Download a car 3d printer

🚙 Best 3D print files for cars and automotive・Cults

🚙 Best 3D print files for cars and automotive

Download free 3D models of cars

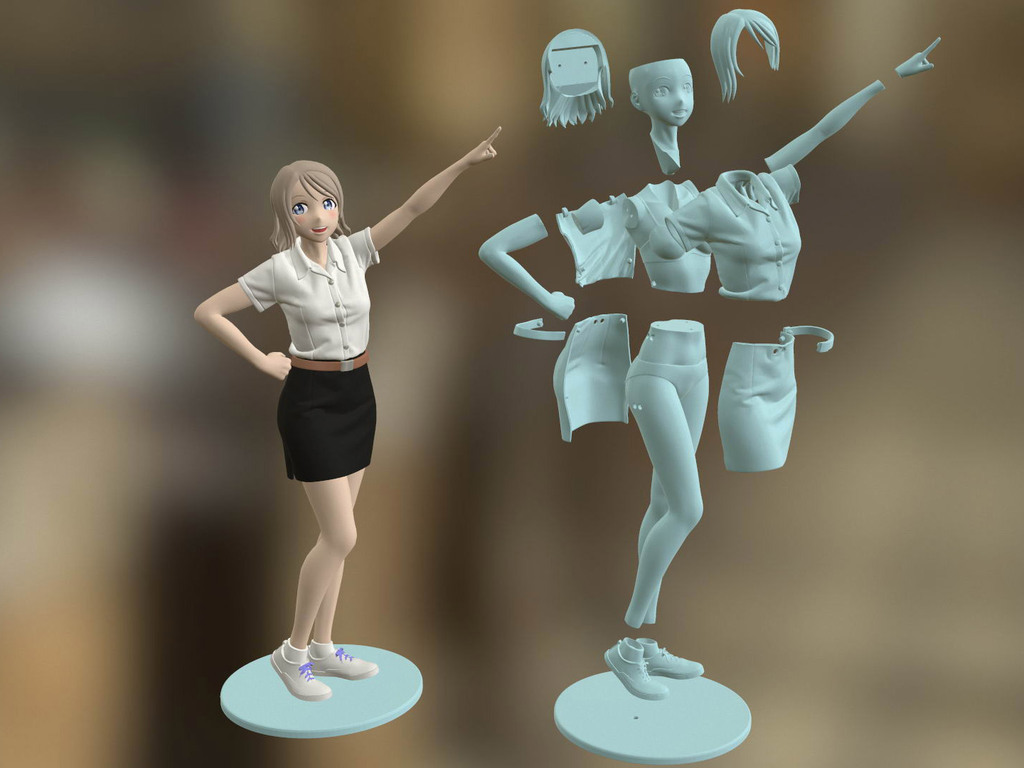

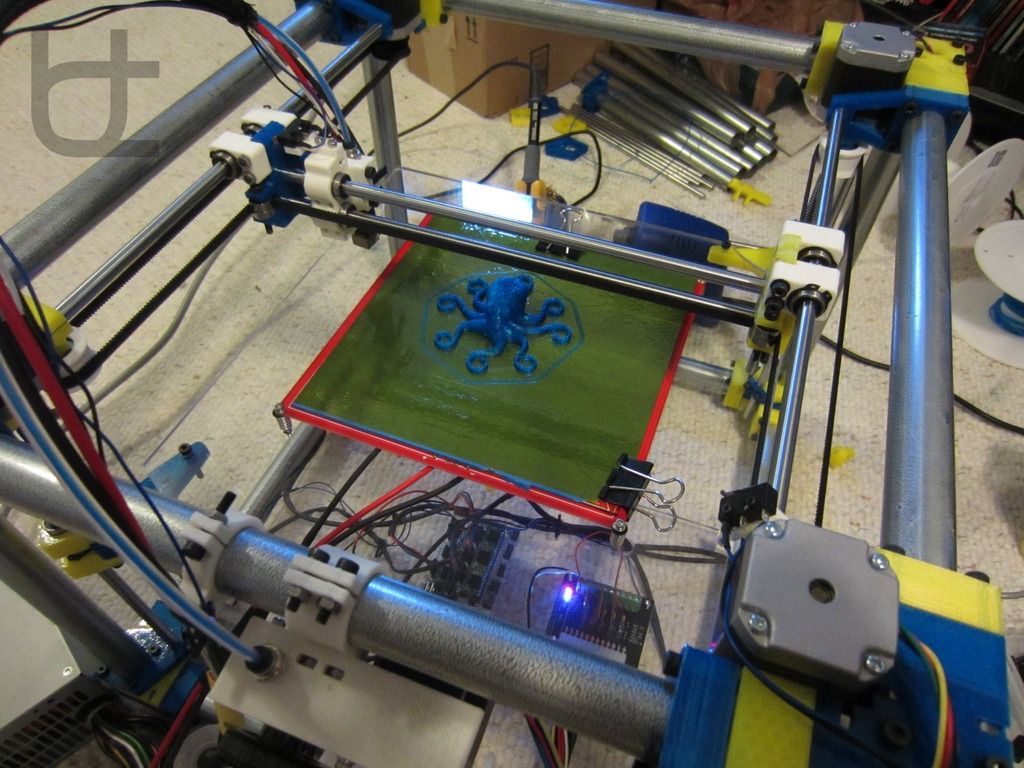

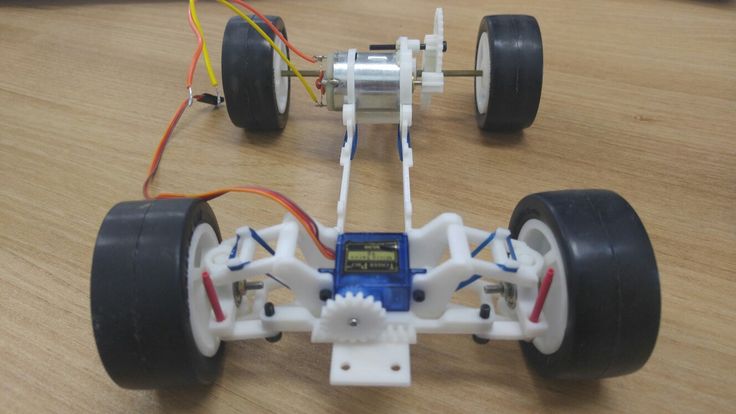

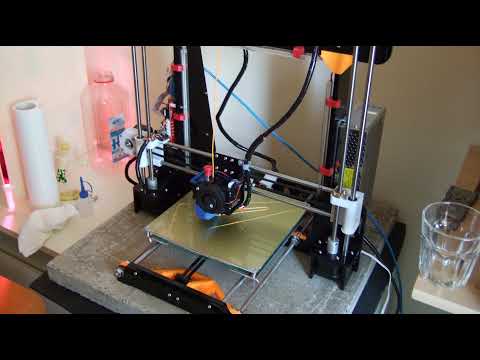

Passionate car designers have succeeded in 3D modeling STL that are real replicas of existing cars. Some of these 3D objects have even the ability to be remote controlled. Formula 1, buggy, city cars... make several types of vehicles becomes possible thanks to 3D printing and the talent of these great designers Guaro3D, MaoCasella, Daniel Norée, etc.

Popularity Ranking

Volkswagen Bus 1970s

Free

Delorean DMC-12/BTTF Time Machine 3D Printed RC Car

Free

Volkswagen Golf GTI - Low Poly Miniature

Free

Pony Toy Car

Free

OpenRC 1:10 4WD Truggy Concept RC Car

Free

RS-LM 2014 Audi R18 E-Tron Quattro “The Ali"

Free

OpenRC Tractor

Free

1991 Mazda 787B 3d Printed RC Car

Free

1:18 Jurassic Park Car for 3.

Free

Lynx - Fully 3D-printable 1/10 4wd buggy

Free

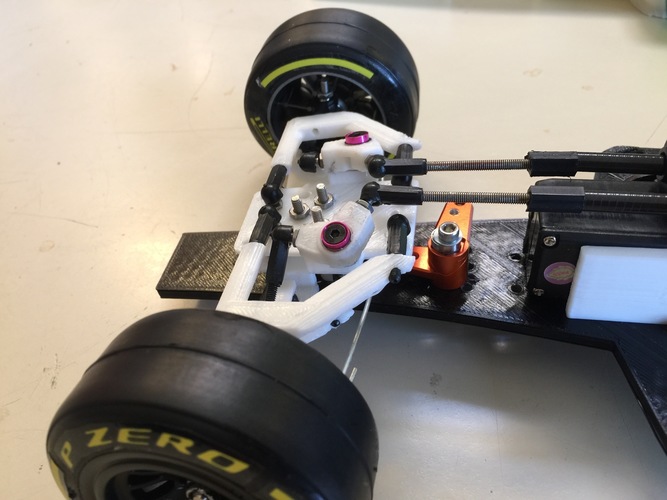

OpenR/C 1:10 Formula 1 car

Free

Aryton Senna's Mclaren MP4/6 3d Printed RC F1 Car

Free

Pickup Truck

Free

OpenRC F1 Dual Color McLaren Edition

Free

VW Beetle BAJA BUG - fully 3D printable

Free

ZIL-157 - RC truck with the WPL transmission

Free

Open R/C F1 MadMax Edition

Free

RC car Ford MUSTANG 1967 Fastback

€4.99

RS-01 Ayrton Senna’s 1993 McLaren MP4/8 Formula 1 RC Car

Free

Coupe body for OpenZ v16c chassis

Free

Chevrolet Blazer K5 - RC model with WPL axles

Free

The Classic Batmobile

Free

Dragster

Free

Print-in-Place Convertible

Free

Quadra V-tech

Free

Backhoe

Free

ECTO - Ghostbusters car

Free

GAZ-MM-V wartime truck 1:87 (H0)

Free

Bulgy - Thomas & Friends

Free

80's van body for the Ursa monster truck

Free

UAZ 469 Assembly model kit 1:35

€1. 89

89

Mystery Machine of Southern IL.

Free

LTZ T-40 - RC soviet tractor

Free

OpenRC F1 MKII RC Car

Free

OpenRC F1 2017 updates

Free

Nintendo OpenRC Mariokart

Free

Truck

Free

Lotus 56B Turbine Formula 1

Free

fire truck toy

Free

Hot Rod North American P-51D Mustang fighter

Free

Tilting reverse trike (fully printable)

€3

RC Lancia Delta S4

Free

Classic 3 Wheels Car no support

Free

1959 Cadillac

Free

Little Jeep Car - PIP (Print In Place) without support

Free

Christinesque Cadillac

Free

ZEBRA 1910 PRESENTATION SHEET

Free

Print-in-Place Audi Quattro S1

Free

1:18 Jurassic Park Car for 3.

75 Inch Figure No Support

75 Inch Figure No Support Hot Rod North American P-51D Mustang fighter

Delorean DMC-12/BTTF Time Machine 3D Printed RC Car

VW Beetle BAJA BUG - fully 3D printable

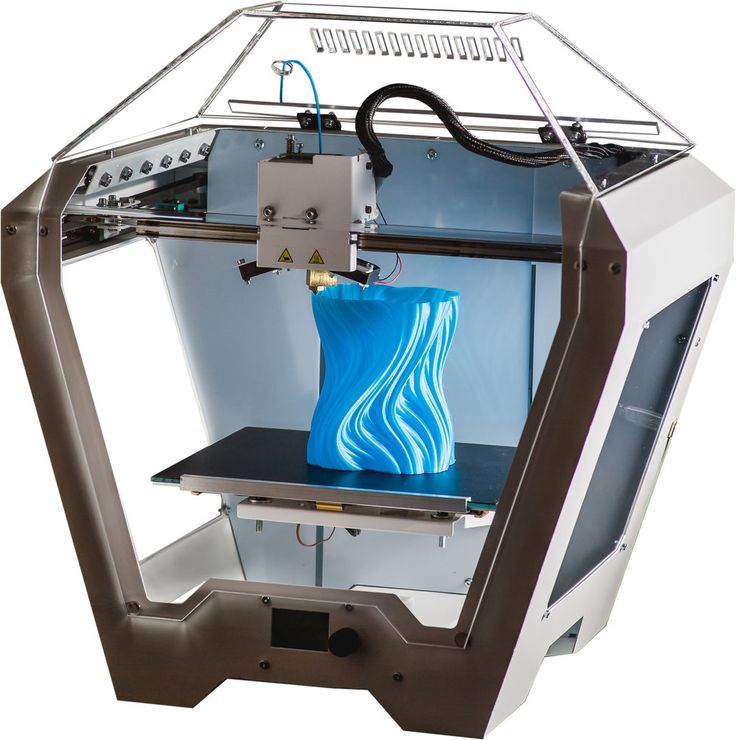

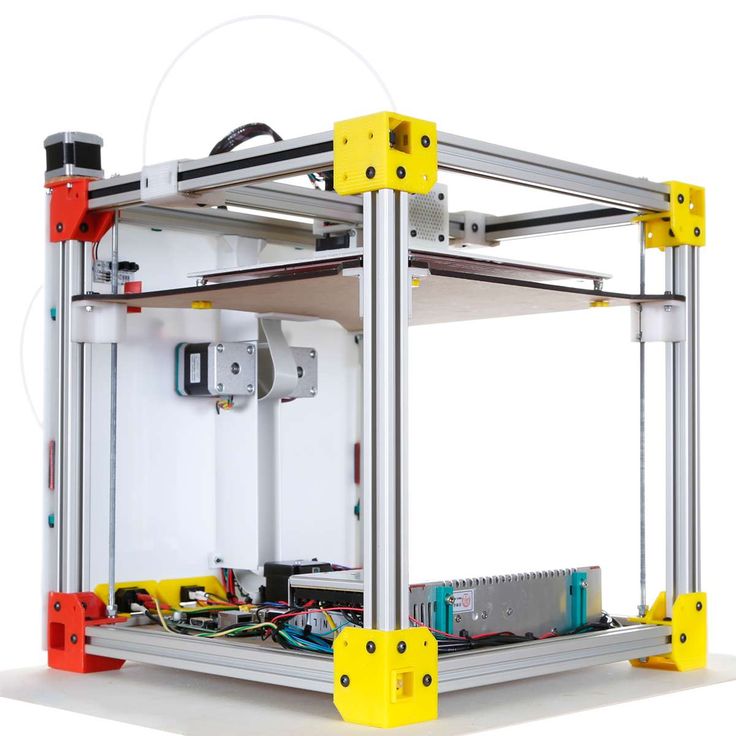

Discover our selection of the best 3D files for 3D printing in the automotive area. All these STL files are perfectly 3D printable, so just download them, heat up your printer and play with them. This collection was created by selecting the best creations from Cults 3D models library.

Here you will find different types of 3D printed cars, there are models to assemble yourself, functional cars that do not require post work but also creations for modelism fans. By adding various elements and a motor you will be able to 3D print your own remote-controlled car.

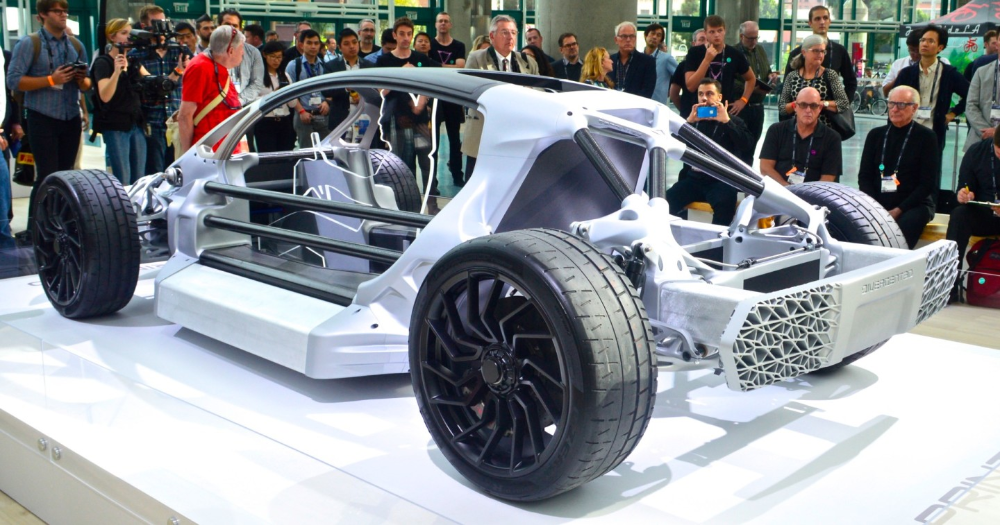

These replicas of cars are created for children but also adults. Many car manufacturers use 3D printing to produce parts of their vehicles, but few projects are 100% 3D printed. This selection may give you the desire to create a true car 100% 3D printed!

Many car manufacturers use 3D printing to produce parts of their vehicles, but few projects are 100% 3D printed. This selection may give you the desire to create a true car 100% 3D printed!

Car best 3D printer models・Cults

BMW 118 2020+ Armrest Storage Organiser

€10

Simple Rover

€0.50

Hugo Rover

€0.50

Car wheel

€0.50

Cub3 Toy

€0.50

s800

€6

Electric hyper car concept

€50

Bugatti type 35 toy car

€6

Magic Tower

€0.50

BMW M8 Prior Style Bodykit

€15

Center console handle old audi a3

€5. 50

50

HOLDEN COMMODORE RACE CAR 1993 (1/24) printable car body

€5.71

HOLDEN COLORADO LX SPACE CAB ALLOY TRAY 2008 (1/24) PRINTABLE CAR BODY

€6.85

HOLDEN COMMODORE 1988 (1/24) PRINTABLE CAR BODY

€5.71

HOLDEN COMMODORE 1980 (1/24) printable car body

€5.71

HOLDEN HURRICANE 1969 (1/24) printable car body

€5.71

Ford Mustang Hoonicorn V2 Printable Car

€12.50

Volkswagen T Roc R line 2022 Printable Car

€12.50

Mercedes Benz AMG GT R Pro 2020 Printable Car

€12.50

Alfa Romeo 8CR Tazio 2020 Printable Body Car

€8. 33

33

Steering Wheel Phone Holder

€2.52

Rope excavator 1/43

€20

Deluge gun in 1/10 v2

€8

Deluge deck gun 1/10

€8

ESR GP14

€3.50

Chevrolet Corvette C8 Stingray 2020

€14.99

Five spoke wheels with Cooper Cobra tires for scale model car/truck

€3.74

Volvo V90 Cross Country 2018

€14.99

Toyota Land Cruiser Prado VX 2017

€14.99

Soft eight spoke wheels and Cooper Cobra tires for scale model car

€3.74

Porsche 911 GT2RS 2018

€14. 99

99

Land Rover Discovery 2018

€14.99

Toyota Hiace

€14.99

Jeep Compass 2020

€14.99

Chevy style rally wheels with Cooper Cobra tires

€4.29

Fiat 126 Rims 1/24

€3.19

phone holder Dacia sandero

€2.50

TreeD Frisbie

€0.50

TreeD Puzzle

€0.50

Wald Duchatelet 2 1/24 Rims

€3.19

Jeep Grand Cherokee Trackhawk

€20 -30% €14

Cartoon V8 vintage engine

€15

Custom car wheel

€0. 99

99

Goghi Rover

€0.50

contanier

Free

trailer contanier 53ft 3axles

€4

trailer contanier 53ft 2axles

€4

trailer contanier 53ft

€4

🚙 Best Automotive & Automotive 3D Printing Files・Cults

🚙 Best Automotive & Automotive 3D Printing Files

Free Download Car 3D Models

Passionate automotive designers have succeeded in creating 3D STL models that are real copies of existing ones cars. Some of these 3D objects even have remote control capabilities. Formula 1, buggies, city cars... the creation of several types of cars was made possible by 3D printing and the talent of these great designers Guaro3D, MaoCasella, Daniel Norée and others.

Popularity Rating

Volkswagen Bus 1970s

Free

3D Printing RC Machine Delorean DMC-12/BTTF Time Machine

Free

Volkswagen Golf GTI - low poly miniature

Free

Pony Toy Car

Free

OpenRC 1:10 4WD Truggy Concept RC Car

Free

RS-LM 2014 Audi R18 E-Tron Quattro “The Ali"

Free

Tractor OpenRC

Free

1991 Mazda 787B 3d Printed RC Car

Free

1:18 Jurassic Park Car for 3.

75 Inch Figure No Support

75 Inch Figure No Support Free

Lynx - Fully 3D-printable 1/10 4wd buggy

Free

OpenR/C 1:10 Formula 1 car

Free

Aryton Senna's Mclaren MP4/6 3d Printed RC F1 Car

Free

Pickup Truck

Free

OpenRC F1 Dual Color McLaren Edition

Free

VW Beetle BAJA BUG - fully 3D printable

Free

ZIL-157 - RC truck with the WPL transmission

Free

Open R/C F1 MadMax Edition

Free

RC car Ford MUSTANG 1967 Fastback

4,99 €

RS-01 Ayrton Senna's 1993 McLaren MP4/8 Formula 1 RC Car

Free

Coupe body for chassis OpenZ v16c

Free

Chevrolet Blazer K5 - RC model with WPL axles

Free

The Classic Batmobile

Free

Dragster

Free

Print-in-Place Convertible

Free

Quadra V-tech

Free

Backhoe

Free

ECTO - Ghostbusters car

Free

GAZ-MM-V wartime truck 1:87 (H0)

Free

Bulgy - Thomas & Friends

Free

80's van body for the Ursa monster truck

Free

UAZ 469 assembly kit 1:35

1,89 €

Mystery Machine of Southern IL.

Free

LTZ T-40 - RC soviet tractor

Free

OpenRC F1 MKII RC Car

Free

OpenRC F1 2017 updates

Free

Nintendo OpenRC Mariokart

Free

Truck

Free

Lotus 56B Turbine Formula 1

Free

fire truck toy

Free

Hot Rod North American P-51D Mustang fighter

Free

Tilting reverse trike (fully printable)

3 €

RC Lancia Delta S4

Free

Classic 3 Wheels Car no support

Free

1959 Cadillac

Free

Small Jeep - PIP (Print In Place) no support

Free

Christinesque Cadillac

Free

ZEBRA 1910 PRESENTATION SHEET

Free

Printed Audi Quattro S1

Free

1:18 Jurassic Park Car for 3.

75 Inch Figure No Support

75 Inch Figure No Support

Hot Rod North American P-51D Mustang fighter

3D Printing RC Machine Delorean DMC-12/BTTF Time Machine

VW Beetle BAJA BUG - fully 3D printable

Discover our selection of best 3D printable automotive 3D files. All these STL files are perfectly 3D printable , so just download them, warm up your printer and play with them. This collection has been created by selecting the best creations from a library of Cults 3D Models.

Here you will find different types of 3D printed cars , there are models for self-assembly, functional vehicles that do not require modification, as well as creations for fans of modeling . By adding various elements and an engine, you can 3D print your own Remote Controlled Vehicle .

These car replicas are created not only for children, but also for adults. Many car manufacturers use 3D printing to produce their car parts, but few projects are 100% 3D printed. This compilation might make you want to create real car 100% 3D printed !

3D-printed pistons - Porsche Innovations

New 3D-printed pistons have passed their first high-load test in the 911 GT2 RS engine. Additive technologies (3D printing) allow you to create designs that cannot be obtained using traditional methods. Thus, the piston structure has been optimized according to the load level and a cooling channel has been added, but at the same time, the mass has been reduced by 10 percent compared to the standard forged piston. “In this way, we can increase the speed, reduce the thermal stress on the pistons and optimize the combustion process,” explains Frank Ickinger, who represents the pre-development of drive systems at Porsche. “The result is increased power and efficiency. ” For 911 GT2 RS with 515 kW (700 hp) can achieve a total increase of 30 hp. The new pistons are being created as part of a collaborative development effort in additive manufacturing for the production of highly stressed drive components. In doing so, Porsche collaborates with Mahle as a supplier and development partner, and the high-tech company Trumpf. Also, Zeiss, a company specializing in optical technology, with extensive experience in the production of control and measuring equipment, was attracted to the project.

” For 911 GT2 RS with 515 kW (700 hp) can achieve a total increase of 30 hp. The new pistons are being created as part of a collaborative development effort in additive manufacturing for the production of highly stressed drive components. In doing so, Porsche collaborates with Mahle as a supplier and development partner, and the high-tech company Trumpf. Also, Zeiss, a company specializing in optical technology, with extensive experience in the production of control and measuring equipment, was attracted to the project.

Optimized pistons: lighter and stronger due to bionic design.

The 911 GT2 RS is equipped as standard with forged pistons, which have almost exhausted their potential for future high-performance engines. Only changes that cannot be implemented using traditional production methods can improve the situation. Thus, additive technologies make it possible to apply the so-called bionic design, that is, to use the material only in those places where it is really needed. In order to optimize the topology in this way, engineers use a special design technique that takes into account the special requirements of 3D printing. Working together with partner companies, Mahle and Trumpf, the piston weight has been reduced by 10 percent and the topological structures are of high quality and efficiency thanks to the use of Zeiss measuring technology. “At the same time, reliability was a priority for us,” says Frank Eckinger. “Our tests show that real weight savings per piston can be up to 20 percent.”

In order to optimize the topology in this way, engineers use a special design technique that takes into account the special requirements of 3D printing. Working together with partner companies, Mahle and Trumpf, the piston weight has been reduced by 10 percent and the topological structures are of high quality and efficiency thanks to the use of Zeiss measuring technology. “At the same time, reliability was a priority for us,” says Frank Eckinger. “Our tests show that real weight savings per piston can be up to 20 percent.”

The second goal was to integrate an annular cooling channel behind the piston rings. This channel has a special cross-section, and it, like a tube, has a closed design, with the exception of two holes for oil inlet and outlet. Such a solution can only be implemented using additive technology. Thanks to the additional cooling, the temperature in the area of the piston rings, which is subjected to particularly high thermal stress, is reduced by more than 20 degrees. All of these measures combine to optimize the combustion process at higher pressures and temperatures, resulting in increased efficiency. "This is an example," says Frank Eckinger, "that the potential of the internal combustion engine is far from exhausted."

All of these measures combine to optimize the combustion process at higher pressures and temperatures, resulting in increased efficiency. "This is an example," says Frank Eckinger, "that the potential of the internal combustion engine is far from exhausted."

Mahle technology, Trumpf 3D printing experience, Zeiss test and measurement technology

As with the production forged pistons for the 911 GT2 RS, Porsche is relying on Mahle's experience in 3D printing pistons. This technology concern has developed a weldable powder for additive manufacturing based on its own M174+ aluminum alloy. The characteristics of the printed material are comparable to the characteristics of the casting from which serial pistons are made. In order to assess the suitability of the powder for production, it was repeatedly tested by the measuring technicians from Zeiss, who used light microscopy, scanning electron microscopy and X-ray microscopy, among others.

The high-tech company Trumpf took over the development of the production process and printing. Trumpf's TruPrint 3000 precision machines welded the powder layer by layer using what is known as the Laser Metal Fusion (LMF) additive laser sintering process, sometimes also referred to as Laser Powder Bed Fusion (LPBF). In this case, the laser beam welds a layer of powder of micrometer thickness (0.02-0.1 mm) and thus prints the piston step by step. In 12 hours, approximately 1200 layers are used to create a blank for the piston. Verification using various non-destructive testing methods such as computed tomography, 3D scanning and microscopy, as well as analysis of cut pistons, was carried out together with partners - Mahle, Trumpf and Zeiss. At the same time, it turned out that the quality of the printed pistons does not differ from the quality of the cast parts.

Trumpf's TruPrint 3000 precision machines welded the powder layer by layer using what is known as the Laser Metal Fusion (LMF) additive laser sintering process, sometimes also referred to as Laser Powder Bed Fusion (LPBF). In this case, the laser beam welds a layer of powder of micrometer thickness (0.02-0.1 mm) and thus prints the piston step by step. In 12 hours, approximately 1200 layers are used to create a blank for the piston. Verification using various non-destructive testing methods such as computed tomography, 3D scanning and microscopy, as well as analysis of cut pistons, was carried out together with partners - Mahle, Trumpf and Zeiss. At the same time, it turned out that the quality of the printed pistons does not differ from the quality of the cast parts.

For practical testing, six pistons were installed in a 911 GT2 RS engine. At the stand, he passed a long 200-hour test in the most severe conditions. The test program simulated a 24-hour race on a high-speed highway: about 6,000 kilometers at an average speed of 250 km/h, including gas stops. In addition, the engine ran for about 135 hours at full load and about 25 hours with additional traction at various speeds. Result: All pistons passed this test.

In addition, the engine ran for about 135 hours at full load and about 25 hours with additional traction at various speeds. Result: All pistons passed this test.

Additive manufacturing of pistons specifically for high performance models not only opens up hitherto untapped possibilities, but also provides exceptional savings in development time. For example, by eliminating the tooling required for castings, the time it takes to produce piston prototypes is reduced by more than 30 percent.

New possibilities and new design requirements.

3D printing opens up many new possibilities for both optimizing existing technologies and developing new technologies. "What was previously impossible is now a reality," says Frank Ickinger. This also applies to highly loaded components such as pistons 911 GT2 RS. The lower mass and higher thermal stability benefit the driver: the reduction of the oscillating masses allows the speed to be increased. “A 300 rpm increase means 30 hp more,” Frank Eckinger calculates. Torsional vibration dampers can be smaller, making the engine even more revving. Greater thermal stability due to lower temperatures allows for higher combustion pressures and earlier ignition timing, resulting in improved engine output and economy.

Torsional vibration dampers can be smaller, making the engine even more revving. Greater thermal stability due to lower temperatures allows for higher combustion pressures and earlier ignition timing, resulting in improved engine output and economy.

However, greater design freedom comes with new design requirements. So, engineers have to carefully monitor the creation of the part - layer by layer. “If, for example, protrusions are provided at an angle of more than 45 degrees, then so-called support structures must be used to prevent deformation,” explains Frank Eckinger. to terminate the process. At the same time, the use of support structures should be kept to a minimum, since later they still have to be removed for the most part. There are a number of requirements not only in terms of the fabrication process itself, but also in terms of economy, such as minimizing the use of support structures, which can be achieved thanks to Trumpf's experience in 3D printing.

Mahle teamed up with Porsche engineers to optimize the piston design. The technology concern has been dealing with the problems of additive manufacturing for several years. The CAD software allowed Mahle to model the structures that were created during the topology optimization. The cooling channel was then dimensioned, which according to Frank Ickinger is "a brilliant example of functional integration". The design data was then verified using the finite element method, and the virtual pistons were tested for reliability, service life and thermal stability. At the same time, the most expedient solution was to create an additional cooling channel at the height of the piston rings: in the most thermally loaded area under the exhaust valves, the temperature dropped by more than 20 degrees. As a result of numerous calculations and development cycles, an optimal design was finally created that met all the requirements. On this basis, engineers created a prototype and drawings for production.

The technology concern has been dealing with the problems of additive manufacturing for several years. The CAD software allowed Mahle to model the structures that were created during the topology optimization. The cooling channel was then dimensioned, which according to Frank Ickinger is "a brilliant example of functional integration". The design data was then verified using the finite element method, and the virtual pistons were tested for reliability, service life and thermal stability. At the same time, the most expedient solution was to create an additional cooling channel at the height of the piston rings: in the most thermally loaded area under the exhaust valves, the temperature dropped by more than 20 degrees. As a result of numerous calculations and development cycles, an optimal design was finally created that met all the requirements. On this basis, engineers created a prototype and drawings for production.

Cast alloy powder

Parallel to the design process, Mahle was looking for the right material. M174+ casting alloy offered the best basic conditions. From it, piston specialists have obtained a powder for additive manufacturing. To test whether it meets the requirements of additive manufacturing, Mahle and Trumpf first tested the powder by measuring its flow and bulk density, moisture content and grain distribution. To recognize pores in powder grains, experts examined their surface using metallographic sections. With the help of the so-called high-temperature gas extraction, the presence of gaseous contaminants was determined. In addition, Zeiss measurement technicians used light microscopy, scanning electron microscopy and X-ray microscopy to check for grain contamination, particle shape, particle distribution and gas inclusions. At the same time, it was important to analyze the behavior and structure of the powder during repeated use, which is an important point in terms of recycling and environmental compliance. Even with repeated use, the powder did not show any significant changes that could affect the quality of the parts made from it.

M174+ casting alloy offered the best basic conditions. From it, piston specialists have obtained a powder for additive manufacturing. To test whether it meets the requirements of additive manufacturing, Mahle and Trumpf first tested the powder by measuring its flow and bulk density, moisture content and grain distribution. To recognize pores in powder grains, experts examined their surface using metallographic sections. With the help of the so-called high-temperature gas extraction, the presence of gaseous contaminants was determined. In addition, Zeiss measurement technicians used light microscopy, scanning electron microscopy and X-ray microscopy to check for grain contamination, particle shape, particle distribution and gas inclusions. At the same time, it was important to analyze the behavior and structure of the powder during repeated use, which is an important point in terms of recycling and environmental compliance. Even with repeated use, the powder did not show any significant changes that could affect the quality of the parts made from it. The aim was to ensure that the powder layer was uniform and reproducible later in production.

The aim was to ensure that the powder layer was uniform and reproducible later in production.

As early prototypes, Trumpf AM produced simple geometries such as cubes and rods for material analysis and characterization. At the same time, many samples were created in order to find the optimal settings for printers using this material. The results of the determination of the parameters were extremely positive: all samples were characterized by evenly distributed round pores ranging in size from 5 to 50 µm. The strength of the samples after conventional heat treatment was at the level of cast pistons. Also, physical indicators were at the level of cast parts. So, the thermal expansion was somewhat lower, the fatigue limit under alternating loads at 150 and 300 degrees Celsius corresponded to the level of the cast material, and in some respects the printed samples even surpassed it.

Trumpf additive manufacturing and expertise

Design and material selection issues were handled in collaboration with Trumpf. This company, which, like Porsche and Mahle, is located near Stuttgart, is a pioneer in the field of metal 3D printing. Since 1999, Trumpf has been conducting research in the field of additive laser sintering (Laser Metall Fusion, LMF) together with the Frauenhof Institute for Laser Technology in Aachen. In 2004, the company introduced its first LMF printer to the market. Therefore, hardly anyone could better choose the optimal parameters for printing parts.

This company, which, like Porsche and Mahle, is located near Stuttgart, is a pioneer in the field of metal 3D printing. Since 1999, Trumpf has been conducting research in the field of additive laser sintering (Laser Metall Fusion, LMF) together with the Frauenhof Institute for Laser Technology in Aachen. In 2004, the company introduced its first LMF printer to the market. Therefore, hardly anyone could better choose the optimal parameters for printing parts.

For the production of pistons, Trumpf used a high precision printer from the TruPrint 3000 series. The LMF method involves the production of parts in layers. The whole process takes place in a special chamber. In it, on the same axis next to each other, there are filling, working and assembly cylinders. The process begins with the device feeding the powder from the filling tank through the working cylinder and depositing a layer of powder. Excess powder falls into a collection container. Then the laser beam, in accordance with the contour of the part, heats the surface of the powder and welds it, turning it into a solid layer of metal and bonding with the layers already existing below. At the next stage, the working cylinder is lowered and the device applies the next layer of powder. This process is repeated until the part is completely printed. The unused powder is then removed from the working cylinder, after which the part can be detached.

At the next stage, the working cylinder is lowered and the device applies the next layer of powder. This process is repeated until the part is completely printed. The unused powder is then removed from the working cylinder, after which the part can be detached.

Tests confirm the uncompromising quality of printed pistons

Layer-by-layer production allows the creation of shapes and structures that would be impossible to produce using traditional methods such as casting or milling. "The collaborative piston demonstrates the benefits of 3D printing. The proposed method allows the production of parts with special properties, while being light and strong. They can be used in almost all industries. Trumpf does not only work for the automotive industry. Its customers include also firms from the aerospace, medical and energy industries," says Stefen Rübling, Project Manager at Trumpf. The TruPrint 3000 printer, with its 30 cm diameter cylindrical working chamber, was ideal for the production of pistons: their 104 mm diameter made it possible to produce five parts at the same time. Trumpf also showed that when using the TruPrint 5000, which uses three lasers, productivity increases by almost three times.

Trumpf also showed that when using the TruPrint 5000, which uses three lasers, productivity increases by almost three times.

The first high-tech pistons produced by the printer have been carefully studied. In addition to the studies at Mahle and Trumpf, project partner Zeiss used the same control methods as in testing the first samples of the material: metallographic sections, light microscopy, X-ray spectroscopy and computed tomography. The scanned data for the piston blank was compared to the CAD data to check if the geometry had changed during production. The detected deviations did not exceed the tolerances for the cast piston and thus corresponded to the norm. Another important point was the quality of the inside of the cooling channel. Were there any particles of powder or welding that could disrupt the operation of the channel? Here, no violations were found. Zeiss' high-resolution computed tomography machines made it possible to look for defects such as small cracks or inclusions in advance, and thus prepare the basis for further tests. Even the smallest signs of defects were “marked” thanks to a special microdefectoscopy method, so that after the first tests, doubtful places could be examined without destroying the part. To determine the porosity and density, in addition to the so-called metallographic sections, the method of flotation of samples and parts of the piston was used: the less gas they contained, the less the buoyancy force. With a density of more than 99.5 percent of the printed pistons were flush with the cast parts. Also, the piston processing at Mahle showed no disadvantages compared to the M174+ cast material. After that, the first test was carried out at Mahle - using a hydropulsor. In this case, the piston was taken by the hole for the piston pin and subjected to a load until destruction. The number of load changes exceeded the required value, and thus the test was passed. The second test was called the "boss pull-off test". In its course, the force that is necessary to tear off the piston bosses was determined.

Even the smallest signs of defects were “marked” thanks to a special microdefectoscopy method, so that after the first tests, doubtful places could be examined without destroying the part. To determine the porosity and density, in addition to the so-called metallographic sections, the method of flotation of samples and parts of the piston was used: the less gas they contained, the less the buoyancy force. With a density of more than 99.5 percent of the printed pistons were flush with the cast parts. Also, the piston processing at Mahle showed no disadvantages compared to the M174+ cast material. After that, the first test was carried out at Mahle - using a hydropulsor. In this case, the piston was taken by the hole for the piston pin and subjected to a load until destruction. The number of load changes exceeded the required value, and thus the test was passed. The second test was called the "boss pull-off test". In its course, the force that is necessary to tear off the piston bosses was determined. And in this case, the value was within the acceptable range, like cast pistons. Real load tests in the engine 9The 11 GT2 RS proved the uncompromising quality of the printed pistons – and their potential for improved power and economy.

And in this case, the value was within the acceptable range, like cast pistons. Real load tests in the engine 9The 11 GT2 RS proved the uncompromising quality of the printed pistons – and their potential for improved power and economy.

High quality printed double jet nozzles

In order to supply this annular channel with oil, as well as to supply oil, as with serial pistons, to the bottom of the piston, another part was created on a 3D printer: a stainless steel double jet nozzle. "Manufacturing using conventional technology would have been too complicated due to the geometry," explains Porsche engineer Marco Klampfl. To create a twin-jet nozzle by conventional methods would require a complex procedure using soldering and milling. In addition, it would be impossible to use it in the engine.

So the engineers designed an S-shaped bifurcated oil passage that was additively fabricated from stainless steel powder. This part with a tubular base and a check valve was soldered to the piston cooling nozzle. "Doubts that the quality of the oil jet would suffer due to poor surface quality as a result of 3D printing were not confirmed," states Marco Klumpf. "On the contrary, comparative measurements showed that the quality of the jets was even higher due to functional integration."

"Doubts that the quality of the oil jet would suffer due to poor surface quality as a result of 3D printing were not confirmed," states Marco Klumpf. "On the contrary, comparative measurements showed that the quality of the jets was even higher due to functional integration."

Widespread use of 3D printing at Porsche

Additive manufacturing opens up a wide range of opportunities for Porsche in new products, technologies and business areas. Product innovations include the use of lightweight designs and functional integration techniques, while new processes include faster development and flexible manufacturing. Among the new business areas, individualization, new offers for customers and the production of spare parts attract attention. This technology is of technical and economic interest to Porsche, especially in the production of special models and small series. In addition, additive technologies are ideal for producing structures that are designed and optimized using artificial intelligence.

Porsche already uses additive technologies in many areas and is actively working to improve them further. For example, since May, a 3D-printed bucket seat has been offered for the 911 and 718 used in motorsports. The central part of the seat, i.e. cushions and backrests, is partly 3D printed. In the future, customers will be able to choose from three levels of seat firmness (hard, medium, soft). The Porsche Classic division uses additive manufacturing to produce plastic, steel and light metal parts that were previously not available to order. For example, the Porsche 9 clutch release lever59, which is used as a spare part, is now 3D printed. Currently, about 20 parts for classic Porsche cars are produced using additive technologies. All manufactured parts are required to meet at least the quality standards of the original production period, but generally meet higher standards. The success of the project is regarded by Porsche as a confirmation of the correctness of the chosen path in the field of 3D printing. Due to the relatively high cost of manufacturing parts, additive technologies are currently used only for the manufacture of small batches of components that, under normal conditions, require the additional use of expensive tools. Since Porsche is constantly producing small series and special models, the company, according to Frank Ickinger, is thinking, for example, of mass-producing pistons for the entire special series of high-performance engines using the LMF method. However, it is in the field of production of highly loaded drive elements using additive technology that many questions remain to be answered. “Designing, manufacturing and finishing parts involve many new parameters and methods that are not available in the classical approach. Being able to master new technologies with confidence is crucial to ensure consistently high quality,” emphasizes the development specialist. we still have a lot to do."

Due to the relatively high cost of manufacturing parts, additive technologies are currently used only for the manufacture of small batches of components that, under normal conditions, require the additional use of expensive tools. Since Porsche is constantly producing small series and special models, the company, according to Frank Ickinger, is thinking, for example, of mass-producing pistons for the entire special series of high-performance engines using the LMF method. However, it is in the field of production of highly loaded drive elements using additive technology that many questions remain to be answered. “Designing, manufacturing and finishing parts involve many new parameters and methods that are not available in the classical approach. Being able to master new technologies with confidence is crucial to ensure consistently high quality,” emphasizes the development specialist. we still have a lot to do."

Development of new projects, new production solutions and increased efficiency

In cooperation with Mahle and Trumpf, another part was created - an additional charge air cooler that is integrated in the channel between the turbocharger and the intercooler. Thanks to the possibilities of 3D printing, the cooler has a significantly larger heat-absorbing area. This allows you to optimize flow dynamics and cooling. The result: the intake air becomes cooler, power and efficiency increase.

Thanks to the possibilities of 3D printing, the cooler has a significantly larger heat-absorbing area. This allows you to optimize flow dynamics and cooling. The result: the intake air becomes cooler, power and efficiency increase.

The potential of additive technologies is also being explored and evaluated in relation to electric drives. “Using a highly integrated electric drive, we can demonstrate not only the potential of the product itself, but also the development possibilities. The use of new design methods has doubled the rigidity of the drive and reduced the weight by about 10 percent. In addition, the integrated gearbox heat exchanger has significantly improved the performance of the thermal management system "The integration of 12 assemblies saves 30 screws, 12 seals and many other parts. This not only improves the layout, but also significantly reduces assembly costs. All these measures saved 20 minutes in production," explains Falk Heilfort from Drive Development. In addition, the use of copper for printing creates interesting ideas that open up new opportunities for creating electric motors. Also, the topic of cooling for pulsed inverters and electric machines was taken to a new level.

Also, the topic of cooling for pulsed inverters and electric machines was taken to a new level.

"For us developers, 3D printing has a number of advantages," adds Frank Eckinger. Since the parts are produced without the use of special equipment required for shaping, significant time can be saved during production, and this allows more options to be tested. As a result, prototypes can turn out to be even more cost-effective, since there are no costs for special equipment. By the way, the equipment itself can also be produced using additive technologies. An injection mold with an integrated cooling channel allows conventional production techniques to be optimized in terms of cycle times. 3D printing allows not only working with metal, but also producing plastic parts and complex sand cores, for example, for casting cylinder heads, crankcases and electric motor cases, and thus provide significant cooling benefits.

Despite the rapid development of additive technologies, there are still many restrictions on their way.