Ut austin 3d printing

3D Printing - School of Architecture Digital Technologies Wiki

Skip to end of banner

Go to start of banner

Skip to end of metadata

- Created by Courtney Morshed, last modified on Dec 22, 2022

Go to start of metadata

Contents

Shortcuts

Prepare Your File

Submit Your 3D Print Job

How-to Articles

| Title | Last Updated |

|---|---|

| How to Prepare Your File for 3D Printing | |

| How to Submit a Model for 3D Printing |

Processes

| Title |

|---|

| No content found. |

Troubleshooting

| Title |

|---|

| No content found. |

Policies

| Title |

|---|

No content found. |

Examples

| Title |

|---|

| No content found. |

- service

- 3d

- student

Overview

Content Tools

Confluence Documentation | Web Privacy Policy | Web Accessibility

New Additive Manufacturing Center Strengthens UT’s Leadership in 3D Printing Technology

Center for Additive Manufacturing and Design Innovation | Cockrell School of Engineering

For decades, Texas Engineers have been on the forefront of what the public knows as 3D printing. And this month they took a major step in moving this exciting technology to the next level.

And this month they took a major step in moving this exciting technology to the next level.

March 5 marked the opening of the new Center for Additive Manufacturing and Design Innovation in the Cockrell School of Engineering. The 3,000-square-foot facility features more than $1.5 million worth of commercial-grade machines that can print complex parts used in a variety of fields, including medical research, aerospace, energy, robotics and more.

“Once again, our mechanical engineering faculty are leading the way in advancing additive manufacturing research and innovation,” said Sharon L. Wood, dean of the Cockrell School. “Not only will the center provide enhanced resources for academic research, but it will also enable exciting new opportunities for industry partnerships.”

The facility will boost the Cockrell School's research capabilities in additive manufacturing, the technical term for 3D printing preferred by those in the field. The center is also launching an industry affiliates membership program where researchers will team up with companies with an eye toward advancing what can be done in additive manufacturing.

The center is also launching an industry affiliates membership program where researchers will team up with companies with an eye toward advancing what can be done in additive manufacturing.

"We are interested in working with partners who want to push the envelope of what we can print — creating new materials, designing new processes and R&D applications that move the technology forward," said Carolyn Seepersad, director of the center and professor in the Walker Department of Mechanical Engineering.

A virtual ribbon-cutting ceremony on March 5 commemorated the opening of the new facility, and a panel discussion on the state of additive manufacturing featured local leaders in the industry, including David K. Leigh, CTO of EOS; Kent Firestone, former CEO of Stratasys Direct Manufacturing and current senior vice president of operations for EOS; Vikram Devarajan, CEO of Evonik subsidiary Structured Polymers; and Samantha Snabes, co-founder and CEO of re:3D.

Austin has become an additive manufacturing hub, due to the presence of leading companies and the prominent role The University of Texas at Austin has played in the industry dating back to its early days. In the future, the panelists expect to see more new facilities pop up both in hotspots and other places that aspire to play a big role in the industry going forward.

In the future, the panelists expect to see more new facilities pop up both in hotspots and other places that aspire to play a big role in the industry going forward.

Over the years, the big picture goal of additive manufacturing production has shifted from an emphasis on making small machines that anyone could use to focus more on large machines used by companies and other creators. That has also shifted how researchers think about the technology.

Challenges remain to advance the industry further, including a lack of machine consistency from print to print and a need for universal standards. Leigh of EOS thinks that once a primary application is found for additive manufacturing, a lot of these problems will be solved quickly.

“Once we get that killer app, we will figure out how to get machine-to-machine consistency because there will be a monetary incentive to do so,” Leigh said.

Innovation requires massive amounts of experimentation. And before success comes failure. Those failed experiments, from centers like the new one at UT Austin, are important because they eventually lead to breakthroughs. And once those breakthroughs happen, that’s when research collaborates with industry to bring them to life.

Those failed experiments, from centers like the new one at UT Austin, are important because they eventually lead to breakthroughs. And once those breakthroughs happen, that’s when research collaborates with industry to bring them to life.

“What you provide is a way for everyone to stand shoulder to shoulder to overcome some of these hurdles,” Snabes said of the new center.

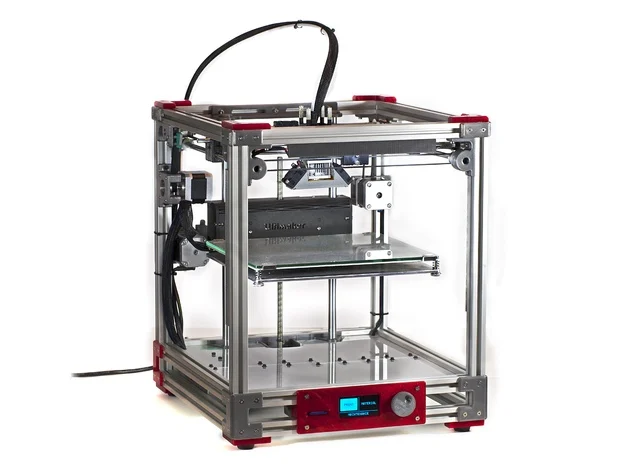

Inside the center, there are several labs and state-of-the-art equipment that Cockrell School researchers and industry affiliates will use:

- Machines in the Metal Powder Bed Fusion Lab can create durable metal parts with complicated shapes and structures. Seepersad said these parts can be used in airplanes, to build tools sent downhole when drilling for energy resources or to create surgical screws and other medical solutions such as pads that go in between vertebrae.

- The Liquid Polymer Lab includes machines capable of printing a variety of flexible materials with a range of potential uses.

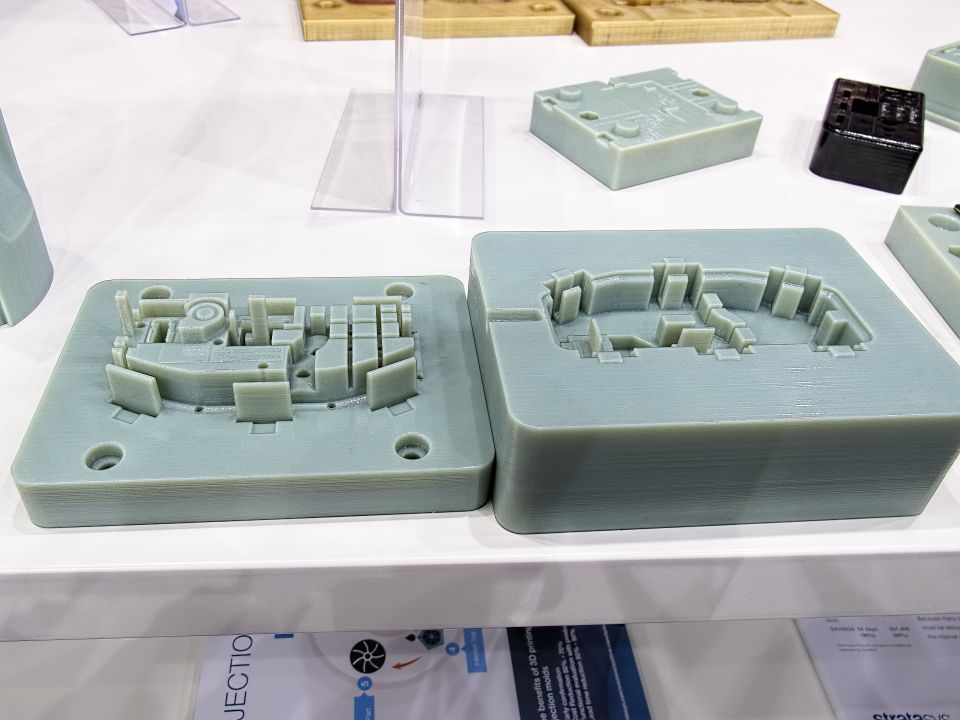

A PolyJet device can create materials that mimic the mechanical function of organs and tissue, which means it can print copies of the anatomy without needing cadaver parts. These materials can be used for surgical practice and robotic surgery, where personnel can say how well machines do operating and then fine-tune them before working on human patients. A stereolithography machine can build highly accurate large polymer parts that can be used in building robots. The device can also print transparent parts, which is important for surgical planning, allowing medical personnel to watch the path instruments take.

A PolyJet device can create materials that mimic the mechanical function of organs and tissue, which means it can print copies of the anatomy without needing cadaver parts. These materials can be used for surgical practice and robotic surgery, where personnel can say how well machines do operating and then fine-tune them before working on human patients. A stereolithography machine can build highly accurate large polymer parts that can be used in building robots. The device can also print transparent parts, which is important for surgical planning, allowing medical personnel to watch the path instruments take.

- Another series of machines arriving soon at the facility will allow researchers to test the accuracy of print jobs. How well did the parts match up to the CAD file used to create them? Heat maps show where the printing process was most accurate on a specific part and where there were departures from the initial design.

The University of Texas at Austin has a rich history in additive manufacturing, with researchers pioneering a new concept in the field in the 1980s. Selective Laser Sintering — the mechanical process of building objects layer by layer, zapping a paper-thin layer of powder dust with a laser to form 3D objects — was created by mechanical engineering professor Joseph Beaman and his graduate student at the time, Carl Deckard.

Selective Laser Sintering — the mechanical process of building objects layer by layer, zapping a paper-thin layer of powder dust with a laser to form 3D objects — was created by mechanical engineering professor Joseph Beaman and his graduate student at the time, Carl Deckard.

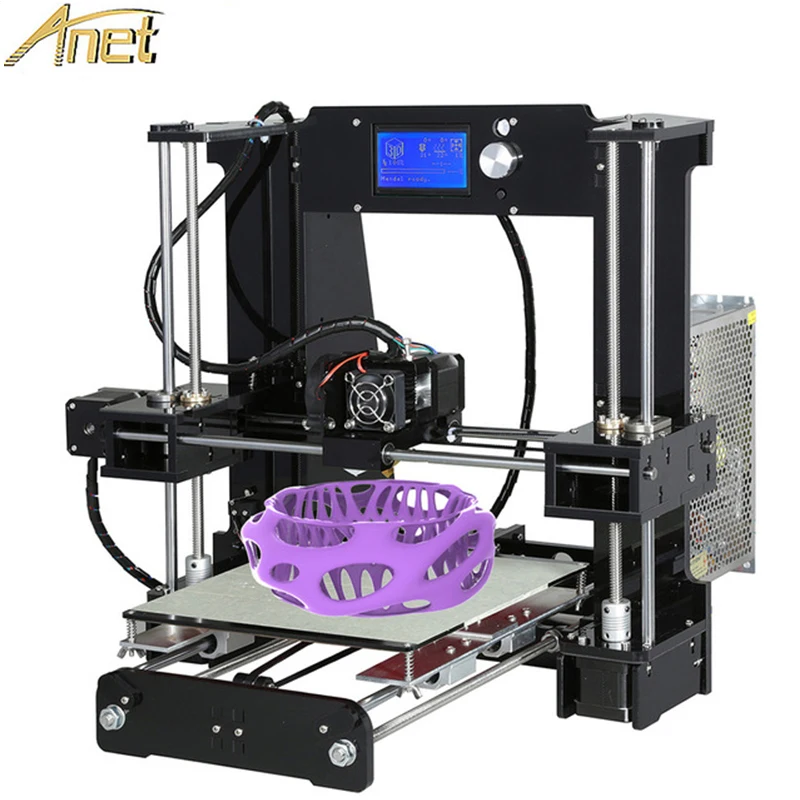

At the time, creating objects from 3D-computer designs seemed impossible, but it has become ubiquitous in recent years. Seepersad credits the explosion of additive manufacturing in part to the availability of desktop printers that cost a couple thousand dollars apiece. These devices had a similar effect on additive manufacturing as smaller desktop machines had on computing.

The next step in the evolution of additive manufacturing, Seepersad said, comes with creating new materials and solving design and accuracy challenges. Researchers in the Cockrell School have their eyes on this next frontier, and the new center, along with future industry partners, will go a long way in making that happen.

Watch the recording of the center's March 5 virtual launch event:

vacuum plastic molding and prototyping, CNC router; 3D printers, industrial equipment and liquid polyurethanes.

Foliplast: vacuum molding of plastics and prototyping, CNC milling; 3D printers, industrial equipment and liquid polyurethanes.First in Russia First rapid prototyping service provider

nine0002 Reverse engineering Development and restoration of parts according to ready-made samplesParticipation in public procurement We participate in tenders and public procurement

Import substitution partner Production of analogues of plastic parts

Catalog

Whole catalog

- Prev

- Next

-

PICASO Designer XL 3D printer (series 2)

3D printers

-

PICASO Designer X PRO 3D printer (series 2)

3D printers

nine0015 -

Standard C

Mixing and dosing equipment

-

RangeVision PRO 3D Scanner

3D scanners

nine0015 -

FVC-3A - vacuum injection molding machine

Vacuum casting equipment

-

Compact C

Mixing and dosing equipment

nine0016 -

KLM V 1500 A

Vacuum casting equipment

-

Elast TDI

Mixing and dosing equipment

-

DC 1090A Metal Milling Center

Machining centers, 3D plotters

PICASO Designer X 3D printer (series 2)

3D printers

XJRP SPS450H 3D Printer

3D printers

TPK Foliplast is a leading manufacturing and engineering company in the field of rapid prototyping, vacuum molding of plastics, CNC milling, 3D printing and scanning.

The basic principles of the company were laid down more than 20 years ago at the time of its creation:

- We work with proven equipment of the latest generation, we test equipment and materials at our production base immediately before sending it to the client. nine0089 — You can buy everything from us for creating engineering models, layouts, forms, their filling, processing.

— If there is no suitable technology in our assortment, we will create a solution for you!

— We cooperate with the best manufacturers and technical laboratories from around the world.

Foliplast is the official distributor of many well-known companies:

KLM (Germany), Harvest (Wings Technology) (Hong Kong), ASD-Technique (Belarus), Altropol (Germany), RangeVision, Shaanxi Hengtong (XJRP), UnionTech (China). nine0089 — We work according to ISO 9001 standards.

Creation of the Prototyping Center

Modification of industrial robot Kuka

Innovative project for the production of flexible ship guardrails

All articles

Articles

nine0002 December 13, 2022December 2, 2022

December 1, 2022

November 16, 2022

October 27, 2022

Houses will be 3D printed - Kommersant FM - Kommersant

A block of houses printed on a 3D printer will appear in Texas. The Lennar Group and ICON will be involved in the construction. A new district will be built in the city of Austin. Engineers claim that the technology will reduce the cost of the construction process and at the same time build high-quality buildings. Lavacrete material will be used to create the houses, a highly durable concrete mix optimized for 3D printing. Developers claim that the material will allow houses to withstand strong earthquakes and extreme weather. This is especially true for Texas, which often suffers from tornadoes and storms. nine0003

The Lennar Group and ICON will be involved in the construction. A new district will be built in the city of Austin. Engineers claim that the technology will reduce the cost of the construction process and at the same time build high-quality buildings. Lavacrete material will be used to create the houses, a highly durable concrete mix optimized for 3D printing. Developers claim that the material will allow houses to withstand strong earthquakes and extreme weather. This is especially true for Texas, which often suffers from tornadoes and storms. nine0003

Photo: ICON Technology, Inc.

Photo: ICON Technology, Inc.

However, it is too early to talk about the complete safety of such houses, says Alexander Peres, co-founder of the Association of Russian Manufacturers in the Sphere of Additive Technologies. In addition, their cost is much higher than analogues built using conventional technologies.

“Very little time has passed since such houses began to be built for life. If a specialist participates in the process of automatic reinforcement with the help of additional pipe arms, it will be safe. Building a very tall house with 3D printing is scary, you have to start with lower buildings. At the moment, such construction is economically unprofitable, since it is not very common and unpopular. nine0003

If a specialist participates in the process of automatic reinforcement with the help of additional pipe arms, it will be safe. Building a very tall house with 3D printing is scary, you have to start with lower buildings. At the moment, such construction is economically unprofitable, since it is not very common and unpopular. nine0003

Since the technology is now in its infancy and the methods of building with 3D printing vary, everyone has their own approach. Nevertheless, very expensive equipment is still required.

The mass market is not ready for this. But if you work out the technique on typical one-story houses that are being built in a certain place, where all the equipment will be located and a large settlement will be created, then it will be cheaper and faster.

However, we are not yet ready to build each building in a new location. If you look at the market, there are already ads for the sale of houses built using 3D printing, and they are always much more expensive, ”Perez notes. nine0003

nine0003

The construction of housing using new technology is due to the lack of housing in the United States. According to The Wall Street Journal, there is a shortage of 5 million homes compared to buyer demand. In Russia, such projects are not in demand due to the high cost of technology. So far, they can only be considered as fashionable ones, Georgy Dzagurov, CEO of Penny Lane Realty, says:

“We assessed the situation and realized that at the moment technology does not allow doing it cheaply. However, I already know several projects in the near Moscow region and on the Black Sea coast, where people were going to at least partially build something using 3D printing and believe that in this way they will catch the hype and attract journalists. nine0003

Thus, this will allow them to save not on building technologies, but on marketing, since attention to the project will certainly be attracted, because these are the first cases in Russia that houses will be built using a 3D printer.