakthrough with the Z portfolio designed and built to improve the way you create. Discover the latest Z Book to help you with your latest creative project.

Experience your design with HP Multi Jet Fusion technology and solutions reinvent design and manufacturing, unlocking the full potential of 3D printing and bringing down the barriers of 3D printing adoption across industries through materials innovation. For more details about Multi Jet Fusion technology click here.

-

Speeding the Innovation Cycle with Rapid Prototyping That Incorporates Real World Feedback with Jasmine Burton of Wish for WASH

Speeding the Innovation Cycle with Rapid Prototyping That Incorporates Real World Feedback with Jasmine Burton of Wish for WASH

By spreading and advocating for 3D print education, we reach out to future designers who can create great 3D print products and help change the world through them. Today’s guest is creating social progress in the world through her product design and social mission. Tom Hazzard and Tracy Hazzard sit down with Jasmine Burton, a social inclusion and design specialist and the founder of Wish for WASH, a social impact organization that saves lives by bringing innovation to sanitation. Jasmine’s story is a great example of the way the product development 3D design process works, which began with education that transformed into prototyping and 3D manufacturing, and then to getting it out there in a more buyable business way to create a positive global social impact.

She takes us into that amazing journey and imparts great insights on being in the social impact design space, highlighting the importance of incorporating real-world feedback throughout the process of innovating. There is more to innovating social inclusion than expected. It takes being humbled by the different realities that people face to find solutions to create positive change. Dive into this inspiring conversation to find the many opportunities there are to utilize rapid prototyping with real world feedback to create products with meaningful impact.

She takes us into that amazing journey and imparts great insights on being in the social impact design space, highlighting the importance of incorporating real-world feedback throughout the process of innovating. There is more to innovating social inclusion than expected. It takes being humbled by the different realities that people face to find solutions to create positive change. Dive into this inspiring conversation to find the many opportunities there are to utilize rapid prototyping with real world feedback to create products with meaningful impact.More About HP:

Capture and Create with Z by HP, Inspiring you for your next creative breakthrough with the Z portfolio designed and built to improve the way you create. Discover the latest Z Book to help you with your latest creative project.

Experience your design with HP Multi Jet Fusion technology and solutions reinvent design and manufacturing, unlocking the full potential of 3D printing and bringing down the barriers of 3D printing adoption across industries through materials innovation.

For more details about Multi Jet Fusion technology click here.

For more details about Multi Jet Fusion technology click here. -

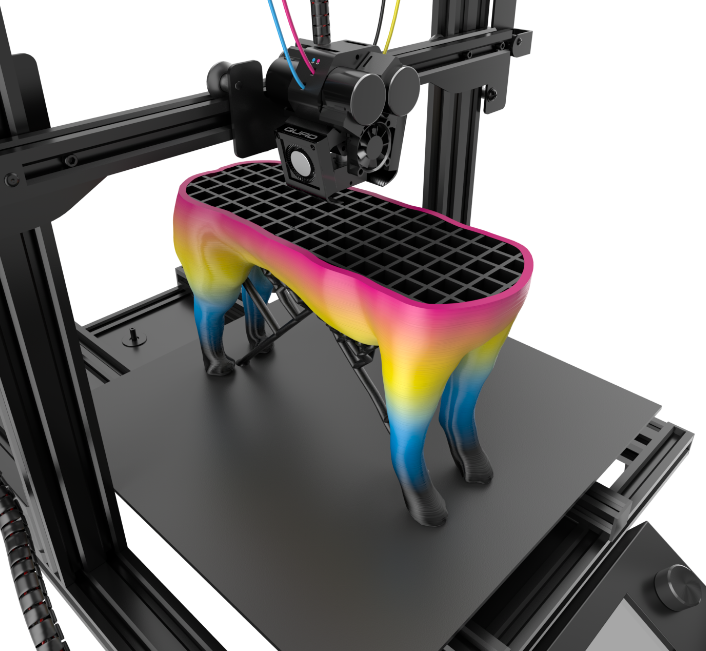

Complexities of Design for Full Color 3D Printing

Complexities of Design for Full Color 3D Printing

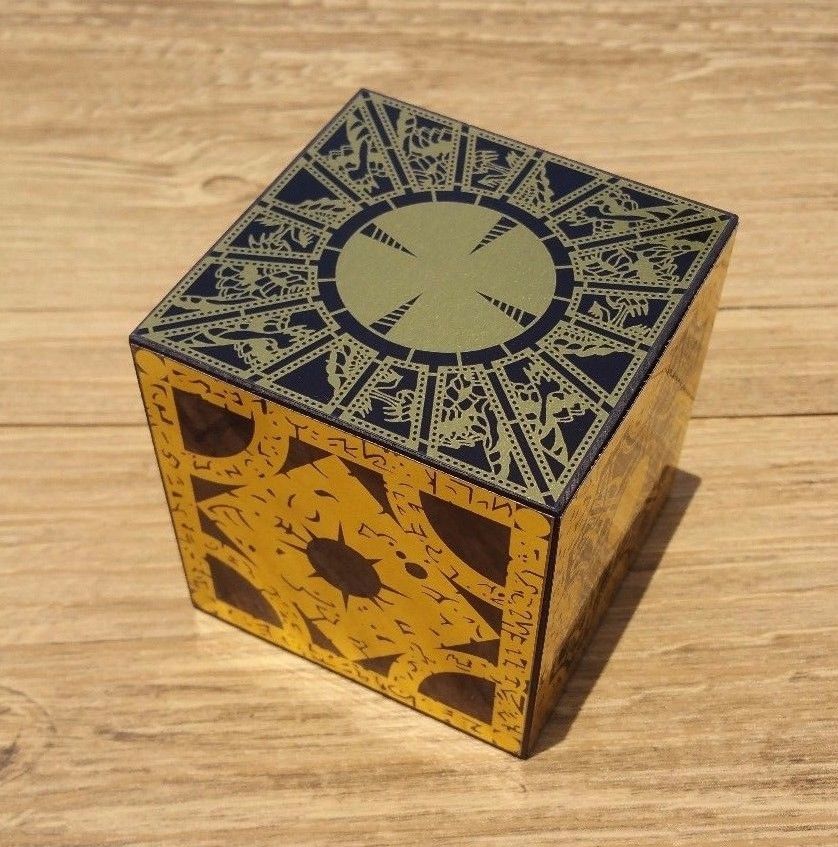

When designing a 3D print product, color tends to be the last thing many designers think about, mainly because 3D printers have not been color friendly, up until now. With the many complexities to full color 3D printing, it helps to reframe and start thinking about it as part of the initial design process rather than an afterthought—most especially because color application opens up the design possibilities. Tom Hazzard and Tracy Hazzard talk about planning, designing, and technically specifying for full color 3D printing. The HP Jet Fusion Full Color 3D Printer is a real game-changer in the hands of a creative designer ready to explore the world of 3D in color.

More About HP:

Capture and Create with Z by HP, Inspiring you for your next creative breakthrough with the Z portfolio designed and built to improve the way you create. Discover the latest Z Book to help you with your latest creative project.

Experience your design with HP Multi Jet Fusion technology and solutions reinvent design and manufacturing, unlocking the full potential of 3D printing and bringing down the barriers of 3D printing adoption across industries through materials innovation. For more details about Multi Jet Fusion technology click here.

-

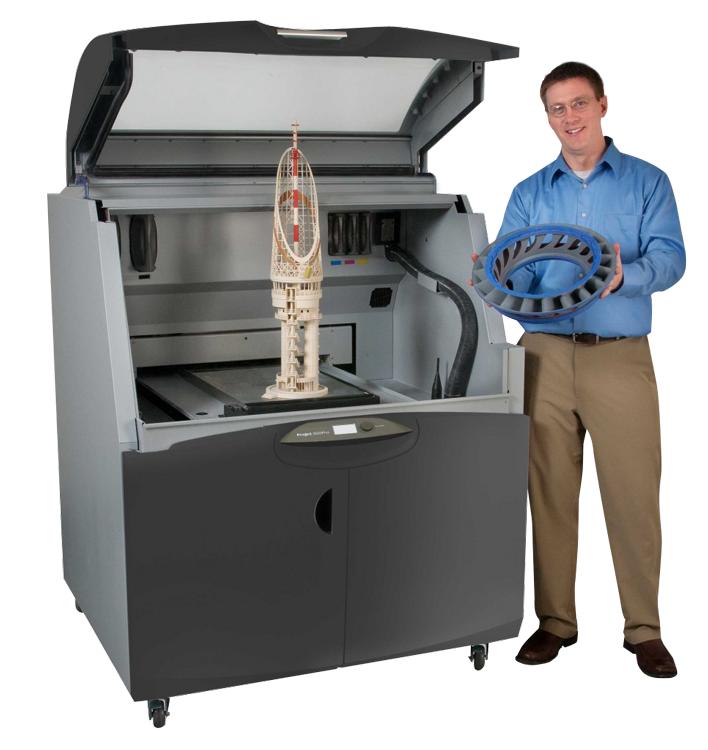

3D Manufacturing Cost: Investing in Opportunities Gained Versus Being Disrupted – Updated 2020

3D Manufacturing Cost: Investing in Opportunities Gained Versus Being Disrupted – Updated 2020

The greatest opportunities tend to come with a cost, and in moments of great disruption, you can either invest in them or let the times steer you away from the opportunities to be gained.

Tom Hazzard and Tracy Hazzard took that massive leap of faith with 3D printing. Now, they are reaping the rewards of that crucial decision. In this episode, they talk about 3D manufacturing costs, going through their own genesis story where they saw how not buying a 3D printer would cost them a great opportunity. They go into how bringing 3D manufacturing in your facility changes your production and design processes, helping you work efficiently on your business. Being in the 3D print industry where everything shifts by the minute, thinking about how you can be disruptive instead of being disrupted has become even more crucial. Listen in on this short yet important episode for more insights.

Tom Hazzard and Tracy Hazzard took that massive leap of faith with 3D printing. Now, they are reaping the rewards of that crucial decision. In this episode, they talk about 3D manufacturing costs, going through their own genesis story where they saw how not buying a 3D printer would cost them a great opportunity. They go into how bringing 3D manufacturing in your facility changes your production and design processes, helping you work efficiently on your business. Being in the 3D print industry where everything shifts by the minute, thinking about how you can be disruptive instead of being disrupted has become even more crucial. Listen in on this short yet important episode for more insights.More About HP:

Capture and Create with Z by HP, Inspiring you for your next creative breakthrough with the Z portfolio designed and built to improve the way you create. Discover the latest Z Book to help you with your latest creative project.

Experience your design with HP Multi Jet Fusion technology and solutions reinvent design and manufacturing, unlocking the full potential of 3D printing and bringing down the barriers of 3D printing adoption across industries through materials innovation.

For more details about Multi Jet Fusion technology click here.

For more details about Multi Jet Fusion technology click here.

Customer Reviews

31 Ratings

Great Podcast - Where did you go?

One year later since your last upload and I’m here wondering when you all are coming back! Let us know :)

CES report

Loved it. Also agree about pushing printers to their limits. Many times I’ve thought, “It can’t do this, and then I think, let’s try it.” And, to my surprise, it can, with maybe a little cleanup. Keep up the great casts!

Do your research...

Some of the episodes are semi-informative but there’s a lot of rants that go on forever.

There’s a whole episode centered around literally one comment that the guy took offense to about some mic holder that he designed. I also just listened to a few of the 3D printed weapons episodes and it was all just subjective opinionated speculative garbage. Ammo is unregulated in the majority of states. Bullets that can expand are not “nefarious” they are actually employed in self defense to prevent over penetration. A lot of people reload ammunition because it’s cheaper and you can control the process directly. Just because you’re uneducated on these aspects doesn’t make them pointless. A quick google search can go a long way...

Top Podcasts In News

3D Printing Today on Apple Podcasts

400 episodes

Dr, Andy Cohen, with 28 years in the high tech industry, and Master Craftsman Whitney Potter both use 3D Printing, 3D capture and 3D Design professionally. These guys dig through all the hype to reveal the real value in what is happening today in the exciting world of 3D Printing. They discuss topics such as how to tune, upgrade and maintain your desktop factory, capturing physical objects into virtual 3D space, how to develop your own designs for 3D Printing, developing businesses related to 3D Printing and all the latest innovations. Each episode includes current events, 3-5 technically focused segments, and a "Thing of the week". The show also includes guest segments from luminaries and specialists including Emmett Lalish, Brook Drumm and lots of others across this incredible new Profession... ? Industry... ? Hobby... ?

They discuss topics such as how to tune, upgrade and maintain your desktop factory, capturing physical objects into virtual 3D space, how to develop your own designs for 3D Printing, developing businesses related to 3D Printing and all the latest innovations. Each episode includes current events, 3-5 technically focused segments, and a "Thing of the week". The show also includes guest segments from luminaries and specialists including Emmett Lalish, Brook Drumm and lots of others across this incredible new Profession... ? Industry... ? Hobby... ?

-

3D Printing Today #460

3D Printing Today #460

News:

Good news from SSYS

https://3dprint.com/295746/3d-printing-financials-stratasys-delivers-highest-q3-revenue-in-7-years-adjusts-outlook/

Segments:

Looking Back 8 Years, Formlabs Serial Names, Tenlog Pricing

Thing of the Week:

Splaty Outlet Cover Plate

https://www. thingiverse.com/thing:5586448

thingiverse.com/thing:5586448

threedprintingtoday.libsyn.com or

Search for 3D Printing Today wherever you get your podcasts -

3D Printing Today #459

3D Printing Today #459

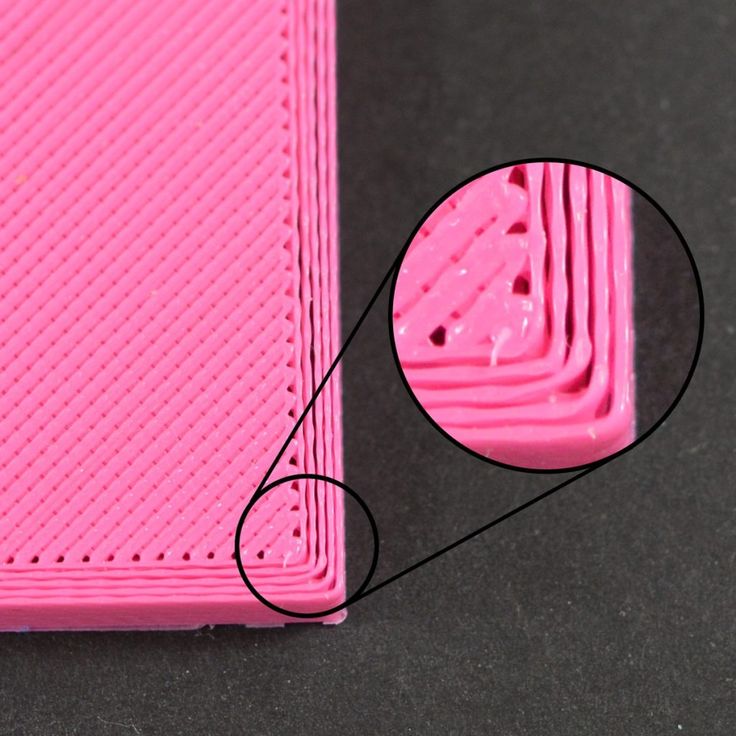

Printing to tolerance, Printing Formlabs Clear Resin, Start and end gcode changes

-

3D Printing Today #458

3D Printing Today #458

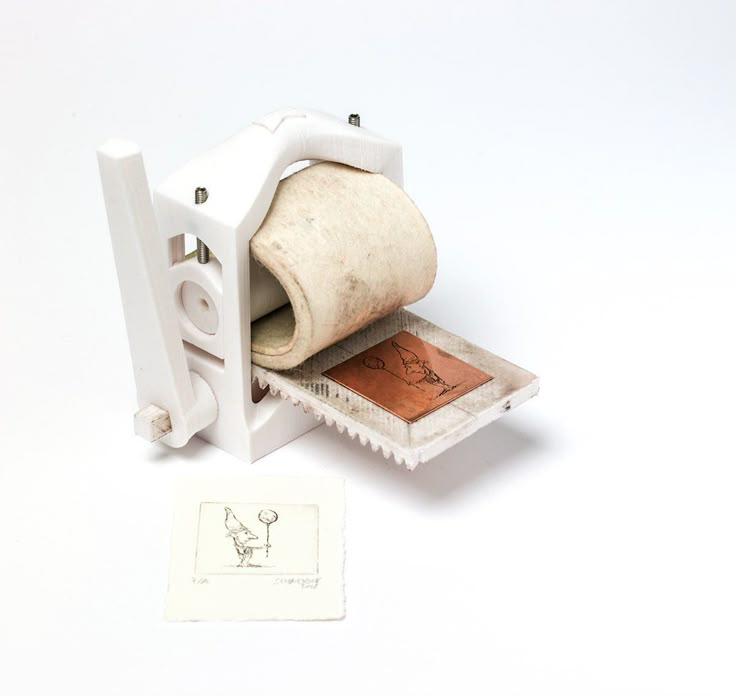

Formlabs Form3+ Prints Legos, 3D Coat Pain, Plastic Repellent Paint, Object orientation in SLA

-

3D Printing Today #457

3D Printing Today #457

Installing nozzles, SLA hollow or not hollow, Formlabs Support Rafts

-

3D Printing Today #456

3D Printing Today #456

Disposing of old printers, Flat on the SLA Build plate, Formlabs Curing

-

3D Printing Today #455

3D Printing Today #455

PrusaSlicer and the Toolchanger , Changing Resins on the Formlabs Form3+, Updating the Toolchanger Firmware

Customer Reviews

172 Ratings

Masterclass in 3D printing

SHOWS ARE TOO SHORT.

MAKE THEM LONGER. I love listening to this podcast. It is unfortunate is only once a week. The selection of topics, the unbiased discussion and breath of knowledge is unparalleled. I learned so much from listening to it. They have a unique and very didactic way to narrate the intricacies of this art.

Like a time machine

I was interested in 3D printing years ago, when the first “consumer” grade printers came on the market. But they were out of my budget, and seemed to come with more problems than I had time to solve. So I let it go for most of a decade, and now I’m back. This show is great — not only for getting me up to speed with the current state of things, but also filling me in on what I’ve missed and how we got to where we are today.

It’s also more than a hobby, as 3D printing and scanning are playing an increasing role in my profession. I’ll need to master this field to remain competitive, regardless of whether my business buys actual hardware or sends it out.

There is so much good information in this show, and it’s interesting! Thank you.

So much great information!

These guys have so much great info to share and I love that they do it without a bunch of advertising. An excellent podcast as long as they stay away from the political stuff 😜

Top Podcasts In Technology

You Might Also Like

Free 3D file PARANORMAL PODCAST・3D printer design for download・Cults

flora nurse

free

Best 3D Printer Files in the Miscellaneous Category

Pencil holder

2,50 €

Deactivated

Mercedes W211 Clip Footwell Net

Free

Magnetic Stirrer + Stir Bar

Free

Russian "normal" tank car 1:87 (H0)

Free

Sphere in 3 parts - kawai tsugite

Free

Mask

Free

halloween cards holder

Free

Bestsellers in Miscellaneous category

ItsLitho "Pure" personalized lithophane Christmas ball

1,90 €

4th planet Fighting pre-Olympic god

12 €

CHRISTMAS TREE v2

1,50 €

Giarados - articulated sea serpent

1,50 €

Mickey Christmas night light Litophane

3,50 €

flexible volute

2 €

Gnome Yes (No support)

€2. -twenty% 1.99 €  49

49

Christmas park

4.64 €

Wolf - Flexi Articulated Animal (printed in place, without supports)

2 €

Articulated Raykuaza Flexible Dragon Pokémon

1 €

Gengar - pokemon with flexible articulation (seal in place, without supports)

2 €

ItsLitho "Creamy" Lithophane Personalized Christmas Ball

€1.90

Polestar 2 cup holder

5.84 €

Adderini - 3D printed repeating slingbow / crossbow pistol

12.50 €

MMPR Dragon Dagger

4,80 €

Chainsaw Man - Denji

€18. -fifty% 9.13 €  25

25

Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people, so it is very easy to support us in maintaining activities and creating future developments of . Here are 4 solutions available to everyone:

-

AD: Disable the AdBlock banner blocker and click on our banner ads.

-

AFFILIATION: Shop online with our affiliate links here Amazon.

-

DONATIONS: If you want, you can donate via PayPal here.

-

* INVITE FRIENDS: * Invite your friends, discover the platform and great 3D files shared by the community!

Build a house and transplant a heart: what 3D printers are capable of ?

Your browser does not support audio player .

Listen to us on any convenient platform: Apple Podcasts, CastBox, Yandex Music, Google Podcasts, Spotify and VK Podcasts. And also follow us on Telegram and Instagram "What has changed?" - there we share interesting materials on the topic.

Guests of the issue:

Sergei Nefedov, technical director and founder of Arfin. Sergey explained how 3D printers print entire houses and why such construction has not yet taken root in Russia.

Alexander Kornveits, Founder and CEO of Tsvetnoy Mir. Alexander told how modern medicine uses 3D printing and when it will be possible to transplant printed organs.

Host of a podcast - artificial intelligence from the future, especially for RBC Trends.

Conversation timeline

1:34 — How 3D printing works

6:58 — Is it possible to print an organ: bioprinting

8:14 — Why don't we print clothes?

17:30 — How and from what do they print at home?

21:54 — Should the state regulate 3D printing technologies

25:27 — The future of additive technologies

How 3D printers work

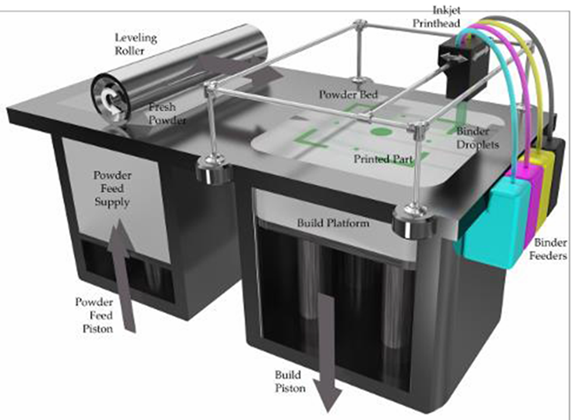

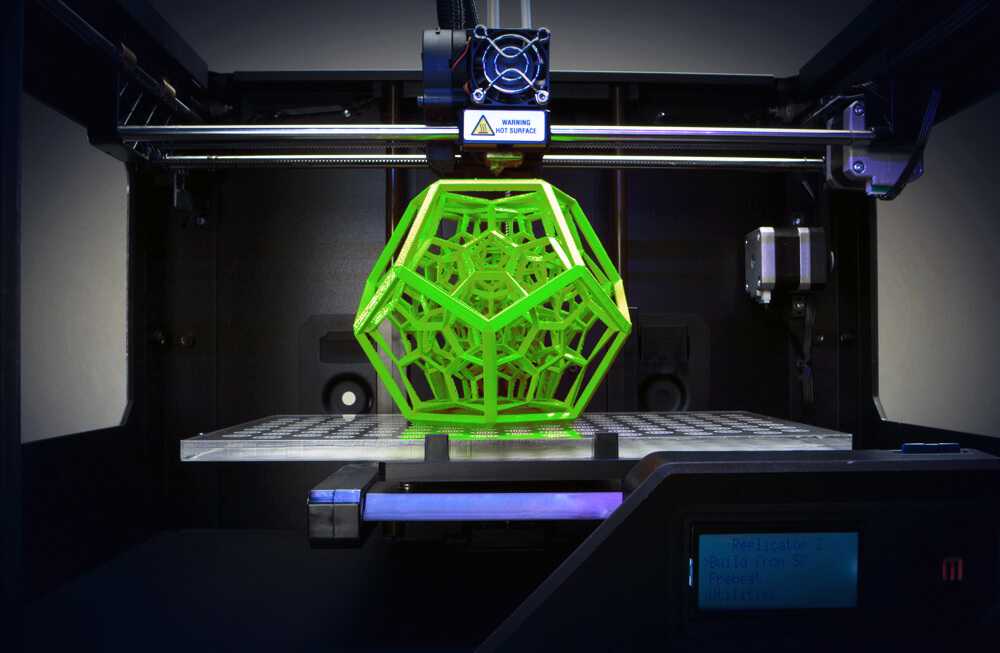

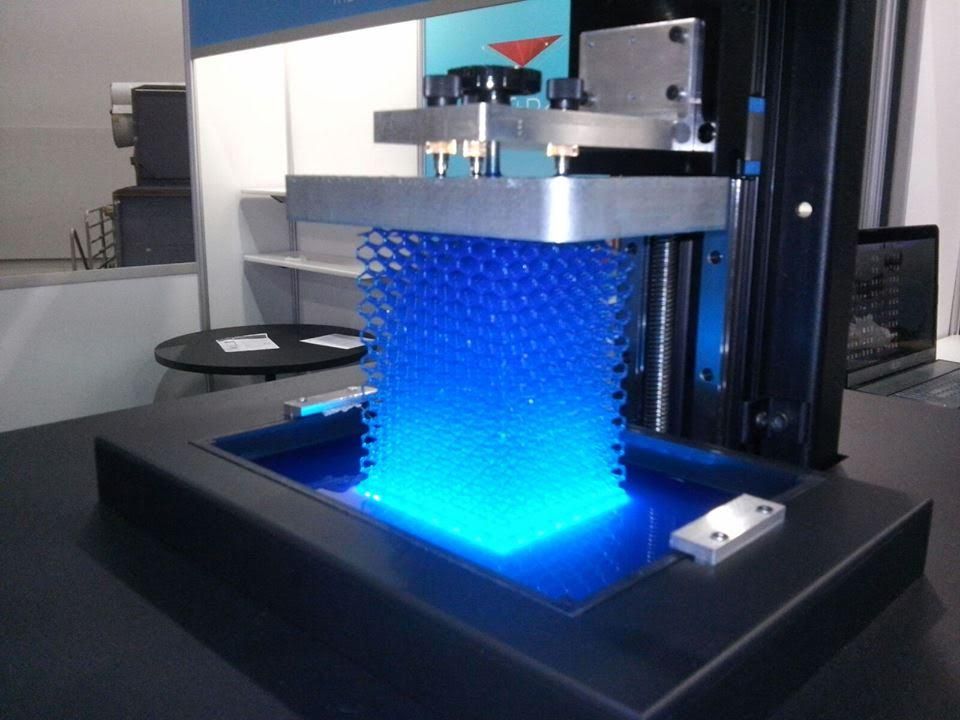

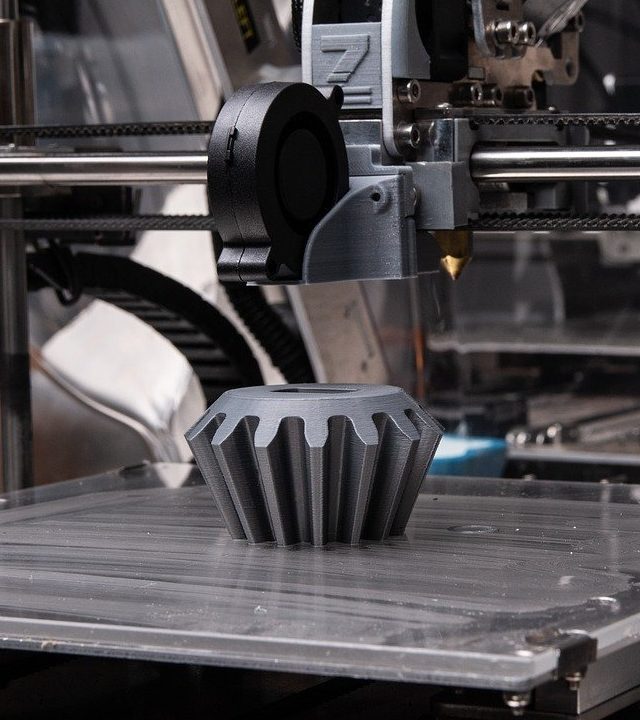

The basic principle of a 3D printer is layer-by-layer application of material. At the same time, you can print anything: concrete, living cells, plastic, chocolate. 3D printing is simply the principle of creating an object, along with any other method of production.

At the same time, you can print anything: concrete, living cells, plastic, chocolate. 3D printing is simply the principle of creating an object, along with any other method of production.

The main use of 3D printing in life is prototyping and creating unique objects. When prototyping, you can print several versions of a product and choose the one that turned out better than the rest. There are industrial enterprises that print plastic items, but it is too early to talk about the widespread use of 3D technology. She has two problems: slow production speed and not high enough quality. Indeed, you can print anything you want, but now it is not economically feasible to launch such mass production, Alexander Kornveits explains.

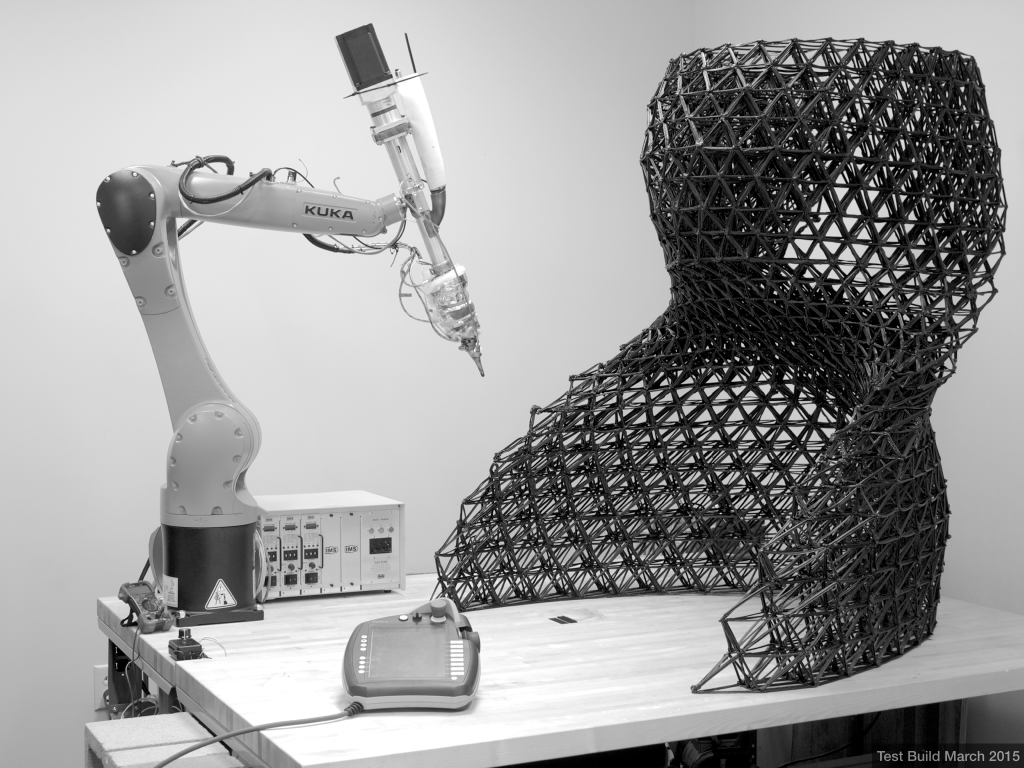

On the other hand, 3D printing can be used to create unique, design elements, sculptures, monuments. For example, in Moscow you can see printed sculptures like “Girl with an oar”. Often, such sculptures are additionally processed to give the appearance of a monument we are used to, made of marble or plaster.

Prospects for 3D printing for medicine

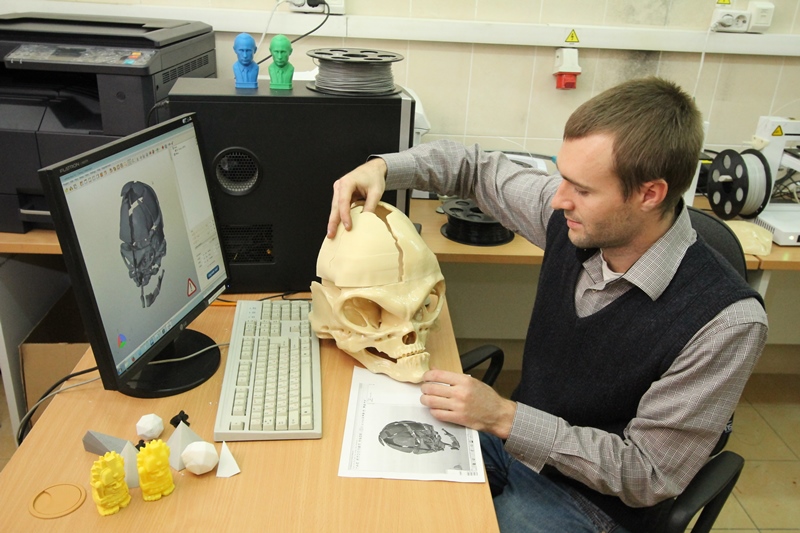

In the medical industry, the most active use of 3D printing is in dentistry. If you go to the dentist now, you will be faced with a 3D scan; or you will be offered 3D printed aligners. This is no longer prototyping, but the creation of final products or blanks for final products.

Bioprinting - organ printing - is currently under development. First, a cell of a damaged organ is taken from a person - skin, liver, kidney. After that, the cell multiplies in a special solution, and then, using a special bio-3D printer, the organ that needs to be replaced is produced. In this case, layer-by-layer stacking of living cells on top of each other also occurs, resulting in living tissue. The ability of such an organ to take root is much higher than that of a donor organ. According to the guests, this technology will be able to be used to treat specific patients in 5-10 years.

Printing a house: 3D printers in construction

Building 3D printing developments are very popular because there is a shortage of housing in the world. In Russia, this area is also developing, but many construction companies work abroad, since there is a higher demand for 3D technologies, Sergey Nefedov explains. For example, the founders of the California startup Mighty Buildings are from Russia. The essence of 3D printing is that it is effective where labor resources are expensive. For example, Australia and New Zealand have a norm that allows construction to be done only for 6 hours a day. This is based on the loads that a person can withstand. The cost of housing in these regions is very high, so it is advisable to replace a person with a robot.

In Russia, this area is also developing, but many construction companies work abroad, since there is a higher demand for 3D technologies, Sergey Nefedov explains. For example, the founders of the California startup Mighty Buildings are from Russia. The essence of 3D printing is that it is effective where labor resources are expensive. For example, Australia and New Zealand have a norm that allows construction to be done only for 6 hours a day. This is based on the loads that a person can withstand. The cost of housing in these regions is very high, so it is advisable to replace a person with a robot.

The problem with 3D construction is that the automation and robotization of this industry has not yet occurred, in contrast to the automotive industry, where production is divided into separate operations. 3D building at the moment is a layered construction of walls, which is not difficult to handle. The portal system allows you to print the entire house: first, a portal is built that is larger than the house in size, and the building is printed inside it. But at the stage of finishing and engineering, problems begin. If a company can streamline all this R&D and replace people with machines, then it might work.

But at the stage of finishing and engineering, problems begin. If a company can streamline all this R&D and replace people with machines, then it might work.

3D printing eliminates the human factor: for example, building mix will always have the right consistency thanks to the settings. But in Russia, all cities are growing skyward, and 3D printing technologies are more applicable to low-rise construction. Unlike the markets in the US and the Netherlands, our market is still unfavorable for 3D construction.

The future of 3D printing: orthopedic insoles and space colonization

The main advantage of 3D printing is customization, the ability to create a unique product, says Kornweitz. For example, the creation of orthopedic insoles will soon be actively developed. Another example is the frames and lenses of glasses, which take into account all personal characteristics. That is, the entire development of 3D technology will take place in areas where a personalized product is created for each individual person.