Formlabs fuse 1 sls 3d printer

Tech Specs for the Fuse Series SLS 3D Printers

Printer

Fuse 1

Fuse 1+ 30W

Technology

Selective Laser Sintering

Selective Laser Sintering

Build Volume (W x D x H)

165 × 165 × 300 mm

6.5 x 6.5 x11.8 in

165 × 165 × 300 mm

6.5 x 6.5 x11.8 in

Layer Thickness

110 microns

0.004 in

110 microns

0.004 in

Laser Type

Ytterbium Fiber 10W

Ytterbium Fiber 30W

Laser Spot Size (FWHM)

200 microns

0.0079 in

247 microns

0.0097 in

Build Chamber

Modular, compatible with Fuse 1 generation printers and Fuse Sift

Modular, compatible with Fuse 1 generation printers and Fuse Sift

Technology

Selective Laser Sintering

Selective Laser Sintering

Build Volume (W × D × H)

16.5 x 16.5 x 30 cm

6.5 x 6. 5 x 11.8 in

16.5 x 16.5 x 30 cm

6.5 x 6.5 x 11.8 in

Layer Thickness (Axis Resolution)

110 microns

0.004 in

110 microns

0.004 in

Hopper Capacity

17.8 Liters

14.5 Liters

Dimensions

68.5 x 64.5 x 106.5 cm

27 x 25.4 x 41.9 in

68.5 x 64.5 x 106.5 cm

27 x 25.4 x 41.9 in

Supports

No supports

No supports

Design/CAD Specifications

Minimum Access Dimensions (W × D × H)

125.5 × 149.5 × 187 cm

49.4 × 59.0 × 73.6 in

125.5 × 149.5 × 187 cm

49.4 × 59.0 × 73.6 in

Printer Dimensions (W × D × H)

64.5 × 68.5 × 107 cm (165.5 cm with stand)

25.4 × 27 × 42 in (65.0 in with stand)

64.5 × 68.5 × 107 cm (165.5 cm with stand)

25.4 × 27 × 42 in (65.0 in with stand)

Recommended Operating Footprint (W × D × H)

145.5 × 149.5 × 167.5 cm (49. 4 × 59 × 66 in) to allow access to the front and sides of the printer.

4 × 59 × 66 in) to allow access to the front and sides of the printer.

145.5 × 149.5 × 167.5 cm (49.4 × 59 × 66 in) to allow access to the front and sides of the printer.

Stand Dimensions (W × D × H)

59.6 x 60 x 58.4 cm

23.5 × 23.6 × 23 in

59.6 x 60 x 58.4 cm

23.5 × 23.6 × 23 in

Weight

114 kg (without build chamber or powder)

251.3 lb (without build chamber or powder)

120 kg (without build chamber or powder)

265 pounds (without build chamber or powder)

Startup Time

< 60 minutes

< 60 minutes

Operating Environment

18 – 28 ºC

68 – 82 ºF

18 – 28 ºC

68 – 82 ºF

Internal Temperature

Up to 200 ºC

Up to 392 ºF

Up to 200 ºC

Up to 392 ºF

Temperature Control

Quartz tube heating elements

Positive temperature coefficient (PTC) cartridges

Quartz Tube Heating Elements

Resistive Air Heater

Air Handling

Pressure-controlled two-stage filtration

(Replaceable HEPA and carbon mediums)

Interface to external inert gas supply

Pressure controlled two-stage filtration

(Replaceable HEPA and carbon mediums)

Power Requirements

EU: 230 VAC, 7. 5 A (dedicated circuit)

5 A (dedicated circuit)

US: 120 VAC, 15 A (dedicated circuit)

EU: 230 VAC, 7.5 A (dedicated circuit)

US: 120 VAC, 15 A (dedicated circuit)

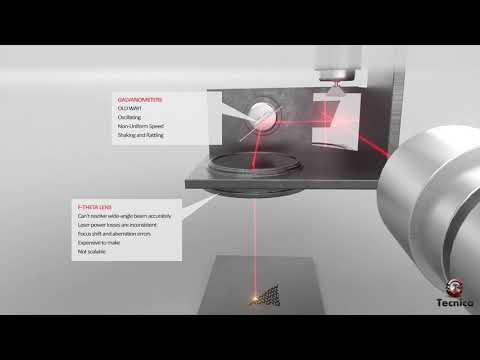

Galvanometers

Formlabs Custom

Formlabs Custom 2nd Generation

Laser Specifications

Ytterbium Fiber

IEC 60825-1: 2014 certified

1070 nm wavelength

Maximum 10 Watts

4.01 mrad beam divergence (nominal, full angle)

Ytterbium Fiber

IEC 60825-1: 2014 certified

1070 nm wavelength

Maximum 30 Watts

3.24 mrad beam divergence (nominal, full angle)

Laser Spot Size (FWHM)

200 microns

.0079 in

247 microns

.0097 in

Radiation Information

The Fuse 1 is a Class 1 Laser product. Accessible radiation is within Class 1 limits.

The Fuse 1+ 30W is a Class 1 Laser product. Accessible radiation is within Class 1 limits.

Connectivity

Wi-Fi (2. 4GHz + 5GHz)

4GHz + 5GHz)

Ethernet (1000 Mbit)

USB 2.0

Wi-Fi (2.4GHz + 5GHz)

Ethernet (1000 Mbit)

USB 2.0

Printer Control

10.1” interactive touchscreen

1280 × 800 resolution

10.1” interactive touchscreen

1280 × 800 resolution

Alerts

Touchscreen alerts and tracking

SMS/email via Dashboard

Live video feed with computer vision

Proactive maintenance alerts

Touchscreen alerts and tracking

SMS/email via Dashboard

Live video feed with computer vision

Proactive maintenance alerts

Print Preparation

PreForm Desktop Software

PreForm Desktop Software

System Requirements

Windows 7 (64-bit) and up

Mac OS X 10.12 and up

OpenGL 2.1

4 GB RAM (8 GB recommended)

Windows 7 (64-bit) and up

Mac OS X 10.12 and up

OpenGL 2.1

4 GB RAM (8 GB recommended)

Hardware Requirements

Fuse 1 generation 3D printer

Fuse 1 generation 3D printer

File Types

. STL or .OBJ

STL or .OBJ

FORM file output

.STL or .OBJ

FORM file output

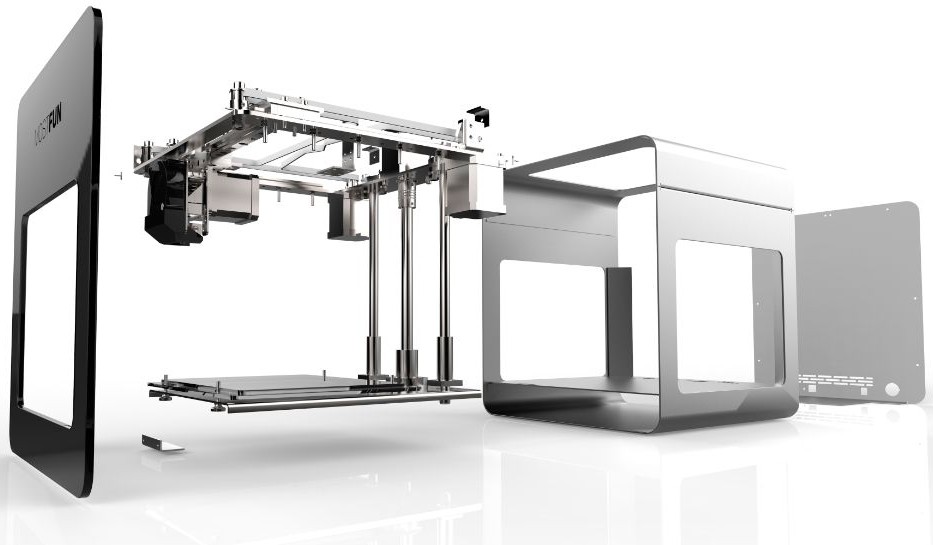

Fuse 1+ 30W for Superior Speed and High Performance Materials

When Formlabs began shipping the Fuse 1 selective laser sintering (SLS) printer, we knew that it would change the 3D printing landscape forever. Since 2020, Formlabs has sold more SLS printers than anyone else. Now, two years later, we’ve taken feedback from our thousands of users, and continued to build on the incredible success of the Fuse 1 by introducing the high-efficiency Fuse 1+ 30W SLS printer with print speeds up to two times faster than the previous generation.

Upgrades to the system include a new, more powerful laser and higher scanning speed, improved powder handling, and optional inert nitrogen environment. Fuse 1+ 30W users can increase their throughput, unlock new, high-performance materials, and deliver parts faster than ever.

Webinar

Discover how the Fuse 1+ 30W, our newest SLS 3D printer, and our new carbon-filled nylon 11 material enable engineers and manufacturers to deliver high-performance durable parts in-house. Chris Haid, SLS Product Manager at Formlabs, will walk you through our newest products and answer any questions during a live Q&A.

Chris Haid, SLS Product Manager at Formlabs, will walk you through our newest products and answer any questions during a live Q&A.

Register Now

Whether printing a single prototype, or running the printer non-stop for end-use production, speed is a top priority for every industry. To reduce overall print time, we started by upgrading the core engine of the printer—the Fuse 1+ 30W has a new, more powerful laser, as well as an updated laser scanning system. These two main updates ensure that interlayer printing is happening as rapidly and efficiently as possible.

Users can now design multiple versions, print them all on the Fuse 1+ 30W utilizing the upgraded packing algorithm, and have them ready to be tested the next day. In today’s market, products are highly specialized, and small components are often the entire focus of a designer or design team. Without other parts or projects to work on, time spent in the printer, or waiting multiple days for parts to arrive from a service provider, meant designers had to wait around before they were able to move the iterative process forward.

Now with the Fuse 1+ 30W’s higher print speeds, this ‘down time’ can happen overnight, helping designers improve the efficiency of their process. More iterations means more time for functional testing and feedback, resulting in better products and a faster ROI.

| Fuse 1 | Fuse 1+ 30W | ||

|---|---|---|---|

| Material | Nylon 12 Powder | Nylon 12 Powder | |

| Packing Density | 9% | 9% | |

| Model Material | 0.35 kg | 0.35 kg | |

| Layers | 2101 | 2101 | |

| Print Time | 18 h 22 min | 14 h 1 min | -24.00% |

After several years of raw materials shortages, rising contractor costs, and factory shut-downs, manufacturers are searching for ways to take control of their supply chains. Recent materials innovations have made 3D printed end-use parts not only possible, but ideal for stop-gap options, validation stages, and customization applications.

Small and medium manufacturers can afford to bring SLS in house with the Fuse 1+ 30W printer in-house and reduce their reliance on expensive external contractors, as well as avoid delays and variability in the production supply chain. Large manufacturers that might already utilize SLS 3D printing can decentralize their 3D printing operation without duplicating the cost of their traditional SLS systems, giving more engineers, designers, and technicians access to industrial quality SLS. With that broader access, new applications in replacement parts, fixtures, jigs, tooling, and more are made possible across the company.

| Fuse 1 | Fuse 1+ 30W | ||

|---|---|---|---|

| Material | Nylon 12 Powder | Nylon 12 Powder | |

| Packing Density | 58% | 58% | 0 waste printing |

| Model Material | 3.96 kg | 3.96 kg | |

| Layers | 2669 | 2669 | |

| Print Time | 66 h 19 min | 32 h 59 min | -52. 20% 20% |

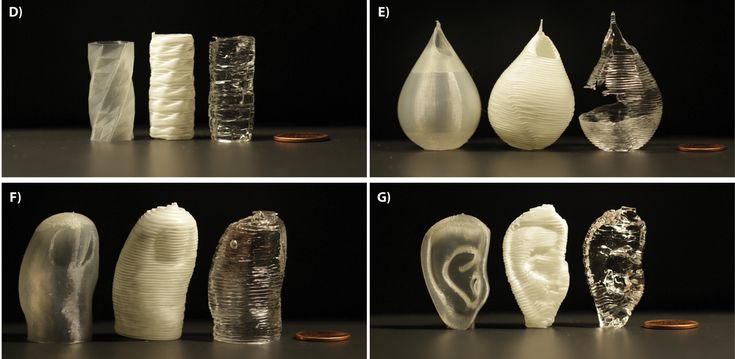

3D printing for production wouldn’t be possible without high performance materials, and the Fuse 1+ 30W integrates two new features that unlock more advanced powder possibilities.

A new optional nitrogen supply feature creates an inert gas environment during the print process, eliminating unwanted oxygen from the sintering environment. When printed in this inert environment, parts exhibit less brittleness and better ductility, enhancing their suitability as end-use components, especially in rugged environments such as automotive or aerospace. Compatible nitrogen generators are widely available for purchase, and recommended models can be found by speaking with a member of our sales team.

The controlled atmosphere also enables a more efficient sintering process for Nylon 11 Powder and Nylon 11 CF Powder by better preserving unsintered powder from oxidation, allowing users to reuse more of it in the next printing cycle. This leads to a higher powder recyclability, and when combined with an optimal packing density, can create a zero-waste printing workflow. Without the inert gas atmosphere, Nylon 11 and Nylon 11 CF Powders have a 50% refresh rate, meaning 50% recycled and 50% fresh powder must be used to create each new cartridge. In a nitrogen environment, this improves to 30% with both materials.

Without the inert gas atmosphere, Nylon 11 and Nylon 11 CF Powders have a 50% refresh rate, meaning 50% recycled and 50% fresh powder must be used to create each new cartridge. In a nitrogen environment, this improves to 30% with both materials.

| Nylon 11 Powder | Nylon 11 CF Powder | |

|---|---|---|

| Air | 50% | 50% |

| Inert Gas | 30% | 30% |

The zero-waste printing workflow is not only a more sustainable option, but also means that every dollar spent on materials will directly convert to printed parts in most common production scenarios. Cost-savings, sustainability, and high-quality parts are now mutually inclusive with the Fuse 1+ 30W.

The Fuse 1+ 30W includes updated hardware that enables new materials, such as Nylon 11 CF Powder, a carbon-fiber reinforced material that allows users to produce stiff, strong, lightweight parts in-house.

Composite materials like Nylon 11 CF Powder owe their heightened strength and durability to the combination of carbon fibers throughout the powder, reinforcing the nylon’s material properties. Advanced materials require a more sophisticated powder handling system, one that can maintain the powder flow integrity during the dosing process.

Advanced materials require a more sophisticated powder handling system, one that can maintain the powder flow integrity during the dosing process.

The Fuse 1+ 30W engineering team designed an elegant solution to facilitate these new materials. The new agitator within the powder hopper creates a consistent, smooth delivery of material into the build chamber, enabling Nylon 11 CF Powder now, and opening up possibilities for future high performance materials in the future. Broader, end-use applications in aerospace, automotive, medical, and consumer goods industries will be made possible by the Fuse 1+ 30W printer’s improved powder management capacity.

Sample part

See and feel Formlabs quality firsthand. We’ll ship a free sample part to your office.

Request a Free Sample Part

White Paper

In this white paper, we evaluate the value proposition of bringing SLS 3D printers in-house, in comparison with outsourcing SLS parts from a service bureau.

Download the White Paper

The Fuse 1+ 30W printer presents an industrial-quality solution with an accessible footprint and affordable entry price, allowing small to medium manufacturers to not only bring SLS in-house, but scale up production. Besides an affordable entry price point, the low cost-per-part, faster turnaround time, and streamlined workflow can also reduce overall manufacturing costs.

Lower refresh rates reduce the amount of new powder needed, and thus lower the ongoing consumables cost of the printer. This reduced spend, coupled with the higher number of iterations and production rounds, lead to a faster ROI for the printer. When compared with many manufacturers’ previous outsourcing costs, having a Fuse 1 series printer in-house can pay back the purchase price within a few months.

We looked at the cost of producing SLS parts in house when compared with outsourcing to an external contractor. We sent files to the top four service bureaus, and requested SLS parts, then took the average of their prices and delivery lead times. For the in-house printed parts, we used the Fuse 1+ 30W printer and Fuse Sift, assuming labor time cost $17/hour.

For the in-house printed parts, we used the Fuse 1+ 30W printer and Fuse Sift, assuming labor time cost $17/hour.

Material: Nylon 12 Powder

Volume: 5 parts

| Fuse 1+ in-house | Service Bureau SLS | |

|---|---|---|

| Print Time | 15 h 20 m | |

| Cooling+Sifting Time | 14 h 35 min | |

| Total Time | 29 h 55 m | 5-7 business days |

| Materials Cost | $31.00 | |

| Labor Cost | $14.11 | |

| Total Cost | $45.11 | $592.20 |

Part printed on the Fuse 1+ 30W in Nylon 12 Powder.

Part printed on a traditional industrial powder-bed fusion 3D printing system with an entry price point 6-10x higher than that of the Fuse 1+ 30W.

Material: Nylon 12 Powder

Volume: 36 parts

| Fuse 1+ 30W in-house | Service Bureau SLS | |

|---|---|---|

| Print Time | 13 h 52 m | |

| Cooling + Sifting Time | 16 h 52 m | |

| Total Time | 30 h 44 m | 7-10 business days |

| Materials Cost | $183. 00 00 | |

| Labor Cost | $51.00 | |

| Total Cost | $233.00 | $1,431.36 |

Part printed on the Fuse 1+ 30W in Nylon 12 Powder.

Part printed on a traditional industrial powder-bed fusion 3D printing system with an entry price point 6-10x higher than that of the Fuse 1+ 30W.

For both prototyping and production runs, in-house 3D printing with the Fuse 1+ 30W printer delivered high quality parts with shorter turnaround times, facilitating a more intensive iterative process for prototypes or greater throughput for production. Current Fuse 1 customers who were previously outsourcing are reporting an average return on the purchase price of the printer of 3-4 months for prototyping cases, and six to seven months for production runs.

The Fuse 1+ 30W SLS printer builds on the success of its previous iteration, taking the streamlined workflow, high accuracy, and accessible format of the Fuse 1, and leveling up the throughput possibilities with improvements to speed and powder handling.

Register for the Fuse 1+ 30W Webinar

Compact Selective Laser Sintering (SLS) 3D Printer

Skip to Main Content

Print Models in Hours Not Days

Generate a QuoteRequest a Free Sample

Fuse 1+ 30W is a compact 3D printer SLS designed for maximum productivity and minimum waste. Use unparalleled print speeds and a wide range of materials for fast in-house production.

High speed printing

Create highly accurate models in 24 hours with a 30W laser that prints at scan speeds up to 12.5 meters per second.

Industrial Grade Materials

Discover new exclusive materials and increase the productivity of existing ones with active powder processing and the ability to print in inert gas.

Zero Waste, High ROI

Thanks to the high density and recyclability of the powder, we have achieved an important goal - to create a waste-free printing method that reduces the cost of models.

From print to finished product:

3D print production-ready final models with our line of SLS powders designed specifically for the Fuse series. We have developed and tested materials, hardware and software to ensure the best performance and optimize the cost of the models.

We have developed and tested materials, hardware and software to ensure the best performance and optimize the cost of the models.

Nutzen Sie auf dem Fuse 1+ 30W die Option des Drucks in Inertgasatmosphäre für noch bessere mechanische Eigenschaften und eine höhere Wiederverwertung des Pulvers.

Available materials: Nylon 11 Powder, Nylon 12 Powder, Nylon 12 GF Powder and Nylon 11 CF Powder. Stay tuned for releases of new materials under development.

Learn more about SLSS materials to ask a free sample

Fuse 1+ 30W

Quick 3D printer SLS for workshops

Lazer type

Voloconium laser with a capacity of 30 W 9000 9000 3D 3D-first-first-time,

Material Compatibility

Full range of powders

Main powder + Nylon 11 Cf Powder

Press Parameters

Inert gas and air

Inert gas improves the properties of materials and suitability for processing

Production 9000 9000 Eallevable seal High density and recyclable Order now Fuse 1 Affordable SLS 3D printer for workshops Lazer type Voloconial laser with a capacity of 10 W Discover a reliable 3D printing on your own Compatibility with materials The main line of thresholds Nylon 12 Powder, Nylon 11 Powder and Nylon 12 GF Powder 12 GF Powder 12 Print environment settings air One setting, easy setup. Productivity Wasteless High Density Order Reimagine your product development process and take control of your production. Customize your printing with the Fuse Series today. Generate a QuoteRequest a Free Sample from Formlabs Starting price $0 - starting price 0 ₽ Starting price Price on request 0 ₽ - 0 ₽ Current price Price on request | / Savings 0 ₽ Savings 0 ₽ Available on order Fuse 1 is an affordable and compact industrial quality SLS 3D printer that ushered in a new era in independent manufacturing and prototyping.

Formlabs Fuse 1: Formlabs

3D Printers  Reimagine your product development process and take control of your own production today!

Reimagine your product development process and take control of your own production today!

3D printing properties

Print technology Selective Laser Sintering (SLS) Application Prototyping, Prototyping, Design, Mechanical engineering, Dentistry, Medicine, For business, Industrial 3D printers, For engineering Maximum print size (LxWxH), mm 165x165x300 Media Nylon Layer thickness 0.1 mm Printable file formats STL, OBJ How to download a project WiFi, Ethernet Power supply

Voltage requirements AC 230~230V Power consumption 2000 W Requirements for conditions of use

Operating Temperature Requirements 20~27°C Dimensions

Width 677 mm Height 1059 mm Depth 668 mm Weight 88 kg

Fuse 1 manual

Fuse 1

Intuitive

Fuse 1 is designed for minimal maintenance.