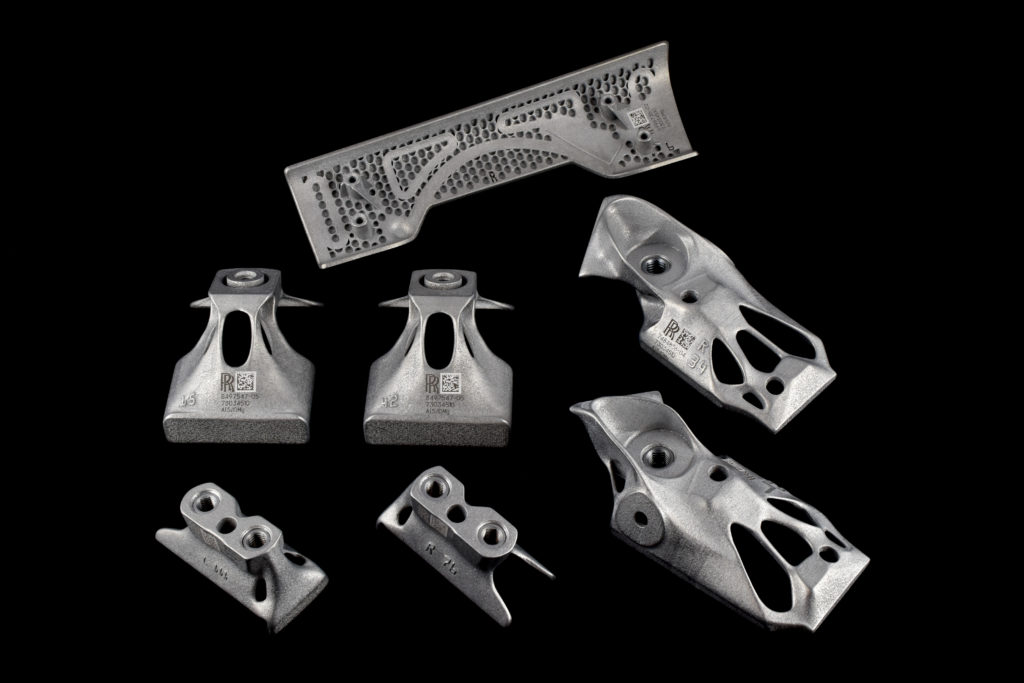

3D printed metal car parts

Metal 3D printing for the automotive industry

Team DM

Platforms

Metal and composites 3D printing 3D printing solutions for health care Industrial-grade polymer 3D printing™

Sand and tooling 3D printing solutions 3D printers for sheet metalMaterials

Breakthrough photopolymer development Advancing 3D printed upcycled woodApps & More

The hydraulic additive manufacturing experts Multi-material powder recoating technology Driving digital transformation in dentistry_Articles

- Download PDF

About the Automotive industry

One of the largest and most important industries for metal parts manufacturing, the automotive industry annually spends trillions producing parts across the manufacturing lifecycle, from research and development to prototyping to mass production and long-term aftermarket parts support.

With its ability to address manufacturers’ needs at each stage of that lifecycle, metal 3D printing opens many new opportunities for automotive manufacturers to make cars faster, better and more efficiently than ever before.

The Challenge

The challenges automotive manufacturers face begin with the often-lengthy - three to five years is common - research and development phase for new models. That long timeline means manufacturers must make decisions based on what they believe the market will look like years in the future.

When vehicles do enter mass production, car makers must take on the monumental task of preparing manufacturing lines to produce thousands of parts. That process involves tooling and programming thousands of machines, developing a wide range of manufacturing processes and more,

But it’s not limited to auto manufacturers - hundreds of Tier 1, 2 and 3 suppliers must also ramp up production lines, all while remaining flexible enough to deal with designs that may change, and specific changes made for different markets.

Finally, cars often remain on the road for 20 years or more, meaning manufacturers must deal with the complex and expensive proposition of providing spare parts for those vehicles. Many of those parts may be in such low demand that manufacturers can no longer justify the cost of producing them, leaving customers to search through scrapyards to find rare parts or purchase low-quality, third party parts.

The Solution

Using metal 3D printing, engineers can dramatically reduce portions of the long research and development timeline, leading to a faster time to market. By speeding up research and development, engineers also have more time to iterate on and optimize designs, leading to improvements in fuel efficiency, performance benefits and overall cost savings.

With the ability to quickly produce custom fixtures and tooling that would otherwise be prohibitively expensive, additive technology makes it easy for manufacturers to optimize production lines.

The technology can also make production lines more flexible. As design changes are made, manufacturers may have to produce new parts for vehicles that may be produced in relatively low numbers. Rather than commit to the time and expense of creating complex tooling or long lead times for third-party suppliers, manufacturers can simply print the parts and keep manufacturing lines running smoothly.

As design changes are made, manufacturers may have to produce new parts for vehicles that may be produced in relatively low numbers. Rather than commit to the time and expense of creating complex tooling or long lead times for third-party suppliers, manufacturers can simply print the parts and keep manufacturing lines running smoothly.

Aftermarket parts - especially those that were once cast - can be easily supported by metal 3D printing. Rather than keeping a huge inventory of tooling for casting parts in large lots of a few thousand, manufacturers can meet the lower demand for parts by printing them on demand as customers order them.

Killacycle Taper Lock Coupling (Shop System)

This part is a taper lock coupling designed for a high-end, custom motorcycle.

The Killacycle is an electrically-powered motorcycle built for drag racing. Using the Shop System, engineers were able to design for function rather than for the manufacturing method, allowing them to use a tapered design that would be difficult to manufacture via traditional methods.

The Shop system allowed for a greatly accelerated manufacturing lead time, allowing the team to rapidly iterate on the part.

Shock Absorber Piston (Studio)

This piston is used in a shock absorber to provide dampening over uneven surfaces.

This part features complex internal channels that are optimized to direct the flow of oil and provide the right level of damping. These internal channels could not be manufactured in any method other than additive manufacturing.

Using the Studio System, engineers were able to quickly produce a number of functional prototypes from 17-4 stainless steel with subtly different geometries and test the performance of each.

That ability, to create multiple iterations of the part while reducing both the cost and development timeline, allowed the team to ultimately identify the piston’s optimum design.

With the final design locked, the parts can be mass-produced using the Shop System.

Gear Shift Knob (Shop)

An example of mass customization, this textured gear shift knob can be printed to customer specifications.

On-demand manufacturing of custom knobs is enabled with the Shop System - expanding design flexibility and avoiding warehousing costs.

The short manufacturing lead times allow for many custom knobs to be produced with a variety of different designs. Printing on the Shop System also allows for a dramatic reduction in cost compared to traditional manufacturing methods.

APG Coining Fixture (Studio)

This fixture is used to achieve critical tolerances on metal injection molded (MIM) parts.

Because 3D printing eliminates the design constraints associated with CNC machining, fixtures like this one can be custom-built for each particular application.

And by dramatically reducing the lead time to produce metal parts, APG was able to put this fixture into use in just three days, allowing them to get manufacturing lines running quickly.

Printing these parts with the Studio System eliminates CNC lead time and frees up the machine shop for more critical work.

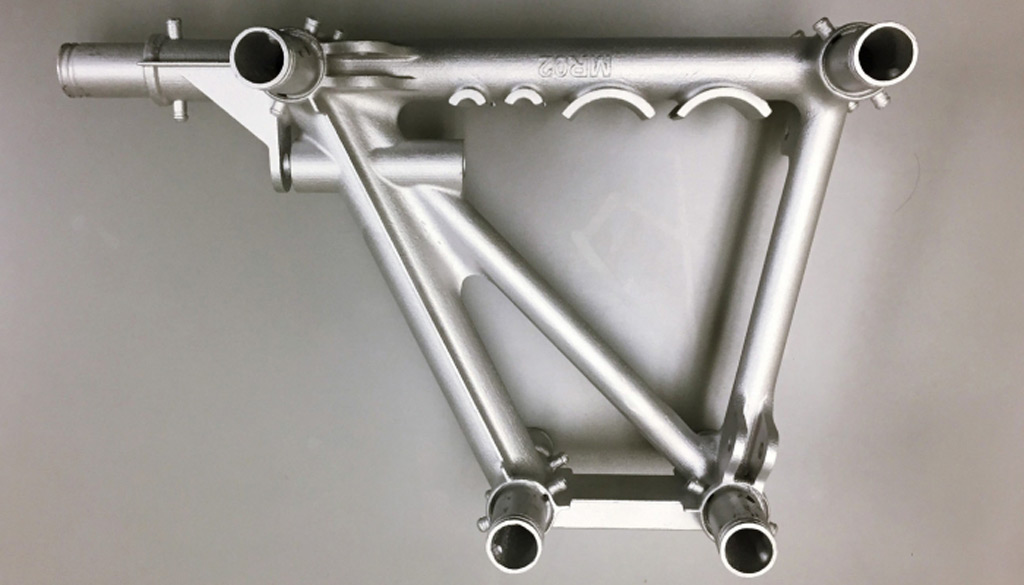

Mercedes Thermostat Housing (Studio)

This thermostat housing is part of the cooling system on a vintage Mercedes Benz engine.

This thermostat housing was originally cast, but as demand for replacement parts dwindled, it was discontinued, and the parts became difficult to find.

Attempts to recreate the part have been frustrated by the fact that the molds and tools used to produce it no longer exist, and geometry that is too complex for machining.

Using the Studio System, however, aftermarket parts suppliers can quickly reproduce rare parts like this housing, keeping vintage cars on the road.

Transmission Shift Fork (Studio)

Shift forks are used to move the synchronizers that change the gears in a manual transmission to ensure a proper mesh. This fork is originally cast in high volumes, but when replacement parts are needed in lower volumes casting is not a suitable manufacturing method due to the very high tooling costs and long foundry lead times.

Printing this part greatly simplifies the process of producing replacements, just upload the files, hit print, and a few days later your replacement part is ready to install; greatly reducing the manufacturing lead time, logistical burden, and part cost.

Keep Up with the Latest News

Sign Up for Access

Top 5 videos: 3D printing metal parts for the automotive industry, and more

3D printing news Videos Top 5 videos: 3D printing metal parts for the automotive industry, and more

Published on September 27, 2020 by Aysha M.

This week we found the top 5 videos about 3D printing and the way additive manufacturing is changing production. The technology has infiltrated many sectors, from medical to automotive – check our selection of the week to keep up with the innovations! If you enjoy these, you can view even more 3D printing videos on our Youtube channel. Hope you’ll enjoy and have a great Sunday!

Top 1: RPG benefits from Markforged AM solutions

Founded in 1995, RPG Industries provides EDM, CNC machining, waterjet cutting and additive manufacturing services. Its customers are diverse and come from the automotive, aerospace, medical and construction industries, among others. To meet the challenges of the industry, the company has now decided to purchase a Markforged 3D printer. RPG has already used the 3D printer for metal printing of automotive parts, specifically for 3D printing of a carburetor for a discontinued classic car. Robert Ginsburg, president of RPG Industries, says: “When I saw the technology and price point, I knew the Metal X system would be a good fit for our company.”

Its customers are diverse and come from the automotive, aerospace, medical and construction industries, among others. To meet the challenges of the industry, the company has now decided to purchase a Markforged 3D printer. RPG has already used the 3D printer for metal printing of automotive parts, specifically for 3D printing of a carburetor for a discontinued classic car. Robert Ginsburg, president of RPG Industries, says: “When I saw the technology and price point, I knew the Metal X system would be a good fit for our company.”

Top 2: AM and professional cycling

This week, we told you about different 3D printing projects related to cycling. And here’s another proof that 3D can help riders perform better: DSM helped the Sunweb team create custom-made armrests for the time trial. The team’s initial idea was to improve the aerodynamic position of the rider and reduce the overall weight of their bike to go further and faster. To achieve this, the position of the rider is essential – when the rider is bent forward, aerodynamic resistance is reduced. That’s why DSM has designed bike armrests that are customized to each rider’s morphology so that they can position their forearms correctly and comfortably. This allows them to stay in this position longer and reduces fatigue.

To achieve this, the position of the rider is essential – when the rider is bent forward, aerodynamic resistance is reduced. That’s why DSM has designed bike armrests that are customized to each rider’s morphology so that they can position their forearms correctly and comfortably. This allows them to stay in this position longer and reduces fatigue.

Top 3: 3D printed house in Canada

The Canadian construction company, Twente Additive Manufacturing (TAM), designs and builds houses and other architectural structures using 3D printing. They used additive manufacturing to create a house in the shape of a Fibonacci spiral. With traditional construction methods, free shaping is usually very costly, so most buildings are rectangular in design. 3D printing of concrete makes it much easier to create curves in buildings. Watch the video to see TAM’s 3D printed house.

Top 4: 3D printing in large scale with BigRep

When we talk about large format 3D printing, we often think of the manufacturer BigRep who has designed a range of FDM machines with a very wide printing platform. One of its solutions, the BigRep PRO, is able to produce large parts in only 4 hours! Thanks to a specific extruder configuration, it increases its printing speed – the video below gives you some examples of parts such as manifolds for the automotive industry. Moreover, the machine is now compatible with various thermoplastics.

Top 5: Sandvik and BEAMIT advance in metal AM

In 2019, Sandvik acquired significant shares of BEAMIT, a trusted supplier of advanced metal AM components for demanding industries. By acquiring ZARE, they gain a leading integrated AM service bureau with a wide range of metal and polymer 3D printers and CNC machines for finishing operations – and corresponding quality certifications. BEAMIT and ZARE will continue to operate under their respective brand names, but the activities will be combined under the BEAMIT Group.

By acquiring ZARE, they gain a leading integrated AM service bureau with a wide range of metal and polymer 3D printers and CNC machines for finishing operations – and corresponding quality certifications. BEAMIT and ZARE will continue to operate under their respective brand names, but the activities will be combined under the BEAMIT Group.

Which one is your favorite video of the week? Drop a comment below or on our Facebook and Twitter pages! And don’t forget to sign up to our free weekly Newsletter to keep updated on all the latest news in the 3D industry coming straight to your inbox!

Printed parts: can 3D printed auto parts replace traditional ones?

It's the 21st century - technological progress in the automotive industry is advancing by leaps and bounds and adjusting the world of auto parts production for itself. Even 30 years ago, we could not even imagine that we would be able to order parts for cars via the Internet and pick them up online in a matter of minutes, but today we have already found a lot of shortcomings in this. Parts often turn out to be not what we expect, spare parts of poor quality, fakes come across. In addition, you often have to wait a long time for an order or until the desired product appears at the seller, etc.

Parts often turn out to be not what we expect, spare parts of poor quality, fakes come across. In addition, you often have to wait a long time for an order or until the desired product appears at the seller, etc.

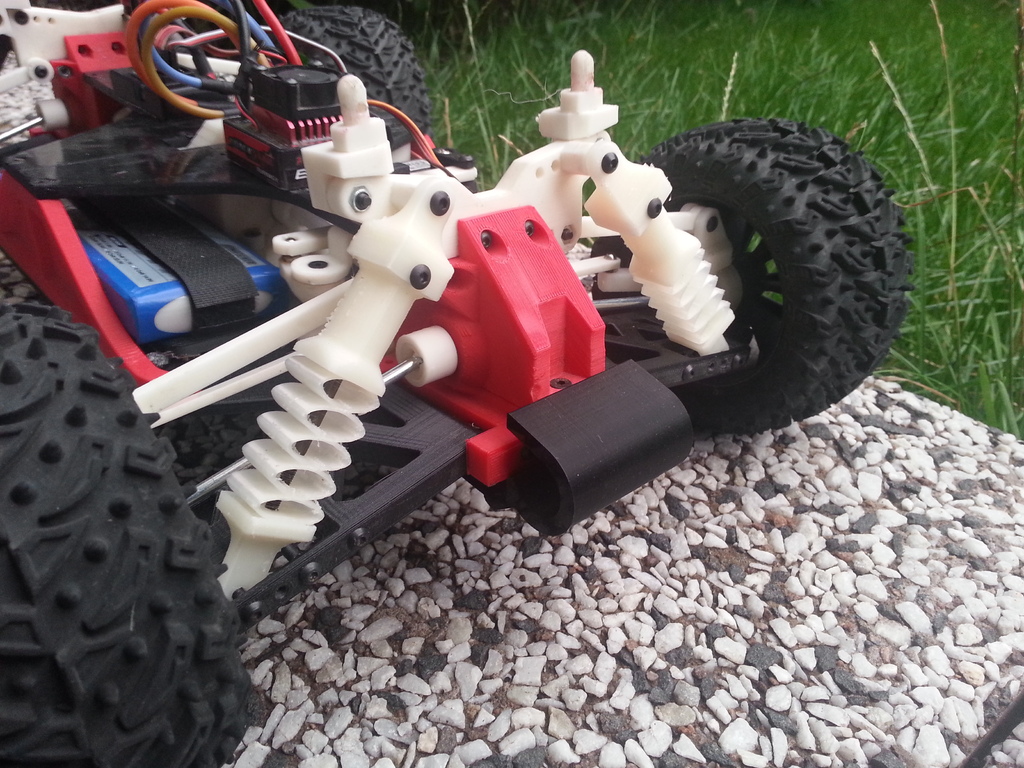

But this situation is about to change thanks to the invention of the 3D printer. Surely, many have already heard about 3D printing technology, and so - today it is already successfully used to create auto parts from plastic and metal. But if plastic parts have been mass-printed for a long time, then in the recent past, at the factories of the Daimler-Benz automobile concern, 3D printing was used for the industrial production of metal parts, and today thermostat housings are produced using this method.

It turned out that the new technology is much more efficient than the traditional one, since the part does not require additional processing, and, accordingly, the time and financial costs for its production are reduced. It seems that soon the technology will become more accessible and will be used everywhere, so we decided to discuss this issue in more detail.

How does the technology work?

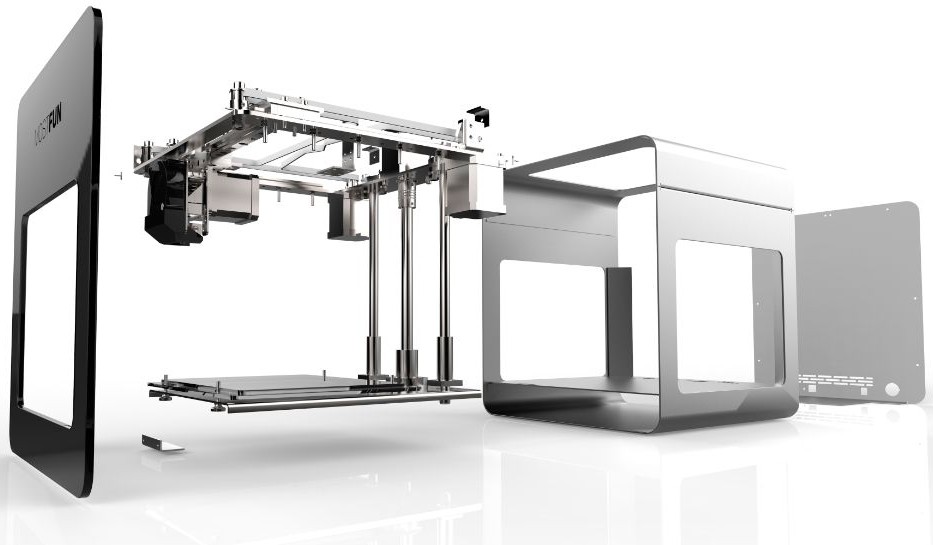

The principle of operation of a 3D printer is to create a three-dimensional object by repeatedly layering the material. In order to obtain the desired shape, it is necessary to build a computer model of the future part. You need highly specialized knowledge and appropriate software. A model created on a computer is a kind of pattern; it serves as the basis for creating a finished product.

In this way, it is possible to manufacture new parts with improvements and modifications, based on old parts, the main thing is that there is a drawing of them. However, with the help of 3D scanning, you can quickly and easily recreate a computer model of a part from an existing part or part. Using technology, you can add or remove some elements of the part, strengthen weak points, etc.

It turns out that 3D technologies will help to simplify production, as many of the additional steps used in traditional methods (in particular, casting and machining) will be skipped. This means that in such production, the cost of a part can be even lower than in traditional production. And now we smoothly approached the issue of price.

This means that in such production, the cost of a part can be even lower than in traditional production. And now we smoothly approached the issue of price.

Will printed parts be more cost effective?

3D printing technology has not yet found wide application in the modern car market, so its cost is initially much higher than traditional. However, with the development of this method, it is becoming cheaper. And now the price of such a seal is rapidly approaching the public.

Why is it better than the traditional method of manufacturing auto parts?

First, as we said, some steps in production are skipped. Casting and machining require additional time and money. And 3D printing makes it easy.

Secondly, in traditional manufacturing, the final cost of a part is affected by a lot of factors: cost, expected margin, various logistics costs, storage. The price is rising. Traditional production can be profitable with large volumes of output. But niches remain where it is much more efficient to produce a small number of parts “here and now”.

All you need for this production:

- Material,

- Printer,

- Computer 3D model of the part.

The ideal scheme is brought to life - from the drawing directly into the finished product. Creating plastic or thin-walled metal parts on a printer is also more profitable than casting them. 3D technologies are able to completely turn the usual vision of the process of manufacturing auto parts.

Minimal production costs and low alloy wastage make 3D printing very profitable, even though alloys are more expensive than traditional printing. The finished part is cheaper, but its characteristics are the same as the usual one, or even better, depending on the technology.

What materials are used for 3D printing?

Of course, most 3D printers today create plastic parts. But in different areas, a wide variety of metal alloys and even some types of concrete are used. In the automotive industry, of course, the most interesting materials are plastic and metal: steel, aluminum, copper.

Consider all the metals that are successfully used today for 3D printing.

Titanium

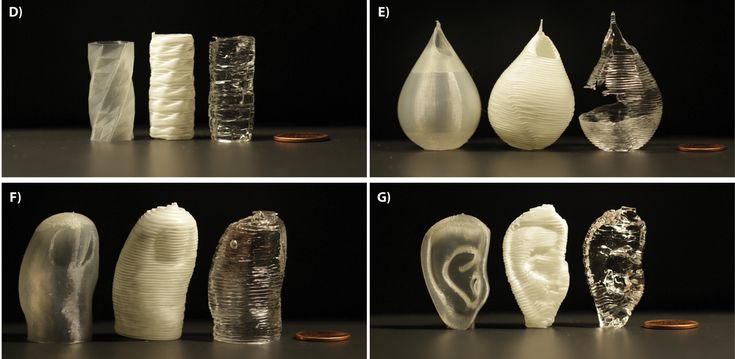

This is one of the most popular metals for 3D printing because of its high strength. It is especially in demand in the field of creating prostheses, as well as in the space and aircraft industries. It is these areas that are the most progressive in terms of the application of this technology.

Stainless steel

This material is great for 3D printing. Compared to non-ferrous metals, it is advantageous in price, although it remains more expensive than cheap steel. It is a very durable metal, due to which it is actively used in a variety of fields.

Aluminum

Allows for lightweight, corrosion resistant parts. It is easy to process, cheap, and therefore is actively gaining popularity as a material for three-dimensional printing. It is important that inexpensive printers that are available to many small businesses today work with it. Its only disadvantage is the explosiveness in the form of a powder.

Cobalt Chromium and Inconel

These alloys are highly specialized. They are designed for printers used in dentistry, medicine, and aerospace. New specialty materials are emerging as 3D printing technologies evolve and provide opportunities for different business areas.

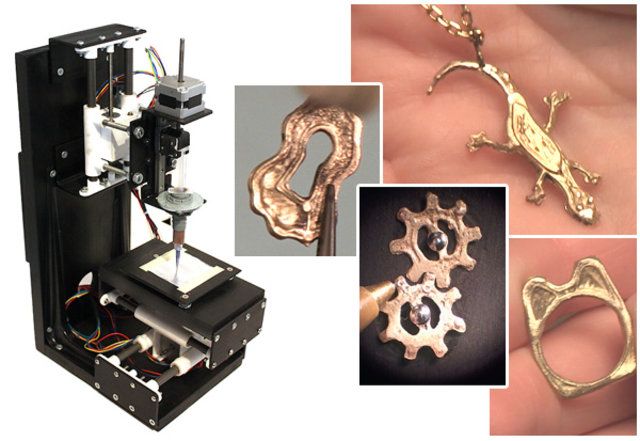

Copper, gold, silver

Common in the jewelry industry. Copper and silver are used in electronics.

Technologies for 3D printing of auto parts

There are several technologies. Each of them has a different principle of operation, cost and gives a different quality of parts at the output. But all of them are successfully used in modern automotive industry.

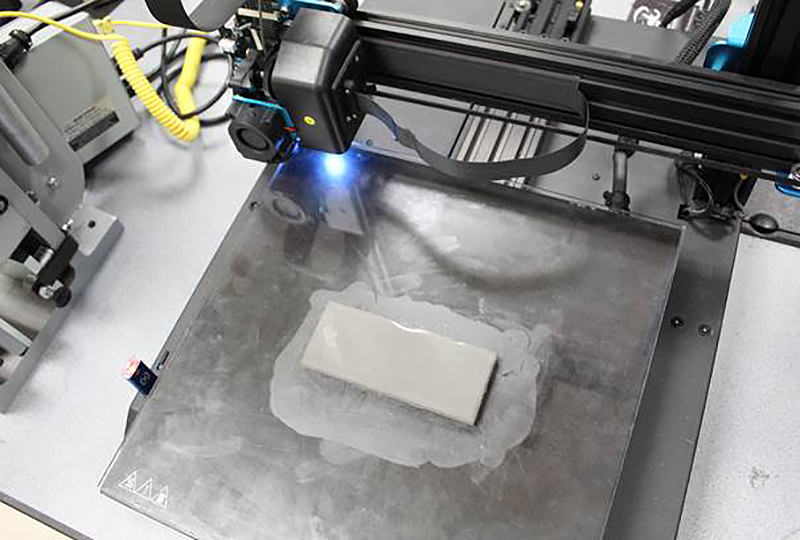

EBM and DED

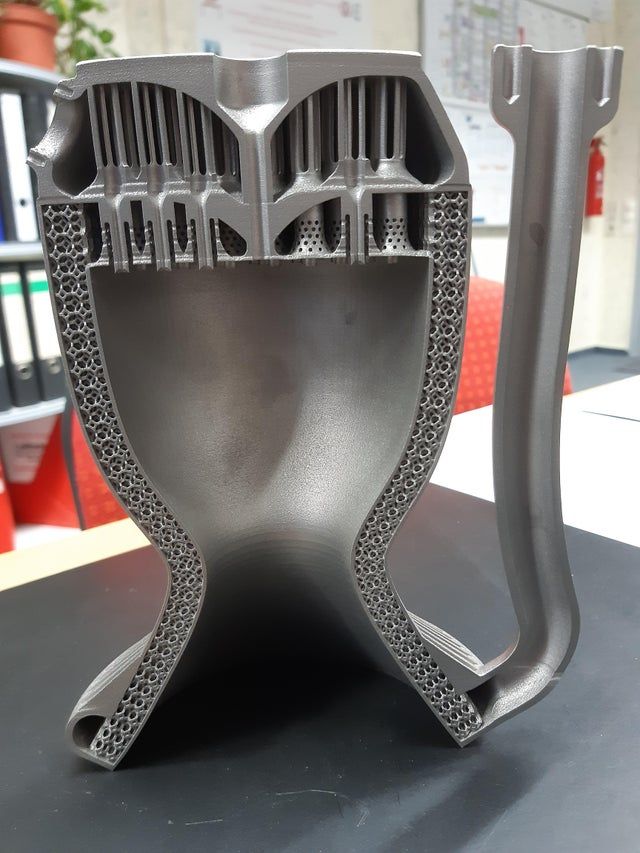

The most commonly used technologies in mass production. They are also the most expensive. EBM stands for Electron Beam Melting - electron beam melting. During this process, the metal powder is exposed to a controlled electron beam. This flow melts the powder exactly along the contour of the model, thus forming the part.

DED stands for Directed Energy Deposition and translates as "direct deposition". With this technology, the building material (metal powder) and the energy for its fusion are supplied simultaneously to the place where the model is built. The energy is a laser or electron beam.

What can be achieved with these technologies:

- High strength parts;

- Metal quality better than cast;

- Ideal homogeneous structure;

- High manufacturing precision;

- Ability to create a part from scratch or restore an existing one;

- Ability to change and modify the product.

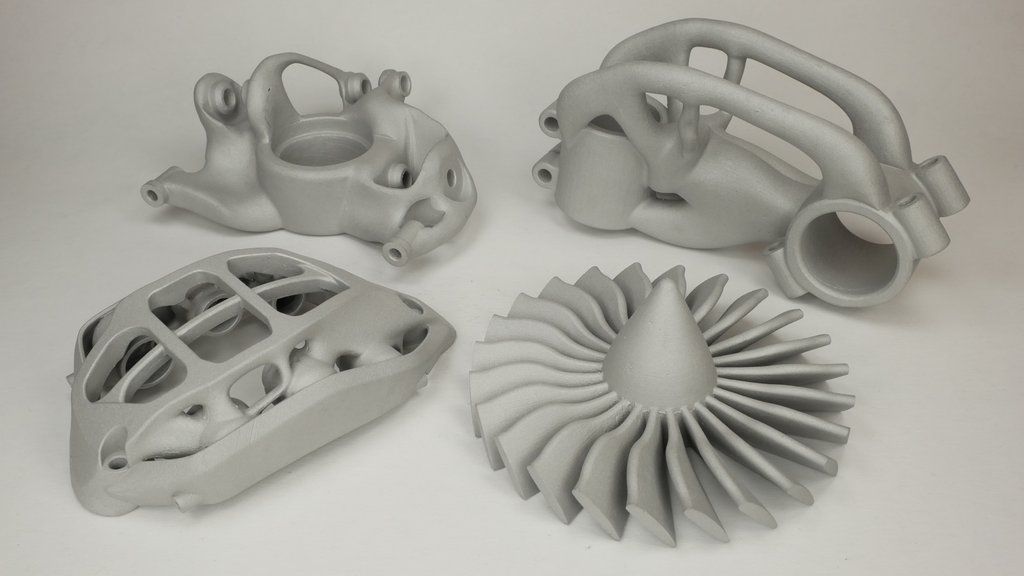

SLM and SLS

SLM stands for selective laser melting. This technology is used more widely, although it is less accurate than the previous two.

Interesting fact: Mercedes-Benz uses this technology to manufacture many spare parts. Moreover, the automaker plans to create parts in this way not only for new car models, but also for existing lines. Thus, replacing old spare parts for foreign cars, you get an original created using the latest technology.

Thus, replacing old spare parts for foreign cars, you get an original created using the latest technology.

SLS, or selective laser sintering, is the same technology, only it is used for plastic parts and translates as "laser sintering".

Both technologies work on the same principle: layer-by-layer melting of the powder under the influence of a laser beam. What is the result:

- Homogeneous composition of the part;

- Mechanical characteristics as cast;

- High precision geometrically complex parts.

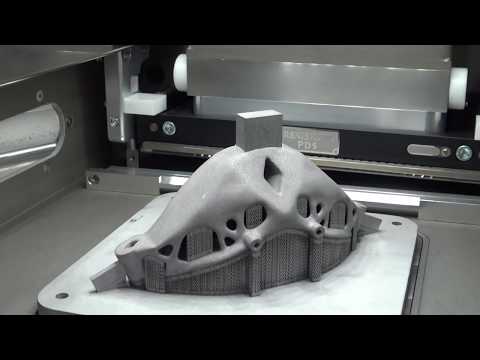

DMLS

Direct Metal Laser Sintering The laser acts on the metal powder, the layer of which is leveled in the working chamber, melting it and creating the necessary geometric shape. Then the next layer of powder is fed, it melts, connecting with the previous one. This is how the detail is created layer by layer. The unmelted powder remains in the chamber and can then be collected and reused, making the technology waste-free.

Advantages:

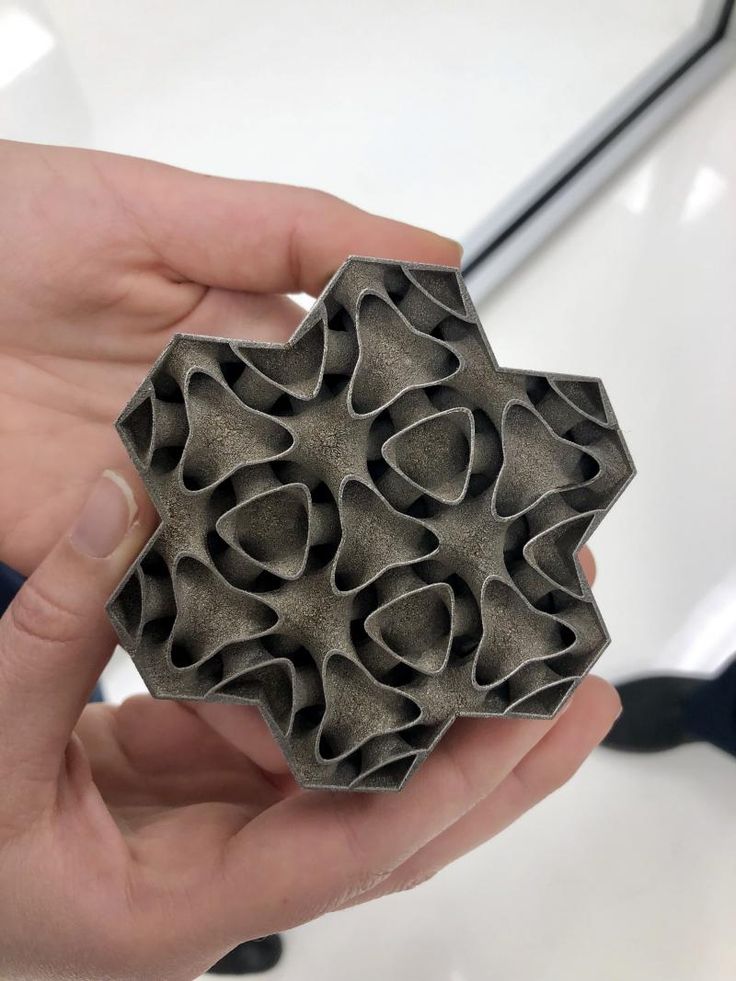

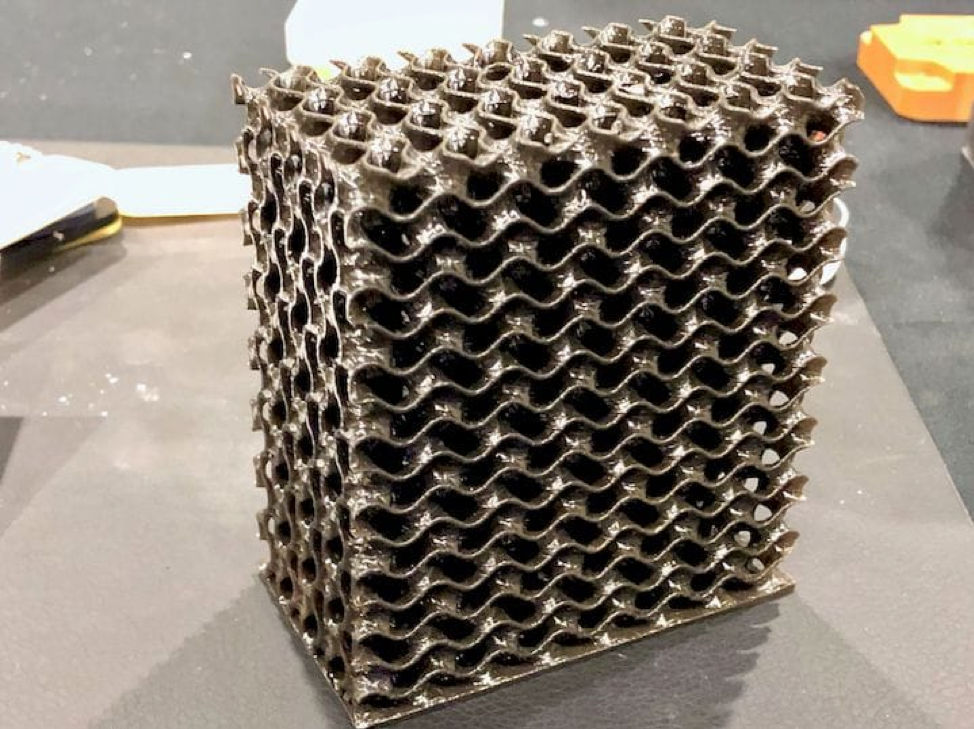

- Allows the creation of geometrically very complex parts;

- It is possible to produce several parts at the same time;

- High precision finished products;

- No need to build supports for overhanging elements - its role is performed by unspent powder in the chamber;

- The process takes less time compared to previous technologies.

Some parts in the Super Draco engine from Elon Musk's company are built using this technology. Inconel alloy powder was used as the material.

Binder Jetting (DoP)

Also known as Drop on Powder. Its principle of operation differs significantly from those listed above. Thin layers of powder are interconnected by a special binder, that is, the particles of the material are simply glued together.

This 3D printing is much cheaper and suitable for small production volumes. It is effective not only in working with metals and plastics, but also, for example, with gypsum and sand. To connect all the metal particles together, they can be "baked" after creation.

To connect all the metal particles together, they can be "baked" after creation.

Naturally, the quality of the part will be lower, but the technology is inexpensive and allows you to create parts from composite materials.

Summing up

Obviously, 3D printing is actively developing today and has penetrated into the automotive industry. If already today auto parts can be simply “printed out”, then in the near future the spare parts market will change a lot. After all, technology allows you to quickly and profitably produce any component, from almost any material, without restrictions on shape and size. In this case, the part will be absolutely identical to the original.

It is quite possible that soon all of us, when choosing parts, will pay attention not only to its quality and manufacturer, but also to what metal the powder for its manufacture was made of and which 3D printer was used.

5 ways 3D printing is changing the automotive industry

You can't buy a fully 3D printed car at a car dealership yet, but additive technologies have been used in car design for many years. Every year, especially in recent years, 3D printing is taking an increasingly important place at all stages of production. This is evidenced by the rapid growth of 3D printing market share in automotive manufacturing, which is projected to reach $2.5 billion by 2023.

Every year, especially in recent years, 3D printing is taking an increasingly important place at all stages of production. This is evidenced by the rapid growth of 3D printing market share in automotive manufacturing, which is projected to reach $2.5 billion by 2023.

For example, luxury car companies including Bentley, Porsche, BMW and Ferrari are using 3D printing to create custom car interior parts. GM, Volvo, Ford are using 3D printing to produce tooling to save money, improve designs and reduce delivery times.

Source 3dprinting.com

3D printing is constantly emerging with new opportunities, it is becoming more accessible. If the first 3D printers cost about $20,000, now you can find 3D equipment for $100. Now companies can, with the help of additive technologies, produce the necessary components directly at their own enterprises and not depend on suppliers.

With new materials, 3D printers can print high-precision, functional end parts. Additive technologies facilitate the production of custom products and increase productivity.

But this is only the beginning of the journey. Here are five key ways 3D printing is driving innovation in the automotive industry, from car design to production. Plus one bonus.

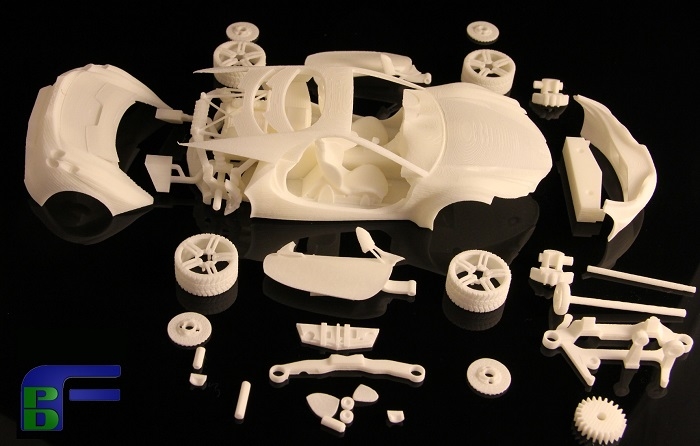

1. Changing the prototyping process

It was with the production of prototypes that the use of 3D printers in the automotive industry began. 3D printed prototypes took much less time than traditional methods required.

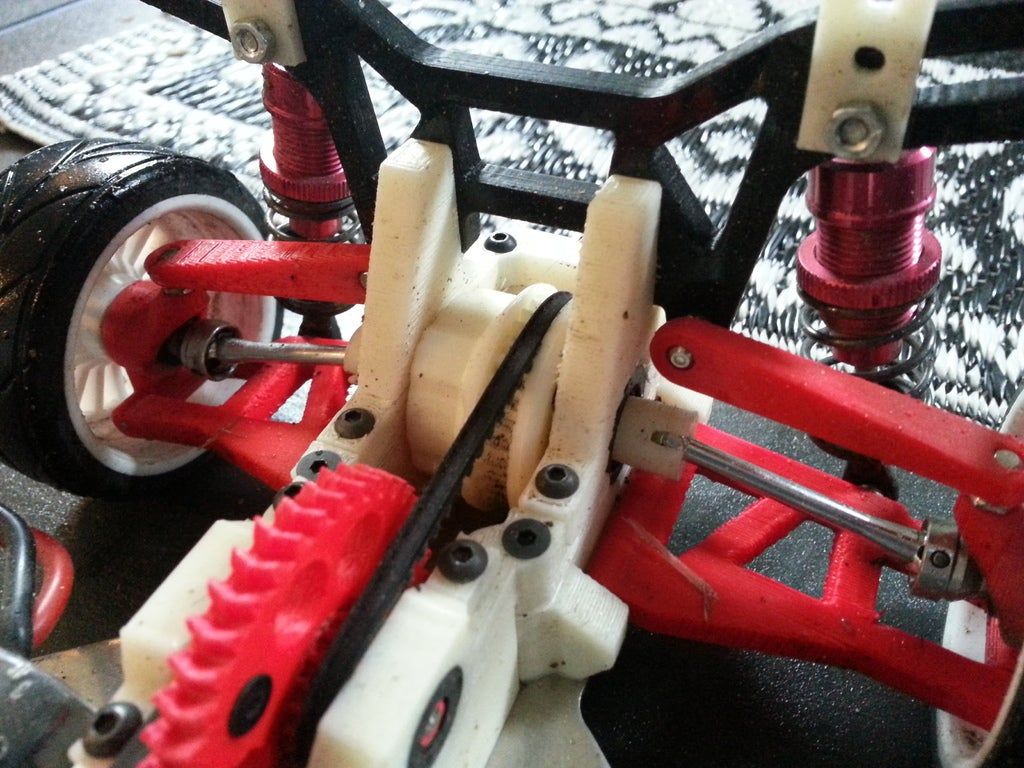

Using Raise3D 3D printers and ideaMaker software, Crazy Grandpa Garage was able to automate the process of creating custom car parts. Production costs have been reduced by 50%, design reliability has improved significantly, and lead time has been reduced by 83%. The parts now come out very well fitted to the car.

Source: facebo ok.com

Using 3D printing, car designers can quickly prototype individual parts or assemblies, from interior detail to dashboard, or even full-size car models. Thanks to 3D prototyping, the initial idea quickly turns into a physical embodiment of the concept - a conceptual model..jpg) The concept can then be developed into full-featured, high-fidelity prototypes, and after several validation steps, mass production begins. For the automotive industry, getting through these steps quickly is vital, and the entire downtime of an automobile production line in just an hour is very costly for the company.

The concept can then be developed into full-featured, high-fidelity prototypes, and after several validation steps, mass production begins. For the automotive industry, getting through these steps quickly is vital, and the entire downtime of an automobile production line in just an hour is very costly for the company.

For example, the assembly plant of the American car manufacturer General Motors claims to have saved more than $300,000 by purchasing a 3D printer in 2016.

Ringbrothers designers and engineers are not dependent on third parties to implement laser stereolithography (SLA) in their facility. The cost is reduced, the development time is reduced. Source: formlabs.com

Tailpipes for BMW M4 by Eventuri, Source: ultimaker.com

Traditional prototyping was time consuming and costly, in part because the product went through more iterations. With 3D printing, you can create high-quality prototypes in one day and at a much lower cost. More examples.

More examples.

The Ford Fiesta ST with 3D printed parts, ext. SEMA 2016, ultimaker.com

For example, General Motors has partnered with Autodesk to produce low-cost, lightweight automotive parts using 3D printers. Tools, fixtures and fittings can now be produced at a fraction of the cost, according to Autodesk. For example, a 3D printed tool used to align engine and transmission ID numbers costs less than $3 at General Motors. A traditionally produced instrument will cost $3,000. In addition, downtime due to faulty tools can be significantly reduced as new tools are produced in-house.

2. Creating custom and complex parts

Daihatsu, Japan's oldest car manufacturer, launched a project in 2016 to customize its Copen model.

Source: 3dprint.com

In partnership with Stratasys, Daihatsu customers can design and order custom 3D printed panels for their front and rear bumpers, with a choice of over 15 basic patterns in 10 different colors.

Source: 3dprint.com

In Europe, the BMW MINI brand also uses 3D printing to create personalized car parts. Since the beginning of 2018, MINI customers have been able to personalize various trim elements such as the instrument panel, LED treadplates and illuminated bumpers, as well as choose from different colors and textures. These parts are then 3D printed using a range of technologies from DLS Carbon to SLS.

Source: formlabs.com

Volkswagen Motorsport's I.D. R Pikes Peak is designed with over 2000 3D printed test parts.

Source amfg.ai

The use of 3D printers makes it possible to experiment in the development of non-standard designs, reduces the cost of their production. Long production processes for custom-made products are becoming much shorter.

Ringbrothers uses 3D printing to create customized end pieces such as ventilation grilles. Source: formlabs.com

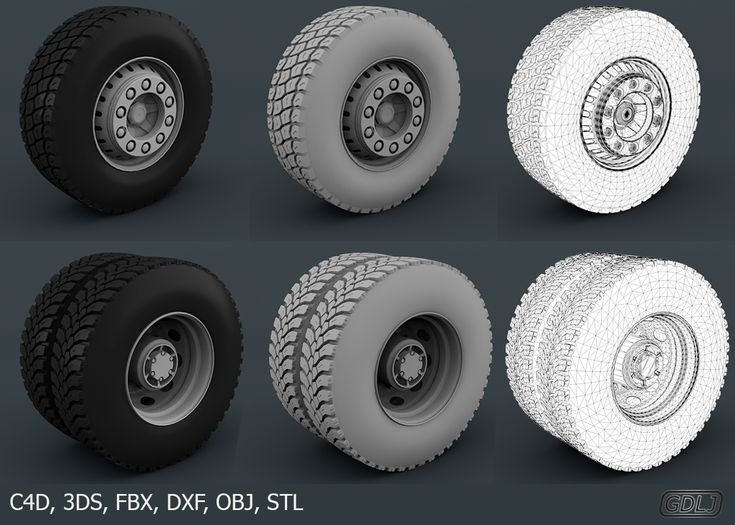

Large companies are merging 3D printing technologies with traditional manufacturing methods. Volkswagen has recreated its iconic 1962 Microbus by replacing the petrol engine with a 120 hp electric one. The Type 20 concept electric minivan has received many improvements using 3D printed parts. These improvements include cast aluminum wheels. Even the wheel hubcaps, while looking like stamped steel, are actually printed on a Formlabs SLA 3D printer, then electroplated and polished.

Volkswagen has recreated its iconic 1962 Microbus by replacing the petrol engine with a 120 hp electric one. The Type 20 concept electric minivan has received many improvements using 3D printed parts. These improvements include cast aluminum wheels. Even the wheel hubcaps, while looking like stamped steel, are actually printed on a Formlabs SLA 3D printer, then electroplated and polished.

Source: formlabs.com

Formlabs Form 2 SLA Specifications

Source: top3dshop.ru

The Bentley Speed 6 is another example. Bentley has used cutting-edge metal 3D printer technology to produce a grille, side vents, door handles and exhaust pipes much more complex than those used on current production models.

Bentley used metal 3D printing to create intricate micron precision parts. Source: formlabs.com

Bugatti's monobloc brake caliper is a prime example. For some components, Bugatti would have preferred titanium due to its high performance, but processing this metal with traditional methods is expensive and difficult. 3D printing has allowed Bugatti to produce a titanium alloy brake caliper. Due to the thin walls, the caliper turned out to be very light - almost two times lighter than forged aluminum. At the same time, the strength of the 3D-printed monoblock is superior to that of aluminum. The 3D printed titanium monoblock has a tensile strength of 1250 N/mm2. This means that a force of just over 125 kg will be applied per square millimeter of this titanium alloy without tearing the material. The new titanium caliper is 41 cm long, 21 cm wide and 13.6 cm high and weighs only 2.9kg compared to currently used aluminum, which weighs 4.9 kg.

For some components, Bugatti would have preferred titanium due to its high performance, but processing this metal with traditional methods is expensive and difficult. 3D printing has allowed Bugatti to produce a titanium alloy brake caliper. Due to the thin walls, the caliper turned out to be very light - almost two times lighter than forged aluminum. At the same time, the strength of the 3D-printed monoblock is superior to that of aluminum. The 3D printed titanium monoblock has a tensile strength of 1250 N/mm2. This means that a force of just over 125 kg will be applied per square millimeter of this titanium alloy without tearing the material. The new titanium caliper is 41 cm long, 21 cm wide and 13.6 cm high and weighs only 2.9kg compared to currently used aluminum, which weighs 4.9 kg.

The Bugatti Brake Monobloc is the industry's largest functional 3D printed titanium vehicle component. Source: formlabs.com

Source: formlabs.com

3. Tool and fixture making

A variety of fixtures help make manufacturing and assembly processes easier and faster, and improve worker safety. Automotive factories and component suppliers use a large number of non-standard tooling that is specifically designed and optimized for end use. As a result, a lot of non-standard equipment and tools are made, which increases production costs.

This 3D protective wheel disc was purchased for 800 euros but can now be printed for just 21 euros. Tool development time has been reduced from 56 to 10 days.

Source: ultimaker.com

Outsourcing custom tooling and fixtures to service providers who machine parts from solid metal or plastic stock can delay production by weeks.

For example, the development and prototype of a commutator motor using traditional manufacturing methods can take up to four months and cost about half a million dollars. Thanks to 3D printing, Ford was able to develop several variants in just 4 days and 99. 4% cheaper - only $3,000.

4% cheaper - only $3,000.

Additive technologies allow you to complete the task in a few hours and significantly reduce costs compared to ordering from a third-party enterprise. Since increasing the complexity of a 3D printed model does not incur additional costs, products can be better optimized for their application. New elastic materials for 3D printing in many cases allow you to print plastic parts instead of metal or create prototypes on a 3D printer to test the tool before using it in production.

Gradually, the production of 3D printed accessories and tools is becoming one of the largest applications of additive technologies.

Pankl Racing Systems uses 3D printed fixtures to attach workpieces to a conveyor belt. Source: formlabs.com

For example, Pankl Racing Systems uses multiple Formlabs SLA 3D printers to make critical manufacturing tools. The multi-stage production of parts for transmissions on automatic lathes requires a series of fixtures and tools designed for each specific part.

The multi-stage production of parts for transmissions on automatic lathes requires a series of fixtures and tools designed for each specific part.

With the help of 3D printing, Pankl's engineers have reduced the production time for the aids by 90%, from 2-3 weeks to around 20 hours. Costs were also reduced by 80-90%, saving $150,000.

The transition to 3D printing has enabled Volkswagen Autoeuropa to cut tooling development costs by 91% and tooling time by 95%.

4. Solving problems with spare parts

Spare parts have always been a problem for the automotive industry. The demand for them is either there or not, so the production of spare parts is not economically viable, and the storage of pre-fabricated replacement components is also costly. But if there are no repair parts available, difficulties arise and the main product becomes less valuable.

3D printing could solve the problem of parts in the automotive industry in many ways. The main factors are printed materials, which can match the characteristics of traditional materials used in parts and be cost-effective. There are prerequisites for this.

The main factors are printed materials, which can match the characteristics of traditional materials used in parts and be cost-effective. There are prerequisites for this.

Using computer-aided design, drawings of all parts can be stored digitally, so there is no need to store the parts themselves. The parts needed by the client can be printed on a 3D printer right in the workshop.

Even obsolete parts whose drawings have not survived can in principle be recreated by making a 3D scan of existing parts of this type and applying reverse engineering (reverse engineering). You can read more about this on our blog. Old projects can take on new life. There are many lovers of vintage cars, with the help of 3D printing it would be possible to create parts for them.

Ringbrother 3D printed the Cadillac emblem for a custom built old car. Source: formlabs.com

5. Production of standard parts

As 3D printers and materials for 3D printing become more affordable, a gradual transition to the production of mass-produced automotive parts using additive technologies is possible.

3D printing makes it possible to combine components into a single whole. Let's say there is a mechanism assembled from six or seven car parts that can be combined into one printed part. It will save time and assembly costs. With 3D printing, it is also possible to reduce the weight of the combined assembly, as a result, the car will use fuel more efficiently.

3D Systems has developed an advanced exhaust pipe for a sport bike. In the image below, you will see 20 sheet metal and hydroformed parts needed to assemble the original exhaust pipe. On the right is a monolithic exhaust pipe that does not require assembly, made using metal 3D printing.

Source: designnews.com

The 3D printed tube was produced using Grade23 titanium in just 23 hours, compared to three weeks for traditional production. Design development time reduced from 6 weeks to 6 days. Additive manufacturing also eliminates the need for tooling, fixtures, multiple welding and multiple inspections.

Geometry optimization has reduced the amount of material required for maximum productivity. All elements of the original exhaust pipe are incorporated into the new design and, when printed with a typical wall thickness of 0.5mm, the 3D printed exhaust pipe is about 25% lighter than the original one.

A wide range of 3D printing materials is beginning to meet the requirements of various vehicle components. Since additive methods reduce costs compared to traditional methods (such as molding and injection molding), it makes a lot of sense from a production and financial point of view to further introduce 3D printing into the production of basic parts.

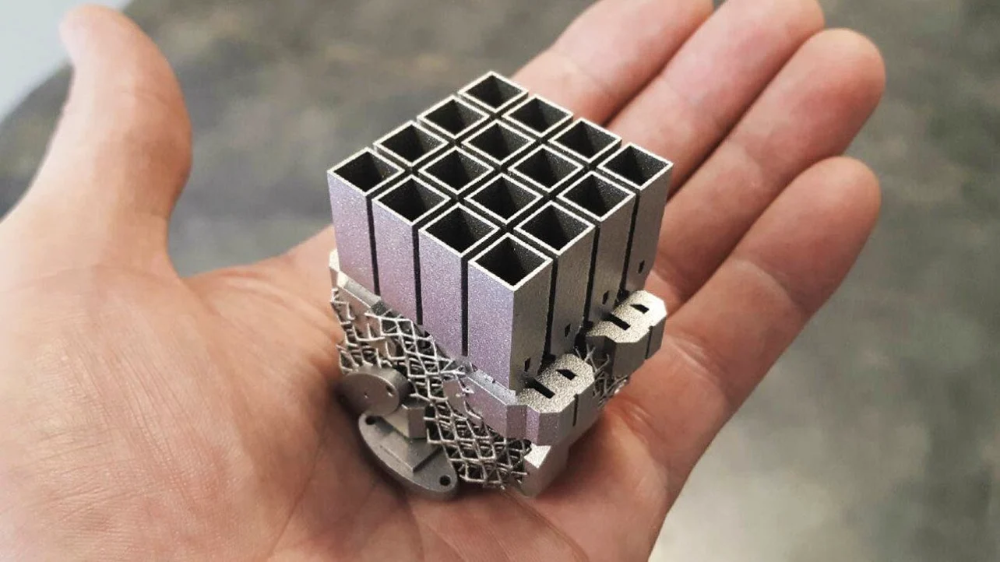

Volkswagen, one of the world's largest and most innovative car manufacturers, is using an HP Metal Jet 3D printer to produce high-performance functional parts with special design requirements, such as shift knobs and mirror mounts. Volkswagen's long-term plans to work with HP include accelerating the production of mass-customized parts such as key rings and exterior nameplates.

+1. 3D Printed Cars

Although complete 3D printed cars have yet to hit the market, some interesting designs and concepts are suggestive of a possible direction for the automotive industry.

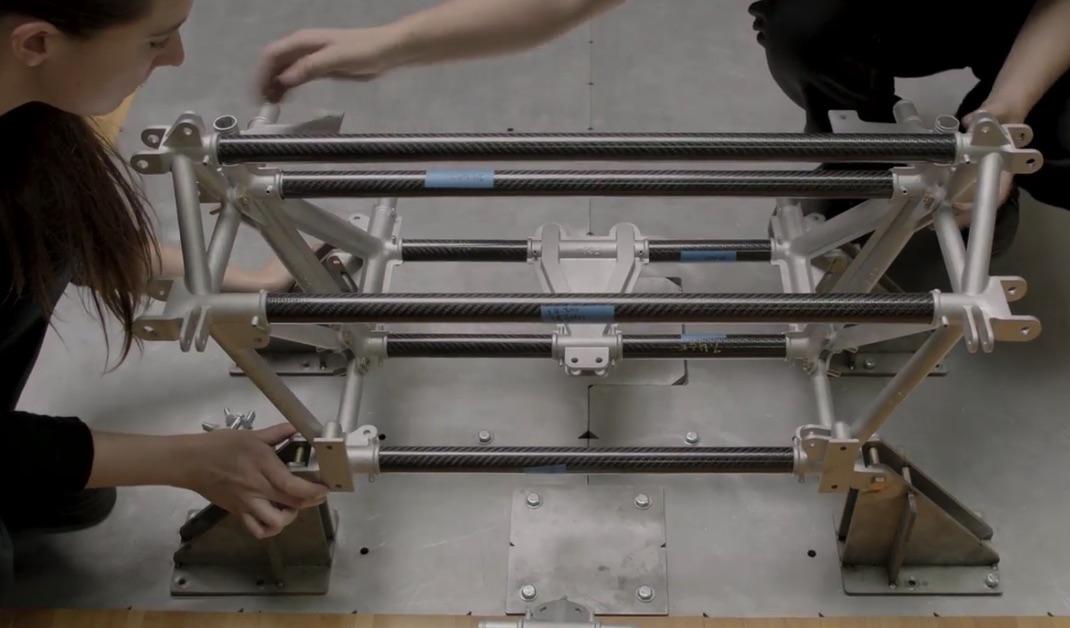

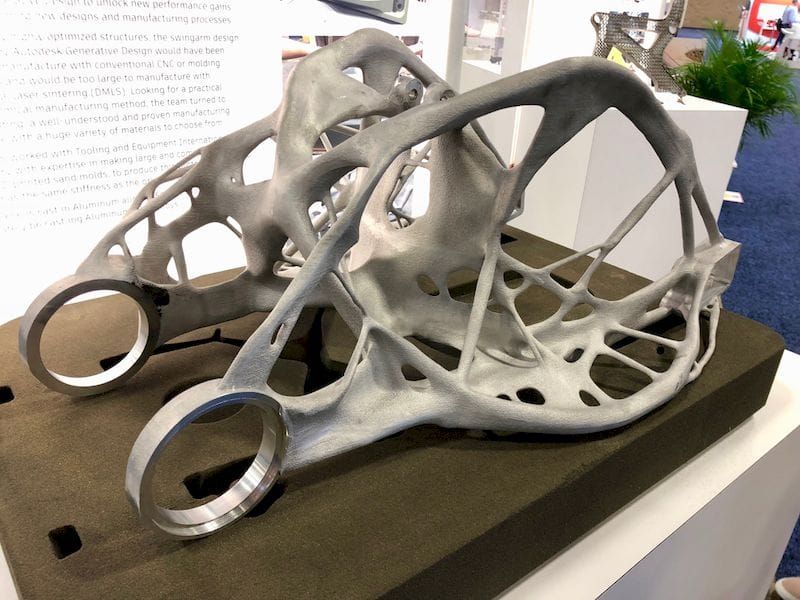

Light Cocoon. German engineering firm EDAG was clearly inspired by nature to create the 3D printed supporting structure of the Light Cocoon concept car. The frame resembles the veins of a tree leaf or its branch. Despite the fact that the design of the EDAG took less material than a conventional frame, all the strength requirements for structurally significant components are met. Outside, the case is covered with a lightweight and durable waterproof fabric.

The cover protects the EDAG Light Cocoon from the weather and gives the car a unique personality. Source: formlabs.com

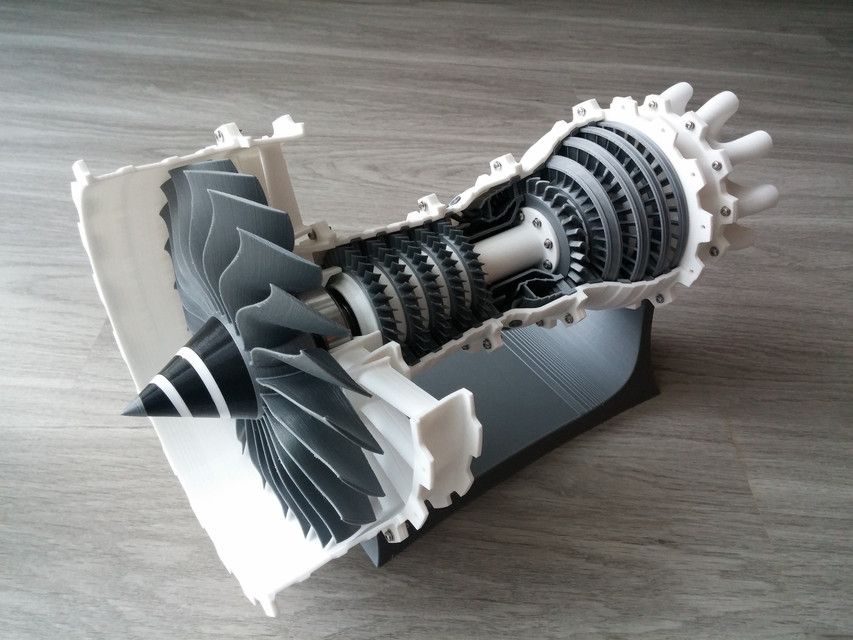

Blade . Blade ("Blade") announced as "the world's first 3D-printed supercar. " It meets supercar standards but is made from inexpensive materials: carbon fiber tubes and aluminum rods, combined with 3D printed metal parts. Blade turned out to be very light and does not take long to assemble.

" It meets supercar standards but is made from inexpensive materials: carbon fiber tubes and aluminum rods, combined with 3D printed metal parts. Blade turned out to be very light and does not take long to assemble.

The world's first 3D printed Blade supercar. Source: formlabs.com

Strati . The American company Local Motors 3D printed and assembled the Strati electric car right at the exhibition stand, in just 44 hours. Most of the components were printed - the body, seats, interior parts. A car is made up of less than 50 assemblies, far fewer than the thousands of parts that go into a traditional car. The company intends to reduce the print time to 10 hours.

The Strati from Local Motors consists of less than 50 individual parts*. Source: formlabs.com

LSEV . Developed by the Italian company XEV, the LSEV could be the first in the 3D printed electric vehicle market when it goes on sale. The 3D printed chassis, seats, windshield and all visible parts of the LSEV.