3D tissue printing slideshare

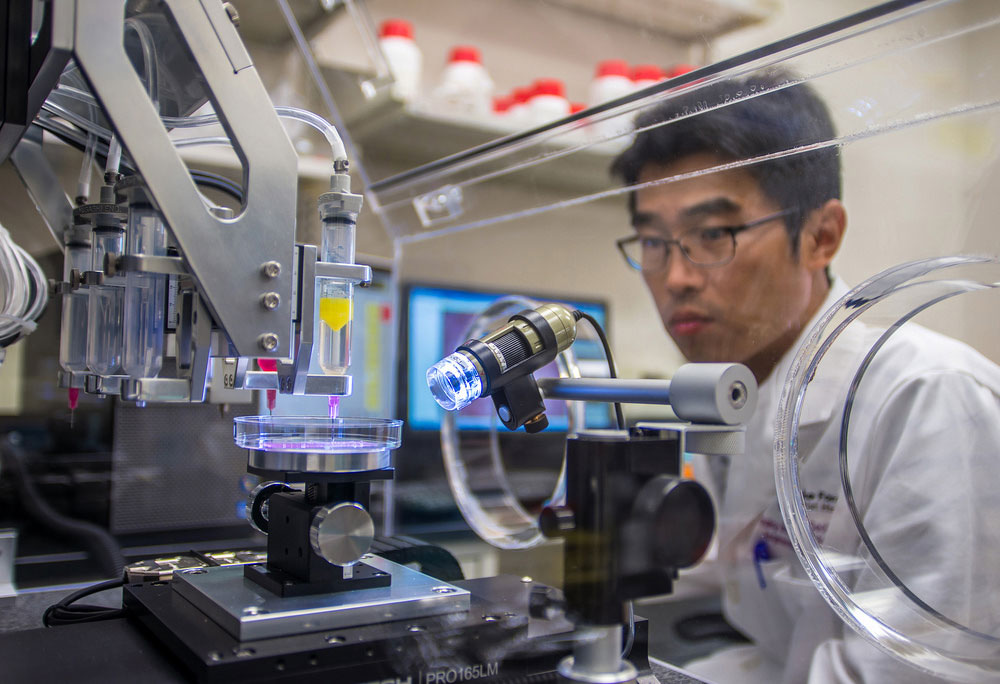

What is 3D bioprinting? | 3D Bioprinting technology

The history of 3D bioprinting – where it all began?3D bioprinting is evolving rapidly since researchers have innovated and driven the field forward. However, as a technology, 3D printing is not a new invention. The first steps in 3D printing were taken in 1980s, when in 1984 Charles Hull filed a patent for the first commercial 3D printing technology. This has been a symbol of the birth of 3D printing, and it created the base for 3D bioprinting as well. Bioprinting came into picture in 1988, when Robert J. Klebe used inkjet printer for printing cells.1 After these first steps, the field has constantly evolved, and new methods and techniques have been discovered. The countless possibilities and opportunities to create something ground-breaking keep intriguing scientists, and thus bioprinting has become a popular technology.

What is 3D bioprinting and how does bioprinting work?

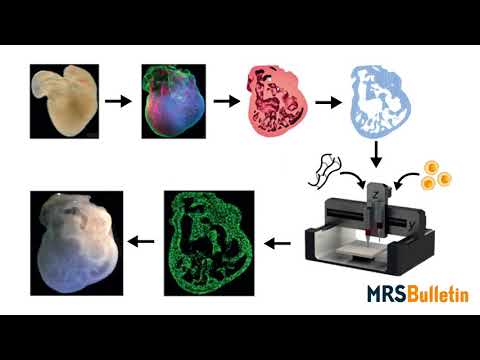

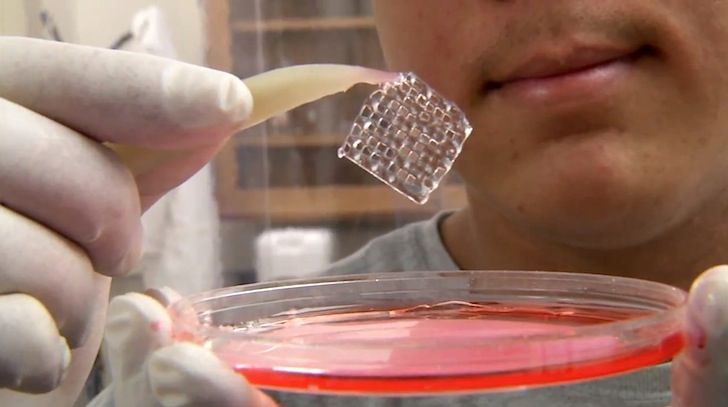

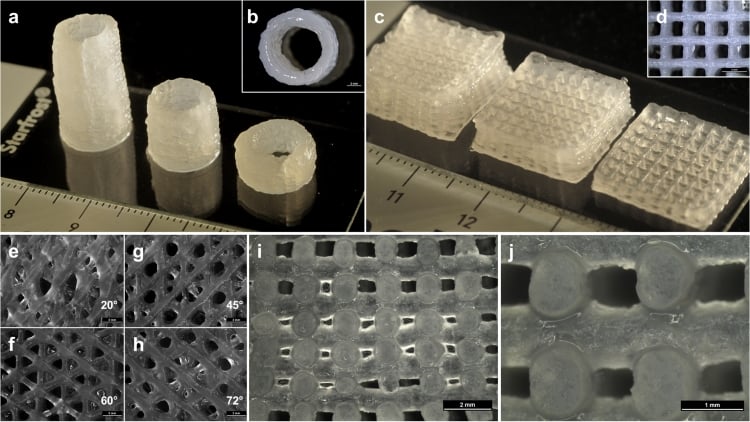

3D bioprinting is an additive manufacturing process that uses bioinks to print living cells developing structures layer-by-layer which imitate the behavior and structures of natural tissues. Bioinks, that are used as a material in bioprinting, are made of natural or synthetic biomaterials that can be mixed with living cells.

The technology and bioprinted structures enable researchers to study functions of the human body in vitro. 3D bioprinted structures are more biologically relevant compared to in vitro studies performed in 2D.

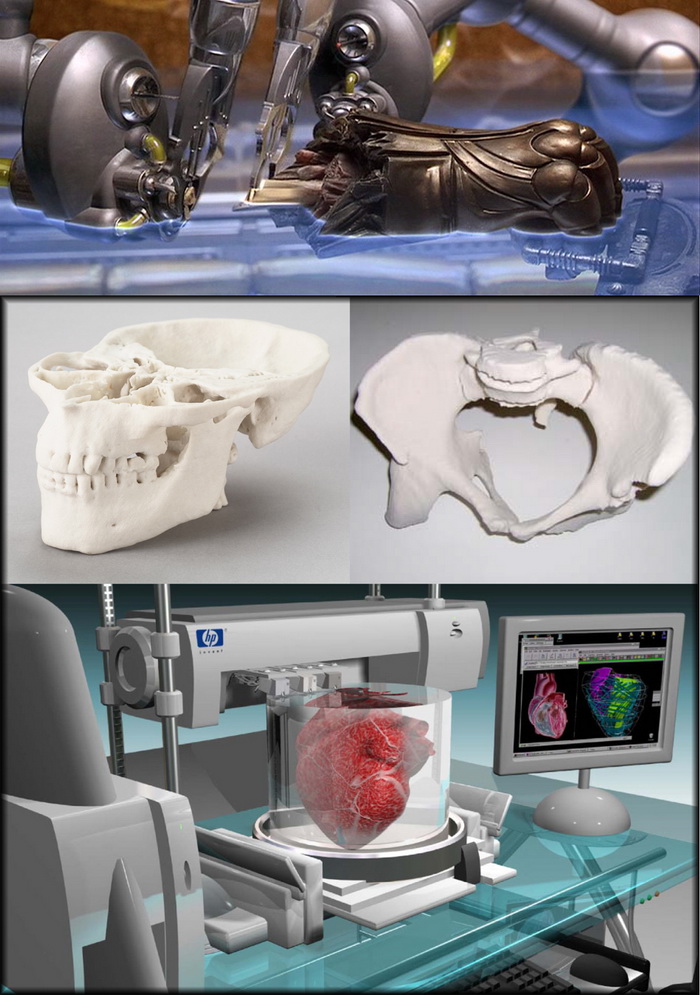

Mostly, 3D bioprinting can be used for several biological applications in the fields of tissue engineering, bioengineering and materials science. The technology is also increasingly used for pharmaceutical development and drug validation. Clinical settings such as 3D printed skin and bone grafts, implants and even full 3D printed organs are currently at the center of bioprinting research.

3D bioprinting of tissues and organs for regenerative medicine

Three-dimensional bioprinting plays an important role in tissue engineering which aims to fabricate functional tissue for applications in regenerative medicine and drug testing. Tissue regeneration and reconstruction could enable the possibility to repair or replace damaged tissues and organs.

Tissue regeneration and reconstruction could enable the possibility to repair or replace damaged tissues and organs.

Advantages and disadvantages of 3D bioprinting

Advantages of 3D bioprinting

- Allows mimicking the real structure of desired tissue/organ etc.

- Possibility to revolutionize future medical treatment capabilities

- Possible creation of patient-specific and organ-specific treatments

- Effects of drugs can be examined more accurately

- Decreases animal testing

- Biocompatibility with human cells and tissues

- Automating complex processes

- Consistency, less human errors

Disadvantages of 3D bioprinting

- Pricing, expensive technology

- Complexity

- Maintaining cell environment can be difficult

- Ethical concerns

- Energy consumption

3D bioprinting bioinks

Bioinks are used as the base material when bioprinting tissue-, organ-, or bone-like structures with bioprinters. 3D bioinks can be cell-laden, scaffold-free, or cell-free, like GrowInk™, which is an easily customizable hydrogel-based bioink made of nanofibrillar cellulose and water.

3D bioinks can be cell-laden, scaffold-free, or cell-free, like GrowInk™, which is an easily customizable hydrogel-based bioink made of nanofibrillar cellulose and water.

GrowInk’s cell-free form allows it to be tailored well to fit multiple research areas and purposes.

Choosing the right composition of bioink, and the bioink density can affect the cell viability and cell density, hence, selecting the most suitable bioink for each research purpose is essential.

Read more about GrowInk

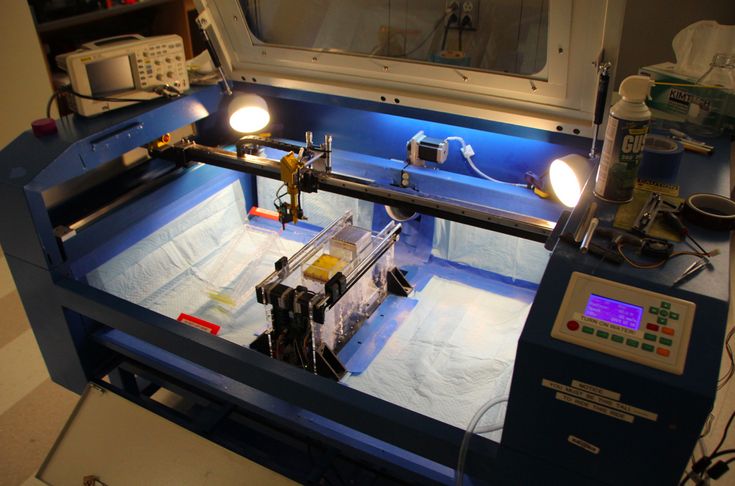

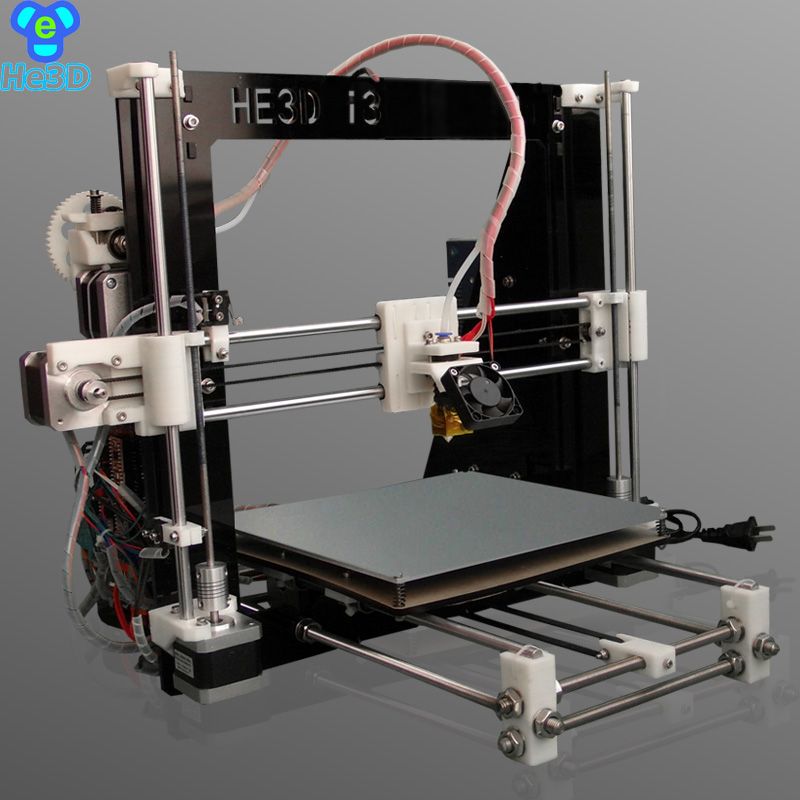

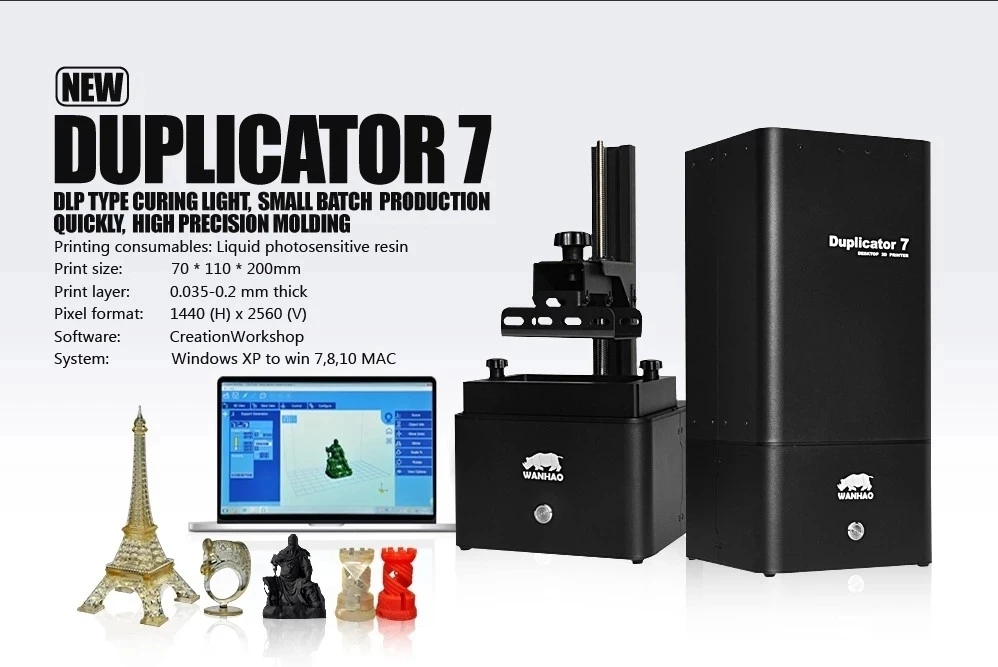

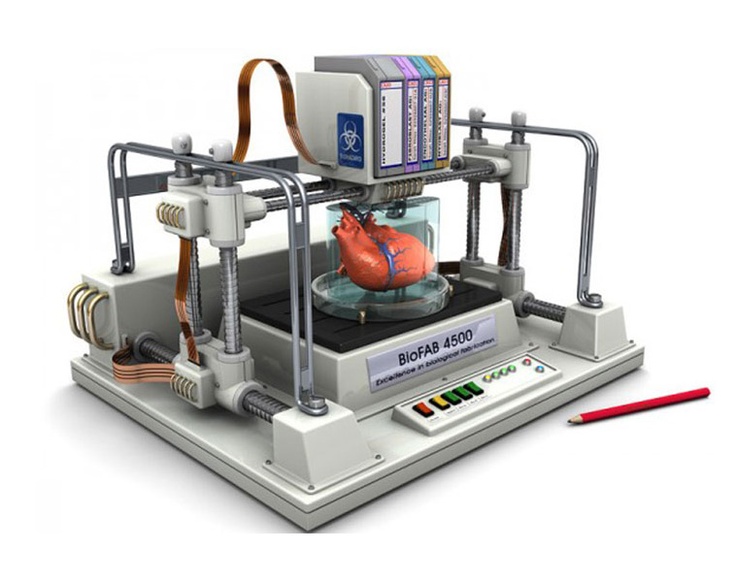

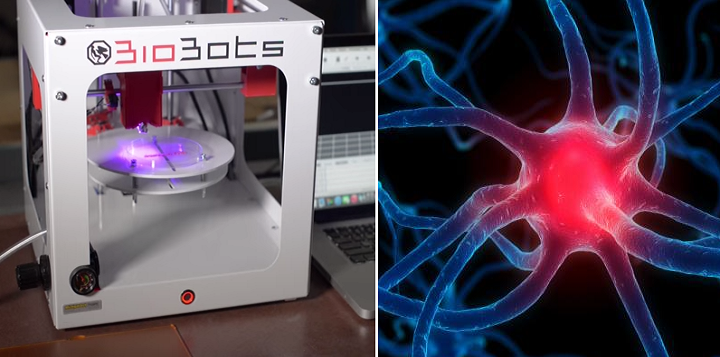

3D bioprinters

3D printers and 3D bioprinters are similar to each other, but 3D printers are designed to print solid materials, where 3D bioprinters are designed to print liquid or gel. 3D bioprinters are also designed to handle sensitive material that contain living cells, without creating too much damage on the end result. Bioprinters can be inkjet based, laser assisted, or extrusion based. Each printer type has its pros and cons when it comes to cost, cell viability, cell density, resolution, and so on. Bioprinters’ compatibility with bioinks also varies, and therefore it is important to ensure the bioprinter and bioink work well together.

Bioprinters’ compatibility with bioinks also varies, and therefore it is important to ensure the bioprinter and bioink work well together.

Commercially available cell printers

3D Bioprinting solutions – hints and tips for bioprinting

- Select the most suitable bioink for your research purpose and ensure the bioink you are using is compatible with the selected printing method and cell types

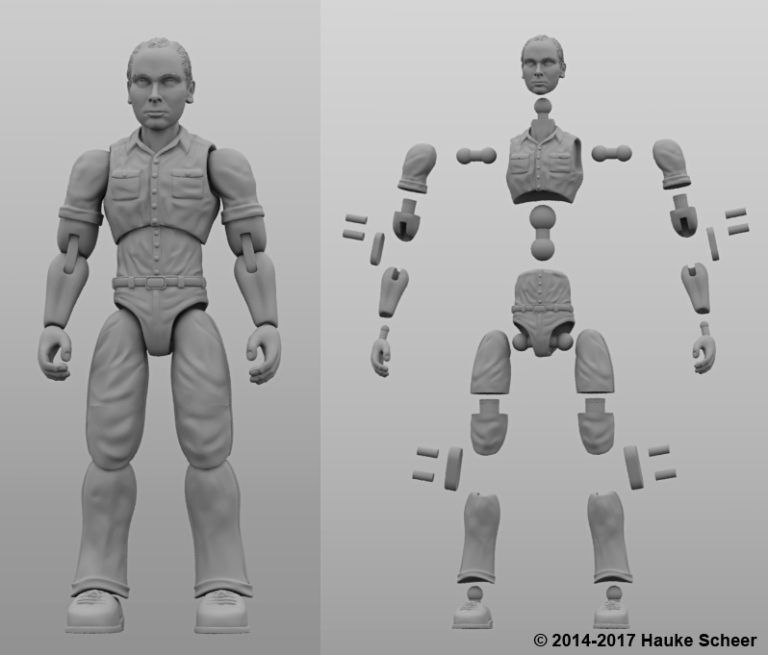

- Know what you are printing – create a new digital 3D model of the structure you want to print or get a license for an existing model

- Use fresh or new printer tips that are specifically fitted for your system

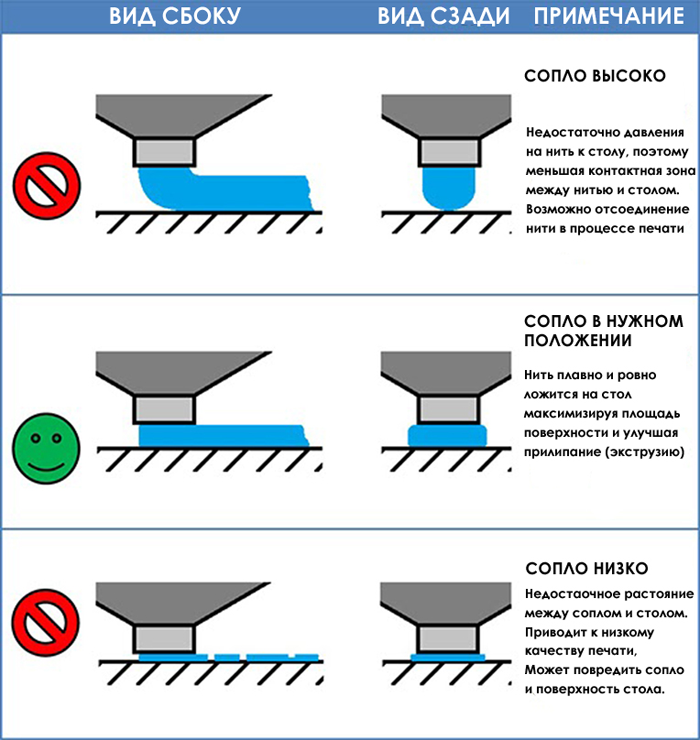

- Test different nozzle/needle sizes, printing speeds, and layer heights and optimize them based on the results

- Make sure the working temperature is suitable for the printer and the used materials

- Set an optimal printing pressure. A bit higher pressure is usually needed when printing with cells

Check out hints and tips when using GrowInk

Future of 3D bioprinting

The rapid development of technology can also be seen in the advancement of bioprinting. Three-dimensional bioprinting technology has the potential to solve numerous problems in areas such as healthcare. Functioning bladders, which have been grown using bioprinted tissue from patients’ own cells have already been transplanted into human body successfully2,3. Researchers are constantly researching the possibility of bioprinting other functioning organs.

Three-dimensional bioprinting technology has the potential to solve numerous problems in areas such as healthcare. Functioning bladders, which have been grown using bioprinted tissue from patients’ own cells have already been transplanted into human body successfully2,3. Researchers are constantly researching the possibility of bioprinting other functioning organs.

One future scenario of 3D bioprinting could be that no-more organ donors are needed, as personalized human organs can be printed using the patients’ own cells or stem cells as a base. This technology can be revolutionizing in preventing and fixing diseases. Eventually, it is hoped that bioprinting technology will enhance medical care and make it more efficient.

Applications of 3D bioprinting

3D printing of GrowInk

™-N and GrowInk™-T with Poietis NGB-R™ bioprinterHigh-throughput production of GrowInk

™-T models by drop-on-demand 3D bioprintingBioprinting publications

Wang, Q. , et al., (2021). Rheological and Printability Assessments on Biomaterial Inks of Nanocellulose/Photo-Crosslinkable Biopolymer in Light-Aided 3D Printing. Available from: https://doi.org/10.3389/fceng.2021.723429.

, et al., (2021). Rheological and Printability Assessments on Biomaterial Inks of Nanocellulose/Photo-Crosslinkable Biopolymer in Light-Aided 3D Printing. Available from: https://doi.org/10.3389/fceng.2021.723429.

Fonseca, A.C., et al., (2020). Emulating Human Tissues and Organs: A Bioprinting Perspective Toward Personalized Medicine. Chemical Reviews. Available from: https://doi.org/10.1021/acs.chemrev.0c00342.

Wang, X., Q. Wang, and C. Xu, (2020). Nanocellulose-Based Inks for 3D Bioprinting: Key Aspects in Research Development and Challenging Perspectives in Applications-A Mini Review. Bioengineering (Basel), 7(2). Available from: https://doi.org/10.3390/bioengineering7020040

Yadav, C., et al., (2020). Plant-based nanocellulose: A review of routine and recent preparation methods with current progress in its applications as rheology modifier and 3D bioprinting. International Journal of Biological Macromolecules. Available from: http://www.sciencedirect.com/science/article/pii/S0141813020349631.

Available from: http://www.sciencedirect.com/science/article/pii/S0141813020349631.

Ashammakhi, N., et al., (2019). Bioinks and bioprinting technologies to make heterogeneous and biomimetic tissue constructs. Materials Today Bio, 1: p. 100008. Available from: https://www.sciencedirect.com/science/article/pii/S2590006419300146.

Di Marzio, N., et al., (2020). Bio-Fabrication: Convergence of 3D Bioprinting and Nano-Biomaterials in Tissue Engineering and Regenerative Medicine. Frontiers in Bioengineering and Biotechnology, 8(326). Available from: https://www.frontiersin.org/article/10.3389/fbioe.2020.00326.

Jovic, T.H., et al., (2019). Plant-Derived Biomaterials: A Review of 3D Bioprinting and Biomedical Applications. Frontiers in Mechanical Engineering, 5(19). Available from: https://www.frontiersin.org/article/10.3389/fmech.2019.00019.

References

1Gu, Z., Fu, J., Lin, H. and He, Y., 2020. Development of 3D bioprinting: From printing methods to biomedical applications. Asian Journal of Pharmaceutical Sciences, 15(5), pp.529-557.

and He, Y., 2020. Development of 3D bioprinting: From printing methods to biomedical applications. Asian Journal of Pharmaceutical Sciences, 15(5), pp.529-557.

2Atala, A., Bauer, S., Soker, S., Yoo, J. and Retik, A., 2006. Tissue-engineered autologous bladders for patients needing cystoplasty. The Lancet, 367(9518), pp.1241-1246.

3 Belton, P., 2018. 'A new bladder made from my cells gave me my life back'. BBC, [online] Available at: <https://www.bbc.com/news/business-45470799> [Accessed 6 August 2021].

What is 3D Bioprinting? | Bioprinting Explained

“3D Bioprinting” or “bioprinting” is a form of additive manufacturing that uses cells and biomaterials instead of traditional metals and plastics to create 3D constructs that are functional 3D tissues. These biomaterials are called bioinks, and they mimic the composition of our tissues. Bioprinting can be applied to a variety of areas including but not limited to regenerative medicine, drug discovery and development, and 3D cell culture.

Bioprinted structures, such as organs-on-chips, can be used to study functions of a human body outside the body, in 3D. The geometry of a 3D bioprinted structure is more similar to that of a naturally occurring biological system than an in vitro 2D model. Structural similarity can in turn lead to functional results that are more physiologically relevant. No other technology enables the level of geometric complexity in engineering tissues that 3D bioprinting enables. That is why this technology has the potential to completely change the way we treat diseases – by replacing animal testing and ending the organ transplant waiting list.

How does 3D bioprinting work?

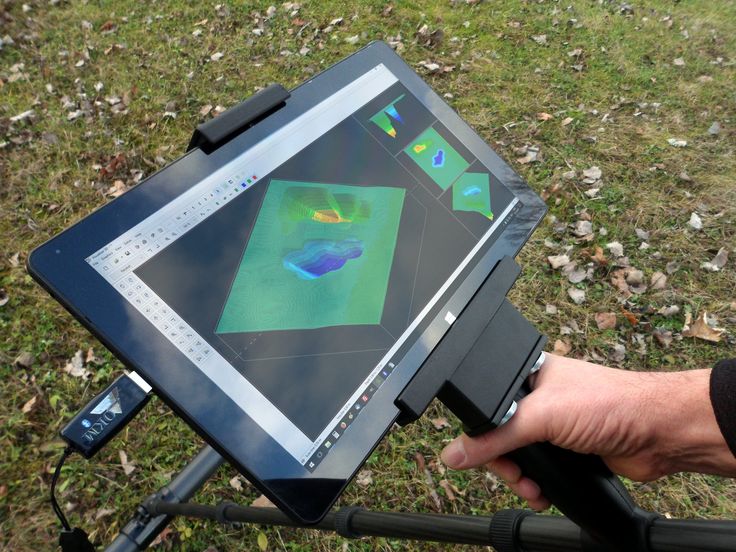

3D bioprinting starts with a model of a structure, which is recreated layer-by-layer out of a bioink either mixed with living cells, or seeded with cells after the print is complete. These starting models can come from anywhere – a CT or MRI scan, a computer generated design (CAD) program, or a file downloaded from the internet.

That 3D model file is then fed into a slicer – a specialized kind of computer program which analyzes the geometry of the model and generates a series of thin layers, or slices, which form the shape of the original model when stacked vertically. Cura and slic3r are examples of slicers commonly used in 3D printing. Allevi also has a specialized slicer, optimized specifically for bioprinting, built into our Allevi Bioprint software.

Once a model is sliced, the slices are transformed into path data, stored as a G-code file, which can be sent to a 3D bioprinter for printing. The bioprinter follows instructions in the G-code file in order, including instructions to control for temperature of the extruders, extrusion pressure, bed plate temperature, crosslinking intensity and frequency, and, of course, the 3D movement path generated by the slicer. Once all of the G-code commands are completed, the print is done and can be cultured or seeded with cells as part of a biostudy.

Why is bioprinting important?

Over 120,000 people in the US alone are on waiting lists for organs, and others experience chronic problems due to the long-term damaging effects of post-transplant immunosuppression. There is a large and growing need for an alternative to the organ transplant waiting list. The scientific community has already succeeded in bringing together multidisciplinary teams of researchers, physicians, and engineers to take on the biggest challenges to human health, and 3D bioprinting is an exciting new tool with the potential to eliminate the organ transplant waiting list.

For pharmaceutical development, 3D bioprinting offers a means of testing drugs faster, at a lower cost, and with better biological relevance to humans than animal testing. In the biomedical devices field, 3D bioprinting has enabled new developments such as sugar stents to help surgeons join veins with fewer complications, and systems for improved drug delivery, among others.

In the biomedical devices field, 3D bioprinting has enabled new developments such as sugar stents to help surgeons join veins with fewer complications, and systems for improved drug delivery, among others.

As bioprinting evolves, it will become possible to use a patient’s own cells to 3D print skin and bone grafts, organ patches, and even full replacement organs. Personalized and regenerative medicine continue to grow in popularity, and 3D bioprinting will give doctors and researchers the tools to better target treatments and improve patient outcomes.

Further reading

Bioprinting 101 – Allevi

3D Bioprinting – Wikipedia

3D Bioprinting of Living Tissues – Wyss Institute, Harvard

Bioprinting – NIH Director’s Blog

3D printed mesh fabric

Prologue

Hello everyone! I am developing "smart sequins" - electromechanical color-reproducing devices for designer clothes. Our team is passionate about the idea of creating clothes and accessories that can change their color at the request of the owner or depending on environmental conditions.

In this article I want to talk about how we used 3D printing in our project, share our experience and tools.

3D printing on fabric

One of the tasks that I had to solve was to figure out how to make an elastic fabric out of plastic sequins, which in its properties would resemble textile materials. At the same time, it is necessary to provide for the possibility of easily creating electrical connections between the sequins.

There are quite a few articles and materials on making clothes on a 3D printer. Many different methods have already been invented, from creating hinges right in the printing process to printing with elastic plastics.

While looking for a solution, I came across this video. From it, I first learned about the method of printing on mesh fabric using a conventional FDM 3D printer.

The author himself claims that he spied the idea here: Shorey Designs.

The essence of the method is very simple. We create a 3D model of a fragment of the future canvas, then arrange a lot of fragments so that we get a whole canvas. We start the slicer and prepare the G-code. Before sending it to the printer, you need to insert a pause and raise the extruder before printing a certain layer. The printer will stop during operation. At this point, we cover the printed layers with a mesh cloth. We continue to print. Due to the presence of large holes in the fabric, the layers of plastic will interlock with each other, as in conventional printing, and the mesh fabric will be firmly integrated into the parts.

We start the slicer and prepare the G-code. Before sending it to the printer, you need to insert a pause and raise the extruder before printing a certain layer. The printer will stop during operation. At this point, we cover the printed layers with a mesh cloth. We continue to print. Due to the presence of large holes in the fabric, the layers of plastic will interlock with each other, as in conventional printing, and the mesh fabric will be firmly integrated into the parts.

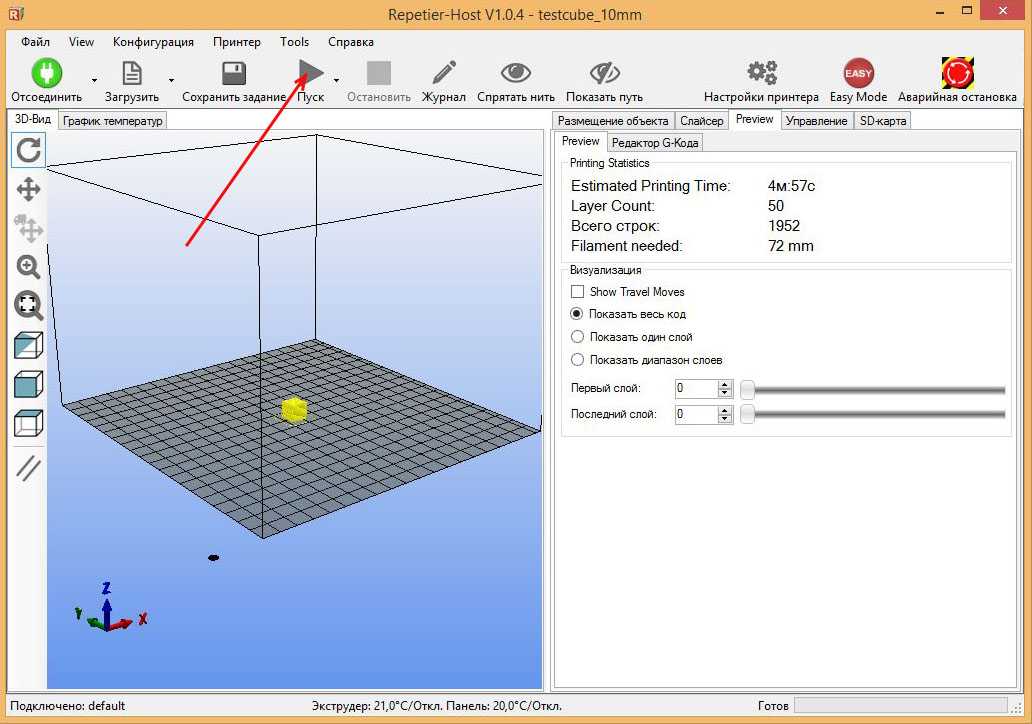

Modifying G-code

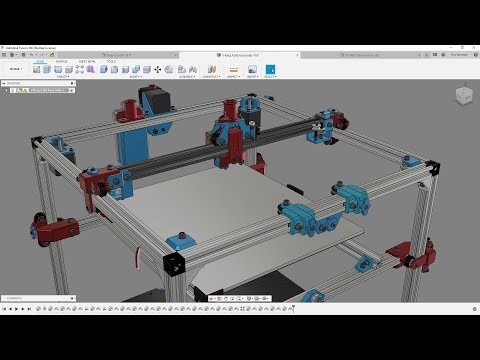

I use Cura version 3.2.1 as a slicer. 3D printer - homemade H-bot controlled by a board based on ATmega2560 (RAMPS 1.4) with Marlin firmware.

To pause the printer, there is an M25 command. Command for lifting in Z by 20mm: G0 Z20. It is noteworthy that the M25 must go before the ascent, otherwise the next command is processed first. Why this happens is a mystery to me, apparently somehow connected with the processing of commands by the printer.

Add commands to G-code:

Operation automation

Manually searching for the required line in the G-code file and inserting commands is not the most modern solution, I thought and wrote a simple program that allows you to open and view toolpaths.

For the convenience of viewing the layers, the “explode” command is provided, which allows you to visually increase the distance between the layers of the model. After pressing the "insert pause" button, the distance between the marked layer (red) and the previous one increases. This means that the print will be interrupted precisely between these layers.

To understand where one layer ends and the next begins, I used the comments that Cura kindly provides in its output files. The keyword ";LAYER:X" allows you to accurately find the boundaries of layers in a text file.

Pressing the "write file" button allows you to save the modified G-code in the specified location.

Save the file to the SD card and bring it to the printer.

It's funny that only while preparing this article, I came across a video that tells how you can do the same using standard Cura tools ... But the process is already running, it's too late to slow down! Here, starting at 7:30, it is described in detail how to do it.

Well ... hurry up - learn how to parse G-code!

Trying to print

Formation of the first layers. We print on glass. Heated table. Table temperature 60⁰С, printing temperature 220⁰С. The print material is PLA plastic. Layer height 0.2mm.

During the pause, place a piece of fabric and fix with magnets. Since the table is aluminum (paramagnetic), we put the magnets on the top and bottom sides of the table. Fixation is made in 4 places, in the corners of the part. This is quite enough. The main thing is not to place them too close to the print area, otherwise the magnets will stick to the print head.

After 40 minutes, this is the structure. The thickness of each 6 carbon element is 1mm. The gap between the elements is 2mm.

In this experiment, tulle was used as the backing fabric. It is a lightweight mesh fabric of medium stiffness, woven from polyester threads.

Experiments have also been made with mosquito net printing. In the hardware store, there were two types of them: fabric and fiberglass. Fabric mesh is softer than tulle, but has greater mechanical tensile strength, as well as less elasticity. The fiberglass mesh is harder than tulle, its mechanical strength is the highest of all participants in the experiment.

In the hardware store, there were two types of them: fabric and fiberglass. Fabric mesh is softer than tulle, but has greater mechanical tensile strength, as well as less elasticity. The fiberglass mesh is harder than tulle, its mechanical strength is the highest of all participants in the experiment.

Hexagonal sequin printing on fiberglass mosquito net. The gap between the elements is 1mm. The matrix is very hard. Clearance is clearly not enough.

Round sequin printing on fiberglass mosquito net. The gap between the circles is 2mm. It has a lot of flexibility, but there is too much unfilled space between the sequins.

After several test prints, the fabric mesh was chosen. She formed the basis of the matrix of smart sequins. The resulting matrix can bend in all directions.

The video demonstrates the operation of the program, the printing process and the final result.

Conclusion

The method of printing on mesh fabric proved to be very good. This is an ideal solution for our task, because the fabric substrate allows us to weave conductive threads into it, which are used to provide electrical connection between the individual sequins of the matrix. Moreover, the formation of a “pattern” of conductors can be carried out at the preparatory stage. And the 3D printing itself is later.

The strength of the resulting structure depends mainly on the strength of the substrate material. But the flexibility will also depend on the distance between the sequins, as well as their shape.

The developed program still needs to be improved. For example, you can finish the retract before lifting, allow the user to adjust the height of the extruder.

Link to the source code for the processing environment.

And also a link to the release with the .exe file of the program.

By the way, we recently launched our "smart sequins" on the crowdfunding platform. For those who want to get to know our work better, I will leave a link.

What is 3D printing - applying 3D images to fabric and souvenirs

Today, 3D printing on fabric is a fairly popular way to create exclusive items. This type of drawing, due to the visual volume and realism, easily attracts attention, which means that it will be in demand among people of different ages for a long time to come.

You can apply 3D drawings on different types of textiles, namely:

- On natural fabrics.

- On synthetic fabrics.

- For tarpaulin material.

This type of print is also often used for large format printing, for example for wallpapers, theatrical scenery or exhibitions. The range of use and application of this type of image is great, it would be a fantasy.

Wallpaper with 3D drawings can transform any space

For example, 3D printing on phone cases has also become a fairly popular service among the population.

3D printing on fabric

In order for 3D printing to be applied by the desired method and the image to be bright and durable, a number of factors must be taken into account when choosing the fabric on which the design will be applied. Namely, you need to pay attention to:

- Material composition.

- Structure.

- Density.

- Processing.

- Storage conditions for textiles.

Cloths can be of textile and knitted weaving. Materials with textile weaving - jeans, linen, silk, velveteen, satin, and with knitted - footer, cooler, interlock, etc.

3D printing is an original way of applying high-quality images of any complexity to fabrics or clothes. Thanks to the latest printing technologies, such designs will perfectly behave after numerous washings and ironings. The main thing is to choose the right transfer method for the image.

There are several technologies for applying images of this type to textiles:

- Digital printing.

The image is applied directly to the fabric, without the use of additional media.

The image is applied directly to the fabric, without the use of additional media. - Sublimation. A special dye is used that penetrates the fibers without changing the properties of the material.

- Screen printing. Drawing is applied through a special stencil by pushing paint, viscous consistency.

- Thermal transfer printing. Use film or paper, high temperature and heat press.

All of these 3D printing methods have their pros and cons. For example, digital printing is most often used because of its inexpensive cost, and the silk-screen printing method makes the image durable even on rough fabrics. But the sublimation method limits the client in the choice of fabric, as it is applied only to synthetic materials, but the colors of the image will remain for a long time. So if you need a print on a product that will not lose its appearance for a long time, then it is better to choose a sublimation printing method on a synthetic or semi-synthetic canvas.

3D printing on fabric and not only from PROpechat

Today, few people do not know what 3D printing is. Images of this type can be used for different purposes due to the originality of the result.

For example, it is practical and profitable to use this type of pattern for advertising purposes to attract customers - printing a three-dimensional image of the company logo will clearly attract potential buyers or partners. So the considered option of applying a print is not only a way to transfer pictures, but also an excellent method of promoting a business.

And so, we draw conclusions. In order for the image to turn out as realistic and durable as possible, it is necessary to take into account only a few components:

- The choice of 3D printing technology.

- Selection of the material on which the image will be applied.

- Scope of the finished product.

3D printing on fabrics and more is a great way to make an original piece of furniture, a souvenir, promotional items, etc.