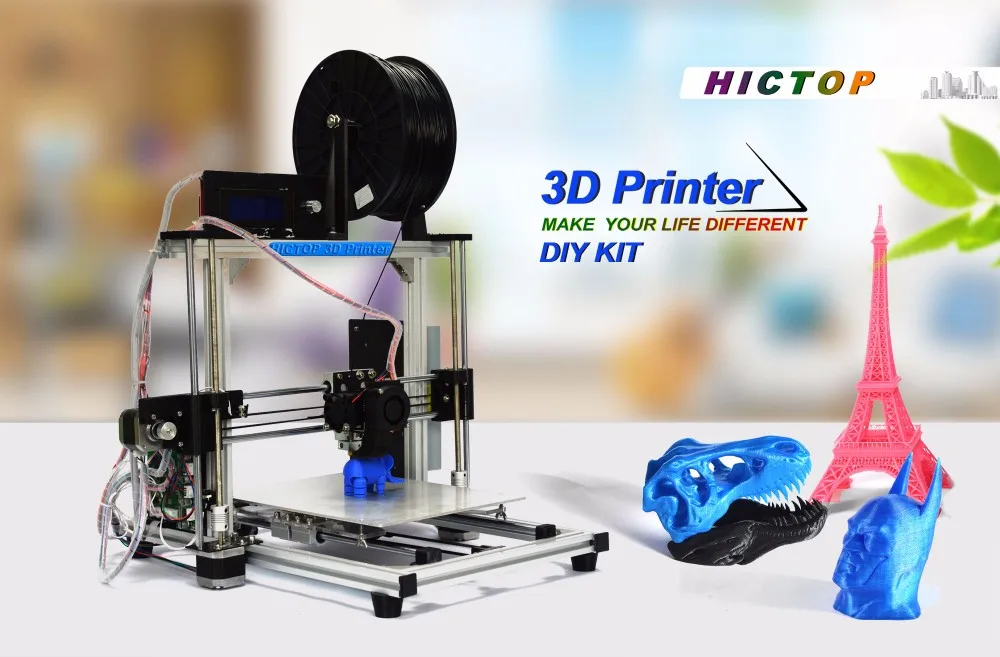

Dlp 3d printers

Guide to Resin 3D Printers

There are many 3D printing processes on the market. Getting familiar with the nuances of each helps to clarify what you can expect from final prints to ultimately decide which technology is suitable for your particular application.

Stereolithography (SLA) and digital light processing (DLP) 3D printing are the two most common processes for resin 3D printing. Resin printers are popular for producing high-accuracy, isotropic, and watertight prototypes and parts in a range of advanced materials with fine features and smooth surface finish.

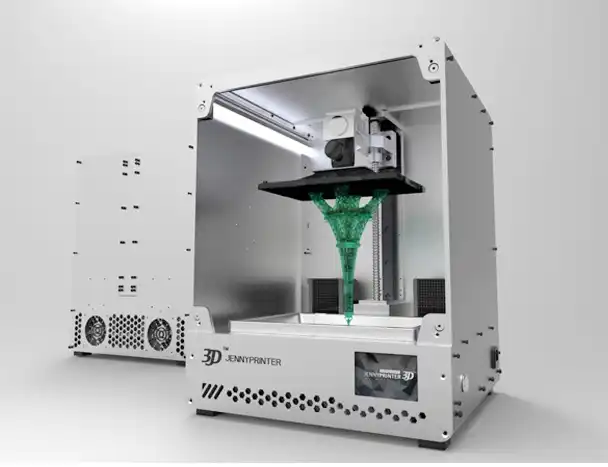

While these technologies were once complex and cost-prohibitive, today’s small-format desktop SLA and DLP resin 3D printers produce industrial-quality parts at an affordable price point and with unmatched versatility thanks to a wide range of materials.

Both processes work by selectively exposing liquid resin to a light source—SLA a laser, DLP a projector—to form very thin solid layers of plastic that stack up to create a solid object. While very similar in principle, the two technologies can produce significantly varying outputs.

In this in-depth guide, we walk through the details of the two resin 3D printing processes and explore how they compare in terms of resolution, accuracy, build volume, speed, workflow, and more.

Sample part

See and feel Formlabs quality firsthand. We’ll ship a free sample part to your office.

Request a Free Sample Part

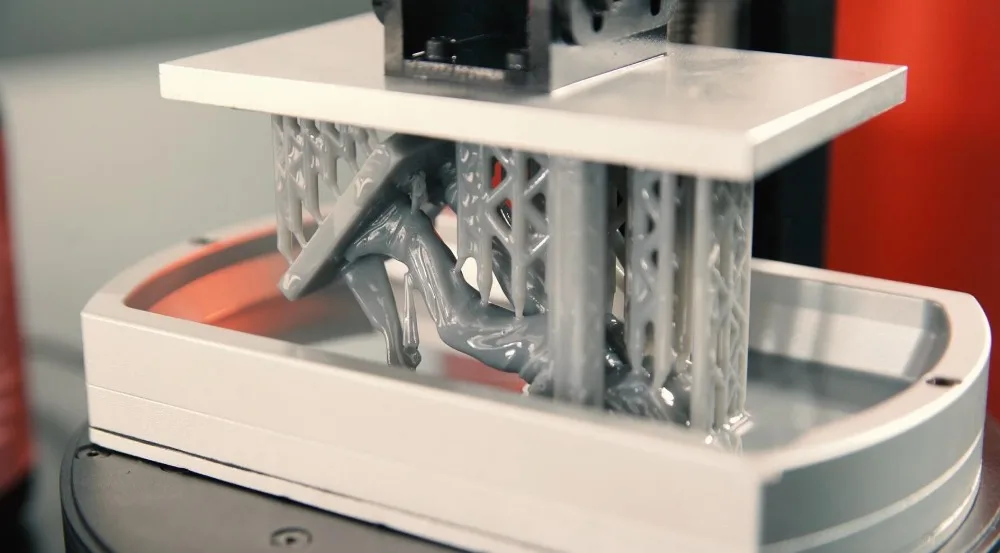

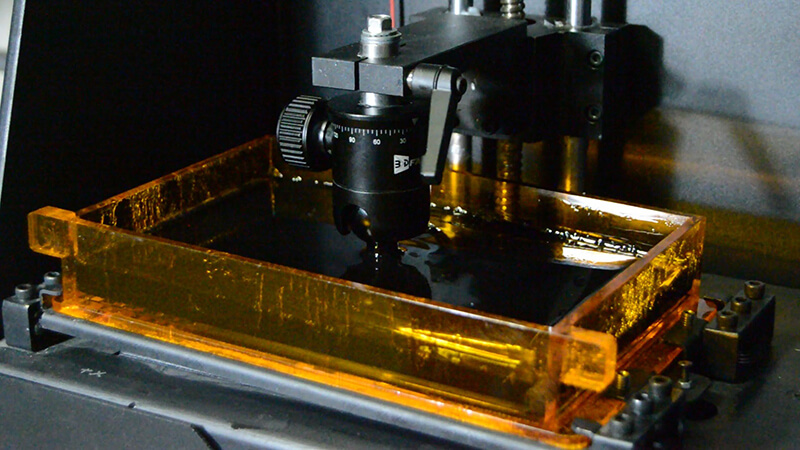

Desktop SLA 3D printers contain a resin tank with a transparent base and non-stick surface, which serves as a substrate for the liquid resin to cure against, allowing for the gentle detachment of newly-formed layers.

The printing process starts as the build platform descends into a resin tank, leaving space equal to the layer height in between the build platform, or the last completed layer, and the bottom of the tank. A laser points at two mirror galvanometers, which direct the light to the correct coordinates on a series of mirrors, focusing the light upward through the bottom of the tank and curing a layer of resin.

The cured layer then gets separated from the bottom of the tank and the build platform moves up to let fresh resin flow beneath. The process repeats until the print is complete.

Low Force Stereolithography (LFS) technology, used by the Form 3+ and Form 3L, is the next phase in SLA 3D printing.

In LFS 3D printers, the optics are enclosed in a Light Processing Unit (LPU). Within the LPU, a galvanometer positions the high-density laser beam in the Y direction, passes it through a spatial filter, and directs it to a fold mirror and parabolic mirror to consistently deliver the beam perpendicular to the build plane and ensure accurate, repeatable prints.

As the LPU moves in the X direction, the printed part is gently peeled away from the flexible bottom of the tank, which drastically reduces the forces exerted on parts during the print process.

LFS 3D printing drastically reduces the forces exerted on parts during the print process, using a flexible tank and linear illumination to deliver incredible surface quality and print accuracy.

This advanced form of stereolithography delivers vastly improved surface quality and print accuracy. Lower print forces also allow for light-touch support structures that tear away with ease, and the process opens up a wide range of possibilities for future development of advanced, production-ready materials.

White Paper

Looking for a 3D printer to realize your 3D models in high resolution? Download our white paper to learn how SLA printing works and why it's the most popular 3D printing process for creating models with incredible details.

Download the White Paper

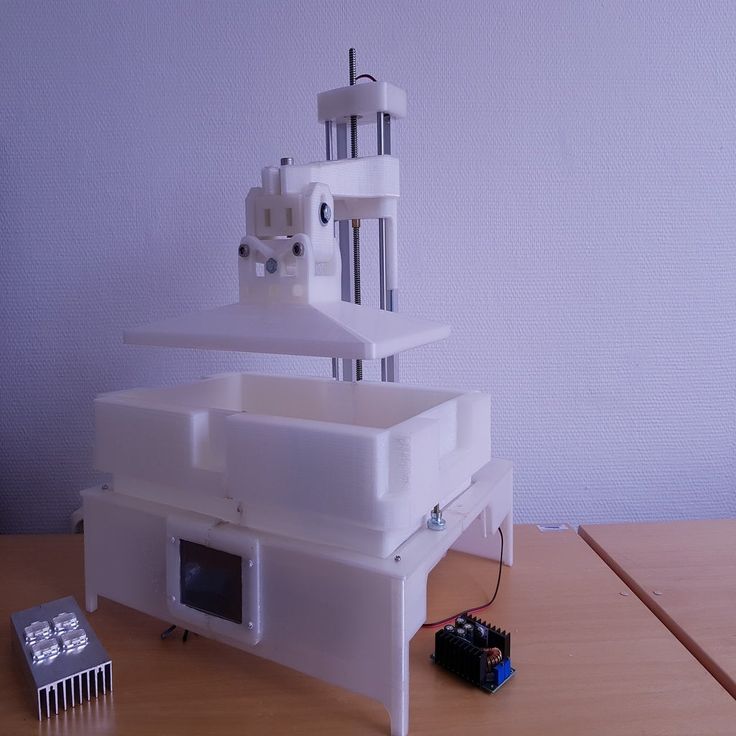

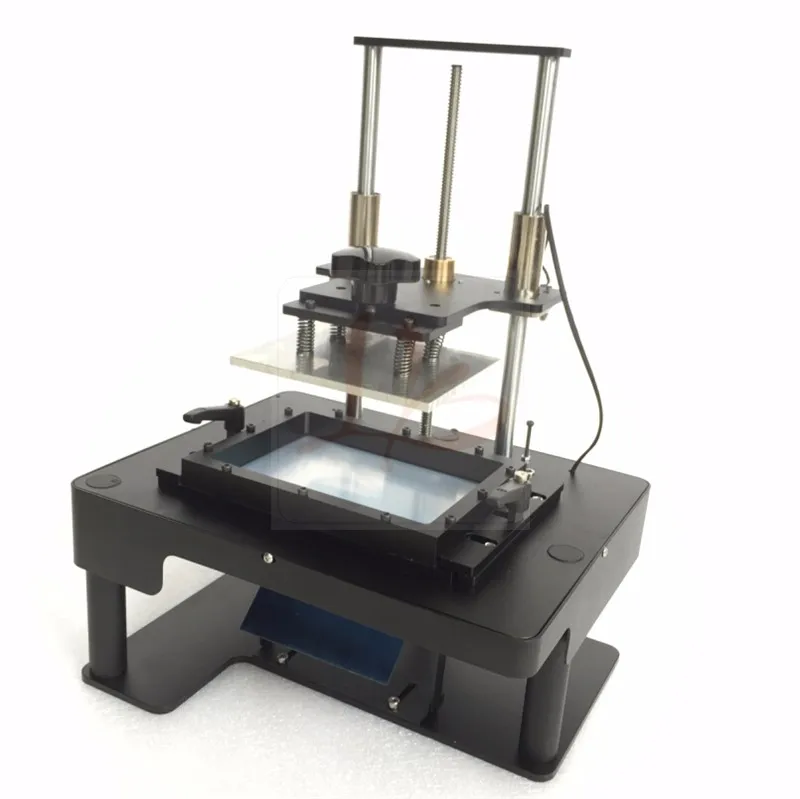

Just like their SLA counterparts, desktop DLP 3D printers are built around a resin tank with transparent bottom and a build platform that descends into a resin tank to create parts upside down, layer by layer.

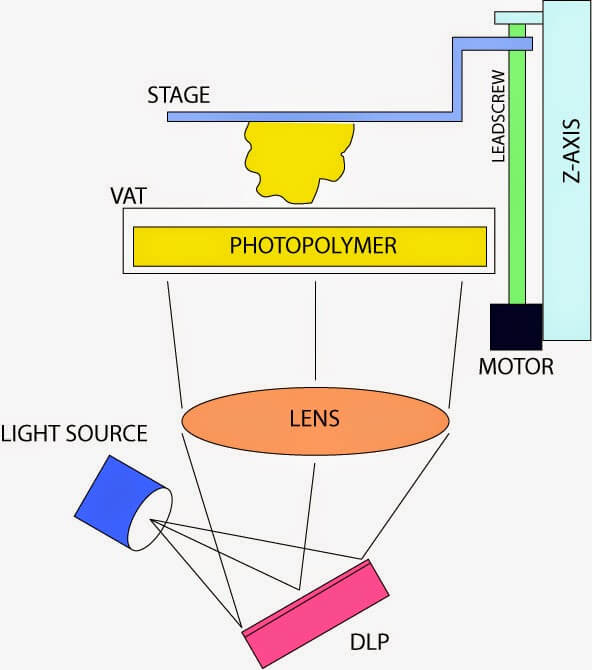

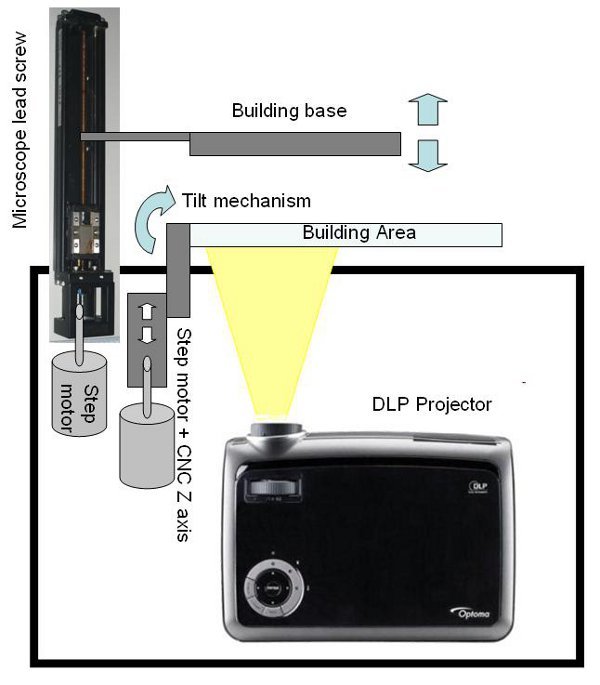

The difference is the light source. DLP 3D printers use a digital projector screen to flash an image of a layer across the entire platform, curing all points simultaneously.

The light is reflected on a Digital Micromirror Device (DMD), a dynamic mask consisting of microscopic-size mirrors laid out in a matrix on a semiconductor chip. Rapidly toggling these tiny mirrors between lens(es) that direct the light towards the bottom of the tank or a heat sink defines the coordinates where the liquid resin cures within the given layer.

Because the projector is a digital screen, the image of each layer is composed of square pixels, resulting in a three-dimensional layer formed from small rectangular cubes called voxels.

Resolution shows up more often than any other value in 3D printer spec sheets, but it’s also a common ground for confusion. The basic units of the SLA and DLP processes are different shapes, making it difficult to compare the different machines by numerical specifications alone.

In 3D printing, there are three dimensions to consider: the two planar 2D dimensions (X and Y) and the third vertical Z dimension that makes 3D printing.

Z resolution is defined by the layer thicknesses a 3D printer can produce. Resin 3D printers like SLA and DLP offer some of the finest Z resolutions—thinnest layers—of all 3D printing processes and users can normally choose from a range of layer height options between 25-300 microns, allowing designers to strike a balance between detail and speed.

In DLP 3D printing, XY resolution is defined by the pixel size, the smallest feature the projector can reproduce within a single layer. This depends on the resolution of the projector, the most common being full HD (1080p), and its distance from the optical window. As a result, most desktop DLP 3D printers have a fixed XY resolution, generally between 35 to 100 microns.

For SLA 3D printers, XY resolution is a combination of the laser’s spot size and the increments by which the laser beam can be controlled. For example, the Form 3 LFS 3D printer features a laser with an 85 micron spot size, but because of the constant line scanning process, the laser can move in smaller increments and the printer can consistently deliver parts with 25 micron XY resolution.

However, resolution in itself is often just a vanity metric. It offers some indication, but it doesn’t necessarily correlate directly with accuracy, precision, and print quality.

Learn more about resolution in 3D printing in our in-depth guide.

Because 3D printing is an additive process, each layer introduces an opportunity for inaccuracy, and the process by which layers are formed affects the level of precision, defined as the repeatability of the accuracy of each layer. Accuracy and precision depend on many different factors: 3D printing process, materials, software settings, post-processing, and more.

In general, both SLA and DLP resin 3D printers are among the most accurate and precise 3D printing processes. Differences in accuracy and precision are often better explained by the differences between machines by various manufacturers than differences between the technologies themselves.

For example, entry-level SLA or DLP printers might use off-the-shelf projectors, lasers, or galvanometers, and their manufacturers will try to get the best performance possible out of these parts. Professional SLA and DLP 3D printers, like the Formlabs Form 3, feature a custom optical system adapted to the specifications required by professional customer applications.

Professional SLA and DLP 3D printers, like the Formlabs Form 3, feature a custom optical system adapted to the specifications required by professional customer applications.

Accuracy and precision are crucial for parts like dental splints (left) and surgical guides (right).

Calibration is also crucial. With DLP projectors, manufacturers need to deal with the non-uniform light distribution on the build plane and optical distortion of the lenses—meaning that pixels in the middle are not the same size or shape as pixels on the edges. SLA 3D printers use the same light source for every part of the print, which means it’s uniform by definition, but they still require extensive calibration to account for distortions.

Even a 3D printer with the highest quality components and degree of calibration can produce widely varying results depending on the material. Different resins require optimized material settings to perform as intended, which might not be available for off-the-shelf materials or resins that are not thoroughly tested with a specific 3D printer model.

The takeaway? Accuracy and precision are almost impossible to understand from the technical specifications alone. Ultimately, the best way to evaluate a 3D printer is to inspect real parts or ask the manufacturer to create a test print of one of your own designs.

With DLP 3D printers, there’s a direct trade-off between resolution and build volume. The resolution depends on the projector, which defines the number of pixels/voxels available. If one moves the projector closer to the optical window, the pixels get smaller, which increases the resolution, but limits the available build area.

Some manufacturers stack multiple projectors next to each other or use a high-definition 4K projector to increase the build volume, but this leads to substantially higher costs that often price these machines out of the desktop market.

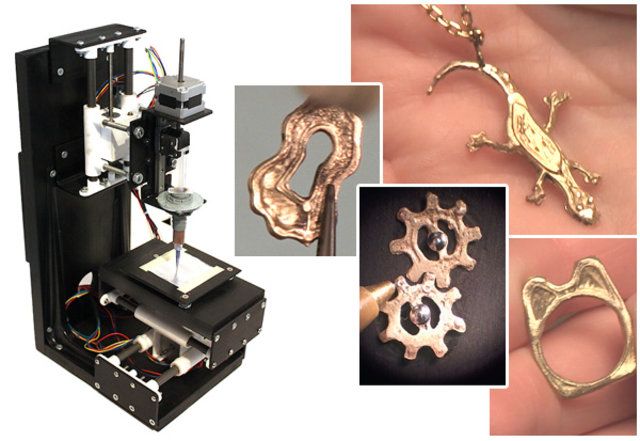

As a result, DLP 3D printers are generally optimized for specific use cases. Some have a smaller build volume and offer high resolution to produce small, detailed pieces like jewelry, while others can produce bigger parts but at a lower resolution.

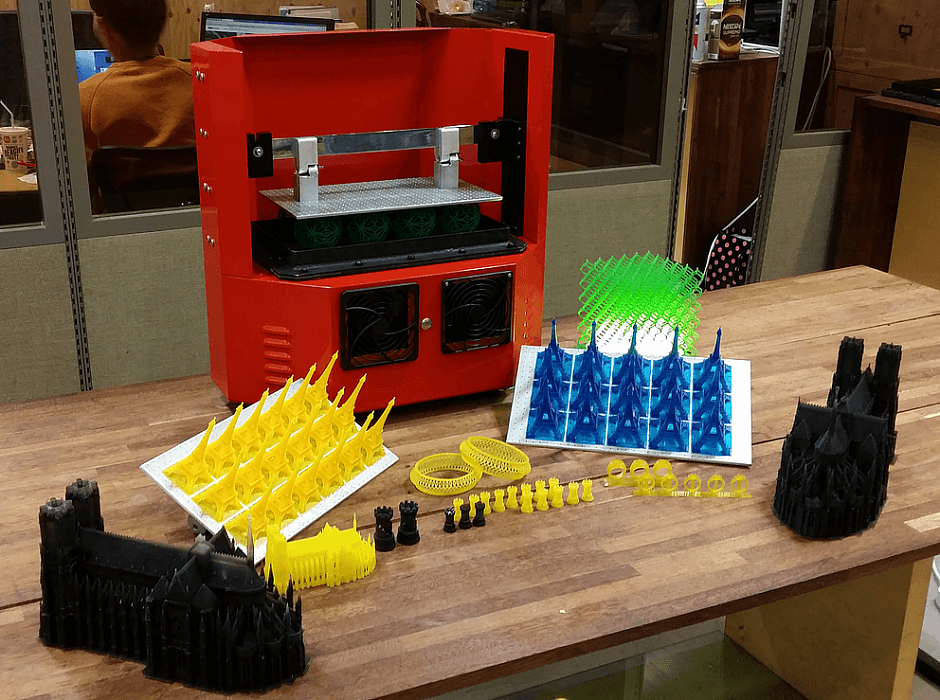

The stereolithography process is inherently more scalable, since an SLA 3D printer’s build volume is completely independent of the resolution of the print. A single print can be any size and any resolution at any location within the build area. This makes it possible to 3D print large parts at high resolution or a large batch of detailed small parts to increase throughput with the same machine.

The other main barrier to increasing build volume in both SLA and DLP 3D printers is the peel force. When printing larger parts, the forces exerted on the parts increase exponentially as a cured layer separates from the tank.

In LFS 3D printing, the flexible film at the base of the resin tank gently peels away as the build platform pulls the part up, significantly reducing the stress on the part. This unique feature has made it possible to substantially increase the build volume for the first accessible large format SLA 3D printer, the Form 3L.

The Form 3L is the first affordable large format SLA 3D printer with a build volume of 30 cm x 33. 5 cm x 20 cm.

5 cm x 20 cm.

Webinar

Want to learn more about the Form 3L and Form 3BL ecosystem, and the new large format post-processing machines?

In this demo, Kyle and Chris will expain how to navigate the Form 3L end-to-end workflow, including post-processing.

Watch Now

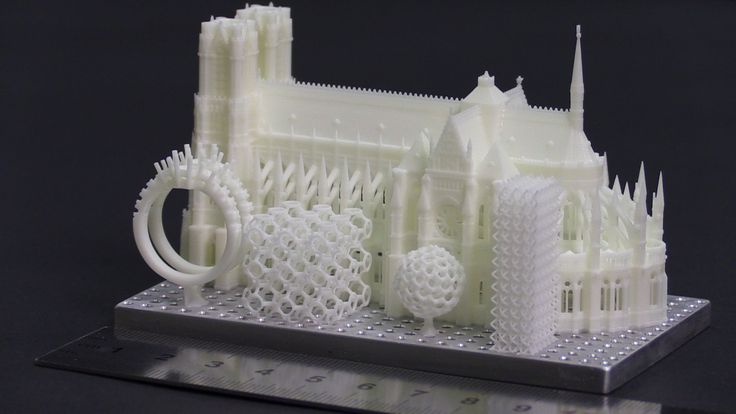

SLA and DLP resin 3D printers both known for creating parts with the smoothest surface finish of all 3D printing processes. When we describe the differences, in most cases these are only visible on tiny parts or highly detailed models.

Because objects are made of layers in 3D printing, 3D prints often have visible, horizontal layer lines. However, because DLP renders images using rectangular voxels, there is also an effect of vertical voxel lines.

DLP 3D printers render images using rectangular voxels, which causes an effect of vertical voxel lines. In this image, see the vertical voxel lines as they appear naturally on the left, and then outlined to more easily identify on the right.

Because the unit is rectangular, voxels also have an effect on curved edges. Think of building a round shape out of LEGO bricks—the edges will appear stepped on both the Z axis and the X-Y plane.

The rectangular shape of voxels makes curved edges appear stepped. Removing the appearance of voxel and layer lines requires post-processing, such as sanding.

In LFS 3D printing, layer lines are close to invisible. As a result, surface roughness is reduced, which ultimately leads to smooth surfaces, and for clear materials, more translucent parts.

When thinking about speed in 3D printing, it’s important to consider not just raw print speed, but also throughput.

Raw print speed for SLA and DLP resin 3D printers is comparable in general. As the projector exposes each entire layer all at once, print speed in DLP 3D printing is uniform and depends only on the height of the build, whereas, SLA 3D printers draw out each part with a laser. As a rule of thumb, this results in SLA 3D printers being comparable or faster when printing small or medium-size single parts, while DLP 3D printers are faster to print large, fully dense prints, or builds with multiple parts that fill up much of the platform.

But once again, it’s worth considering the trade-off between resolution and build volume for DLP printers. A small DLP 3D printer can print a small part or a (small) batch of smaller parts fast, at high resolution, but the build volume limits the part size and the throughput. A different machine with a larger build volume can print larger parts or a batch of smaller parts faster, but at a lower resolution than SLA.

SLA 3D printers can produce all of these options in one machine and offer the user the freedom to decide whether she wants to optimize for resolution, speed, or throughput.

SLA 3D printers offer a larger build volume, allowing users to batch parts and print overnight to increase throughput.

Speed can also depend on the material choice. Printing four times faster than Formlabs standard materials, Draft Resin fast-printing resin that is ideal for initial prototypes, rapid iterations, as well as dental and orthodontic models. From fast print initiation speeds to minimal support removal, wash, and cure times, Draft Resin has an optimized workflow to truly maximize efficiency.

100 microns | 200 microns |

|---|---|

100 microns | 200 microns |

|---|---|

100 microns | 200 microns |

|---|---|

Interactive

Try our interactive ROI tool to see how much time and cost you can save when 3D printing on Formlabs 3D printers.

Calculate Your Savings

Just like with accuracy and precision, the workflow and available materials differ more from machine to machine than technology to technology.

Most SLA and DLP 3D printers are “plug and play,” with easily swappable build platforms and resin tanks. Some more advanced models also come with a cartridge system to automatically refill the tank with liquid resin, which requires less attention and facilitates printing overnight.

Some printers come with proprietary software to prepare 3D models for printing, such as PreForm for Formlabs SLA 3D printers, while other manufacturers offer off-the-shelf solutions. Features differ by software tool, for example, PreForm offers one-click print setup, powerful manual controls to optimize support density and size, adaptive layer thickness, or functions to save material and time. Luckily, the software can be easy to download and test before purchasing a 3D printer.

Resin 3D printers offer a variety of materials for a wide range of applications.

One of the most significant benefits of resin 3D printing is the variety of materials that make it possible to create parts for diverse applications. Resins can feature a wide range of formulation configurations: materials can be soft or hard, heavily filled with secondary materials like glass and ceramic, or imbued with mechanical properties like high heat deflection temperature or impact resistance.

Resins can feature a wide range of formulation configurations: materials can be soft or hard, heavily filled with secondary materials like glass and ceramic, or imbued with mechanical properties like high heat deflection temperature or impact resistance.

However, the range of supported material options depend on the 3D printer model, so we recommend inquiring with the manufacturer before purchase.

Parts printed with both SLA and DLP technologies require post-processing after printing. First, the parts need to be washed in a solvent to remove excess resin. Some functional materials like engineering or biocompatible parts also require post-curing. For SLA 3D printers, Formlabs offers solutions to automate these steps, saving time and effort.

At last, 3D printed parts printed on supports require these structures to be removed, a manual process that is similar for both SLA and DLP 3D printers. LFS 3D printing simplifies this step by offering light-touch support structures that use very small touchpoints to enable easy removal with minimal support marks left behind.

Interactive

Need some help figuring out which 3D printing material you should choose? Our new interactive material wizard helps you make the right material decisions based on your application and the properties you care the most about from our growing library of resins.

Recommend Me a Material

After sorting out the differences in technology and outcomes, we hope it’s much easier to select a resin 3D printer that best matches your workflow and output needs.

To explore the next generation of SLA 3D printing, learn more about the Form 3 and Form 3L LFS 3D printers.

Curious to see the quality firsthand? Order a sample part shipped to your office.

Request a Free Sample Part

SLA vs DLP: Which Resin 3D Printing Process Should You Choose?

3D printing news News SLA vs DLP: Which Resin 3D Printing Process Should You Choose?

Published on November 5, 2022 by Madeleine P.

Since the invention of stereolithography (SLA) in 1984 by Charles Hull, multiple technologies such as FDM, SLS, and MJF, have emerged. Some are even derived from SLA like Digital Light Processing (DLP). As you probably know, each of these processes is intended for various industries and applications. Today we will focus on SLA and DLP technologies , and we will determine their characteristics in order to establish a comparison between the two processes. And while the two technologies have many things in common, there are some notable differences. How do these technologies work? What materials can be used? Who are the main manufacturers? We go over all you need to know below!

SLA and DLP technologies

While SLA and DLP printing processes have several differences, there are some similarities between the two. They both expose liquid photopolymers to a light source. As they both have a resin tank, they are intended for printing small models with precise details. The methods are compatible with flexible or hard materials, and can also print composite materials, filled with glass or ceramic for example. Note that the printed parts are relatively fragile, liable to deteriorate if they are exposed to the sun and may be subject to warping.

The methods are compatible with flexible or hard materials, and can also print composite materials, filled with glass or ceramic for example. Note that the printed parts are relatively fragile, liable to deteriorate if they are exposed to the sun and may be subject to warping.

Liquid resin is used for both SLA and DLP.

The first 3D printing technology developed in 1984, stereolithography is now considered to be one of the most accurate 3D printing processes on the market. Unlike DLP technology, the light source used is a laser. The laser beam sweeps across the resin tank moving on the horizontal axis and solidifies the material layer by layer. Two types of machines exist today: those where the laser acts from top to bottom, with a plate which will descend with each new layer and those with a laser that acts from the bottom up, with a platform that goes up as you go. The SLA achieves smooth surfaces and a layer thickness between 0.05 and 0.01 mm, thus allowing the printing of objects with extremely thin layers.

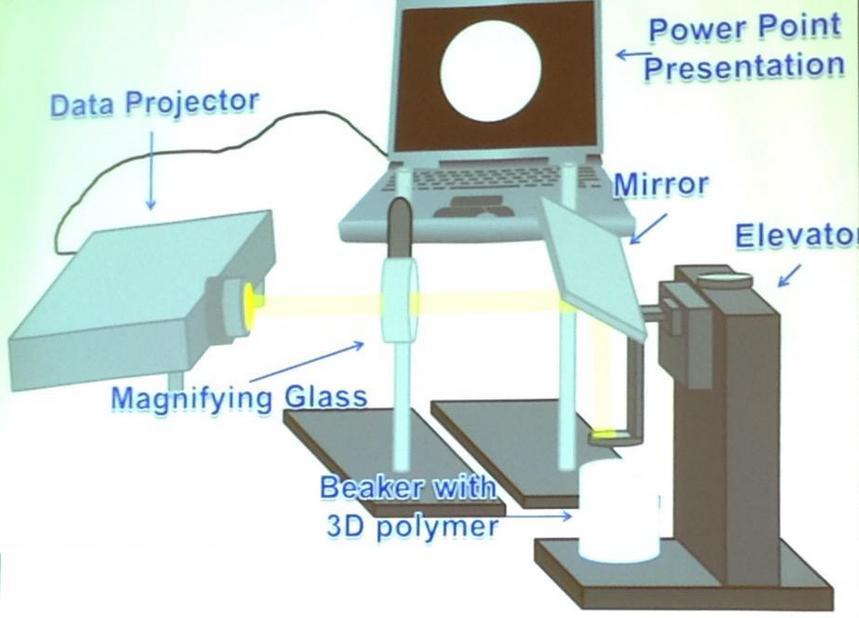

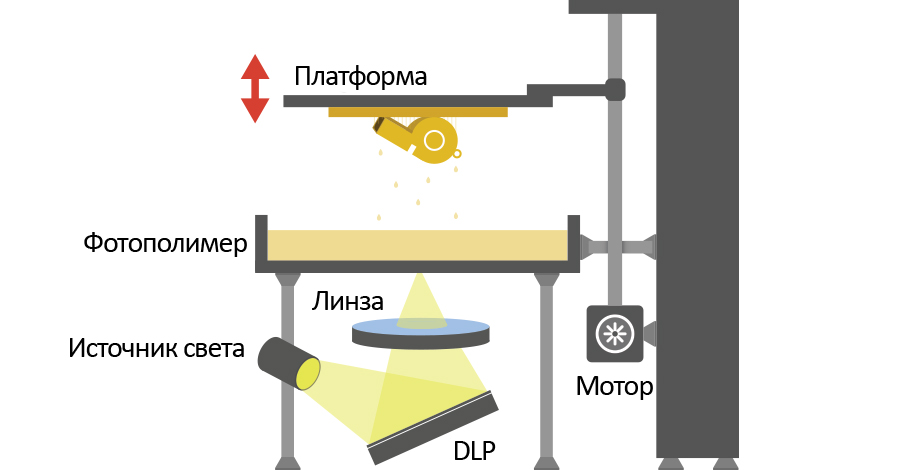

Coming from image projection technology (dating back to the 1980s), the Digital Light Processing method uses a projector as a light source. In this way, a single projection of light impacts the entire resin tray at once. At the heart of this process is a digital micromirror device (DMD), located between the projector and the resin. It is made up of several microscopic mirrors controlled and activated individually: if they are active, they will reflect the light towards the resin and light-cure it. So they produce a kind of mask to harden the resin depending on the desired model. Some 3D printers have now replaced this DMD with an LCD screen, drastically lowering the price of the machine. We however will not be focusing on those solutions today.

SLA and DLP printing process diagrams (photo credits: 3D Hubs / bitfab)

The DLP process is considered to be faster than stereolithography since it does not work point by point. Additionally, as a result of their projectors, DLP printers are larger. Most of the time, the resin tank on DLP machines is shallower than those used by the SLA process.

Most of the time, the resin tank on DLP machines is shallower than those used by the SLA process.

Finally, the last difference between SLA and DLP technologies is in the maintenance. DLP printers require little maintenance and are often easier to repair – the presence of the laser in SLA machines has a lot to do with this.

Print quality

Print quality is often a deciding factor in choosing between two technologies. Especially if 3D printing is to be used for the production of finished parts meaning that the level of detail, structure and surface play a very important role. In principle, it can be said that the two technologies make it possible to design precise, high-resolution models with the finest level of detail. However, it is not only the process itself that is decisive for the quality of the print, but also the choice of material. The latter often depends on the manufacturer, with most machines being closed in terms of compatibility.

When printing with the SLA process, the resin is polymerized point by point on the print bed. The longer the part, the longer the printing time required will be since the laser will have to pass through the entire bed. SLA is therefore more suitable for printing objects with a length between a few millimeters and 1.50 meters. There is, however, no loss of quality due to the length and a Z resolution of up to 25 microns can be achieved: they are both independent of the model size.

The longer the part, the longer the printing time required will be since the laser will have to pass through the entire bed. SLA is therefore more suitable for printing objects with a length between a few millimeters and 1.50 meters. There is, however, no loss of quality due to the length and a Z resolution of up to 25 microns can be achieved: they are both independent of the model size.

Photo credits: Formlabs

DLP technology allows for a layer thickness of up to 5 microns. However, it is important to note that DLP 3D printers can create a “stair-stepped” phenomenon on the final product due to pixel projection, which affects the final surface of the printed parts. When printing long components, quality loss may occur on the sides. The center of the plate indeed receives the greatest concentration of energy from the projector; its light is then gradually diffused on the edges.

Technical characteristics

Printing Speed

In terms of print speed, DLP technology is clearly in the lead. As DLP cures an entire layer of resin in one go, the printing process is much faster. Unlike the SLA process, in which the resin is polymerized point by point, in the DLP process only the height of the component affects the printing speed.

Print Volume

Stereolithography is not necessarily used to produce large components due to the high cost of materials compared to other processes, such as FDM . Further, the build volume is limited to the size of the tank which contains the liquid resin.

The build volume for the Formlabs 3L SLA printers is 335 x 200 x 300 mm and 1500 x 750 x 550 mm for the 3D Systems Pro X 950. For DLP printers, the build volume of the Envison TEC Xtrem 8K machine is 450 x 371 x 399 mm and 400 x 330 x 500 mm for the Carima model DM400A.

The Form 3L has a larger build volume (photo credits: Formlabs)

Post-Treatment

In all resin 3D printing processes, post-treatment of parts is mandatory. This is due to the fact that for printing very thin models, supporting structures are required and must be removed after curing. This step can be time consuming and is probably one of the main disadvantages of resin 3D printing. The differences in post-processing are mainly related to the material used, both in the SLA and DLP process. In addition to cleaning the parts of the liquid resin with isopropyl alcohol (IPA) or tripropylene glycol monomethyl ether (TPM), also count the drying, the removal of the support structures, a possible post-curing and, if necessary, sanding and painting the parts.

This step can be time consuming and is probably one of the main disadvantages of resin 3D printing. The differences in post-processing are mainly related to the material used, both in the SLA and DLP process. In addition to cleaning the parts of the liquid resin with isopropyl alcohol (IPA) or tripropylene glycol monomethyl ether (TPM), also count the drying, the removal of the support structures, a possible post-curing and, if necessary, sanding and painting the parts.

In principle, it can be said that post-processing in the SLA and DLP process can not only be time consuming, but also requires a certain degree of expertise on the part of the user or should be left to specialists. Post-processing in 3D printing is often a challenge for users, which is why some companies have already specialized in optimizing or automating this step.

Removing print media is a post-processing step that can take time.

Application Cases

When it comes to application cases, SLA and DLP technologies are mostly used in similar industries. In particular, the jewelry and dental sectors regularly use resin 3D printing. For example, the manufacturer Formlabs offers various resins intended for medical professionals. Many companies use them to create all types of medical devices, such as surgical guides. But due to the wide variety of materials available, many other sectors also use resin 3D printing. Whether for prototyping, injection molds or even engineering, several suitable resins exist.

In particular, the jewelry and dental sectors regularly use resin 3D printing. For example, the manufacturer Formlabs offers various resins intended for medical professionals. Many companies use them to create all types of medical devices, such as surgical guides. But due to the wide variety of materials available, many other sectors also use resin 3D printing. Whether for prototyping, injection molds or even engineering, several suitable resins exist.

Regardless of whether its SLA or DLP the accuracy is remarkable.

Main Manufacturers

Currently there are a few 3D printer manufacturers who have turned to SLA technology. Obviously, one of the main manufacturers remains 3D Systems, the company founded by Charles Hull. But over time, other manufacturers have emerged. This is particularly the case with Formlabs, which has established itself as one of the leaders in SLA 3D printers. And in addition to supplying SLA machines, the American company also offers many resins and materials, such as Castable Wax 40 Resin for the dental sector. With its range of XFAB printers, the manufacturer DWS also offers machines based on stereolithography.

With its range of XFAB printers, the manufacturer DWS also offers machines based on stereolithography.

When it comes to DLP 3D printers, EnvisionTEC, founded in 2002, is considered a pioneer in the technology. And like B9 Creator and Asiga, several companies then seized the DLP process to develop their printers. We can also mention manufacturers who have relied on the DLP process to offer faster technology: Carbon 3D with Digital Light Synthesis (DLS) which can control the flow of oxygen or Photocentric and Daylight Polymer Printing (DPP). Finally, the French company Prodways has also patented a process similar to DLP, the MOVINGLight technology.

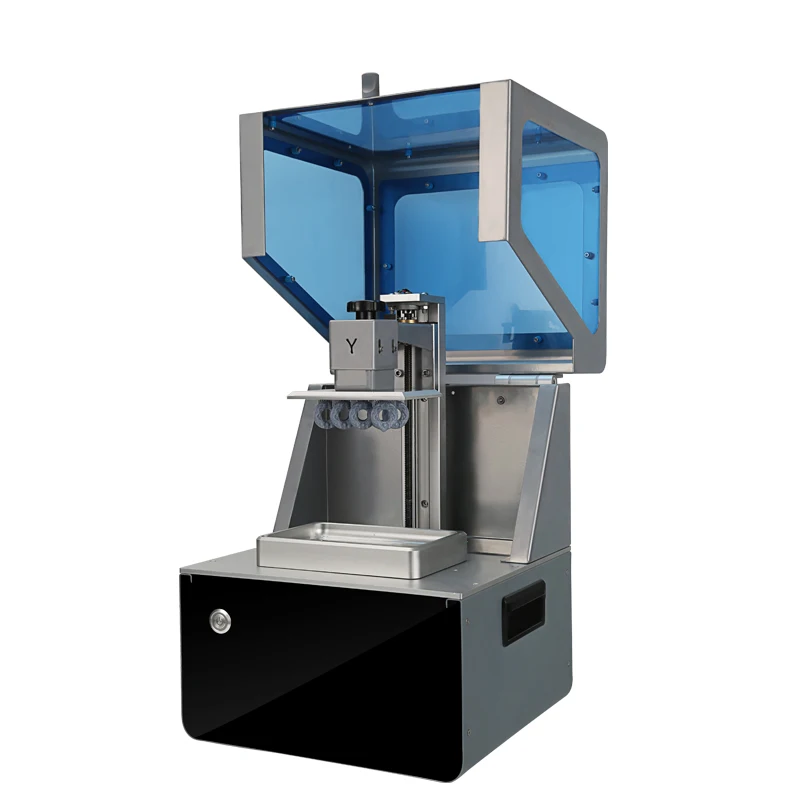

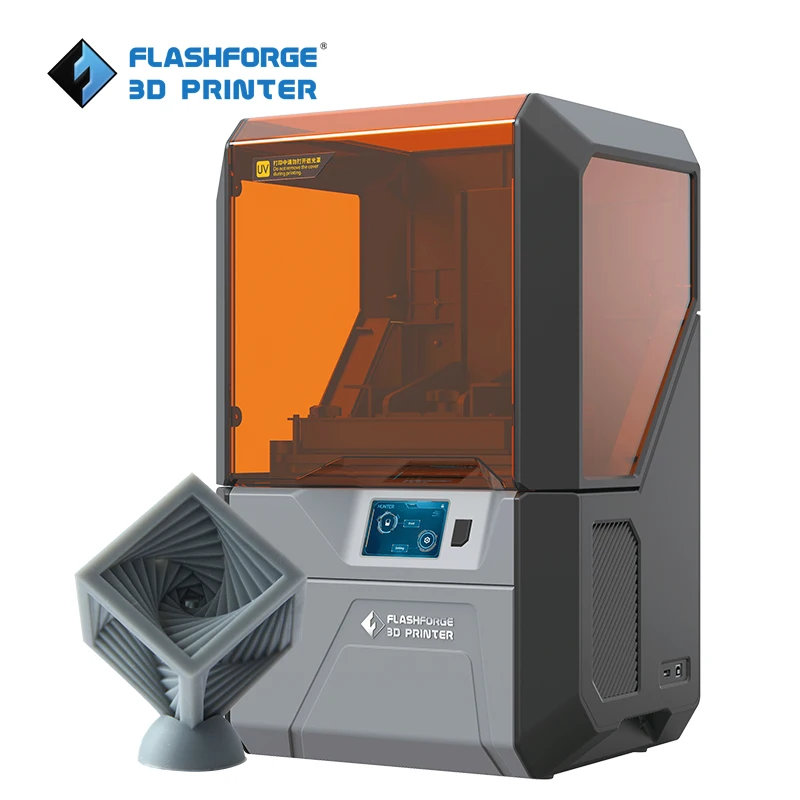

EnvisionTEC is considered the pioneer of the DLP process in 3D printing (photo credits: EnvisionTEC)

Price

In the majority of cases, DLP printers are less expensive than SLA. But as with all ranges of 3D printers , it is important to differentiate between desktop and industrial printers.

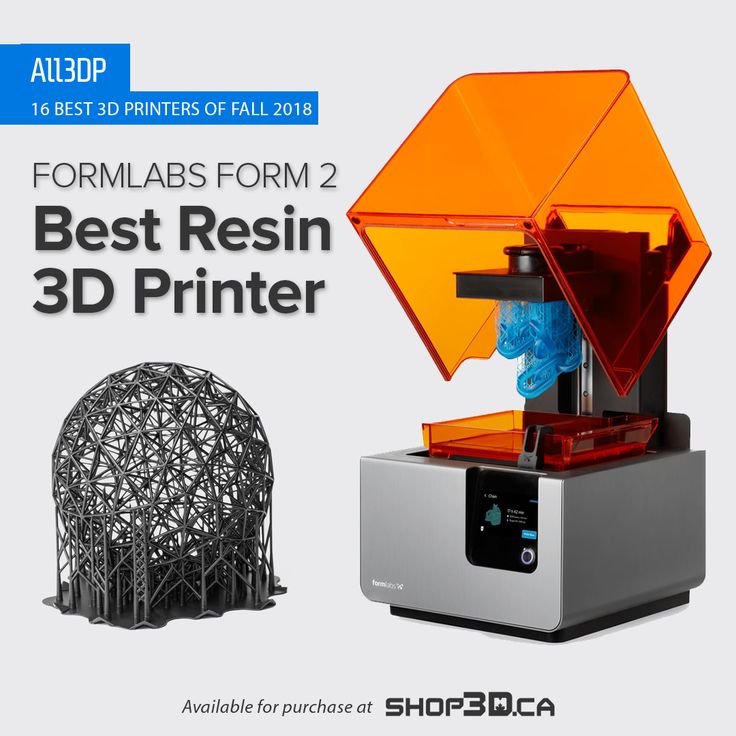

For entry-level SLA printers, the most accessible machine is the Form 2 from Formlabs. With a print volume of 145 x 145 x 175 cm, the Form 2 boasts a point accuracy of around 145 microns. Available from $ 2,400, the machine has been on the market since 2015. Note, however, that the American manufacturer has since developed a new range made up of the Form 3 and the Form 3L.

With a print volume of 145 x 145 x 175 cm, the Form 2 boasts a point accuracy of around 145 microns. Available from $ 2,400, the machine has been on the market since 2015. Note, however, that the American manufacturer has since developed a new range made up of the Form 3 and the Form 3L.

On average, the price of SLA 3D printers is between $ 3,000 and $ 4,000. However, if you are looking for industrial machinery, the prices go up dramatically. For example, 3D Systems’ industrial SLA solutions are marketed at prices as high as $ 500,000. Also note that machines whose laser works from top to bottom will generally be more expensive.

Much more accessible, DLP 3D printers appeal to many additive manufacturing enthusiasts. Anycubic sells several DLP machines for prices approaching $ 200, as is the case with its Photon Zero printer. Machines for professionals, including those offered by EnvisionTEC for the dental and jewelry industry, are available at around $ 15,000. But as always, depending on the manufacturer, the prices vary. The manufacturer Asiga also offers DLP 3D printers for professionals, but with prices around $1,000.

The manufacturer Asiga also offers DLP 3D printers for professionals, but with prices around $1,000.

Comparison of SLA and DLP technologies (specifications refer to a desktop 3D printer)

Do you use SLA or DLP ? Let us know in a comment below or on our Facebook, Twitter and LinkedIn pages! Sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox!

3D printer comparison in 2020

A variety of 3D printing technologies are available on the market today. Getting to know the nuances of each helps you understand what you can expect from the final models and decide which technology is right for you.

Stereolithography (SLA) and digital light processing (DLP) are the two most common 3D printing technologies using resins. 3D printers that use resin as consumables have become very popular due to their ability to produce highly accurate, isotropic and waterproof prototypes and models with high detail and smooth surfaces.

While these technologies used to be complex and prohibitively expensive, today's compact desktop SLA and DLP printers produce industrial quality parts at an affordable price and offer tremendous application flexibility through a wide range of materials.

Both of these processes selectively expose liquid polymer to a light source: an SLA laser, a DLP projector, forming very thin, hard layers of plastic that fold into a solid object. Although the principle of operation of these technologies is very similar, they can give significantly different results.

In this detailed guide, we will explain the features of these two 3D printing processes and see how they differ in terms of resolution, accuracy, print volume, speed, workflows, etc.

sample print

printing from my own experience. We will send a free sample of the Formlabs stereolithographic 3D printed model directly to your office.

Request a free print sample

Desktop stereolithography 3D printers contain a resin tank with a transparent bottom and a non-adhesive surface that serves as a base for the liquid resin to solidify, allowing the newly formed layers to be gently peeled off.

The printing process begins with the platform lowered into the resin tank, leaving a free space corresponding to the height of the layer between the platform or the last finished layer and the bottom of the tank. The laser beam is fed to two mirror galvanometers, with the help of which it enters the desired coordinates on a series of mirrors. This allows a focused beam of light to be fed upwards through the bottom of the tank, under the influence of which the polymer layer hardens.

Then the hardened layer is separated from the bottom of the tank, and the platform rises higher, and liquid polymer enters the freed space. This process is repeated until printing is complete.

The Form 3 and Form 3L Low Force Lithography (LFS) stereolithography technology is a new step in the development of stereolithographic 3D printing.

In LFS-based 3D printers, the optical components are located in the Light Processing Unit (LPU). Inside the LPU, a galvanometer positions the high-density laser beam in the y-direction, passes it through a spatial filter, and directs it into a deflecting and parabolic mirror to ensure that the beam always remains perpendicular to the plane of the platform, ensuring print accuracy and reproducibility.

As the LPU moves in the X direction, the printed model is gently separated from the flexible bottom of the tank, which greatly reduces the forces on the models during the printing process.

LFS-based 3D printing greatly reduces the stress placed on parts during the printing process by using a flexible reservoir and linear illumination to deliver incredible surface quality and print accuracy.

This advanced stereo lithography technology features higher surface quality and print accuracy. The lower print tear force also allows the creation of lightweight support structures that can be detached without force, and the method itself opens up great opportunities for the further development of advanced production-ready materials. Learn more about stereolithographic 3D printing

White Paper

Download our in-depth white paper to learn how SLA printing works, why thousands of professionals use it today, and how this 3D printing technology can help your work.

Download white paper

Desktop DLP printers use a resin tank with a transparent bottom and a platform that descends into the tank to layer upside down models. In this they are no different from stereolithographic 3D printers.

The difference between them is the light source. DLP-based 3D printers use a digital screen to project the image of the layer onto the entire platform, causing all the desired dots to solidify at the same time.

Light is reflected on a digital micromirror screen (DMD), a dynamic mask consisting of microscopic mirrors that are located in a matrix on a semiconductor chip. The rapid switching of these tiny mirrors between lenses that direct light to the bottom of a tank or radiator determines the coordinates at which the liquid polymer must solidify in order to form the current layer.

Because the projector is a digital screen, each layer's image is made up of square pixels, resulting in a three-dimensional layer of rectangular cubes called voxels.

When it comes to 3D printer specifications, resolution is the focus, but it often leads to confusion. The basic units of the SLA and DLP processes are different forms, making it difficult to compare printers by numbers alone.

In 3D printing, there are three dimensions to consider: two planar 2D dimensions (X and Y) and a third vertical Z dimension, which is used for 3D printing.

The resolution of the Z measurement is determined by the thickness of the layer that the 3D printer can print. Printers based on SLA and DLP technology have one of the best Z resolutions of any other process, allowing you to print layers with minimal thickness. Typically, users can set the layer height to between 25-300µm, allowing developers to trade-off between level of detail and speed.

In DLP printers, XY resolution is determined by the pixel size, the smallest detail that the projector can reproduce in a single layer. It depends on the resolution of the projector (the most common is Full HD (1080p)) and its distance from the optical glass. Therefore, most desktop DLP printers have a constant XY resolution of 35 to 100 microns.

Therefore, most desktop DLP printers have a constant XY resolution of 35 to 100 microns.

In stereolithographic 3D printers, the XY resolution is determined based on the size of the laser spot and the number of steps that can be used to control the beam. For example, a Form 3 3D printer based on LFS technology has a laser with a spot size of 85 μm, but due to the constant line scanning process, the laser can move at a smaller step, and the printer can consistently print models with an XY resolution of 25 μm.

Resolution itself is often only an indicator of vanity. It gives some idea of the performance, but does not necessarily directly correspond to the accuracy and quality of the print.

Learn more about resolution in 3D printing in our detailed guide.

Since 3D printing is an additive process, violations can potentially occur in every layer. The process of forming layers affects the level of accuracy and correctness of each layer. Accuracy and accuracy depend on many factors: 3D printing process, materials, software settings, post-processing, etc.

In general, SLA and DLP printers are among the most accurate. Differences in print accuracy are often more noticeable between printers from different manufacturers than between the technologies themselves.

For example, entry-level SLA or DLP printers may use off-the-shelf projectors, lasers, or galvanometers, and their manufacturers strive to achieve optimum performance from these parts. Professional SLA and DLP printers (such as Formlabs Form 3) have a special optical system that is adjusted according to the needs of users.

Precision is critical for parts such as mouth guards (left) and surgical guides (right).

Precision is critical for parts such as mouth guards (left) and surgical guides (right).

Equally important is calibration. When using DLP projectors, manufacturers face uneven distribution of light on the platform and optical lens distortion, which means that the size and shape of the pixels in the middle and at the edges are different. Stereolithographic 3D printers use the same light source for all parts of the model, ensuring uniformity, but they still need to be carefully calibrated to avoid distortion.

Stereolithographic 3D printers use the same light source for all parts of the model, ensuring uniformity, but they still need to be carefully calibrated to avoid distortion.

Even a 3D printer with the best components and the best degree of calibration can produce different results depending on the consumables used. Resin parameters have to be changed to ensure the best quality, but they may not be available for new materials that have not been properly tested with the appropriate 3D printer model.

What conclusion can be drawn from this? Knowing only the technical characteristics, it is impossible to get a complete picture of the quality. The best way to evaluate a 3D printer is to study the models printed on it or ask the manufacturer to make a test model for your project.

DLP printers have an inverse relationship between resolution and working volume. The resolution depends on the projector, which determines the number of pixels/voxels available. If you move the projector closer to the optical glass, the pixels will become smaller and the resolution will increase, but the working area will be limited.

Some manufacturers install multiple projectors side by side or use a 4K high-definition projector to increase the working area, but this increases the cost significantly. The price of such models is much higher than other desktop 3D printers.

Therefore, DLP printers are usually optimized for specific purposes. Some of them have a smaller workspace and allow you to produce in high resolution such small and detailed models as jewelry, while others can print larger parts, but with a lower resolution.

The stereolithography process is inherently more scalable because the print volume of an SLA printer is independent of model resolution. A single model can be of any size and resolution, and can be placed anywhere on the workspace. This allows you to print large high-resolution 3D models or large batches of finely detailed models to increase printer performance.

Another hurdle to increasing print volume in both SL and DLP printers is the release force. When printing large models, the forces applied to them increase exponentially as the cured layer separates from the reservoir.

With LFS printing, the flexible film at the base of the resin reservoir gently peels off when the platform pulls the model up, greatly reducing stress on the model. This unique feature has dramatically increased print volume in the first affordable large-format stereolithography printer, the Form 3L.

Form 3L is the first affordable 30 x 33.5 x 20cm large format 3D lithography 3D printer. compared to solutions based on other technologies. When we talk about differences, in most cases they are only visible on very small parts and models with a high degree of detail.

Because 3D printers print in layers, finished models often have noticeable horizontal lines. And due to the fact that digital light processing technology uses rectangular voxels, the effect of vertical lines can also be observed.

DLP printers use rectangular voxels to render images, which can result in vertical lines. In this image, the vertical voxel lines are shown as they appear when printed (left), highlighted for better visibility (right).

Since voxels are rectangular, they affect the shape of the curved edges. Let's draw an analogy with creating a round shape from a LEGO constructor - the edges will have a stepped shape both along the Z axis and on the X-Y plane.

Due to the rectangular shape of the voxels, curved edges appear jagged. Removing visible voxels and layer lines requires post-processing such as sanding.

Layer lines are virtually invisible when printed with LFS-based 3D printers. As a result, surface roughness is reduced, resulting in a smooth surface, and when using transparent materials, models with greater transparency.

When talking about the speed of 3D printing, it is important to consider not only the printing speed itself, but also the performance.

The overall print speed of 3D printers based on SLA and DLP technologies is approximately the same. Since the projector exposes each layer as a whole, the speed of DLP 3D printing is uniform and depends only on the height of the model, while SLA 3D printers laser shape each part. As practice shows, as a result, stereolithographic 3D printers become comparable in speed or even faster when printing one small or medium model, while DLP printers are faster at printing large solid models or several models that almost completely fill the space of the platform.

As practice shows, as a result, stereolithographic 3D printers become comparable in speed or even faster when printing one small or medium model, while DLP printers are faster at printing large solid models or several models that almost completely fill the space of the platform.

But do not forget that in printers based on DLP technology, there is an inverse relationship between resolution and working volume. A small DLP printer can quickly print small models or high-resolution (small) batches of small models, but print volume limits model size and device performance. Another high volume device can produce larger models, or batches of smaller models, faster but at lower resolution than a stereolithographic printer.

With a stereolithographic 3D printer, all this can be done on one machine. At the same time, users can decide what they want to optimize in each case: resolution, speed or performance.

DLP printers use rectangular voxels to render images, which can result in vertical lines. In this image, the vertical voxel lines are shown as they appear when printed (left), highlighted for better visibility (right).

In this image, the vertical voxel lines are shown as they appear when printed (left), highlighted for better visibility (right).

Stereolithographic 3D printers have higher print volumes, batch production, and overnight printing for increased productivity.

| 100 microns | 200 microns |

|---|---|

| | |

| nine0141 Grey Resin 100 microns | 200 microns |

|---|---|

| | |

| 100 Microns | 200 Microns |

|---|---|

| | |

Stereolithographic 3D printers have higher print volumes, batch production, and overnight printing of models, increasing productivity.

INTERACTIVE

Try our interactive ROI tool to see how much time and money you can save by printing with Formlabs 3D printers.

Calculate savings

As with accuracy, differences in workflows and available materials are more printer specific than technology.

Most SLA and DLP printers are plug and play and allow easy replacement of platforms and resin tanks. Some more sophisticated models come with a cartridge system to automatically refill the reservoir with liquid resin, requiring less attention and making it easier to print at night.

Some printers come with their own software for preparing 3D models for printing (for example, PreForm for Formlabs stereolithographic 3D printers), while other manufacturers offer ready-made standard solutions. Different software tools have different features, such as PreForm allows you to customize the printing process with one click, powerful tools for optimizing the density and size of supporting structures, adjustable layer thickness, and features to save materials and time. Fortunately, the software can be downloaded and tested before purchasing a 3D printer.

Fortunately, the software can be downloaded and tested before purchasing a 3D printer.

As with precision, differences in workflows and available media are more printer dependent than technology.

3D printers can work with a wide range of polymer materials for different applications.

One of the main advantages of polymer-based 3D printing is the large number of materials from which models can be made for various purposes. Polymers with different compositions have a variety of characteristics: they can be soft or hard, contain additives such as glass and ceramics, or have special mechanical properties such as high bending temperature under load or impact resistance.

But at the same time, the range of supported materials depends on the specific model of the 3D printer, so we recommend that you check this information with the manufacturer before making a purchase.

SLA and DLP prints require post-processing after printing. First, the models must be washed in solvent to remove excess resin. In some cases, such as models made from engineering and biocompatible materials, final polymerization is also required. For stereolithographic 3D printers, Formlabs offers solutions to automate these steps, saving you time and effort.

In some cases, such as models made from engineering and biocompatible materials, final polymerization is also required. For stereolithographic 3D printers, Formlabs offers solutions to automate these steps, saving you time and effort.

Finally, 3D models printed on supporting structures require the removal of such structures. This must be done manually - the process is similar for both SLA and DLP printers. LFS-based 3D printers use lightweight support structures with very small contact points, allowing for easy release with minimal marks.

Interactive

Need some help figuring out which 3D printing material you should choose? Our new interactive material wizard helps you make the right material decisions based on your application and the properties you care the most about from our growing library of resins.

Recommend Me a Material

We hope that after understanding the differences in technologies and print results, it will be much easier for you to choose the 3D printer that best suits your needs and workflow.

To learn more about the next generation of stereolithographic 3D printers, check out the Form 3 and Form 3L devices based on LFS technology.

Would you like to see the resulting quality with your own eyes? Order a print sample, which will be delivered directly to your office.

Request a free print sample

DLP 3D printing | Description and features of the technique

What is DLP 3D printing?

DLP 3D printing is an additive manufacturing technique that uses liquid photopolymer resins to build objects that are cured by light waves. “Yes, this is an SLA print!” - exclaim those who are already familiar with the methods of additive manufacturing. Indeed, the principle of operation of these two technologies is almost identical. However, the curing of the object in DLP printing occurs under the influence of a different light source.

In general, DLP 3D printing can be described as a direct analogue of SLA 3D printing, in some aspects even superior to it. For example, the print speed in DLP 3D printers is an order of magnitude higher than in SLA devices. And the difference in fidelity varies depending on the specific equipment and consumable, and is generally small. Now let's move on to the technical aspects and talk about the principle of operation of DLP technology.

For example, the print speed in DLP 3D printers is an order of magnitude higher than in SLA devices. And the difference in fidelity varies depending on the specific equipment and consumable, and is generally small. Now let's move on to the technical aspects and talk about the principle of operation of DLP technology.

Technology Description

As with all 3D printing technologies, the first step in manufacturing a physical object is to create a 3D digital model of it. We will not delve into the details of this stage, you can read more about 3D modeling for 3D printing here. The finished 3D model is loaded into a slicer program designed to set print settings and “cut” the model into layers. This step also generates supporting structures under the overhanging elements of the object. The received settings are saved, the model is converted into a control code for a 3D printer. Now you can start printing.

Above we mentioned the similarities between DLP and SLA 3D printing. It's time to talk about their difference and how DLP printers work. Instead of a laser machine (as in SLA), DLP 3D printing works with a special projector as a light source. This technique is not new: you can also find such DLP projectors in other, more common devices, for example, in TVs. Here they are also used for curing liquid consumables - photopolymer resins.

It's time to talk about their difference and how DLP printers work. Instead of a laser machine (as in SLA), DLP 3D printing works with a special projector as a light source. This technique is not new: you can also find such DLP projectors in other, more common devices, for example, in TVs. Here they are also used for curing liquid consumables - photopolymer resins.

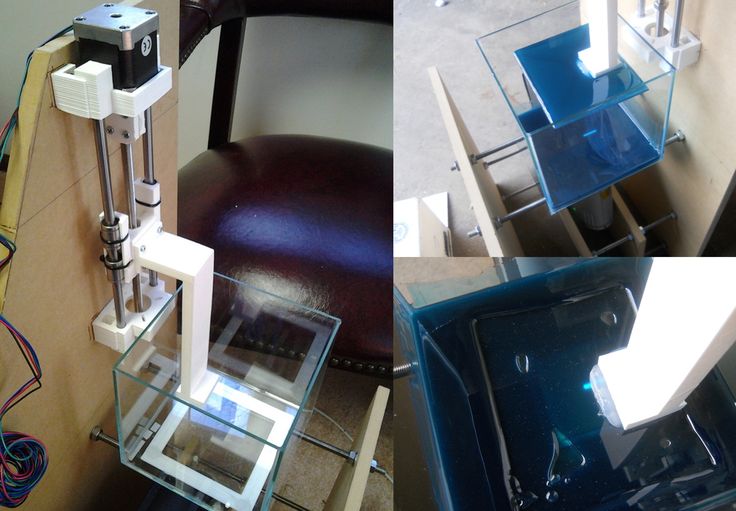

As in SLA printing, there are two options for DLP 3D printing devices: in one, the object is built from the bottom up (the working platform goes down), and vice versa (the working platform goes up). In our article, we will consider DLP 3D printing using both types of devices as an example.

Reverse DLP 3D printing

So, a special container of a 3D printer is filled with photopolymer resin to a certain level. The building platform is lowered into the container so that the gap between it and the bottom is equal to the height of one layer. Under the tank is a DLP projector. Light corresponding to the section of the first layer of the model is projected onto the platform. After its curing, the platform rises and the illumination of the second layer begins.

After its curing, the platform rises and the illumination of the second layer begins.

So, step by step, a physical object is created. Upon completion of printing, the platform rises above the level of the photopolymer, the product is removed and cleaned of the remnants of the consumable. After that, it is necessary to perform the final illumination in a UV lamp for complete curing of the material.

Direct DLP 3D printing

In contrast to reverse printing, the DLP projector is located on top, above the resin tank. In this case, the working platform is located directly in it. To build the first layer, the platform rises so that the gap between it and the surface of the consumable corresponds to the height of the first layer.

The cross section of the first layer is projected onto the platform, curing the photopolymer, after which the platform is lowered down to the height of one layer. These steps are repeated until the complete construction of the product. Further actions are identical to those described in the previous paragraph: the object is removed, cleaned of consumables and subjected to additional illumination.

Further actions are identical to those described in the previous paragraph: the object is removed, cleaned of consumables and subjected to additional illumination.

Advantages of

Why is DLP 3D printing so interesting? What features of it help this technique to gain more and more popularity every day? Let's watch:

- Faster print speed than SLA 3 D printers. Unlike laser stereolithography, DLP 3D printing projects a whole layer onto the photopolymer at once, and does not gradually pass through its sections with a laser. Due to this, the speed of creating products increases several times;

- High print precision. In terms of the accuracy of the created objects, DLP 3D printing is in no way inferior to SLA 3D printing: the layer height in this technique can reach 15 microns! However, it all depends on the type of 3D printer and the specific material;

- Large selection of consumables.

As for photopolymers, their range in the 3D printing market is so wide today that it is sometimes difficult to decide. Moreover, often DLP 3D printers can work with the same consumables as SLA printers;

As for photopolymers, their range in the 3D printing market is so wide today that it is sometimes difficult to decide. Moreover, often DLP 3D printers can work with the same consumables as SLA printers; - Affordable equipment price. DLP projectors are much cheaper than laser systems, which affects the cost of 3D printers for DLP printing for the better. Technology is developing rapidly and many today are opting for digital LED projection.

Of the shortcomings, it is worth highlighting only the rather high cost of consumables.

Materials used

DLP 3D printing works with liquid photopolymer resins (much the same as SLA 3D printing). Some consumables are even suitable for both methods. It depends on the wavelength of illumination and consumables. However, even specifically for digital LED projection, excellent professional lines of photopolymer resins have been developed.

So, today in the 3D printing market you can find flexible and rigid materials, transparent photopolymers and resins of a wide variety of colors.