Existing patents on 3d printers

3d Printer Patents | UpCounsel 2022

Technologies and inventions that facilitate the 3D printing process are legally protected from the use of others by 3D printer patents.3 min read

1. 3D Printer Patents

2. More 3D Printing Patents Expiring

3. How Expiring Patents Are Ushering in the Next Generation of 3D Printing

Updated November 24, 2020:

3D Printer Patents

Technologies and inventions that facilitate the 3D printing process are legally protected from the use of others by 3D printer patents. Within the past few years, controversy arose about the simultaneous expiration of many critical 3D printing patents.

Opponents spoke out against the conventional idea that patents create competition by forcing others to invent workarounds for protected inventions and intellectual property. They argued that 3D printing patents prevent innovation since companies and individuals may avoid creating similar technologies and investing in research and development in the 3D printing industry for fear of being sued. They believe that this may have hurt the progress of this technology by barring new players from entering the market, reducing competition, and inflating prices.

Between 2013 and 2015, patent protection expired for several nascent 3D printing inventions. While new 3D printers based on these technologies have been created by several different companies since 2015, it is unclear whether this occurred as a direct result of the end date of these patents.

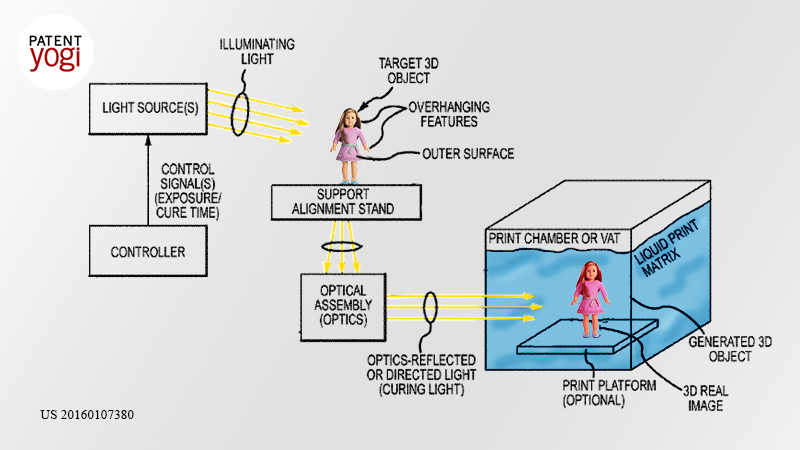

In 2016, the first product by new 3D printing company Carbon was announced. This creation, the Carbon M1, takes advantage of the company's Continuous Liquid Interface Product, or CLIP, which some believe is a derivative of an early VPP 3D printing patent. However, the two patent applications filed for CLIP at the end of 2014 indicate that this is not the case. Since PBF patents expired, new companies have begun to offer low-cost versions of this type of 3D printer, but again, whether this directly resulted from the patent expiration is unclear. Two of these companies are Sinterit and Norge Systems.

Two of these companies are Sinterit and Norge Systems.

In 2014, Norge Systems began an ultimately unsuccessful fundraising campaign via the online community Kickstarter for two affordable home PBF printer models. After the failure of this campaign, the company was bought out by another company and never released a consumer-grade 3D printer. Sinterit recently released an affordable 3D printer called Lisa, but it is unclear as of yet whether this product will ultimately be a commercial success.

More 3D Printing Patents Expiring

The following 3D printing patents will expire within the next few years, listed in order of the soonest expiration date.

- A McAlea patent for a process for 3D fabrication that involves repeatedly dispensing and fusing layers of powder that consists of spherical particles.

- A Lohner and Wilkening patent for an apparatus that can 3D print objects using radiation. The invention has a removable base that facilitates faster creation time for 3D prototypes.

- A patent granted to Russell for an apparatus that can 3D print from a stored memory.

- A Batchelder patent for a prototyping method for predetermined 3D shapes. It uses a thermal substance that becomes solid at a specific temperature.

- A patent granted to Manning for apparatuses and methods for laser sintering. The invention includes a powder spreading system that layers the substance onto a surface and a laser with a scanner that is used to direct the beam of light along a vector.

- A patent granted to Meiners for a manufacturing procedure that can be used for any molded body, including a product prototype or component, tool prototype, or spare part. It uses 3D CAD data to deposit metallic powder in layers to create the desired object.

- A Swanson et al. patent for a thin-wall tube liquefier. This invention uses an extruder to deposit layers of a solidifying material that can be used to create 3D objects.

How Expiring Patents Are Ushering in the Next Generation of 3D Printing

2016 has seen more 3D printing innovation than ever before. Although it's not yet clear whether this will be the next industrial revolution, we do know that we can expect the price of 3D printing to drop as the quality of the objects created increases. This development is directly related to the new accessibility of existing technologies as the patents for these 3D printing innovations expire. The companies who owned these original patents no longer have a monopoly on the 3D printer industry.

Although it's not yet clear whether this will be the next industrial revolution, we do know that we can expect the price of 3D printing to drop as the quality of the objects created increases. This development is directly related to the new accessibility of existing technologies as the patents for these 3D printing innovations expire. The companies who owned these original patents no longer have a monopoly on the 3D printer industry.

As with similar technologies, the new wave of 3D printing innovation is traveling from industry to the consumer and retail sectors. This wave includes metal, powder, and liquid-based methods for 3D printing.

If you need help with 3D printer patents, you can post your legal need on UpCounsel's marketplace. UpCounsel accepts only the top 5 percent of lawyers to its site. Lawyers on UpCounsel come from law schools such as Harvard Law and Yale Law and average 14 years of legal experience, including work with or on behalf of companies like Google, Menlo Ventures, and Airbnb.

3D Printing Patents landscape » 3D Printing Media Network

The scenario for 3D printing patents is as complex as one can imagine. Not only is 3D printing the most horizontal technology that exists, with specific patentable applications in just about every segment of manufacturing, but it also spans across multiple technology areas including mechanical (hardware), IT (software and automation) and material science. In addition, not only can 3D printing technologies be patented but also anything made with a 3D printer that was not made before (and most things have never been made before with a 3D printer). Finally, 3D printing can be used to easily copy patented (and copyrighted) products, adding more complexity to the legal landscape.

We all know that the success story of 3D printing officially began in 1984 when Charles W Hull applied for a patent for stereolithography. In 1989 S Scott Crump of Stratasys invented fused deposition modeling, which fuses material layer by layer until a 3D object is created. This style of additive manufacturing is what most people associate with 3D printing today. In 2009 the patent for fused deposition modeling expired and companies started to take a different approach by trying to sell to consumers instead of business to business. Together with the rise of Kickstarter, a perfect storm formed and hype around 3D printing in the early 2010s was born.

This style of additive manufacturing is what most people associate with 3D printing today. In 2009 the patent for fused deposition modeling expired and companies started to take a different approach by trying to sell to consumers instead of business to business. Together with the rise of Kickstarter, a perfect storm formed and hype around 3D printing in the early 2010s was born.

Top 3 owners of 3D printing patents. Please consult the IPlytics report for the full list of the top 10 companies. Source credit: IPlytics.

Several patent experts have undertaken the challenge of trying to clarify the 3D printing patent landscape and how it is evolving. SmarTech Analysis just released a fully comprehensive interactive report that will enable companies to easily search for and identify previously released metal AM patents. The report is going to be released shortly so stay tuned. In the meantime, a great resource to start learning about 3D printing patents is this free report from Tech Insights. It dates back to 2013 – which is an eternity in 3D printing – but it will give you a very detailed and full overview of everything that happened until then. More recently, German company IPlytics published a free report on the evolution of 3D printing patents and relative litigation.

It dates back to 2013 – which is an eternity in 3D printing – but it will give you a very detailed and full overview of everything that happened until then. More recently, German company IPlytics published a free report on the evolution of 3D printing patents and relative litigation.

This IPlytics report looks at additive manufacturing and 3D printing from an IP perspective, again demonstrating that 3D printing patents are on the rise. In order to identify 3D print-related patents, the IPlytics platform database performed an extensive keyword search of worldwide filed patents in the 3D-print technology field. The search was based on the patent’s content, making use of state-of-the-art stemming and semantic indexing methods. Between 2007 and 2019 the analysis identifies 95,302 patents and 43,718 patent families (unique patents in the INPADOC database) relevant for 3D printing. The report then goes on to identify the largest patent holders (spoiler: GE has the most, HP a close second) and the countries where the most 3D printing patents have been filed (spoiler: the US is first).

The number of 3D printing patent applications filed per year (source credit: IPlytics)

One very interesting chart is the one that concerns litigation cases: between 2000 and 2018 there have been 155 litigation cases in the United States in the 3D printing field. IPlytics found that from the 155 litigated patents in 3D printing a total of 71 (45%) have been transferred (reassigned) at some point in time. By comparing the date of the first transfer with the date of the first litigation the IPlytics platform was used to assess the transfer timing before or after the litigation took place. It turned out that 80% of all patents that have been both litigated and transferred have changed owners before the litigation, with 22.5% doing so within the same year.

3D printing patent litigation cases in the US (source credit: IPlytics)

Patenting is increasing sharply for 3D printing technologies. Further, 3D printing patents are increasingly transferred and litigated. Senior patent managers and patent directors involved in industries where 3D printing has an impact should constantly monitor this evolving situation. 3dpbm‘s AM Focus Patents intends to provide an updated patent landscape and an access point to the tools to help you do just that.

3dpbm‘s AM Focus Patents intends to provide an updated patent landscape and an access point to the tools to help you do just that.

-

Desktop Metal has completed the qualification of Grade 420 stainless steel (420 SS) for use on the Production System platform, which leverages patent-pending Single Pass JettingTM (SPJ) technology for high throughput AM production. Manufacturers can now leverage SPJ technology for the mass production of high-strength, end-use parts in 420 SS…

Read More -

Tethon Corporation Inc. (Tethon 3D) announces issuance and publication of the company’s U.S. patent number 11,126,088 “Photopolymer Development Resin Base for Use with Three-dimensional Printer” on September 21, 2021.

Read More Genesis resins are used as a composite matrix to create materials for ceramic AM via stereolithographic processes. The patented product line…

Genesis resins are used as a composite matrix to create materials for ceramic AM via stereolithographic processes. The patented product line… -

The Australian Patent Office has examined the Australian member of AML3D‘s International Patent Portfolio and has now granted the company an Australian patent for its Wire Additive Manufacturing (WAM) process. AML3D’s Australian patent provides coverage over the method and apparatus for manufacturing 3D metal parts. Key coverage items include the…

Read More -

Desktop Health, a service recently launched by Desktop Metal, received the Conformité Européenne (CE) Mark certification for its Flexcera resin, a proprietary technology for use in 3D fabrication of high-quality dental prosthetics. The CE Mark affirms that Flexcera resins meet the requirements of the European Medical Devices Directive, paving the…

Read More -

Global materials company Tethon Corporation (dba Tethon 3D), of Omaha Nebraska USA, received the US patent “Three-Dimensional Printed Objects with Optimized Particles for Sintering and Controlled Porosity”, for optimally sintering parts that 3D printed via photopolymerization processes of bound metal and bound ceramic slurries.

Read More The patent covers objects made from…

The patent covers objects made from… -

NUBURU, a leader in high power blue laser technology, today announced that it has been awarded seven new blue laser IP patents, further demonstrating its dominant intellectual property portfolio in visible laser technology and its applications across 3D printing and material processing. NUBURU was awarded US Patent No. 10,562,132, No.…

Read More -

PostProcess Technologies Inc. has been granted another U.S. patent for its automated 3D printing post-processing solutions. This patent, U.S. Patent No. 10,737,440, pertains to the company’s support removal process, specifically its Submersed Vortex Cavitation (SVC) technology. The company’s SVC technology is one of its polymer support removal and resin removal…

Read More -

AM quality assurance software developer Sigma Labs has been granted two U.S. patents for its PrintRite3D software platform. The recently obtained patents expand the company’s intellectual property portfolio, making for a total of 11 issued patents and 24 pending patents.

Read More Sigma Labs’ PrintRite3D software enables manufacturers to detect defects that…

Sigma Labs’ PrintRite3D software enables manufacturers to detect defects that… -

Chicago-based biofabrication company Dimension Inx has been granted a U.S. patent covering its 3D-Painting System, a platform built for designing and manufacturing next-gen biomaterials for organ and tissue repair and regeneration. The company says the patent issuance strengthens its position on the market by showcasing the differentiation of its biomaterials…

Read More -

FATHOM, an advanced manufacturer with extensive expertise in 3D printing and additive manufacturing was issued a United States Patent for the systems and methods powering its online digital manufacturing platform. The team also received its seventh consecutive ranking on the Inc 5000 list of fastest-growing private companies in America—only 1.5%…

Read More

Load More

Robbo received a patent for a 3D printer

Technique

|

Share

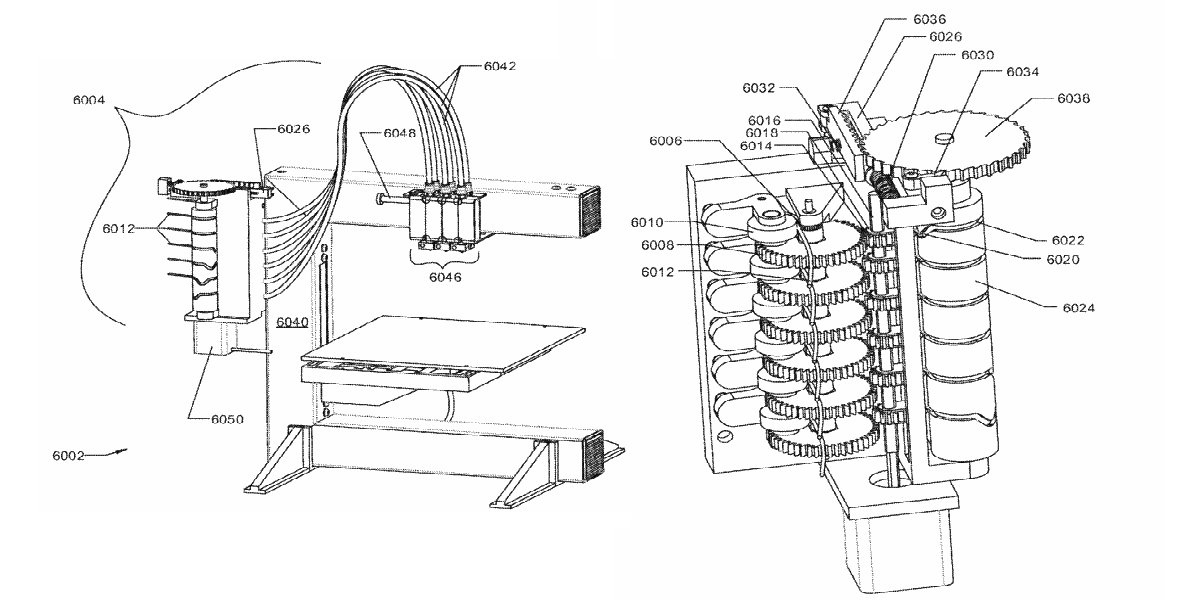

Robbo, a Russian manufacturer of educational robotics for children, received a patent from the Federal Service for Intellectual Property for one of its developments, the Robbo Mini 3D Printer, designed for teaching children 3D modeling and 3D printing at home. The decision to grant a patent was made on the basis of the patentability conditions "novelty" and "originality" provided for in paragraph 1 of Art. 1352 of the Civil Code of the Russian Federation.

The decision to grant a patent was made on the basis of the patentability conditions "novelty" and "originality" provided for in paragraph 1 of Art. 1352 of the Civil Code of the Russian Federation.

Robbo's patent application was filed in August 2020. As a result of the examination, the compliance of the 3D printer with the requirements of articles 1231.1, 1349 and 1352 of the Civil Code of the Russian Federation was established, on the basis of which a patent for industrial design No. 122799 was issued. The patent will be valid until August 2025

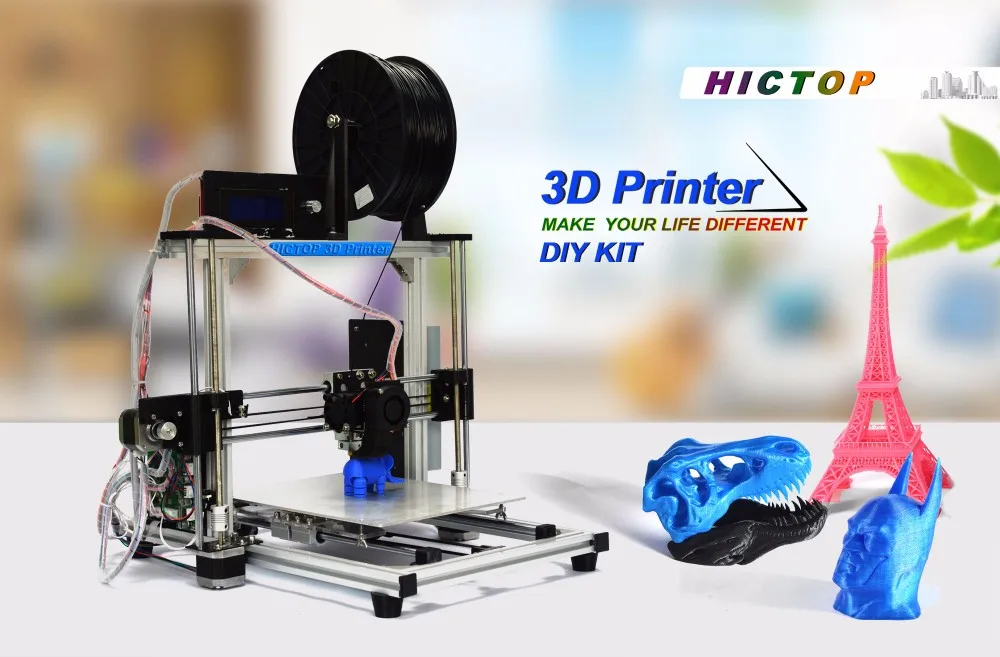

Robbo Mini 3D Printer is designed as a 3D printing tutorial and runs on open source software and hardware. The 3D printer turns any model drawn by a child into a real three-dimensional object made of safe, biodegradable PLA plastic. Children can create models of products and plastic mechanisms up to 170x100x100 in size. At the same time, thanks to its compact design, the 3D printer takes up little space: its dimensions are 370x280x350 mm, and its weight is only 3. 5 kg. In addition to the printer itself, the kit also includes a USB stick with software and settings, a bar filter, a power supply, and a USB cable.

5 kg. In addition to the printer itself, the kit also includes a USB stick with software and settings, a bar filter, a power supply, and a USB cable.

Already in the near future, as noted by the company, additive technologies will be widely used in domestic production, medicine and the space industry. And "Robbo" will take a direct part in the training of personnel for the new segment of the IT industry.

New rules for accreditation and tax benefits for IT companies: what you need to know

IT industry support

“The global 3D printing market is forecast to grow by almost 2.5 times over the next five years. However, unlike other countries where additive technologies have been actively used for several decades, for example, in industry and manufacturing, in Russia the 3D prototyping industry is only in its infancy. The appearance of the product “Robbo 3D-printer Mini” in Russian homes and schools will make it possible to prepare a pool of specialists capable of bringing the domestic industry of additive technologies to a qualitatively new level in the future. Moreover, our educational 3D printer has no analogues yet,” said Pavel Frolov , founder and producer of the Robbo company.

Moreover, our educational 3D printer has no analogues yet,” said Pavel Frolov , founder and producer of the Robbo company.

- Applications for spying on someone else's smartphone, for which you will get nothing

The second part of the 3D printing guide for beginners. Timeline of 3D printing

The birth of modern 3D printing. 1980-1990

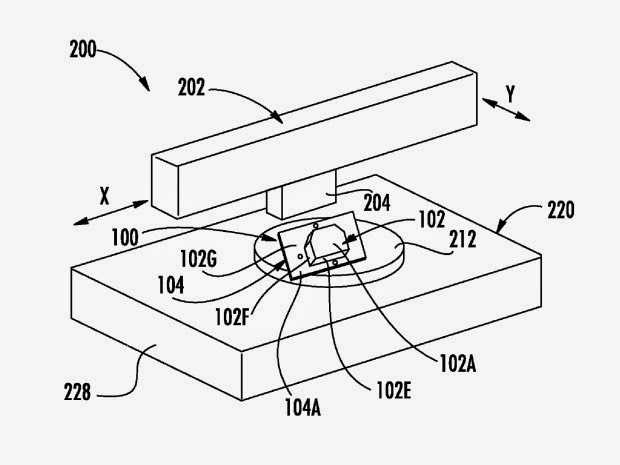

The earliest modern 3D printing technologies first appeared in the late 1980s, at which time they were called Rapid Prototype (RP) technologies - RapydPrototype (RP). This is because processes were originally conceived as a fast and cost-effective way to create prototypes for industrial product development.

Interestingly, the very first patent application for BP technology was filed by Dr. Kodama in Japan in May 1980. Unfortunately for Dr. Kodama, the full patent specification was not filed until one year after application, which is particularly unfortunate given that he was a patent lawyer.

Hideo Kodama (Hideo Kodama)

In reality, however, 3D printing started in 1986, when the first stereolithography apparatus (SLA) patent was issued. This patent belonged to Charles (Chuck) Hull, who first invented the SLA machine at 1983 year. Hull continued to collaborate with 3D Systems Corporation, one of the largest and most prolific organizations active in the 3D printing sector today.

3D Systems created its first commercial SLA-1 rapid prototyping system in 1987 and after extensive testing sold it in 1988. However, despite the fact that SLA technology may claim the first place in the history of 3D printing, it was not the only rapid prototyping technology at this time. At 19In 1987, Carl Deckard, who worked at the University of Texas, applied for a US patent for selective laser sintering (SLS-Selective Laser Sintering). This patent was issued in 1989 and SLS was later licensed from DTM Inc. and subsequently acquired by 3D Systems. Also in 1989, Scott Crump, co-founder of Stratasys Inc. , applied for a patent for FDM-Fused Deposition Modeling technology, which the company still owns today, the technology used today by many entry-level printers. open source level RepRap (Replicating Rapid Prototyper). The FDM patent was issued to Stratasys in 1992 in Europe.

, applied for a patent for FDM-Fused Deposition Modeling technology, which the company still owns today, the technology used today by many entry-level printers. open source level RepRap (Replicating Rapid Prototyper). The FDM patent was issued to Stratasys in 1992 in Europe.

Scott Crump Co-founder of Stratasys

In 1989, Hans Langer founded EOS GmbH in Germany. After playing around with SL technology, EOS shifted its focus to SLS technology. Today, EOS is recognized worldwide for the quality of its products for industrial prototyping. In 1990, EOS sold its first Direct Metal Laser Sintering (DMLS) stereo system in cooperation with Electrolux Finland, which was later acquired by EOS.

Other 3D printing technologies emerging in these years include Ballistic Particle Manufacturing (BPM) originally patented by William Masters, Laminated Object Manufacturing (LOM) patented by Mikhail Feigin, mask stereolithography ( SGS - Solid Ground Curing), patented by Itzhak Pomeranz and three-dimensional printing (3DP), patented by Emanuel Sachs. So in the early nineties, there was an increase in the number of competing companies in the rapid prototyping market, but only three of them have survived to this day - 3D Systems, EOS and Stratasys.

So in the early nineties, there was an increase in the number of competing companies in the rapid prototyping market, but only three of them have survived to this day - 3D Systems, EOS and Stratasys.

Development of various 3D printing technologies. 1990-2000

Throughout the 1990s and into the early 2000s, many new technologies continued to be introduced, but they all remained exclusively focused on industrial production. Through research and development (R&D), more advanced technology has been introduced for specific casting tools. This marked the beginning of a new terminology, namely high-speed machining (RT-Rapid Tooling), rapid casting (Rapid Casting) and rapid production (RM-Rapid Manufacturing).

So in 1996 SandersPrototype (later Solidscape) and ZCorporation were created, in 1997 - Arcam, Objet Geometries - in 1998, in 2000 MCP Technologies introduced the technology of selective laser melting (SLM), in 2002 EnvisionTec was founded, In 2005, ExOne was established as a subsidiary of Extrude Hone Corporation and SciakyInc. introduced its pioneering additive process based on patented electron beam welding technology.

introduced its pioneering additive process based on patented electron beam welding technology.

All these organizations joined the ranks of Western companies operating in the world market. Terminology has also evolved with the spread of manufacturing applications, and a common term for all technologies has been adopted - additive manufacturing (AM - Additive Manufacturing). It is noteworthy that at the same time there were many parallel processes in the Eastern Hemisphere, but in the end, all of them did not have a significant impact on the world market.

The mid-2000s began to show signs of diversification in two specific areas of focus that are much more clearly defined today.

First of all, these are high-end 3D systems, still very expensive equipment, which was aimed at producing high-quality, high-tech complex parts. The growth of this field continues to this day, but only now, after years of research and development, the results are becoming more visible when using technologies in the aerospace, automotive, medical and jewelry sectors. Much still remains behind closed doors and/or under non-disclosure agreements.

Much still remains behind closed doors and/or under non-disclosure agreements.

On the other hand, some manufacturers of 3D printing systems are directing their efforts towards the development and promotion of the concept of modelers, as they were called at the time. In particular, these were 3D printers that kept the focus on improving functional prototyping, which were designed specifically as office-friendly, cost-effective systems. This was the prelude to today's desktop printers. However, most of these systems were still being developed for industrial prototyping.

In hindsight, this was indeed the calm before the storm.

Opening 3D printing to the general public 2007 - ...

In the low-end segment, 3D printers are currently in the middle of the price range, as price struggles have come along with incremental improvements in the materials used, as well as the speed and accuracy of printing.

In 2007, the market saw the first $10,000 printers from 3D Systems, but they failed to achieve their intended goal. This was partly due to the system itself, partly to market influences. According to many industry insiders, users, and commentators, the holy grail at the time was getting a $5,000 3D printer as the key to opening up 3D printing technology to a wider audience.

This was partly due to the system itself, partly to market influences. According to many industry insiders, users, and commentators, the holy grail at the time was getting a $5,000 3D printer as the key to opening up 3D printing technology to a wider audience.

For most of the year, the world was looking forward to the arrival of the long-awaited Desktop Factory, as many predicted that they would find the Holy Grail. However, the expectations were in vain, as production faltered in anticipation of the release. Desktop Factory, led by Cathy Lewis, was acquired by 3D Sysytems in 2008, and that was it. As it turned out later, 2007 did become a turning point for the opening of 3D printing technology to a wide audience, although at that moment no one realized that the RepRap phenomenon had already taken root. Dr Bowyer conceived the concept of an open source, self-replicating RepRap 3D printer back in 2004. In the years that followed, the seeds gradually germinated, with major contributions from members of his Bath team, especially Vic Oliver and Rhys Jones, who developed the concept of working prototype 3D printers based on deposition modeling technology. In 2007, shoots began to appear, and the promotion of 3D printing to the masses began to gain momentum.

In 2007, shoots began to appear, and the promotion of 3D printing to the masses began to gain momentum.

Adriano Bowyer (left) and Vik Olliver (right)

However, the first commercially available disassembled 3D printer based on the RepRap concept was only put up for sale in January 2009. It was a BfB RapMan 3D printer. MakerBot Industries closely followed this technology, the founders were actively involved in the development of the RepRap printer, until, due to extensive investments, they moved away from the philosophy of open source printers. In 2009, a lot of similar printers appeared, sold in various parts of the world, and this continues to this day. The RepRap phenomenon has spawned a new sector of entry-level commercial 3D printers.

2012 was the year of introducing alternative printing technologies to the entry level market. B9Creator with color LED projection technology (DLP-Digital Light Processing) appeared in June, and Form 1 in December. Both projects were launched with Kickstarter funding and both have been huge successes.