Color jet printing 3d

ColorJet Printing (CJP)/ZPrinting » 3D Printing Media Network

Stay up to date with everything that is happening in the wonderful world of AM via our LinkedIn community.

In 1993, Binder Jetting technology was developed at the Massachusetts Institute of Technology. One of the licensee of the technology was Zcorp or Zcoproration, which named built 3D printers based on binder jetting and renamed the technology Zprinitng (as in printing on the Z axis). When Zcopr was acquired by 3D Systems, the stereolithography market leader, in the early 2000’s, the company began offering binder systems and renamed its technology Color Jet Printing (CJP) since, with the addition of an inkjet head, it was able to color outer layer, and thus the surface of the parts.

| Advantages | Disadvantages |

|---|---|

|

|

|

|

|

|

How does ColorJet Printing/Zprinting work?

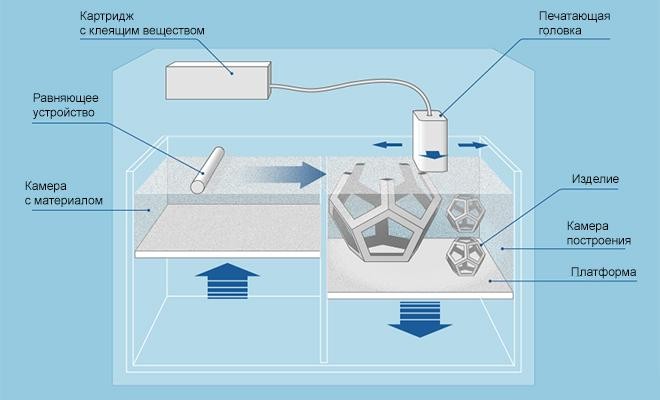

As in many other rapid prototyping processes, in CJP/Zprinting the part to be printed is built up from many thin cross-sections of the 3D model. In ZPrinters, an inkjet-like printing head moves across a bed of powder, selectively depositing a liquid binding material in the shape of the section. A fresh layer of powder is spread across the top of the model, and the process is repeated. When the model is complete, unbound powder is automatically removed. Parts can be built on a ZPrinter at a rate of approximately 1 vertical inch per hour, which makes it one of the fastest technologies available today. In Color Jet Printing, the outer edge of each layer is colored resulting in fully colored final objects.

Available CJP/ZPrint 3D printers:

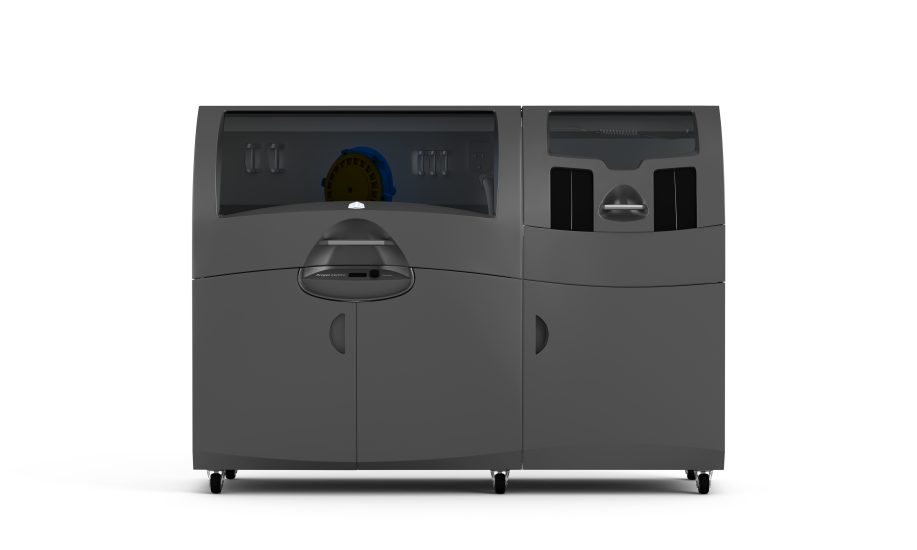

While ceramics materials are still used mainly in legacy Zcorp 310 and 510 systems, due to their high accessibility in terms of cost (used systems are available for a few thousand dollars), the most advanced system to 3D print ceramics using Zprinting/CJP technology is the ProJet 660 Pro 3D printer from 3D Systems.

| Model | ProJet 660 Pro |

| Manufacturer | 3D Systems |

| Price | $60,000 |

| Technology | CJP/Zprint |

| Materials | Ceramics, Gypsum |

| Effective Build Volume | 200 x 200 x 250 |

| Layer Thickness | 100 μm |

You can find more information and the specifications for the machines here.

Further reading on 3D Systems and CJP/Zprint:

• SmarTech Issues First Report on Traditional and Technical Ceramics AM

• Underperforming 3D Systems Still Sold $153M Worth of AM in Q3

• Ceramics, Breaking Through the Next 3D Printing Material Frontier / Part 2

Colorjet Printing

Printing Tehnique

Printing technique

ColorJet Printing technology (CJP) makes it possible to make ready-to-use parts.

It uses two essential components: durable, flexible and robust Visijet C4 Spectrum plastic, and cyan, magenta and yellow binders that incorporate pixel-to-pixel colors, creating nearly one million unique colors.

The material in the form of powder is applied in thin layers on the manufacturing platform by a roller.

After the application of each of the layers of material, the color binder is selectively projected by the ink-jet printheads thereon, thereby solidifying the material.

The manufacturing platform lowers after each of the successive layers of material and binder, until the model is finished.

ColorJet Printing technology (CJP) allows to print ready-to-use parts.

It uses two essential components: Visijet C4 Spectrum powder a durable, flexible and robust plastic, and Binders (transparent,cyan, magenta and yellow) that incorporate pixel-to-pixel colors, creating nearly one million unique colors.

The material is applied in thin layers on the platform by a roller.

After the application of each of the layer of material, the color binder is selectively projected by the ink-jet printheads thereon, thereby solidifying the material.

The manufacturing platform lowers after each of the successive layers of material and binder, until the model is finished.

We offer 4 types of finishes for the Visijet C4 Spectrum material:

Shiny varnish finish: the object is covered by spraying with 2 coats of varnish in order to obtain a perfect shine.

Satin varnish finish: the object is covered by spraying with 2 coats of varnish in order to obtain a slight gloss.

Matt varnish finish: the object is covered by spraying with 2 coats of varnish in order to obtain a raw appearance while protecting it from shocks.

Rough finish: the object is cleaned, the appearance to the touch is granular and can not be sanded without being damaged.

Finishing Primer: The object is sprayed with a transparent Primer which will reduce its porosity.

We offer 5 types of finishes for the Visijet C4 Spectrum material:

- Shiny varnish finish: the object is covered by spraying with 2 coats of varnish in order to obtain a perfect shine.

- Satin varnish finish: the object is covered by spraying with 2 coats of varnish in order to obtain a slight gloss.

- Matt varnish finish: the object is covered by spraying with 2 coats of varnish in order to obtain a raw appearance while protecting it from shocks.

- Standard finish: the object is cleaned, the appearance to the touch is granular and can not be sanded without being damaged.

- Finishing Primer: The object is sprayed with a transparent Primer which will reduce its porosity.

Minimum thickness of the details of your object on our 3D printers Projet 4500:

It is important when designing your object under a 3D design software to consider the minimum thickness for printing on our Projet 4500 3D printers.

- Minimum thickness of the fine elements assembled: 1mm

Minimum thickness of the details of your object on our 3D printers Projet 4500:

It is important when designing your object under a 3D design software to consider the minimum thickness for printing on our Projet 4500 3D printers.

- Minimum thickness of the fine elements assembled: 1mm

- Minimum thickness of the fine elements unassembled: 2mm

- Minimum thickness of the fine elements unassembled: 2mm

Assembled elements with reinforcements.

Assembled elements with reinforcements.

Unassembled elements with reinforcements.

Pricing

The price depends on the design and volume of your object.But Mainly 3 Diferent parameters are used to calculate pricing: Material volume,printing time,printing tray take up.

Remember to optimize your part when designing, for example to hollow out the part through strategically positioned holesso that taht allows us to extract the unfused powder .

This will give you a more competitive price and a lighter item.

Mainly 3 Diferent parameters are used to calculate pricing: Material volume,printing time and printing tray take up.

Remember to optimize your part when designing, for example to hollow out the part through strategically positioned holes to allows us to extract the unfused powder to get a more competitive price and a lighter item.

Color Inkjet (CJP)

- 1 CJP Technology

- 2 Process

- 3 Materials

- 4 Application

- 5 Other additive manufacturing technologies

CJP technology

Color inkjet printing (CJP) is a type of 3D inkjet printing (3DP) proprietary technology from 3D Systems.

Process

3D Systems ProJet 660 Professional CJP Printer

As with 3D inkjet printing (3DP), CJP technology involves the application of thin layers of powdered consumables, followed by selective application of a binder polymer. A distinctive feature of the technology is the use of multi-colored connecting elements, which allows you to create complex color 3D models.

Unused materials are not removed from the working chamber during the process, but serve as a support for subsequent layers, which allows you to create objects of high geometric complexity. However, at the end of the print cycle, the residual powder can be collected and reused.

However, at the end of the print cycle, the residual powder can be collected and reused.

Materials

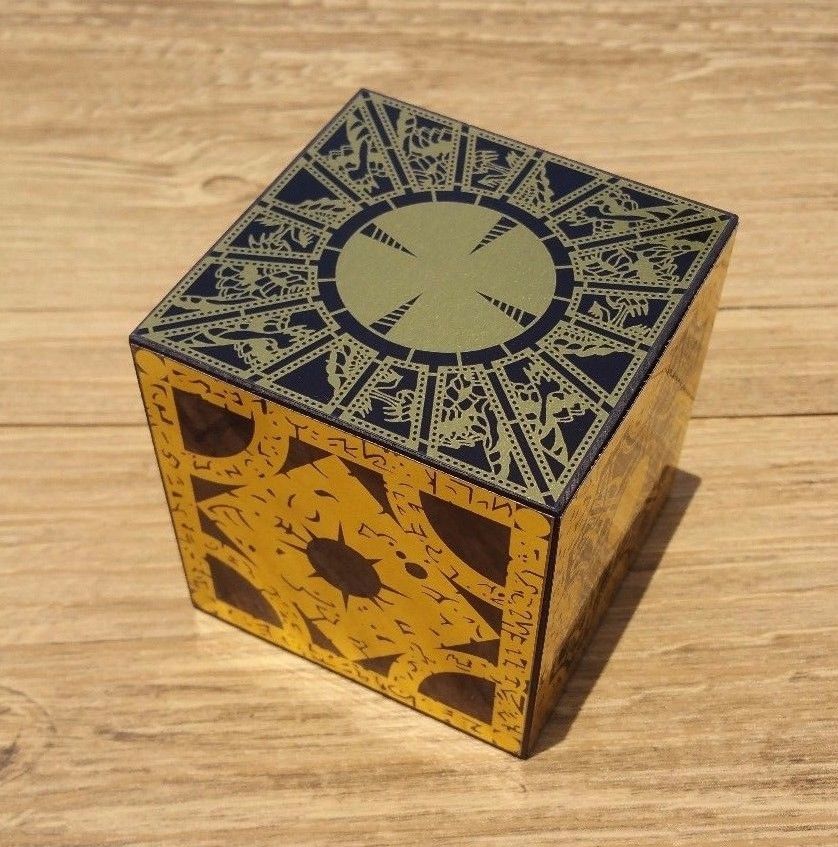

Color tires created with the 3D Systems ProJet 660 CJP printer

Plastics with various mechanical properties imitating rubber, impact-resistant thermoplastics and other materials are used as consumables.

For example, 3D Systems CJP printers use VisiJet PXL impregnated with ColorBond (to strengthen color models), StrengthMax (high strength impregnation for functional models), or Salt Water Cure (environmentally friendly impregnation to improve the strength of surface layers).

Application

Color inkjet (CJP) dolls used in the ParaNorman cartoon

Color inkjet printing (CJP) technology is mainly used for prototyping products of complex geometric shapes and colors, as well as for the production of small batches finished products.

The method is used in medicine, industrial design, education, architectural design and even puppet animation.

Due to the relatively high cost of CJP printers, this technology is not yet widely used in the home and is used mainly in professional environments. At the same time, CJP technology is much more affordable than using high-precision rapid prototyping methods such as selective laser sintering (SLS) and more versatile in terms of creating color models than laser stereolithography (SLA).

Other additive manufacturing technologies

- Mask stereolithography (SGC)

- Multi-Jet Simulation (MJM) Technology

- Digital LED Projection (DLP)

- 3D Inkjet Printing (3DP)

- Selective Laser Sintering (SLS)

- Selective laser melting (SLM)

- Stereolithography (SLA)

- Selective heat sintering (SHS)

- Lamination Object Manufacturing (LOM)

- Electron Beam Melting (EBM)

- Direct Metal Laser Sintering (DMLS)

- Electron Beam Fusion Manufacturing (EBFȝ)

- Fused Deposition Modeling (FDM)

Go to the main page of Encyclopedia of 3D printing

Color Inkjet Printing (CJP) by Sprint 3D

Color Inkjet Printing (CJP)

Color Inkjet Printing or ColorJet Printing (CJP) is a new color inkjet 3D printing technology used to create full color demonstration and concept models. It is actively used in architecture, science, healthcare and other branches of human activity.

It is actively used in architecture, science, healthcare and other branches of human activity.

Thanks to its flexible settings, color inkjet printing offers a high level of variability. You can create a variety of models:

- color and monochrome;

- Rough and smooth coated.

Models produced with CJP technology allow you to better convey the style and design of the product, create the necessary accents and realize complex projects in a shorter time than before. And the SPRINT3D team provides this service to its customers.

Color Inkjet 3D Printing (CJP) Examples

Materials and Printing Process

CJP printing uses plastics with different mechanical properties. They can be impact-resistant, heat-resistant, imitate other materials, etc. This, in turn, adds even more variability in production.

To strengthen products, special impregnations can be used to increase strength, protecting them from moisture and other external factors.

Direct CJP printing is almost identical to classic 3D inkjet printing. Thin layers of powdered material are layer-by-layer applied to each other using a special binder polymer. The main difference of the technology is a large selection of colors of binder polymers, which allows you to create models that could not be obtained with 3DP printing.

An important feature of the technology is that unused materials are not removed from the working chamber during printing. They serve as a support for the following layers. This allows you to further improve the accuracy of products and geometric correctness. Residual material is removed after printing is completed, after which it can be reused. Accordingly, waste minimization makes color inkjet printing more economical.

Where color inkjet printing is currently used

CJP's main area of application is prototyping products with complex geometric shapes and a variety of colors. The technology is also applicable in the manufacture of small-scale batches of products.